-

Posts

50 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Little Runaway

-

McCauley D-6012-1 SOLD

Little Runaway replied to Little Runaway's topic in Avionics / Parts Classifieds

Sorry for the delayed reply. It's been sold. Thanks, Aaron -

Copy of RAJAY STC SA1411WE

Little Runaway replied to tomgo2's topic in Vintage Mooneys (pre-J models)

Just sent via PM. Aaron -

A full composite Mooney. Possible or not?

Little Runaway replied to Cargil48's topic in General Mooney Talk

There are a lot of misconceptions out there regarding the use of composite materials in aircraft. Many people immediately think of carbon fiber but composite aircraft are also designed from fiberglass, Kevlar, and other plastic materials. Carbon fiber can be used to create very complex structures with low parts counts. It can also be stiff and lightweight. Notice the use of the word "can" above. Poor designs/layups end up being heavier/weaker than an aluminum alloy part. One of the really cool things about working with it is that different fiber weaves/strand orientations can be used to precisely control strength and stiffness in specific orientations with respect to the part. Carbon structures aren't the magic bullet, however. Working with composites generates hazardous fumes and dust, requires complex tooling, molds, autoclave, etc. Oh yeah, it's really expensive too. Carbon Fiber is also reactive so there are special considerations when bonding/mating it with other materials. There are special HIRF and Lightning considerations as well. One of the biggest challenges with small aircraft like Cirrus or Diamond is structural repair. It often requires an engineering analysis authorized by the factory. I purchased a salvage DA-20 several years ago that had a relatively simple nose wheel collapse and the factory refused to approve a repair. All that being said, Cirrus, Diamond, and others have successfully produced many small composite aircraft without rivets and there are many happy owners. So to your question about making a Mooney exclusively from composite materials--I think you would find that the aircraft wouldn't look just like the Mooney. Much of what makes a Mooney look like a Mooney is because of how it was constructed. Metal fuselage frame with unstressed skin bolted to a semi-monocoque empennage with an all-moving tail. Lots of parts! You can see where the OML changes on a Mooney in these areas. It would probably be more practical to do what Cirrus does--just join two fuselage halves together, which would likely result in a more blended look, i.e., Cirrus. My 2 cents. Hopefully this provides some additional insight. Aaron -

McCauley D-6012-1 SOLD

Little Runaway replied to Little Runaway's topic in Avionics / Parts Classifieds

Carusoam, thanks again! Richard, I still have it for sale. Will send you a PM. Thanks, Aaron -

You might consider updating your software. There have been some important bugfixes as well as several new features and additional functionality. Your GTN is several releases out of date: https://www.garmin.com/en-US/aviationalerts/approval-of-gtn-v6-50-flight-stream-210-v2-90-flight-stream-510-v2-40-and-gtn-com-v2-30-software-for-aml-stc-sa02019se-d/ https://www.garmin.com/en-US/aviationalerts/approval-of-gtn-6xx-7xx-software-version-6-51/ https://www.garmin.com/en-US/aviationalerts/approval-of-gtn-6xx-7xx-software-version-6-62-and-flight-stream-510-software-version-2-51/ Aaron

-

I purchased it new about a year ago as a temporary solution for digital CHT in my panel. It's probably the best I've seen for CHT as it shows the coldest and hottest cylinders at the same time. Doing a full panel overhaul so I don't need it any more. It's in excellent working condition. (picture from Aerospace Logic website) Excellent instrument. This is a TSOd unit. Includes the type J probes, connectors, and harness. $380 plus actual shipping cost with carrier/method of your choice. More info here: http://www.aerospacelogic.com/index.php?dispatch=products.view&product_id=64

-

I had an RF ablation procedure in 2011 to correct A-Fib. I was 37 at the time. It took about 6 months to get the procedure scheduled with a cardiologist. I had to be on Warfarin (Coumadin) for a few months prior to the procedure, if I remember correctly. It was a PITA having to have bloodwork done a couple times a week for three months but the procedure went well with a pretty short recovery time. The FAA required a 6-month waiting period before they would consider a special issuance. They required a report from my cardiologist after wearing a Holter monitor for a week or two and having some bloodwork done. My cardiologist gave me a letter and I took it to my AME, who, submitted the cardiologist letter with my application for a 2nd Class medical. It didn't take long (a few weeks, maybe) before I received a mail response from OKC with a Special Issuance 3rd Class medical enclosed (I can't recall what else they wanted before they would issue a 2nd class--it may have been more information from my cardiologist but I was able to get a 2nd Class shortly thereafter). The conditions of the Special Issuance were that I was required to wear a Holter monitor for 24 hours and see an AME every year for five years (the Special Issuance was only valid for one year). I was also required, of course, to report any further symptoms. After the fifth year I received a letter from Oklahoma City informing me that a Special Issuance was no longer required. I did a lot of research prior to choosing RF ablation, and more importantly, my cardiologist. I fly professionally (not airlines) so I wanted to minimize the time I would be without a medical. My supervisor, at the time, had a great idea. He had a contact at the FAA in OKC and was able to find out which cardiologists in my area were able to get the paperwork to the FAA, with the right information, in a timely manner. Apparently some are terrible and don't want to deal with it. I chose the cardiology clinic based on this information. I didn't have much control over who in the clinic performed the procedure but he was top-notch. He sat down with me for about 45 minutes and made sure all of my questions were answered prior to scheduling the procedure. I asked him about success statistics and how he mitigated risk. He was able to answer all of my questions and it was clear he was methodical and knew his trade. He also agreed to help me with whatever the FAA required following my recovery. My procedure lasted about 8 hours--they had trouble getting me into fibrillation and I actually had a couple of different fibrillation modes. As far as getting back to sinus rythm, that's probably bordering on medical advice so I'm not comfortable posting what worked for me on this forum. I'm happy to discuss it with you if you want to PM me. Good luck. It's a stressful experience but it definitely worked out for me and I've been in sinus rhythm for years. I've heard that the new cryo stuff is less likely to damage surrounding tissue, or result in the need for a pacemaker, but I'm not sure as I haven't needed to look into it! Aaron

