Flymac

Verified Member-

Posts

67 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Flymac

-

IO-550 Complete Ignition/Magnetos Package

Flymac replied to Flymac's topic in Avionics / Parts Classifieds

These mags/harness/plugs are still available, updated final hours as I was delayed in removing them: also dropping price to $2000 shipped. Emailing mackenzie.brian@gmail.com is best. TCM / BENDIX S-20 Magnetos, 10-500556-1, S6RSC-25 356 Hrs SNEW 147 HRs Since 500Hr Inspection – See Service Sheet, were found as essentially new, sent to premier Aircraft Magneto Service shop. Left Harness: 10-423674-19 Rev “A”, K20H “Left” Right Harness: 10-823674-1 Rev “D”, K20H “Right” -

IO-550 Complete Ignition/Magnetos Package

Flymac replied to Flymac's topic in Avionics / Parts Classifieds

I was too late to reply back to Jerry so these are all still available! Please email if interested, thanks, happy new year! -

IO-550 Complete Ignition/Magnetos Package

Flymac replied to Flymac's topic in Avionics / Parts Classifieds

Still available, email mackenzie.brian@gmail.com any questions/details needed! -

Airwolf Remote Oil Filter Mount/Kit K008-F for IO-550

Flymac replied to Flymac's topic in Avionics / Parts Classifieds

Still available, make an offer, email mackenzie.brian@gmail.com -

IO-550 Complete Ignition Package with practically NEW magentos. Removed from IO-550N and running perfectly, upgrading to electronic ignition. $3500 shipped for all, not separating at this time. TCM / BENDIX S-20 Magnetos, 10-500556-1, S6RSC-25 265 Hrs SNEW 78 HRs Since 500Hr Inspection – See Service Sheet, were found as essentially new, sent to premier Aircraft Magneto Service shop. Left Harness: 10-423674-19 Rev “A”, K20H “Left” Right Harness: 10-823674-1 Rev “D”, K20H “Right” Tempest Massive Plugs: URHB-32E, Qty 12 with 149 Hrs SNEW, 2 Brand new/spares Mag Sale.pdf

-

Airwolf Remote Oil Filter Mount K008-F Complete remote oil filter mounting kit, less the mounting hardware for the bracket(AN3 Bolts). Screws right on to the stock IO-550 oil filter pad, remote mount where you like. Size 10 lines included, was mounted on a IO550N. New for $595 on ACS without hoses, posting for $450 shipped with hoses. Paypal. Email mackenzie.brian@gmail.com

-

Engine slightly Rough/Stumble when LOP?

