Fix

Verified Member-

Posts

152 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Fix

-

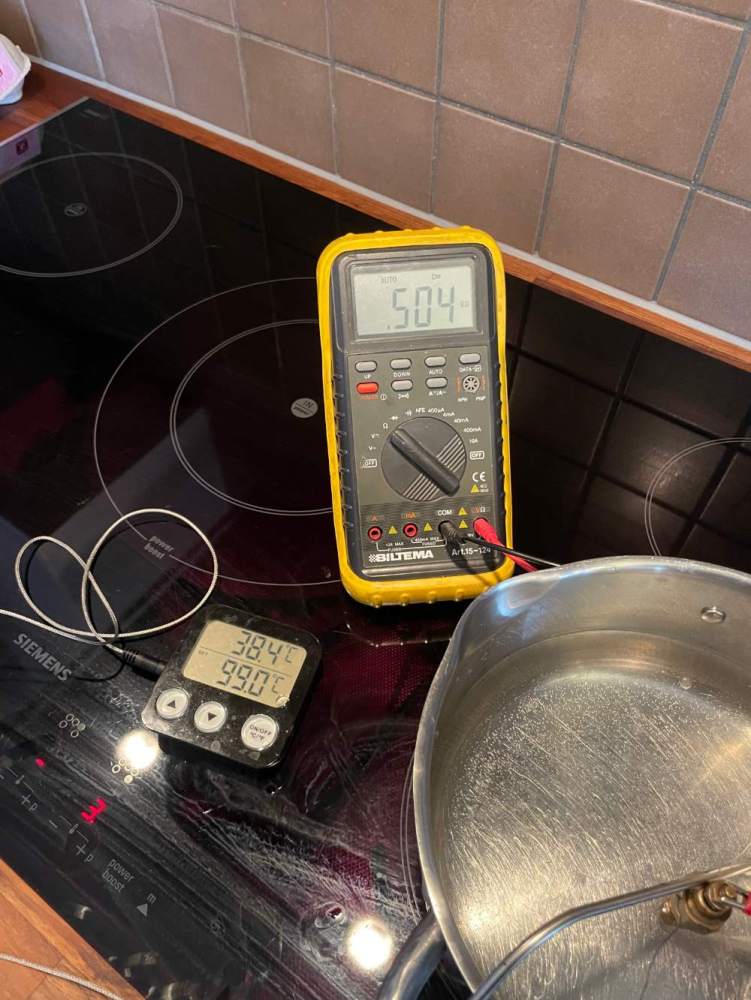

Since the Oil Temp Gauge in my (our) Mooney 252's more or less have a Green Arc all over the Gauge I always wondered where 180f is etc. Straight up, little to the left or right... POH says it's OK to fly as long it's in the green. But I want to have 180f Oil temp when flying. Today I started to do some measurements on Rochester 3080-37 Oil Temp Probe that I have in my Mooney. Suspect that this is the standard one we have. Found some values from Rochester in some data sheet... 100°F: ~497Ω 150°F: ~179Ω 200°F: ~72Ω 250°F: ~34Ω Could only test up to ~212f (100c) since this is boiling water. With the list of values I now can put a Pot (Variable resistor) on the Oil Temp Cable and Ground. And then turn it and the how the Oil Temp Gauge changes. Will post more pictures when I done the tests. Oil Temp Probe Values.pdf

-

M20K Encore - Purchase advice & Cockpit feel for tall pilot

Fix replied to MartinN3's topic in General Mooney Talk

I order most parts from USA like: Aircraft Spruce, Air Power, Mc Fairline etc... -

M20K Encore - Purchase advice & Cockpit feel for tall pilot

Fix replied to MartinN3's topic in General Mooney Talk

Not harder to get parts here than USA. UPS or FedEx 1-2 days express if I need something to Europe. -

