-

Posts

65 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by HawkGT

-

Geoff, I really appreciate the pictures. Thanks! Jason

-

Long story short, I had the fuel system overhauled on my -MB M20K and the A&P reinstalled the system but I had to find a new mechanic. Now we are sorting out higher than normal MP gauge readings that aren’t making sense and we found the MAP gauge tube is connected to the rear 90deg elbow on the fuel manifold. This makes sense for the weird readings on the gauges but not for where it should be connected. I can’t find on the TCO IPC or the service manual where this is supposed to connect. Can someone share the proper routing and connection for the manifold pressure gauge tubing at the engine? Pics would be ideal if you have them. Thanks! Jason

-

I also noticed that mine is polished versus most of the other pictures I have seen which are not. No clue why or when this was done. I agree it's likely when the -MB engine was added. Your picture clearly shows more threads sticking out on the engine side for the female adapter to connect. That's part of what was confusing me on mine as there wasn't enough sticking out to connect gauges or lines. Likely just how they are adjusted/installed. Thanks for all the help!

-

I understand two STC have been installed in my airplane but I dont understand the purpose of the three ports in the footwell. The Turbo plus web page has pictures with and without those ports. Are they vents/drains? Are they bulkhead connections for test gauges, doesnt look like it? Are you saying it was part of the TurboPlus STC that was abandoned when the ModWorks conversion was done?They appeared to be plugged with RTV and before I do anything I want to understand what they are for. Thanks! PS- yes the baffle/cowl seals look like trash and I plan to replace them asap.

-

Are the three ports on the passenger side footwell vent lines in the below pic? What do they vent? I dont see them on the IPC. Scanning the internet I see some M20Ks have these and some don't. Thanks! Jason

-

An A&P/IA who several months ago took a job with the FAA and no longer able to help. I called him 6 weeks ago looking for help.

-

I bought the plane in annual with a PPI with no squawks however upon the first ferry attempt the pilot identified an oil leak from a high rpm run. The seller of the plane is the owner of the only on field shop declined to work on it post sale despite multiple pleas for help. I found a local A&P who also identified fluctuations in fuel pressure so we sent the fuel system off for overhaul and reinstall but that took 4 months, the actual overhaul was one week. During that time the plane fell out of annual. The A&P reported the plane ran well once the fuel system was reinstalled but he couldn’t find the source of the oil leak and recommended I rebuild the engine, a recommendation I couldn’t support given the current information. I found another A&P wiling to help look for the leak but he flaked out 3 times. I reached out to a Savvy recommended shop in Greenville who sent an A&P out and found a loose oil line to the turbo but the plane wouldn’t start due to a weak battery to verify he fixed the leak. The battery is 17 months old and likely weak due to all the troubleshoot and repair work. He came out again and tried to start the plane with the external power connection and suggested the solenoid for the external port might be bad. The shop then said they were to busy to keep sending people out. I have found another A&P through beechtalk last week wiling to drive to the airport, jump the plane off the battery, inspect for leaks and hopefully sign it off for ferry. Waiting for him to take a look at it this weekend. I know changing a battery and doing ground runs are allowed by owners but I am multiple states away from the plane. My goal is to ensure the plane is safe to ferry it to a nearby airport with a shop willing to work on it. So far this has been a nightmare experience as a new owner. I knew the plane would require work and I am willing to give it what it needs but I never dreamed I would be stuck for 5 months and pleading with people to work on it. I get it, if I owned a shop and had a long wait list of steady customers I wouldn’t want to spend time at a remote field working on the ramp. I”m just getting frustrated and a little desperate.