Flymac replied to Flymac's topic in Modern Mooney Discussion

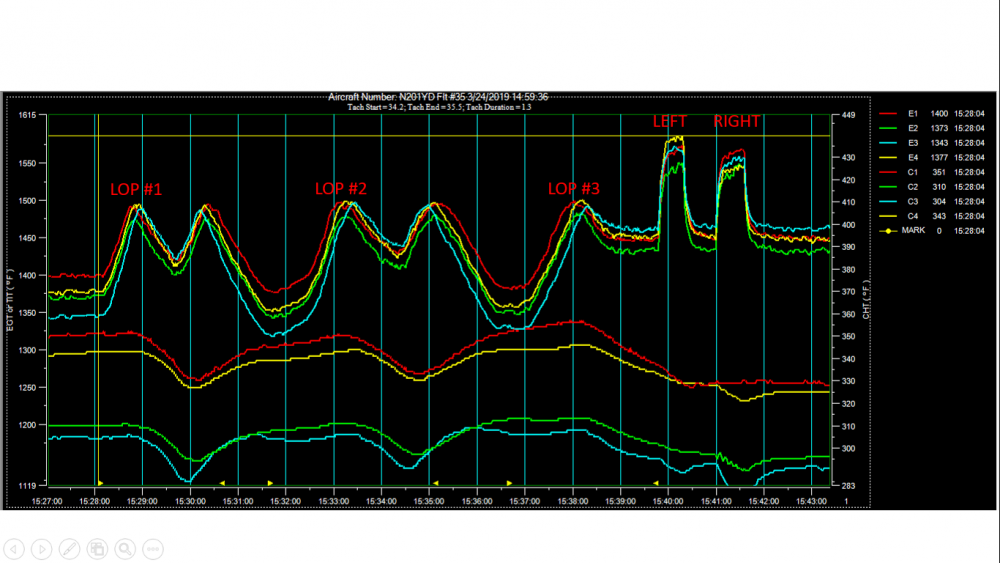

Posted to Savvy: https://www.savvyanalysis.com/flight/3059779/d58d1342-106c-4897-9a76-4896a17e41ac I put all the labels on the posted picture just to help see what happened when, but I know its harder not to be able to freely zoom/scroll, so for the savvy graph: 29min: LOP #1, 33min: LOP #2, 38min LOP #3 with the LOP mag test right after from 40-42min. Per the other questions: all are fine wire plugs, pretty new with only ~130hrs on all of them. -

Engine slightly Rough/Stumble when LOP?

Flymac replied to Flymac's topic in Modern Mooney Discussion

Yep, see 2nd graph i had posted above right after the ground mag check graph -

Engine slightly Rough/Stumble when LOP?

