-

Posts

66 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Moonbat

-

Way too early, but IO-360 A1A is kaput

Moonbat replied to Moonbat's topic in Vintage Mooneys (pre-J models)

The engine is on the bench and split, and all the components are arrayed over three shop tables. We spent some time just ooohiing and aaaahhing, draining oil and doing preliminary forensics. The underlying thinking was, "what the hell kept this plane in the air?" The answer is two and a half cylinders - but not for much longer. A long trip to Texas for the Mooney Formation Flying clinic might have been its last hurrah, We'll never know for certain. More detailed pictures tomorrow if I can get some good shots. Here's what we've seen on an engine that had only 850 SMOH on it (400 of those are mine in the last 3 years) so far. You can only imagine the amount of soul searching that is going on about the right and wrong ways to run an engine like this! My over-riding opinion is that I am very lucky to have followed the array of symptoms to this point before something worse than an overhaul happened. Extreme pitting on two tappets, but notable pitting on all of them. One nearly completely missing lobe of an intake cam. Crank shaft may be serviceable as it has only one step of an oversize bearing so far. Definite wear marks from metal shards on the crank shaft Metal shards "welded" to the sides of several pistons. One can feel the roughness with a finger. Magnetic metal shards in the oil screen, the oil filter canister, the oil filter magnet and in the oil pan. (Oil report not back yet - due in a couple of days.) Several (if not all) piston rod bearings finish was worn badly down to bronze in some spots Cylinders may not be too bad, BUT there is a circumferential rust line in all four of them indicating this plane sat somewhere for a very long time Savvy analysis trend report over the last year (May 2019 - May 2020, 45 flights) show: Statistically significant declining HP in cruise Statistically significant decreasing maximum CHT during flight Statistically significant decreasing maximum CHT in flight Statistically significant decreasing maximum fuel flow during flight As I said, perhaps photos tomorrow... -

850 hours on this engine SMOH. A lot of symptoms now begin to make sense after looking at the cam lobe for the input valves on cylinders 1 & 2. There was barely a bump much less a lobe! Engine comes out, big overhaul underway, might as well do the turbo, the prop, the fuel servo, the exhaust pipes, and governor while at it. They’re all due or nearly due. Now the “fun” begins. Given: this is a 1967 M20E, with t-n, GAMI’s and most every speed mod available, a decent panel recently upgraded With an Aspen E5 to do away with vacuum related stuff. It is the perfect plane for me and my “missions”. The paint’s nice. Then interior is nice. The glass is nice. The plastic is nice. The panel and avionics are nice... not all glass, but nice. Autopilot is STEC 55X. The tanks are long range O&N bladders. I am 68 yo, so this may well be our last hurrah as far as new planes go. (Well, not including the Starduster I’m perseverating on, but that’s another thread on another site.) My wife will have to sell the plane after I’m gone. (I’ve told her to just call Garrison or McGee at All American, assuming they outlast me!) What fun or practical upgrade items would you definitely do in this situation. Electronic ignition? Digital a/p? Digital servos on control surfaces? Go for an overhaul to new specs instead of to service limit specs? New engine instead of major overhaul? Other? Let ‘er rip. I know how you like spending opm!

-

How to find date of my airplane's factory rollout?

