Gary0747

Supporter-

Posts

505 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Gary0747

-

Based on the G100UL fuel leak thread what's your position?

Gary0747 replied to gabez's topic in General Mooney Talk

I am late to this discussion but wanted to throw in a couple of comments I attended the presentation in Buckeye last year and asked the question about what testing had been done on our polysulfide fuel tank sealants. I just got a cursory answer that it was currently in an airplane fuel tank with no signs of leaks. I would like to see testing that might predict the long term effects on these sealants. Perhaps measuring surface hardness readings or adhesion force measurements both over exposure time. Any new fuel that replaces lead and straight chain hydrocarbons with aromatic hydrocarbons like toluene, benzene, xylene, etc to maintain octane will be more aggressive on paint and sealants and some types of rubber. The aromatics will typically increase the octane lost by removing the lead, but should have initially raised red warning flags in the development of this or any new fuel. I would have thought it critical to test the long term compatibility effects on day one of any new fuel development project like this. I think polyurethane paints and sealants will better resist aromatic chemical attack than acrylic paints and polysulfide sealants -

I have been closely monitoring the exhaust valves in my Lycoming IO 360A1A for a couple of years (which is only about the last 100 hours). I have 1400 hours on the engine and it is running fine. I am tracking the data closely on my JPI900. I have two exhaust valves that have the non symmetrical pizza pattern that are likely not rotating. There does not appear to be any signs of burning and they have had this distorted pattern for the whole time. Is there a way to get them rotating or should I just keep monitoring? I understand the Lycoming rotator caps are passive and only allow the valve to rotate if they want to so changing them may not do much?

-

How to seal most forward left panel aft of Cowling?

Gary0747 replied to Saira's topic in General Mooney Talk

I have the SWTA aircraft windshield smaller access panels with a simple solution that is reusable. Put a bead of RTV Silicone and cover it with Saran Wrap before installing the cover then trim the excess. -

Those cracks look pretty big but for smaller cracks, there are a few solvents that work well for bonding acrylic. Methylene Chloride, Ethylene Dichloride and Methyl Ethyl Keytone come to mind. One could put some in a a glass eye dropper and see if it will weep into the cracks.

-

Possible fuel pump failure or...?

Gary0747 replied to The Other Red Baron's topic in Vintage Mooneys (pre-J models)

Was it leaking fuel outside the engine? -

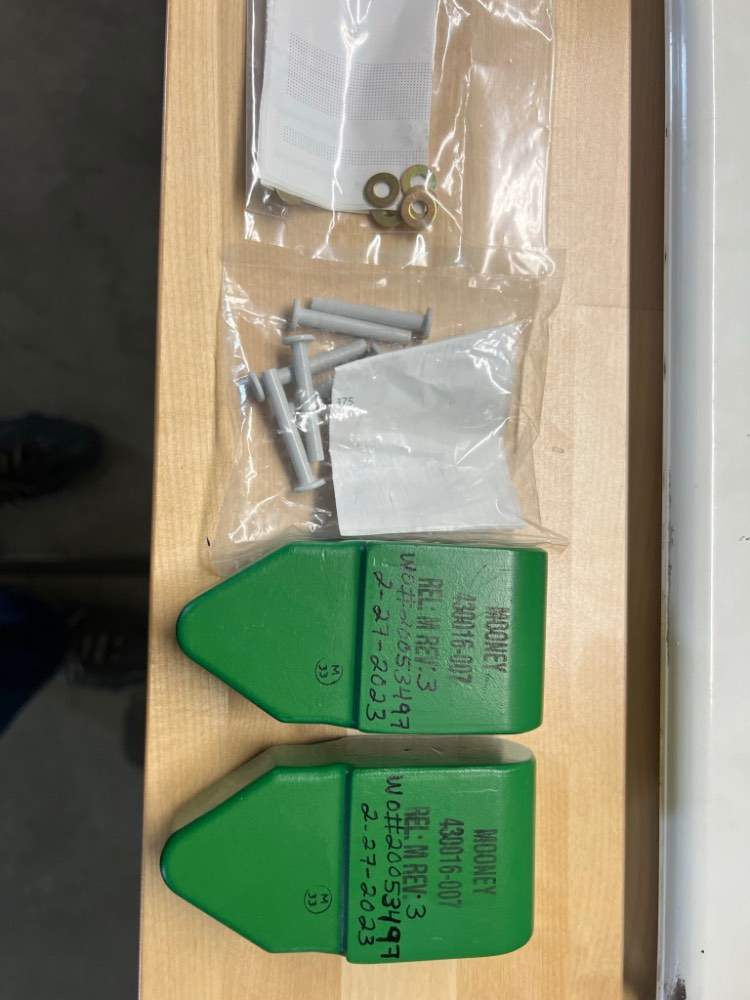

The new weights come right in spec with the service bulletin without filing so that worked perfect. The only issue I see is did the mechanic install rivets too short for the specific elevator he worked on. As mentioned above DMax has longer ones that can be cut to the proper length for a good set.

-

3.18 pounds. Both the same.

-

-

Apparently this QC check is called a “Conformity Check” and it is done by the FAA? I have never heard of this on previously manufactured and installed parts like this 40016-7 weight? If true we may have a longer wait given all the Continental AD stuff on the FAA plate now?

-

Anybody have info on the status of new weights from Mooney?