M20K Encore - Purchase advice & Cockpit feel for tall pilot

Fix replied to MartinN3's topic in General Mooney Talk

I also had those same questions you have, and Mooneys with Seats that you can move up/down is good for us longer pilots. I have my seat almost in the most forward position so there are plenty of space. There is also good head room to the roof. I mostly fly in good weather and avoid ice... I'm IFR rated and my Mooney has a good IFR avionics panel. Maintenance: I guess there are no more maintenance with a Mooney or an Piper PA28 Arrow or similar. A Mooney is an Aircraft like many others... Sure Mooney are fast and well built and the nicest :-) If you break it down, it's an Airframe and Engine and Avionics. The Airframe has "Mooney" specific parts... But most of them you won't need to buy if you don't break anything. Many parts attached to the Airframe is "general parts" that you will find in other Aircrafts. And the Engine is either a Lycomming or Continental. So it's not a big deal to own a Mooney maintenance wise compared to a PA28 Arrow. They both need some love and maintenance. What's importance is not to buy an maintenance hog, buy the finest you can afford and do a proper inspection. I've read somewhere that it will take 2 years after you bought an aircraft to fix all small stuff you find and get it into your standard. I would recommend to sign up with Savvy Aviation when you bought your aircraft, I'm very happy with their support. (Hi Paul) Since we are talking about Mooney 252TSE/Encore there are some things that you should look closer on. * Gear actuator Check if it's a Plessy or Eaton, if you have a Plessy there are no spaceparts... So you need to find a used or buy a new Eaton. Plessy was used 1986-1989 if I remember correctly, see logbooks for details. * M20K Pre-Buy guide is good to read through. (Attached) I'm very happy with my Mooney M20K 252/Encore, this is my forever aircraft. Try to buy your last aircraft first! Drop me a PM if you need further info. M20K PRE-BUY.pdf -

M20K Encore - Purchase advice & Cockpit feel for tall pilot

Fix replied to MartinN3's topic in General Mooney Talk

A Mooney M20K 252 Encore is a very nice and comfortable aircraft to fly and sit in. I'm 1.92cm tall and 95kg and it fit like a glove, absolutely no problem. The true Encore is a little bit more smaller inside due to different interior, but still not a problem. Standard 252's like mine has some space, but it's not an issue. I've flown both. I had a PA28 Arrow III before and sure it was nice, but you can't compare them. Mooney is so much nicer to have. In general try to find the nicest 252 you can get and take it from there. If you can find an Encore or upgraded 252 with Encore it's even more nice since you get higher MTOW. As other wrote, you can upgrade but parts can be tricky to find. But you could always start to source parts before you upgrade. I think my 252 was the last 252/Encore upgraded in Europe back in 2014. ACG in Germany did the upgrade, ask Justus for details. -

Your question is difficult to answer, but in general buy the nicest Mooney you can find. Examine if properly and read every thing about Mooney and aircrafts in general. Then you learn from other owner problems and how they solved it. Also if you can do some work or assist is a good way to learn what your aircraft needs in parts in future. I bought some parts that I don't need now, but I will need them in future. Try to be ahead of your maintenance, and order parts when you suspect you need it. There are lots of used parts available from like BAS in USA.

-

I also have some problems to get the Oil temp up when it's cold or less than 10c. Suspect that AeroShell 100W is little bit to cold to flow properly then, giving me MP fluctuations. Philips X/C 20W50 would most probably work much better, and I will change next week or at next annual and use it both summer/winter. Have 7x AeroShell 80W on the shelf that I might use this time, since I won't fly many hours until my Annual i February due to bad weather here.

-

Then I can use AeroShell 80W Plus if I want to use "two" different oils. Will use Philips X/C 20W50 + Camguard all the time in future.

-

In the Service Manual it says that the Cowl Flap should be "flush" when fully closed. Will test to open it 1/2" next time...

-

I also never have any CHT issues in Climb or Cruise with Cowl Flap fully close in cruise. 350-370f in summer.

-

I was about to make a post some weeks ago about this topic, saw in that there was a Post in another section. But would like to talk more specific about M20K. Is there a "official" Winterization Kit? I found something about it on some Mooney document, but could find anything when I Google the part #. Here at Northern Europe we get semi cold weather from October to March. I use AeroShell 100W Plus + Camguard and this authumn I didn't change to Aeroshell 80W Plus and I started to get some "issues" with fluctuating MP when OAT were about 10 Celsius. When below >10 Celsius I pre-heat my engine, but it didn't help with the fluctuating MP. So I started to cover my oil cooler about 40% with Aluminum foil tape. When I did a flight at FL100 with OAT around 7-9 Celsius engine temp was fine and MP stable. But when OAT was around 5-6 on ground it started to fluctuate again. Will change oil next week to Philips X/C 20W50 + Camguard so I can use same oil whole year without changing from 100W to 80W and vice versa. Questions: How much of the oil cooler is OK to cover? - I've found somewhere that some covered whole oil cooler, too much? (depending on OAT) Is there a good way to check the Oil Temp Probe (Stock) - Measure Ohm and heat it? And what Ohm/Temp on the probe to check the Oil Temp gauge (Stock) so it's correct.

