hazek

Supporter-

Posts

264 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by hazek

-

Lasar Aviation Mooney Assurance Program - Really?

hazek replied to PeteMc's topic in General Mooney Talk

Ah I see now. You don't consider management employees. They are. And while I have no doubt that there are some good lower level employees just trying to make a living there that fulfill their obligations to the company and try to do so to the best of their abilities, this isn't a charity, and we're not handing out participation trophies. Bad management means bad lower level employees. I see it all the time. People like people that are like themselves. And bad management typically hires people of the same rotten profile. They don't want to but yet the manage. And while some are probably worth keeping, this needs to go through a process of determining who is and who isn't worth keeping around. I'm not trying to shit on individuals here. I have no clue who works there, what they do, how much they're paid, what their qualifications are and what they even do if the factory isn't doing anything. I'm just being rational and am looking at the situation. This situation didn't just happen. There are objective reasons for it. I'm sure people involved will have plenty of excuses but at the end of the day they are failing. And that's the bottom line. There's a reason why Elon Musk has several successful companies and other people can't run even one. Like people said, there is not going to be a solution here that keeps the status quo, in today's world no one is so stupid or naive anymore to throw away that much money. -

Lasar Aviation Mooney Assurance Program - Really?

hazek replied to PeteMc's topic in General Mooney Talk

Submit your evidence, I'm all ears. -

Lasar Aviation Mooney Assurance Program - Really?

hazek replied to PeteMc's topic in General Mooney Talk

By the looks of things, Mooney IS gone. But that's not the alternative. This is the alternative. Yes they could. But I suspect this whole thing is a people problem. People who think too highly of themselves in terms of their capabilities and what their actual capabilities are worth. The value as some pointed out is the design approvals and certificates. But I bet the employees think that the real value is in them and are being overpaid for what they contribute. And then there are the owners. One that likely wanted to do something but got stuck with useless employees and one that just thought they could put lipstick on this pig and make a quick buck. A motivated clever leadership and motivated employees could indeed make something out of this. But not the current entrenched lot. They've proven as much. Exactly. The entire crew, from the corner office to the cubicles, has to hit the exits; they're the root of the rot. Once the assets are auctioned off at fair market value, a fresh start on stable ground might just emerge from the ashes. -

Reading everything they released recently they do indeed sound confident they have something that works for the entire fleet. It has brought back some cautious optimism for my Bravo, I have to say.

-

This is true in Europe where we have the nanny state but you have this because of your litigious culture. To us Europeans it's downright crazy the lawsuits you have. You just sue over anything to get a payday. And you can just file frivolous lawsuits as just the mere threat of having to pay to defend is sometimes enough to get a settlement because the loser doesn't have to pay the legal costs. Crazy. It's this that did you in. It's this that your regulators tried to solve to at least keep some of the companies alive that got sued into oblivion by greedy widows.

-

Rght out of the gate? Seriously???

hazek replied to Freddb34's topic in Vintage Mooneys (pre-J models)

Without saying the data from the engine data monitor it's anybody's guess what went wrong. Do you have the data? -

Link to SB?

-

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

hazek replied to cliffy's topic in General Mooney Talk

How much? -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

hazek replied to cliffy's topic in General Mooney Talk

So that's the real issue then. If they're not giving away the data, not even in exchange for money then yeah, we're on our own. Suckers we were that we bought from such a company that either can't or won't manufacture needed parts and likewise will not release the data so that we can do it ourselves. Are you sure they're not giving the data away not even in exchange for money? -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

hazek replied to cliffy's topic in General Mooney Talk

@Sabremech My point is that if one has the approved data it is trivial, really absolutely trivial to put together the documentation to have it manufactured if really all it takes is for the owner to participate in just one of those 5 steps. You feed the approved data to an AI and it spits out the necessary documentation in the next minute. You go to any machining shop and ask for the part to be made according to your documentation. Presto, part done. Or am I missing something? -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

hazek replied to cliffy's topic in General Mooney Talk

But Mooney is still there and has all this data. So you're telling me we could produce these parts by participating in just one of those 5 steps of manufacturing the part and the part can be manufactured by literally anyone as long as we get the design data from Mooney?? What am I missing? Btw I used AI to draft the necessary documents to participate in all 5 steps in literally 49 seconds. https://x.com/i/grok/share/oKiFudifIdBOOzVdbYYNUSBQH -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

hazek replied to cliffy's topic in General Mooney Talk

If this would guarantee me parts when I need them, no problem! Sign me up. I wonder if this is a factual statement. Perhaps it matters how documentation is submitted. I have no idea but just going off of my personal anecdotal experience in life that when I need to pass through a bureaucratic process I seem to have less difficulty than others when I come with well prepared documentation. Perhaps this is an exception but, like I say, I wonder if that's really true. -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

hazek replied to cliffy's topic in General Mooney Talk

Sure that makes sense. This less so. In today's age with computers, especially now with quite useful AI this paperwork stuff should be an easy problem. Perhaps it's not attempted by people who excel in this sort of stuff but by people that are savvy in other relevant areas. Hopefully Lasar knows how to get these steps done cheaply enough so that the manufacturing process itself can be feasible. This parts problem is another huge concern of mine regarding the future, like AVGAS phase out, that makes me very motivated to only think about how I should find a way to drive a turbine Piper asap. -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

hazek replied to cliffy's topic in General Mooney Talk

How can it be so difficult to transfer manufacturing to modern practices? Are regulations really that stiff and the process to obtain approval that cumbersome and slow? I'm pretty sure any decent shop manufacturing parts could manufacture any part for our planes. Where's the catch? And why doesn't someone just do this? -

Yikes. Do you know how this was tested? And if you're using an EDM, is it your main gauge or do you still have the factory gauge and what did that show? My factory gauge shows about 20dF higher than what I see on the EDM830.