Flymac replied to Flymac's topic in Modern Mooney Discussion

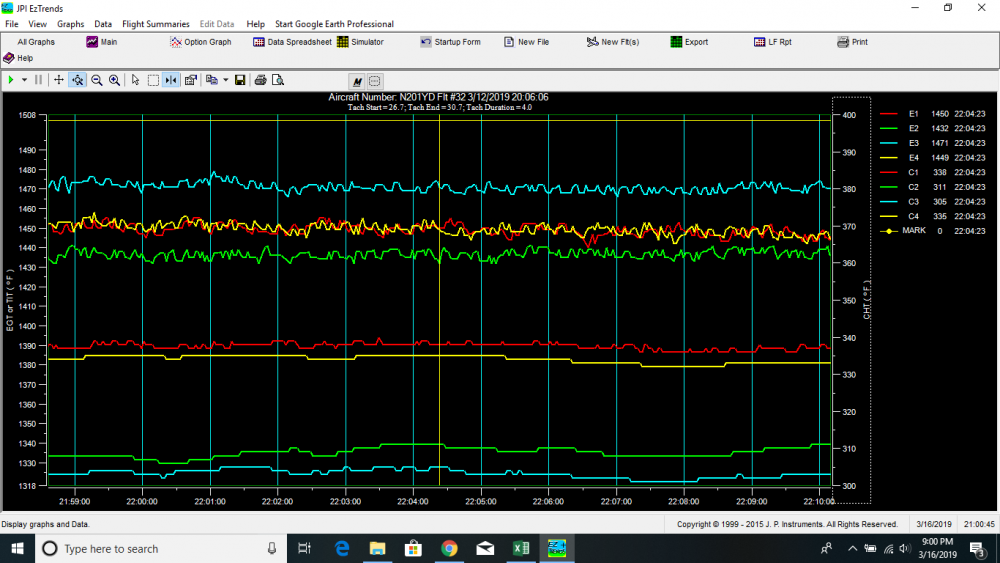

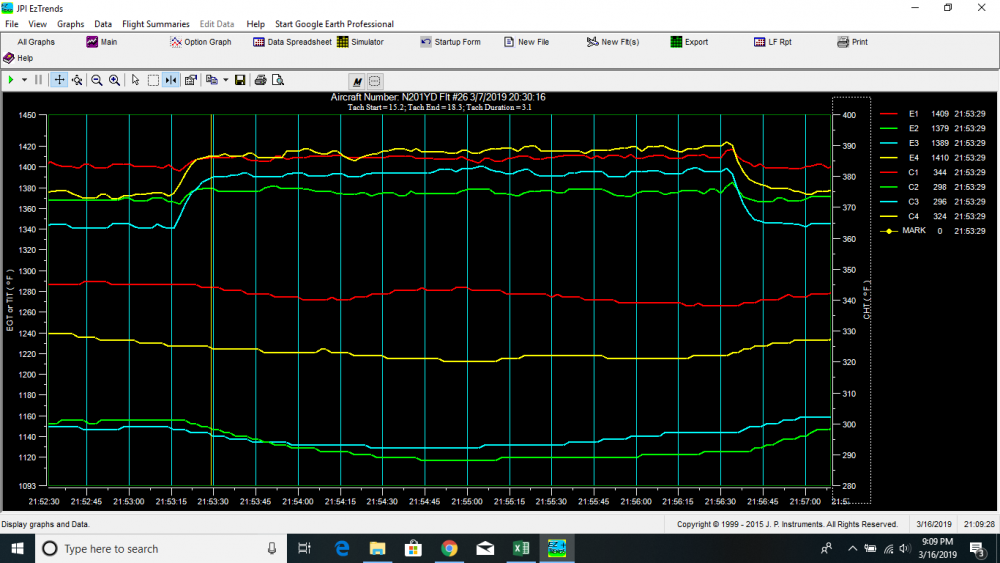

Following up with more data after getting to do the detailed Savvy inflight test today finally, and the LOP mag test I had originally forgotten to do before my last flight and posting all of the original data... Runup to usual 1900RPM, 30 Sec Both, 30 Left, 30 Both, 30 Right...if we're able to nitpick 30 seconds worth of data and only 20 degrees...I see here that L mag E2/Green is alittle cool compared to others...until on R mag, where in general all EGTs are much closer together..apart from E4/Yellow. What this means...not sure! Ha. I have the dual mag, so the balance between the 2 overall EGT temps is in line as expected...possibly clean plugs on #2/#4 is all I get here... LOP/ROP sweeps, 7500 0 Deg C, LOP Mag Check The JPI data taking the time to do the seeps much much slower revealed a spread of closer to 0.6-0.8 Gami spread...so maybe that is part of my issue vs all by prior data, even with pretty slow sweeps, was showing 0.5gph spread every time.. -Funny E4 on this one is much higher on that others on the L mag vs the R mag on the runup above.... -LOP order is consistent...E4/Yellow and E3/Blue still rising significantly and crossing others j -

Double Check your Batteries are Secured after Annual

Flymac replied to Mooney_Allegro's topic in Modern Mooney Discussion

back to the battery topic, if thats now on your personal list to check the tie-downs...I'd add checking the water levels (if not sealed)...that was my learning this year (always heavily involved in owner assisted every year, but always learning more to check, and what to check earliest in)...my battery levels were extremely low, probably added 2oz per compartment...just one more item thats on my personal list to "trust but verify" the shops...easy item to help maintain. -

Engine slightly Rough/Stumble when LOP?