-

I have a 1980 M20k stuck on the ramp in Spartanburg SC (SPA) and need a referral for a mobile A&P/IA. I bought the plane from the on-field shop and have been trying to deal with a few squawks and the shop is not willing to work on it. My goal is to safely ferry the plane to a nearby airport where it can be worked on. Any referrals are greatly appreciated! Jason

-

I looked at several "project" Mooneys back in the spring. The first was a C that was routinely flown but needed a lot of love and we found spar cap corrosion in the PPI so I walked. The second was a Turbo F that hadn't flown in 10 years. We agreed on price but couldn't agree on having an independent inspection so I walked. I talked to the eventual buyer who indicated they were having problems with the plane. I ended up buying an in annual K that hadn't flown in 10 years. It has set on the ramp for 5 months while I work with a mobile A&P to overhaul the fuel system and now it's out of annual. The point to sharing this is only to make sure you buy the right project for the right price, with realistic expectations for what it will take to make it safe to fly again. No regrets on my project but that's only because I have learned the hard way. Best wishes in finding the right plane for you!

-

N1996J found its new home at CHA!

HawkGT replied to MoMooneyMoProblems's topic in Modern Mooney Discussion

Beautiful plane and just down the road from “home”. Best wishes and safe journeys. Go Vols! -

Another option to consider is a M20K 231 that was converted to a 261 or 262 with a -MB engine by Mod Works or Mod Squad. You get all the benefits of the 252 engine which includes an improved intake runners, intercooler and wastegate but the price is closer to a 231. As stated before, it may also have the second alternator but not all do. There seem to be plenty of these around so they pop up routinely in the market. This is the path I chose in my search for a M20K and very happy with my selection. I’ll also point out that built in O2 was an option for the 231s and many of the planes I considered had it installed. I would love the brakes and useful load increase of an Encore but just couldn’t justify the cost.

-

All of the above. Get on Jimmy's mailing list and have everything ready to pull the trigger when you find something. Facebook marketplace and Craigslist are aditional sources. Its frustrating because the planes that are priced well sale same day so you have to be on it. I closed in May on one that I found on Trade A Plane. Prior to that one fell through due to purchase agreement/inspection disagreement. The second fell through in inspection due to spar cap corrosion. The successful candidate took a ton of leg work to resolve issues before closing. Good luck!

-

Take the training linked above, print out the certificate and keep it with you while you are in the area. There are unique requirements and procedures in the SFRA which the training does a good job of covering. Its highly congested airspace but the good people at Potomac are friendly and helpful at working people through. Lastly, keep Com2 on Guard if you are not talking to Potomac so you can be aware of whats going on in the area.

-

What products did you use? Looks great!

-

Preferably before April 1st as I will be out of town the first week of April.

-

Looking for a ferry pilot to move a M20K 261 from KSPA Spartanburg downtown to KPSC Pasco Washington. Open pilot requires IR 500tt, 100 complex, 50 model. Ideally the pilot would be a CFI and support 5hrs transition training upon arrival. Thanks! Jason

-

I have been actively shopping for a Mooney since December. I finally closed on a new to me m20K model yesterday. The market is crazy right now. What I noticed is planes that were priced right sold in a matter of hours for asking price and planes listed for obnoxious amounts tended to sit for weeks/months. Whats more amazing than the prices is the amount of low/no recent flighy time planes that people are pulling out of the hangar to capitalize on the prices. My first question was always "how much flight time has the plane had in the last 1, 5 and 10yrs" and surprisingly there were several that havent flown in 20 years. I agree this could be a good thing if people actually spend the money to fix these planes and use them. Hopefully it will also open up some hangar space, but I havent seen that yet as demand seems to be equally high with limited supply..so those prices are going up as well. Unfortunately gas prices are also increasing so my fear is this further limits access to GA for new and existing pilots. Economics 101 I guess but it will be interesting to see how current world events effect prices going into warmer weather.

-

@jetdriven That was the point I was trying to verify with the IA when he started talking about not being able to remove the followers. Clearly we were not communicating well. I know replacing the lifters doesnt address corrosion on the cam lobes but it would give a great view of the cam without pulling cylinders and give you a clean surface on the lifters. Thanks for everyones feedback.