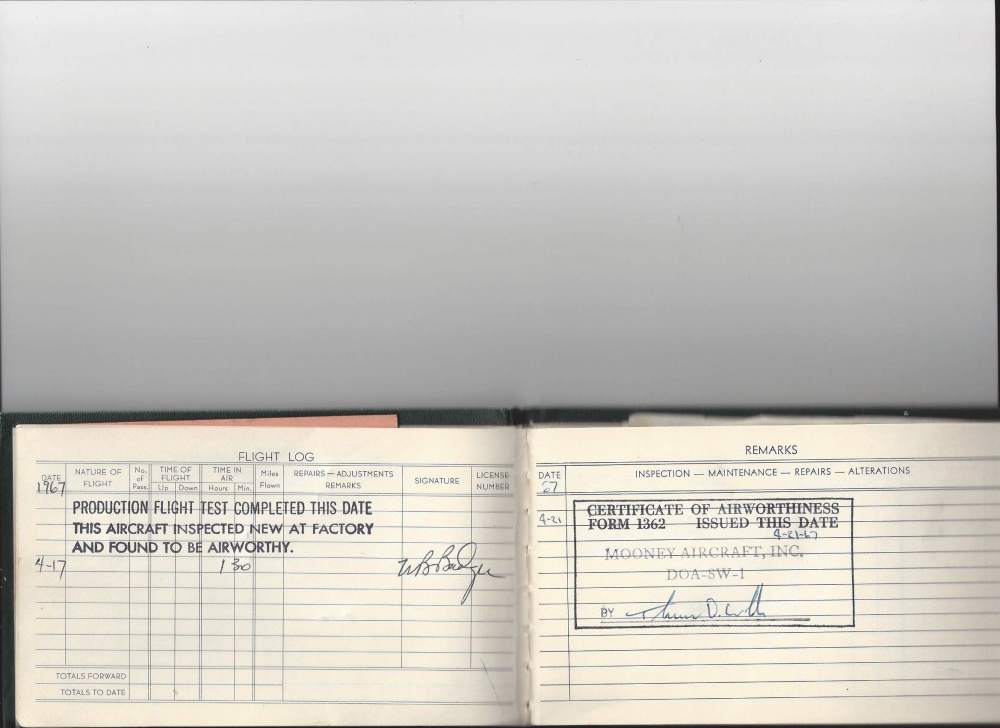

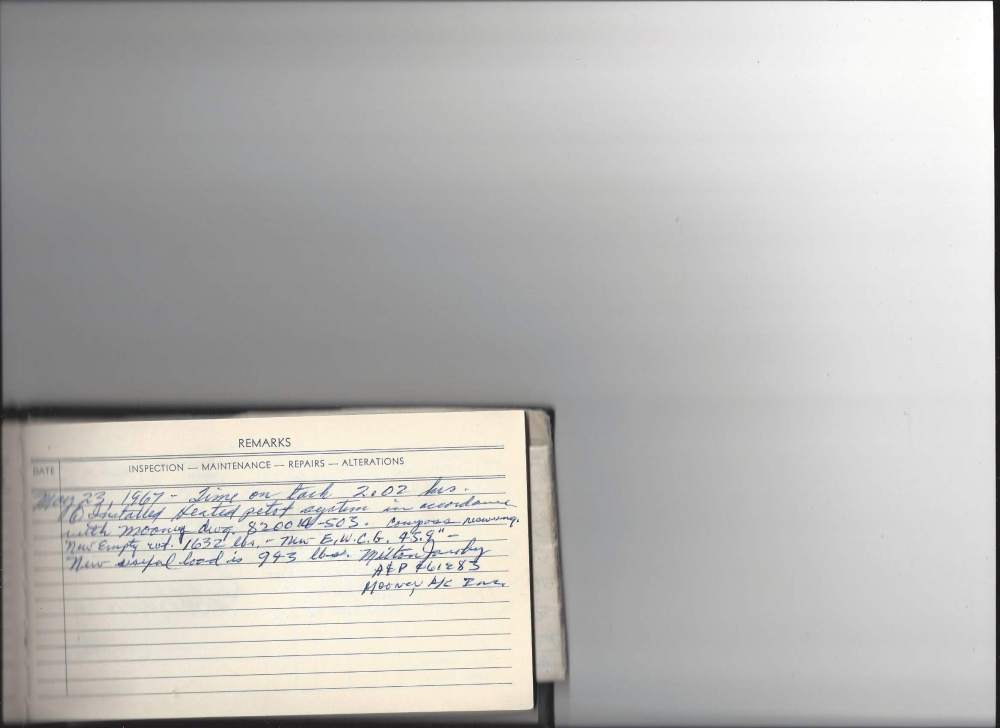

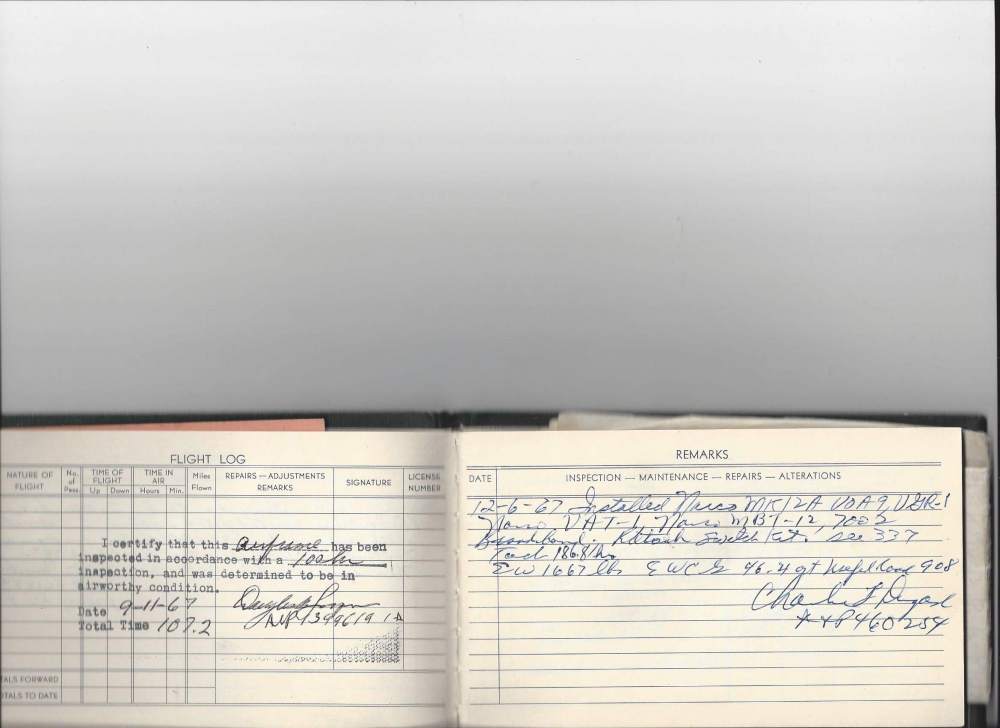

Moonbat replied to airbuspilot2436's topic in General Mooney Talk

I was wondering if this signature in the airframe logbook for my plane (M20E, 670008) is the same as the one you mention? The signature in my logbook for the Production Flight is "W B Badger". That can't be "Bill Wheat". Then the Air Worthiness is signed by ??? Maybe one of you recognizes that signature. I can't read it. Then another very early sign off at 2 hours TT by "Milton Jacoby". And another later one (186 TT) by "Charles Dugosh". All of which means I had better get baking a cake, as Casper’s birthday is next week on April 21 and he’ll be 53! -

Do you recall if you could actually see the air bubble in the tube before you fixed it?

-

When the idea of MOVING AROUND THE COUNTRY IN MOONEYS gets some traction, perhaps we could implement something like the Pilots 'n Paws (PnP) web site (pilotsnpaws.org) that shows where rescue animals come from / go to. It is really useful to see a map with vectors showing start / stop points. Click on a vector and the details show up. Then pilots can negotiate in a message board format how to manage the flight. Those of you involved with PnP know what I'm talking about. Just an idea for a future incarnation of the idea to help move Mooneys around the USA. I think it is a great idea and might find a lot of participants... although too many vectors pointing toward the vicinity of Kerrville TX might be a problem... PilotsnPaws mission map.pdf

-

Thanks A. We must avoid the dreaded "panel sag" at all costs! I'll post if I find out anything conclusive. Should be within a day or so.

-

Did you ever figure out what was causing the turn coordinator ball to hang out slightly to the right side?

-

Terrific look... and I’ll bet she’ll fly faster too!

-

Persistent horn alarm on take-off after gear retraction?

Moonbat replied to Moonbat's topic in Vintage Mooneys (pre-J models)

I was able to crawl upside down under the panel to find, loosen, slightly re-position ever-so-slightly closer to the shaft of the throttle cable, and then re-tighten the position mounting screws for the switch. I now understand EXACTLY how this thing works. I could hear the micro-switch make and break contact each time. Flight tested it today, too - a very nice but cold day - and when I tucked the gear into the wheel wells after take-off, a blissful, horn-free, silence followed - except for the sound of Casper's engine carrying me higher and higher. Success! -

Persistent horn alarm on take-off after gear retraction?