-

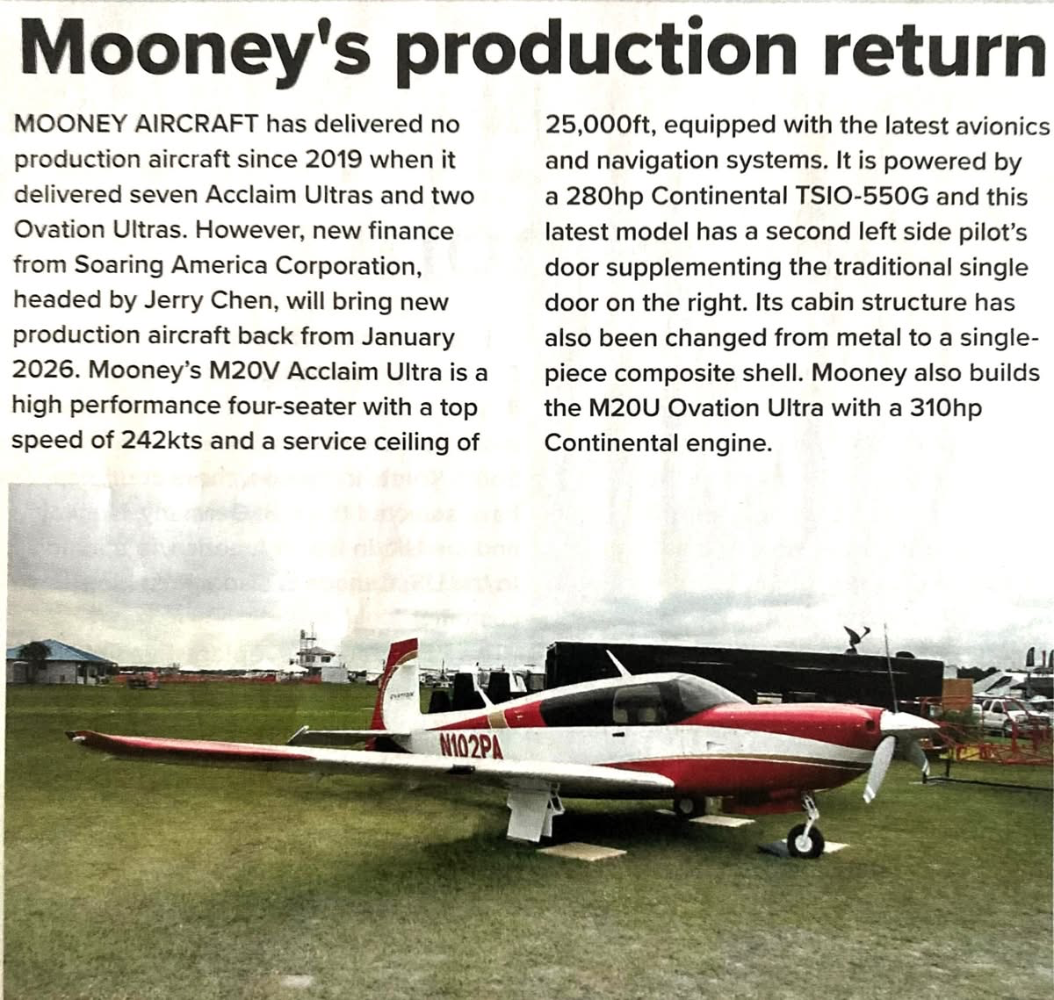

Found it on Facebook from an serious flight enthusiast page. Where I asked him where he found it. Source: Aviation News (Key Publishing) November Issue I can’t see any reference on their webpage since it’s a paid subscription. I

-

-

Updated my Gami Injectors and did a quick flight today. Now I have a Gami spread of 0.3 - 0.4g/h instead of 0.6-0.7g/h. Will do a proper test flight soon as the weather is favorable here again.