-

@philiplane Thank you for confirming what I previously understood. Does anyone know if these cases have the oil galley plug that offers a view of a few lobes and lifters?

-

I did read that post and it is consistent with what I expected to see but I didnt really see anything that answered either question.

-

Yesterday I was watching a Mike Bush video on cam and lifter corrosion. Most of the video was focused on Contenintal engines discussing how Lycoming lifters have a larger tip which requires splitting the case to replace them where Contenintal engine lifter look more like traditional automotive lifters and can be easily replaced. He also talked about how Continental permacast cases had a oil galley plug that can be removed to view a few lifters/cam by boroscope, however sandcast cases dont have this feature. Are the TSIO-360 engines used in M20K Mooney's sand cast or permamold? Better stated, do these engines offer the oil galley inspection point? I was talking to an IA yesterday about whether it would be a good idea to replace the lifters on a engine that has sat for an extended duration since it is easy to do on Continentals, based on the above video. He corrected me by saying the lifter can be easily replaced but not the follower which is the point of interference between the cam and lifter. Im used to the lifter riding against the cam lobe and the pictures I have seen seem to show the same. Is replacimg lifters an option on a M20K TSIO-360 with potential corrosion issues? Searched both questions but couldnt find the answer. Thanks! Jason

-

Thats 231JN, but I agree it looks more like a W. 337 looks similar but serial number matches.

-

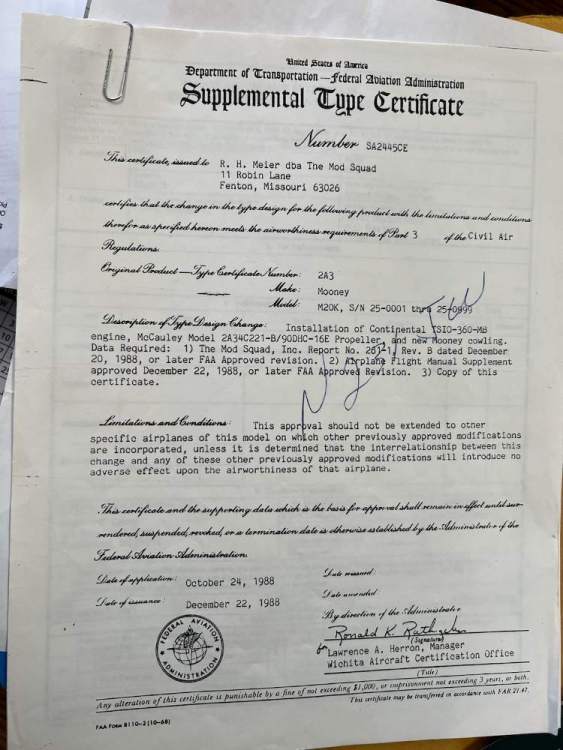

Just to wrap this up, the owner found the original STC and 337s which were signed by Robert "Bob" Meier. The STC lists Robert Meier doing business as Mod Squad. It also references this as a 261, consistent with the posts above. The 337 says the -MB engime, new propellar and a new Mooney cowling were installed, but it does not give the part number for the cowlimg. The owner (IA) is filing this with the FAA to clean up the documentation in the FAA's file. Thanks for all the great information above!

-

I don’t think this is the case, the original install was signed by the STC owner. Further there is another log entry two years later from a separate IA noting the 337 discrepancy and indicating that the modification was inspected against the STC and associated drawings and found to be complete and correct. I just talked to the broker and the owner has found the original 337s, which I think will go a long way to resolving this if I can find a copy of the STC. As for the single/double cowl flaps, it seems there were multiple STCs for this 231 conversion with a -MB and some of them maintained the manual cowl flaps while others provided for the electric variable position flaps. At least thats what I have gathered from reading up on this topic over the last few days, but again I would love to read the STC and the drawings to understand the details for myself.