-

The final report is out: Someone should change the thread title from "New “impossible turn” video - Acclaim S" to "New “very likely to kill you 180 to the runway turn” video - Acclaim S

-

If I were you I wouldn't do this unless they are asking for your data first and taking a good hard look at that first. To understand why that is important watch this:

-

Find a way to record the data and upload a flight to savvy and share the link, let's see the data. Hard to say anything without that.

-

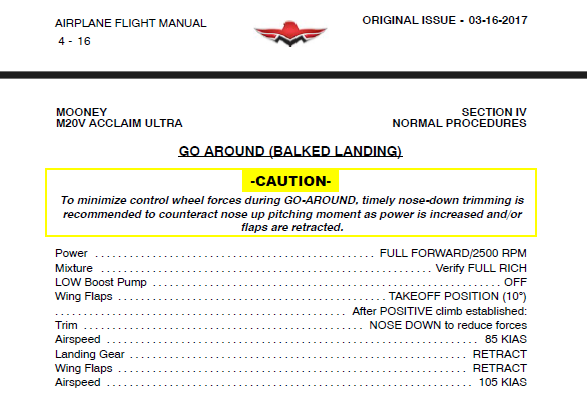

Retract Gear or Flaps First in a Go Around ?

hazek replied to donkaye, MCFI's topic in Modern Mooney Discussion

Ha. So they didn't correct a mistake by putting a new order in, they made a mistake! But a test that I really wish someone would do is testing the acceleration after either gear is raised or flaps is raised from a slow near stall speed - Vref or slightly below. Because correct me if I'm wrong but isn't gear only parasitic(form) drag, which increases with the square of speed and therefore it's minimal at slowest speeds? And aren't flaps at slow speeds far more induced drag than parasitic drag, which increases with the decrease of speed which therefore requires a higher AoA i.e. higher Cl? Plus full flaps add far more drag than lift? Perhaps the logic of raising flaps first to flaps TO at slow speeds is that we want to remove the insidious part of the configuration AT slow speeds first? Maybe the danger of full flaps vs gear is at speeds so slow that put you on the backside of the power curve? In that situation raising gear will not help as much as raising flaps partially first in order to quickly reduce a lot of drag allowing us to accelerate out of the backside and establish a positive rate of climb? This discussion appears to me as if we're talking past each other because at no point was it clearly defined what this supposed go around looks like. How low are we? How fast are we? I will concede that raising gear first vs flaps to TO does not matter when still 300ft AGL and at Vapp and is potentially beneficial as it's "simpler". But I would argue it does mater when bouncing and at nearly Vs0. And to me it makes sense to have the muscle memory that works in all scenarios. -

Retract Gear or Flaps First in a Go Around ?

hazek replied to donkaye, MCFI's topic in Modern Mooney Discussion

Arguably if you had raised flaps to take off position first, and tried to retrim that pressure, then raised the gear, perhaps you wouldn't have been in a position to struggle against the full pitch up moment of retracted flaps with no functioning trim and at the higher airspeed due to retracted gear. I'm basically a baby compared to your experience and so obviously no one should listen to me and perhaps I too will learn the same lessons as you have and changed my ways someday. But I've done several go arounds already, the way the POH says for my Bravo, and found that to work out well. So I'll stick to that, if nothing else, due to the law of primacy. I also think my arguments why raising flaps to take off first hold water and it's perhaps the reason why POH was written this way. To repeat, the moment is less at slower speed, and more gradual when flaps are reduced in stages allowing time to retrim the pressure, the gear staying down longer provides a safety net if an inadvertent touch down happens when performing the go around late, and finally flaps TO and gear down is the takeoff configuration in which my plane can climb above obstacles. This is probably the most important point. I brief the go around sequence before every single landing, always. -

Retract Gear or Flaps First in a Go Around ?

hazek replied to donkaye, MCFI's topic in Modern Mooney Discussion

I see. How would you explain them reverting back to the previous procedure for the Ultra? Seems to poke a hole in your argument. -

Retract Gear or Flaps First in a Go Around ?

hazek replied to donkaye, MCFI's topic in Modern Mooney Discussion

-

I don't understand why people are speaking theoretically about car engines and what is and isn't possible when we have this:

-

Oh yeah definitely! When you want to be totally precise and determine whether or not you are at 65% power or 68% then yeah you should mention FF. EDIT: And only to determine the mixture as that is really what is a factor, not the absolute FF value.

-

Okay, to clarify precisely: Power equals torque times angular velocity. Angular velocity is proportional to RPM (specifically, it’s 2π times RPM divided by 60 to convert revolutions per minute to radians per second). Therefore power is proportional to torque * RPM. Torque is proportional to manifold absolute pressure under ROP conditions with constant mixture and timing, since manifold absolute pressure drives mean effective pressure. Therefore, power is proportional to MAP × RPM when ROP at constant mixture/timing. The suggestion of power = MAP × RPM × FF is incorrect for ROP, where power is air-limited (excess fuel), not fuel-limited. FF correlates with power ROP but isn’t a direct multiplier in the formula like it is LOP, where at lean mixture power is proportional to FF due to excess air. Varying mixture ROP introduces an efficiency factor: power ≈ η × MAP × RPM, with η peaking at best power (~50-100°F ROP) and dropping at full rich or leaner due to incomplete combustion.