Moonbat replied to Moonbat's topic in Vintage Mooneys (pre-J models)

If the alarm circuit was working correctly, what is the condition about which the circuit and alarm are trying to warn me? Is it trying to warn me when there is a low power setting AND the gear is up / retracted / J- bar on the floor in the horizontal position? If so, and there’s a high power setting, i.e. throttle pushed well in, the throttle microswitch should be OPEN, so as not to ground the alarm buzzer, right? I think once I understand the “logic” the circuit is trying to implement, I’ll be able to trouble shoot it. -

Persistent horn alarm on take-off after gear retraction?

Moonbat replied to Moonbat's topic in Vintage Mooneys (pre-J models)

Aha! Thanks. Is it usually behind the panel or somewhere in the engine compartment? What does it look like? Sent from my iPad using Tapatalk -

Persistent horn alarm on take-off after gear retraction?

Moonbat replied to Moonbat's topic in Vintage Mooneys (pre-J models)

The microswitch in the hole is exquisitely responsive. The slightest touch upward, horn stops. Let it down, horn starts. What stops the horn is pulling back the throttle... way back to 12” or 13” . That is why I am asking, is there another microswitch “looking” at the throttle position somewhere / somehow? Sent from my iPad using Tapatalk -

66' M20E Panel/Overhead Lighting

Moonbat replied to Tahir K's topic in Vintage Mooneys (pre-J models)

The most quirky part of that circuit is the dimmer. It can fail entirely on, entirely off, be “jumpy” or erratic, or anywhere in between.so be sure to exercise it fully throughout its range to see if that has any effect on your LED (Light Emitting Diode). (PP opinion only, with the distinct disadvantage of also being an EE) Sent from my iPad using Tapatalk -

This happens consistently every time for the last couple of months. When I raise/retract the gear during take-off, moving the J-bar from vertical to horizontal on the floor, the alarm horn begins to sound. I can make it stop it by gently pushing up with my finger the little metal arm in the now vacant capture collar on the bottom of the panel where the J-bar goes when the gear is lowered. Generally the noise persists until I level off. When I level off, I pull the throttle way back to 12-13” ever so briefly, the horn stops. Then I go back to a normal setting (20” or more) for cruise, and the horn never is a problem again for the rest of the flight. Is there a “throttle sensor relay” or the like that is failing? If so, where exactly is it located? ( I’ve got to solve this one, as it is very loud and annoying and really bothers any passengers.) Sent from my iPad using Tapatalk

-

I am going to retract that statement until further notice. I looked back into where I saw that, and it was the (mostly) unreliable Wikipedia. Sorry. I'll keep digging.

-

Just to wrap this up, the applicable STC to my Mooney N3215F s/n 670008, with an IO360 A1A engine (with 6th order counterbalances) and an MTV-12-B-180-59b three-bladed composite prop is FAA STC SA02461NY. The limits noted under the "Tachometer" section of the STC are: Green Arc: 1500 to 2700 RPM (Normal Operating) 2700 RPM (Maximum limit) I've already sent the information to JPI and they'll prepare a way to upgrade the digital tachometer face for my EDM930 to reflect this limit and eliminate the 2100-2350 red band. Life is good. (Interesting side note: While carefully reading this STC and the documentation about this prop, I discovered it was made to be a hot prop. Hmmmm... )

-

That sounds like the answer I was hoping for! I'll do a bit more research first, but, in summary: 1. M20E s/n 670008 with its original Hartzell prop has a limit in the POH for a range of RPM's to avoid. 2. M20E s/n 670008 with a replacement Hartzell prop, a different model than the original in #1, has a limit in its STC for a slightly different range of RPM's to avoid. 3. M20E s/n 670008 with a replacement MT-PROP has a limit in its STC for >2700 RPM operation. So, the assumption is that with the MT-PROP, one can operate continuously and safely anywhere south of 2700 RPM.

-

Thanks for those replies. I have read the STC's related to the MT PROP, and find only this limit statement: No continuous operation above 2700 RPM. Do you think the statement in the STC supercedes the limit stated in the POH? Super 21 Model M20E Owners Manual - POH1196 M20E - page 45.pdf