Flymac replied to Flymac's topic in Modern Mooney Discussion

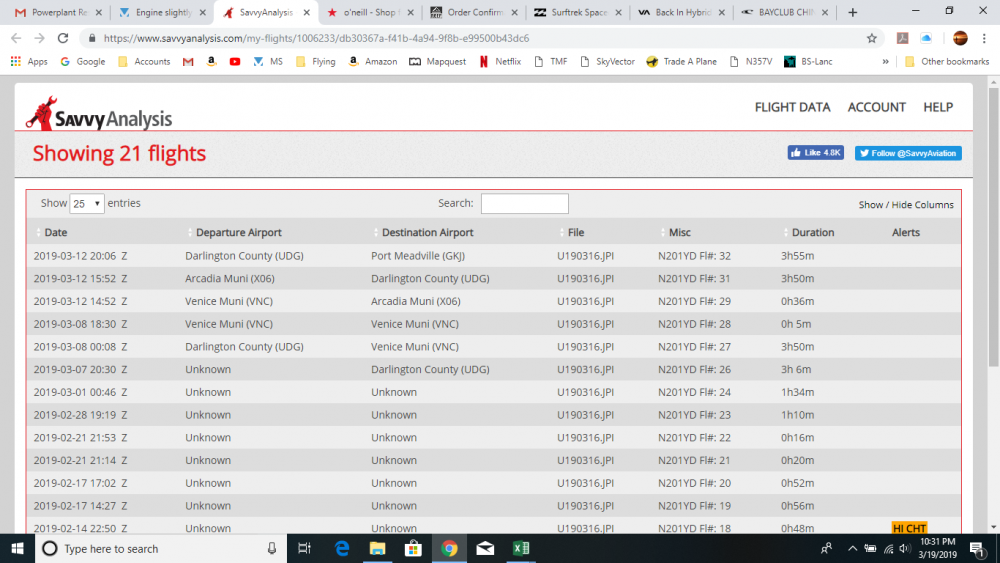

I get this view/web when I click the link...but maybe its different to others, see the "Misc" column is the Flight numbers I was referring to in the notes above. Thank you much for taking the time to check it out and all your feedback! -

Engine slightly Rough/Stumble when LOP?

Flymac replied to Flymac's topic in Modern Mooney Discussion

I've posted my file (was a download all) to Savvy...it says I can share a link for individual flights, but I only see a link to share them all it seems. The 2 focus flight might be #26 and #32, and as described below. I agree on a in flight LOP Mag check, it was my absolute intention before landing, just forgot, certainly hope no ignition issues being a brand new harness and new fine wires with only ~100 hrs. https://www.savvyanalysis.com/my-flights/1006233/db30367a-f41b-4a94-9f8b-e99500b43dc6 #32 Was pretty much all LOP, 5500, a climb at 1:06 to 7500, then right back to LOP rest of flight, was the slight rumbley/stumble as described... #26 Was the "failed attemp" flight of 8500 trying LOP 2 times that was just a tab too rumbly to accept after trying for ~5 min or so, 8500ft...at 29 min and 54min were first 2 LOP attempts for a few minutes -

Engine slightly Rough/Stumble when LOP?

Flymac replied to Flymac's topic in Modern Mooney Discussion

2 seconds -

Engine slightly Rough/Stumble when LOP?

Flymac replied to Flymac's topic in Modern Mooney Discussion

Help me understand your feedback alittle more if you could, and thanks for taking a look...you noted E1/E2, red/green which match up so I dont think a typo, but I dont see these crossing each other, or otherwise why you believe their ill behaved? If I have exhaust temps crossing each other, especially at this small scale, I would actually take this as a good thing that their running so close/consistent together (not take I care vs having the fuel mixtures close rather than temps)..but just want to understand your feedback. It does seem #1 is a tad lean to begin with as I dont get much rise out of it compared to the others...will have to see if I could possibly richen it up with another injector swap... -

Engine slightly Rough/Stumble when LOP?