-

I've timed my mags several times with flower pot and digital meter and piston pin. Maybe I messed up, I've double checked it. At least both mags are even, maybe could try to adjust both mags 1 degree. At 29" 2300 RPM at 10.1g/h LOP I my TIT show just above 1550f on the analog gauge, most likley 1510-1560f range. Maybe it's higher than "normal", but on the other side it's still well below 1650f and also if the reading is "higher" even if the real TIT should be lower I have a margin to ~1600-1610f were my personal limit is. If I had a very low TIT with a functional TIT probe, then I might get above 1650f with out knowing it? On the Garmin G500, do you calibrate the TIT against the analog gauge or how does it work? I can also see that your EGT is lower than mine, what would be normal EGT temp? Is there any difference between JPI probes and Garmin Probes and the original Probes with read out?

-

Had another trip last friday at FL100. This flight my engine behaved as it should :-) FL100 29.5" 2300rpm @ 9.9-10.0g/h TAS: ~163KT TIT: ~1575F Will install my replacement Gami Injectors next week for Cyl 1 + 3 and it will be interesting to see how engine behaves then and if I get below 0.5g.

-

Can you Swap the Mags from Left to Right and vice versa? If the problems moves you know it's the mag...

-

Let's buy Mooney - Crowdsourced Version - Straw dog.

Fix replied to Yetti's topic in General Mooney Talk

I would have no problems to donate/subscribe yearly $1000-2000 if it was directly to Mooney. Now I'm financing a another company that would make profit from our donations/subscriptions. -

Lasar Aviation Mooney Assurance Program - Really?

Fix replied to PeteMc's topic in General Mooney Talk

I would be more happy to pay directly to Mooney as an supporter than to Lasar. Now I feel the money get into the wrong pockets. As I wrote before Lasar did markup a part with 60% just to drop ship it directly to me. Would be 100times better if Mooney took 40% of that money, and then Lasar had a normal cut like 20% instead. Will see what happens, but for $200 each month and only 10% discount on parts not worth it. Let's say I will need a part in 2 years that cost $5000, then I get 10% ($500 off) and then pay $4800 in "subscription fees" = $4500+4800 = $9300... Guess it's better to pay full price instead. Why not add an "supporter" subscription for $10-$30 instead to help out in general. -

Would be interesting to gather some more information here... I assume regarding EGT is where the probes are mounted/drilled in the exhaust. Or are they "factory drilled" at exactly the same position? Also with TIT Probe, is that location always the same on all -MB / -SB

-

I replaced my Stock TIT prove around 60h ago, so I expect it should be OK. I've noticed that if I calibrate my JPI TIT after the stock TIT, they will differ depending on what altitude I fly on. If I calibrate it for at 4000ft at some power setting, JPI TIT will under read if I then fly higher, and vice versa. Right now I think it's calibrated so it's not showing "too low" values on the JPI, where I think it's better to be safe than sorry. Used flower pot, digital meter and spark plug pin. If I didn't mess up, my mags should be timed within 0.5degress. At FL 160 where the turbo have to work harder I have: 25" 2500 12.6g/h (65% ROP) EGT: Highest 1418f - Lowest 1353f - TIT: 1499f CHT: 359f - 330f - - 29.5" 2300 10.1 (65% LOP) EGT: Highest 1493f - Lowest 1406f - TIT: 1599f CHT: 353f - 316f My Cyl 6 EGT is lowest by ~40f from the others. *** I've checked some other flights at FL140. There my TIT was ~1500F at 25" 2500 12.6g/h