-

The JPI EDM930 in my plane came with the settings between 2100 and 2350 RPM designated in RED. So I have studiously avoided continuous operation in that range. The plane has a turbo-normalized IO360-A1A engine and an MT-Prop (3 blade). Before I owned this plane, it had two different Hartzell 2-bladed props on it (no - not at the same time!), and, of course, at one time it was not turbo-normalized. I have read all the STC's related to my equipment, and find only that the current MT-PROP has a limit: No continuous operation above 2700 RPM. I see in the older Hartzell prop STC's, there are limits on ranges similar to the 2100-2350 range that is marked in RED on the JPI digital tachometer. There is also a "Power Plant Limitation" noted in the original POA. On page 45, it says "No Continuous Operation in this Range": 2100-2350. This is the likely reason for the "Red Arc-Wide" limitation on continuous operation between 2100-2350 RPM. Does anyone know the "why" of that limitation? (I am aware that most props on planes like this run more efficiently at around 2400. Efficiency is not what I am asking about. I am asking if there is some other reason that the 2100 - 2350 RPM zone might be RED. I've never noticed any vibration in that zone as I transition through it.)

-

Contact at Century Flight Systems re: NSD-1000 HSI

Moonbat replied to Moonbat's topic in Avionics/Panel Discussion

Next on the list is the fun part, which is to figure out how to use this stuff! I’m working my way through the Operational Checks given to the pilot (that’s me) and I haven’t yet completed them. Thus I can’t legally fly with anyone else in the plane yet. In the process I actually uncovered a problem that might be addressed with a configuration change to the Aspen Evolution. I can do that in my hangar and then continue the Operational Checks in the air. If that isn’t the complete fix, then a wiring change may be needed, and for that, it is back to the avionics shop for a day... or so. For anyone interested, the part of the test that failed was not tested by the avionics shop because they said the plane had to be moving 40+ kts in order to check this particular mode, and that was not possible while in the avionics hangar. Of course, that is the precise mode that failed in the air. My thinking is that the navigator (GNS480) has a very robust simulator mode, in which it outputs all the necessary signals to the A/P and on the ARINC 429 bus to the Aspen Evolution. One can set a location, an altitude, and A SPEED! Editorial comment: the shop should have tried that method before they turned the plane over to me. That’s what I’ll do when I push the plane out into the 0F temperature and before launching. After all this fun, and while the bank account is in recovery, I plan to figure out why the GAMI spread is so large (2.5 gph) preventing me from flying anything LOP. But that is another entire thread!- 20 replies

-

- 1

-

-

Aircraft: 1967 M20E Me: 68 yrs old, no skeletons, 1700 hrs TT, 400 hrs in type, MAPA PPP, current BFR, current IPC Policy: $85K hull, $100K per person, $1M total (not sure about open pilot clause) 2019 premium: $900 quote #1 through AOPA for 2020: $1450 quote #2 through AVEMCO: $1580 ouch!

-

Contact at Century Flight Systems re: NSD-1000 HSI

Moonbat replied to Moonbat's topic in Avionics/Panel Discussion

Project "Aspen Evolution" is completed. I couldn't be happier. No more vacuum anything. No more WSI weather. No more slaving gyro magnetometer. Gained 15+ lbs more useful load in the process. I uploaded a photo of the new panel and an annotated version of the new panel. See attachments. N3215F Panel_v5.pdf- 20 replies

-

- 5

-

-

First, a correction to the s/n of my plane - 670008 (not 67008). Second, I had a chance to get upside down under the panel before Christmas and test the Sonalert buzzer directly. It is NOT the problem. So, back to the original assumption that it is the switch in the wing. I found that I can reach my arm through the nearest inspection plate and get a hand on the culprit. I have sprayed contact cleaner liberally in that vicinity. I have exercised the stall vane every time I even pat the wings, so more often than I fly. I think that last item had the most impact in making the stall warning 99%+ reliable. Of course there is that tiny, worrisome fraction of a percent to deal with... and that is where I leave this thread.

-

Thanks to all of you for helping me out on this issue. Clarence - Did you mean "spendy" as in expensive, or was that a typo and you meant "speedy"? Anthony - What does "+1 on getting it to work properly" mean?

-

In a Mooney M20E, 1967, s/n 67008, the stall horn relay (in the port wing) is intermittent. I can liberally apply electronic cleaner (tuner) spray to it and exercise it enough to convince most folks that it is working, but... truth is, it bothers me. It works less well after sitting for a few days. It works better when I flip it up-and-down a zillion times as part of my pre-flight ritual. Does anyone have any idea where to find replacements for this relay? I've checked the obvious places (LASAR, Aircraft Spruce, Sporty's) with no luck so far. So I thought I'd ask here.