Flymac replied to Flymac's topic in Modern Mooney Discussion

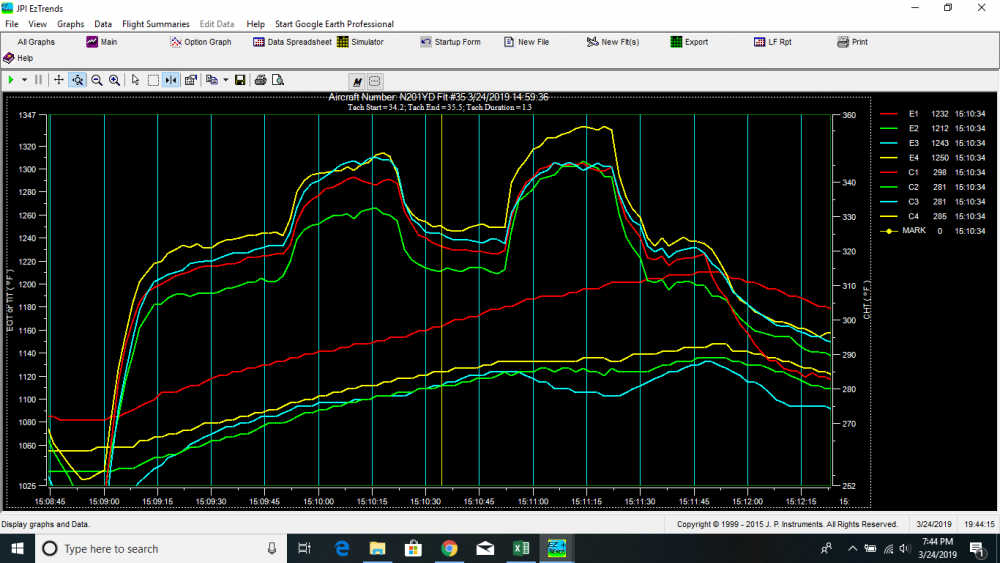

I did try different RPM/MP settings...essentially varying between 2400 to 2550 RPM...my default is/was WOT during the trip, I tried backing that off some with varying RPM, but it didnt seem to have any affect. I just had the prop balanced down to 0.02 as well, so I believe what I'm feeling/hearing is truly this slight stumble-ish behavior of the engine. -When we were swapping injectors around, I believe my mechanic cleaned them with spray/cleaner, no ultrasonic. we started at ~1.2GPH spread post-OH so definitely worked our way forward The JPI EZTrends is still a bit boggling to me how to change the scales, get FF together with the temps..etc...attempting to post... This is 5500Ft running LOP, ~8.8GPH...slightly rumbly as I have described..but was happier than trying at 8500 This was at 8500Ft trying LOP when it was just too unhappy to continue LOP...same WOT, ~2400, was still about 9GPH...as you can see still being 9gph not trying to get excessively deep LOP, just enough to peak all cylinders, still which were still all within ~0.4gph -

I highly prefer to fly LOP, usually cruise 6500-9500', currently 30Hrs post OH, IO-360, finewire plugs ~100 Hrs, new harness at overhaul. After breakin used my JPI data to swap around some injectors to get my GAMI spread back in line, and have it at 0.4-0.5 GPH spread, so quite happy with that. Just took my first big trip with the plane post overhaul, but engine does not seem to be entirely happy running LOP despite the nice(low) GAMI spread...when I transition to running LOP, the engine just seems to run a bit "rumbly"...not quite full stumbles or skips, but its like you can tell its just not entirely happy for some reason. Just feels by sound its not smooth running... This is without going extremely deep LOP or such, only 30-40deg LOP, and different that kind of the roughness you get when going too deep LOP where perhaps the GAMI spread gets worse and power disparity between the cylinders. One leg at 8500 it just seemed too unhappy to continue LOP, but next leg at 6500 seemed alittle smoother, both where same GAMI spread when transitioned. Any ideas/suggestions why the engine would be running like this, even with a pretty good GAMI spread? I forgot a LOP mag check before landing from the trip was only other idea currently.

-

For learning, why would any inspection panel be secured with rivets in the first place? This also makes me think of every annual (that I aim to do everything possible my mechanic allows me/has taught me/inspects for me) and looking at the sea of what feels like a hundred panels under each wing...what do most limit their removal/inspection to, just where there are any bellcranks or such? Sorry if thats alittle bit of thread creep!

-

Large EGT difference / stuttering at idle after flight

Flymac replied to bdash's topic in Modern Mooney Discussion

Just went through same issue/finally biting the bullet with my 730...for years the data downloading has never worked (would only record a 2 min file or such)...no parameter change in the world fixed it, tried many USB sticks, even the "JPI" one they sent...no change. A factory reset didnt fix, and trying the firmware update would not recognize the new data files on the USB I downloaded from the JPI website(JPI techs on phone couldnt figure it out either). Had to go back to JPI to update firmware. I had 2.13, which I read between the lines as that version didnt seem to really support the downloading as it should, or as mentioned above, must have been very picky on its USB sticks! -

Mystery Tube - Fuel Dripping When Flooded

Flymac replied to rangermb's topic in Modern Mooney Discussion

Is every IO-360 supposed to have the sniffle valve? Was just checking my Parts Bullentin for my 78 201, Ser 522...and sniffle valve is listed (Section 28-20-00, Item 63, 610122-501) however Has Note I...Note I details for serials 1-83, 85-377.... I'm curious how/why the need would be eliminated after that unless that also tied to some IO-360 variant where it was no longer required or factored into the fuel servo? Seems above discussion and other threads on the notorious sniffle valve indicate everyone should have one...but seeing otherwise in parts bulletin (in the middle of checking to see if I have one next cowl off!) -