-

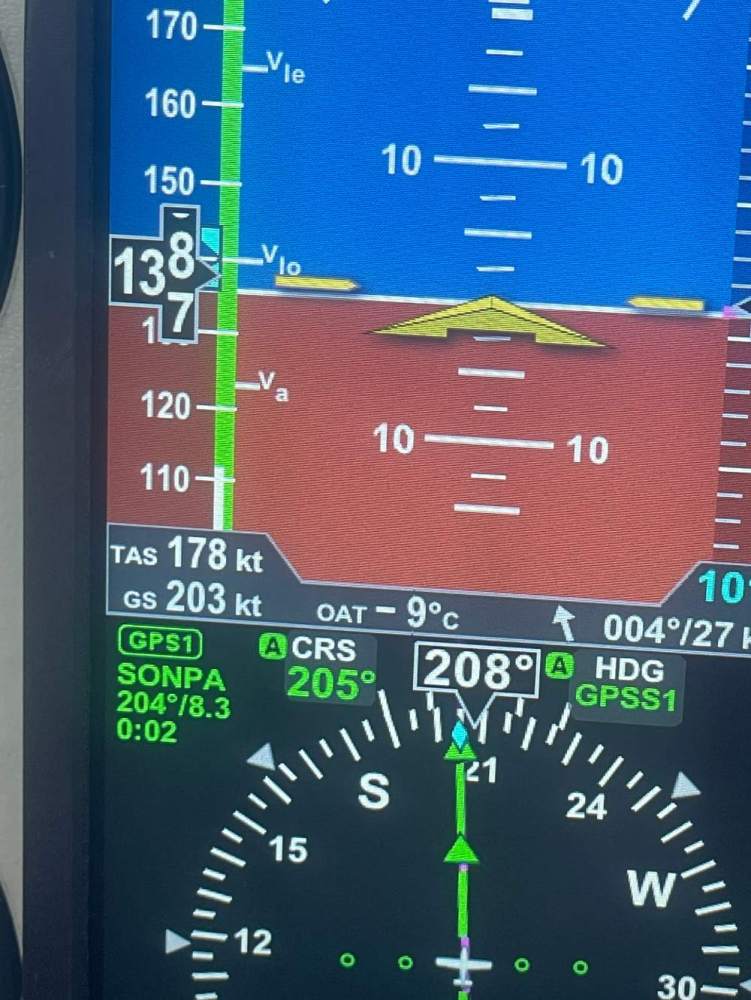

Update: New Maggie Harness, Gami Injectors and new Tempest Fine wire Spark plugs... Engine runs runs smoother, more even RPM drop at Engine run up. Also idle is stable after a flight when taxi, before I had some issues were I needed to add some rpm to have it running and not quit. Guess the harness fixed that. Did some Gami spread test and most likely in average I have 0.7 with Gami. Cyl 1 & 3 is to lean. Hopefully Gami will send replacement, they are not the fastest to respond. LOP, is not perfect but now I can at least fly LOP 29.5" 2300 10.1 (LOP 5-15 degree). After some fiddling I can get engine to run OK, but I expect improvement when I get replacement injectors. On my from ESSB to ESML I got a new speed record at FL160. 29" 2300rpm 10.1g/h, Cowl flap closed, All CHT under 369f, TIT ~1590-1600f Tail winds are nice :-)

-

30% increase is maybe reasonable if we can get the parts we need. But, when I ordered a part from Lasar and Mooney sent it directly to me the forgot to remove the invoice to Lasar. Sadly Lasar added 60% on top of the Mooney price just to order that part. Sure, Price and Demand... But 60% markup is ridiculous... and now an additional 30% on that. I would be much more happy to give that 60% markup directly to Mooney instead of Lasar.

-

If you can consider an M20K 252 Encore or 252 with Encore upgrade you can load it pretty good.

-

My road to getting my -SB engine to run smoothly at LOP continues... I now got my Maggie Harness (Thanks Paul for assisting) and also my Gami Injectors arrived. I've suspected lots of things, but made the decision to change ignition harness to be 100% that there wasn't any issues. They looked fine when we looked at it, but since left mag even when I changed it and also did an 500h inspection didn't solve rough LOP I decided to buy one anyway. What can you say, I'm glad that I did order a new harness, since there was damage to the old one on several wires. One of the wires were actually really bad, and was in direct contact with metal. This was 5B on Left Mag... rest of chaffed wires were on bottom plugs too. This was only on ~550h since new! All damage was in clamp. (You needed to remove wire to see it) Wire with most chaffing was forced against an rivet due to wrong installation and wrong clamp. Also impossible to see without removing wire. Even if this don't solve my LOP issues, I now have a fresh and correctly installed ignition harness. Started to install new harness yesterday. Gami injectors will be next up. Cylinder 5B. Severe chaffing, through outer rubber and braid shield... Some more chaffing, due to JPI probe wire in same clamp. Some more chaffing, due to JPI probe wire in same clamp. When the installed new engine, they used old/wrong clamps that put lots of force on wires. On several wires when clamped together. After some hours of careful wire planning it slowly looks much better. Now all Ignition wires will be in own clamps, and all JPI probe wires in separate clamps.