-

Yes that has bothered a lot me since I have been flying my M20F for over 30 years and well over 2,000 hours and some times near VNE with no sign of flutter. So why would I want to change the balance of the elevator by this large amount? I can only hope that there is more than one correct answer to the flutter prevention scenario. I do recall a post by a knowledgeable contributor (PT20J) in September that said the following which I hope is true: “Most control surfaces are overbalanced (i.e., leading edge heavy) to control flutter. With the control surface CG ahead of the hinge line, a deflection of the control surface causes a correcting hinge moment that tends to dampen out motions caused by aerodynamic forces. Evidently the Mooney control system is stiff enough that flutter is not an issue and so the control surfaces are underbalanced (i.e., trailing edge heavy) most likely for improving handling qualities. The Mooney ailerons have fairly heavy control forces due to their short span, wide chord design and the elevator forces are a bit high due to the springs and bobweights. Underbalancing would tend to reduce the initial hinge moment when a surface is deflected. But, that's just a guess; to know for certain the designer's intent you'd have to ask Al. “ Skip

-

The other thing that may cause the 540 M20Fs made prior to 1968 to require different balance setting is the bunges are different as well as the elevators. So if changing elevators pre 68 to post 68 is ever needed the bunges will likely need changing also.

-

There must have been a lot of -7 non hybrid weights used since there were only 130 sets of -1 hybrid weights. The remaining 410 M20Fs in the pre 1968 time period appeared to have the same balance criteria as the hybrid weights since no distinction is noted in the service manual. I wonder if the solid -7 elevators were actually balanced to the spec in the service manual? I see no way to get there with the current -7 weight a full pound heavier than the hybrid weight.

-

I measured my elevator when it came off and the weight was 1.60 pounds to 1.62 pounds. So now I am being told these numbers are not correct even though they are correct according to my service manual that applied to the first 540 M20F? The parts catalog only lists the -1 hybrid weight not the -7. So the question is which one was tested with the smooth elevators?

-

Looking at the type certificate for the M20F the rigging of the elevator is different for the pre 1968 models compared to those made after so it seems a stretch to say they are all the same. “(for Aircraft with Serial Nos. to 680001): With stabilizer set at 31⁄2° negative setting to the thrust line, adjust trim assist unit 740128 for elevator up angle of 5° +⁄− 1° at the zero spring travel position. (for Aircraft with Serial Nos. 680001 and up): With stabilizer set at 3° negative setting to the thrust line, adjust trim assist bungees 740188 for elevator position of 19° +⁄− 1° at the zero spring travel position of the bungees. (This rigging to be obtained before installation of the 740171 extension springs).”

-

Yes Ribbed elevators should not be part of the AD unless somebody switched weights. The AD primarily affects the smooth skinned early M20F. The issue is why is the AD using unbalance weights for the ribbed elevator instead of the unbalanced weight for the earlier smooth skinned elevator? Perhaps they have flutter test data that says there is no difference but this is contrary to the original service manual numbers?

-

Yes step 2 is for the case the current hybrid -1 weight passes the stripping and 10x magnifier test and the owner wants to continue pulling the elevator off for an annual re-inspection. (No one will want to do this.) Step 4 is replacement of the hybrid -1 weight with a new solid -7 weight. The early M20Fs before 1968 (540 in this category) had both -1 and -7 weights since there were only about 130 hybrid weight sets installed. Does anybody know for sure when the transition from smooth to ribbed elevators occurred? I am assuming 1968 but am not sure? I hope the original test flight data still exists?

-

I can not figure how the SB changes the original service manual unbalance requirements of 1.57 to 1.725 pounds? For the smooth skin pre 1968 M20F? Did they go test fly VNE to test for flutter or was it a calculation? The numbers you are quoting and using 1.09 to 1.3 pounds happen to be for all the post 1968 M20F and 201 aircraft which have ribbed elevators not smooth. Is this a mistake? And what about all the pre SB elevator rebalancing with smooth weights or repainting? Which balance number did they use since presumably only the service manual was the only reference. I brought this up before but apparently no one has an answer

-

What I was worried about is the lower weight limit allowed in the SB of 3.0 pounds The hybrids are no doubt lighter and they may well be less than that 3.0 pound lower limit. The early smooth skin elevators had a significantly higher unbalance weight specification than the later Ribed skin elevators. So that also points to needing lighter weights for the smooth skinned elevators. I can not find any weight limits in any of the early service manuals and it is not clear where they come from in the SB?

-

This is what I was thinking also but was wondering if the new -7 weights were close enough in weight to file them for proper balance. this is from the SBM20-345A “The 430018-1 balance weight is similar in size and shape (but not in weight) to the 430016-7 balance weight.”

-

The new -7 weights are supposed to be between 3.0 and 3.5 pounds when installed. Does anybody know the weight of the old -1 hybrid weights?

-

So If this is the reason for elevator removal, stripping paint for inspection, repainting and rebalancing, every 100hours, do you think it would be acceptable to either leave the weight bare or paint it with clear coat? The 100 hour elevator removal will force replacement of good weights since nobody will want to be removing and balancing elevators every 100 hours.

-

Here is another good video on flutter and things to look for and do to correct while flying. Good learning for me since I was never taught all of this.

-

I know this is true for high speed aircraft but Is this true for GA aircraft flying at normal speeds? I can’t recall reading an accident report on any GA aircraft where flutter was mentioned as the cause? Yes GA aircraft have lost tails when accidentally penetrating thunderstorms or conducting abrupt control movements but the cause there has been exceeding the g force limits of the aircraft design.

-

Sounds like a good idea if there was a good way to attach it? Do you know which SB that was? Not sure what adding weight to the end of the weight inside the elevator would do that would hurt? Changing the CG of the weight should not hurt anything as long as the correct specified moment was maintained?