-

Need a Solid From Someone Going to Oshkosh!

Little Runaway replied to DualRatedFlyer's topic in General Mooney Talk

I'll also be there Monday morning. Happy to stop by and do it if Brian E. is unable. Aaron -

McCauley D-6012-1 SOLD

Little Runaway replied to Little Runaway's topic in Avionics / Parts Classifieds

Thanks, carusoam. I still have it, Captnmack. I'll send you a PM with contact info. thanks, Aaron -

Panel file requested - 1974 M20E

Little Runaway replied to Little Runaway's topic in Vintage Mooneys (pre-J models)

Thanks, John! -

Anyone have a panel file for a 1974 M20E they are willing to share? It doesn't matter what instrument layout you have--I'm just looking for the outer shape to clean-sheet a panel for my E. File format doesn't matter--I can convert if necessary. I'm guessing a 1974 M20C or M20F would be the same. Thanks! Aaron

-

-

Applying high-temp anti-seize to the slip joints helps prevent cracking (reduces stress) and makes it much easier to disassemble the next time. I recently had to R&R the Rayjay exhaust on my M20E because it was installed incorrectly by a shop that should have known better. They didn't anti-seize the slip joints and it was a real bear to remove. Permatex Copper Anti-Seize Lubricant Aaron

-

Hooker harness should/lap belt

Little Runaway replied to par's topic in Vintage Mooneys (pre-J models)

Resurrecting this thread: I would also appreciate part numbers for this kit, if anyone has them. I spoke with the Hooker folks at the Airventure booth and they said they didn't make a kit for Mooneys. thanks, Aaron -

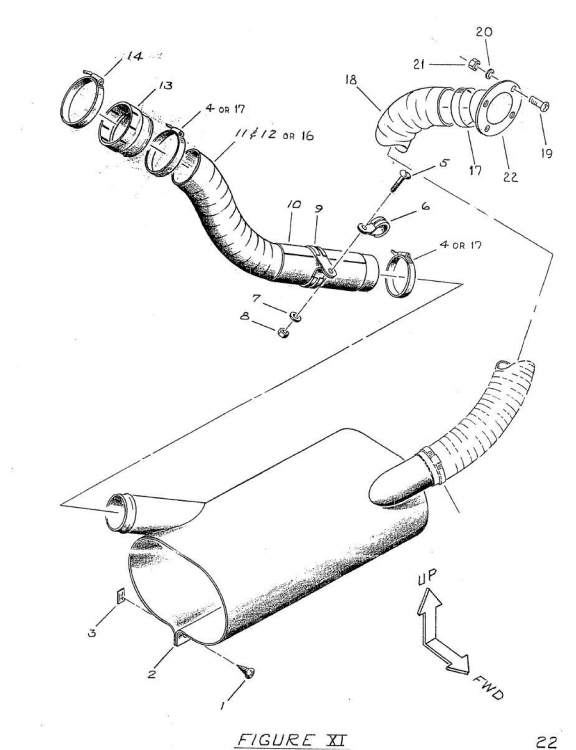

Thanks for the pic. That's interesting. It's definitely a tight fit. It looks like the high-pressure oil line routing in your aircraft also differs from the STC instructions. I'm told the black orange SCAT ducting holds up better in the heat. The STC also calls for an asbestos cover near the exhaust heater muff (item 10 in figure below).

-

Hello, folks. I have a couple of requests for you Rayjay M20E/F owners: Would you mind sharing a picture of your heater hose/SCAT routing leading to the heater control valve on the firewall? I have a recently overhauled engine/Rayjay system that I suspect may have some incorrectly routed hoses. I've attached a couple side view images of my engine with and without the Scat heater hose removed. From what I can tell, there is very limited space to route a hose between the intake tube and oil sump. The wire on the Scat tubing was chafing the bottom of the oil sump and the shop deformed the flange to get it to fit. I have the STC owner's manual and installation manual but they seem quite vague when it comes to routing. The pressure oil line to the turbo appears to have a male-male 1/8 NPT fitting with a NPT-AN adapter fitting. This seems like a hoakey setup and I believe the pipe threads may be partially stripped. I would greatly appreciate any pictures you have of your setup or advice on the matter. Tapping these small pipe threads seems like a real potential headache. Pics attached, thanks!