Overhaul review, Jewell Aviation and powerflow exhaust

Flymac replied to aaronk25's topic in Modern Mooney Discussion

Just completed an overhaul at Jewell as well, hoping to get first startup next week and begin flying again! I can echo the comments made in the post a few years ago still stand today, David was very helpful, patient with me answering all kinds of questions and checking in during the process. Pricing was just as advertised on the website, no surprises, and timeline spot-on as he estimated (granted I think I missed the winter rush!) as engine came back before thanksgiving. We had 2010 Hrs on our engine so hoping for a few knots back of performance would at least be something to feel good after this $$$$ process! -

I ended up ordering the rod end Byron had noted (in a separate thread) and we'll see how that ends up...an Aurora CW-3, noted with a 20* misalignment angle per Aurora's product manual, should help. To put link with this thread: https://www.amazon.com/gp/product/B003JQLNC6/ref=oh_details_o06_s00_i00?ie=UTF8&psc=1

-

Thanks for the feedback so far...I agree for what I noted and re-stated above, the cable is supposed to mount on the outside, even though that really crates all of the inward angle...the thought on possibly my servo arm not being correct was a good idea in that maybe theres one that extends further outward, but it really looks to match Byrons in size (I'll be back there in an hour and measure how far it extends out.) I'm not sure I follow what the idea is on moving the arm 1 notch clockwise in terms of relieving any of the binding if you could elaborate? (to note I dont recall what position I had the mixture knob in this photo if that was driving the comments) My mechanic and I considered that as full rich we have about 3/16" gap on the knob before hitting the stop nut in the cabin, but we thought 1 notch might be greater than that and not allow us to then hit the full rich limit of the servo...but can certainly try. Certainly agree on replacing washers with a bushing/tube...other than that maybe just a different rod end is needed... I thought I saw Byron note the one he purchased was a "distressed angle" rod end...that could make perfect sense to cover more of the angle, I wasnt aware they made such a thing, but will confirm my thread and maybe try.

-

Old post but same topic/issue as my mechanic and i are in the middle of re-attaching mixture cable to servo...just not happy with how it binds up slightly on the mixture cutoff end...he played with the rod end for awhile, checked service book and saw how it has that mooney part mentioned above and thought that was issue and having “correct” part would mechanically link up better and deal with the angle more smoothly...well after researching this thread and others, seems everyone is doing the opposite and getting rid of that link ha! So i think we are best off with the rod end, but its just so crappily spaced/shimmed/angled that needs fixed, or maybe a different one...does anyone have any pics of your your installation and how your cable is attached to the engine standoff? See mine, its such an angle but manual does show having cable on outside...not a fan of all the washers for spacing either, but then the angle of the rod to the rod end would be even worse...appreciate any comparison

-

Ive been hoping to finally start putting together some of my GoPro videos I've been recorded...but have been bogged down trying to figure out the quickest/easiest way to edit the massive videos and such...I'm kind of stuck...looking for input or quick cheats/software people are using? Typically I'll record say a 2 hours flight or so...so Gopro splits it up in the ~12min video segments.. I want to be able to put these all together in 1 video, and then speed up most of the flight, normal/slow play at interesting points, freeze frame, etc...I'd say pretty normal, not too complex stuff. Frustration of what I'm running in to: GoPro Studio seems it was king of user friendly editing and doing these basic features...but no longer available New GoPro Quick can merge the videos...but SUPER basic functions of only up to 1 minute video, can pick "highlites" but cant control anything more GoPro Splice...also merges the clips together, but can only do 2X speed, and cant pick specific segments, only the full video clip...also only on IOS vs managing large files on the laptop... I've experimented trying to use some of the other free, more advanced editors: Davinci Resolve seems like a nice one...but has pretty high system reqs I dont meet (i7, 14GB Ram, etc)...so it wont run Filmora - still trying to figure it out...but then leaves a watermark on exported file... Ugh! Just want a quick, easy way to do basic edits and enjoy some cool videos! What are people using? @gsxrpilot how did you edit that Burning Man video for example where you had multiple segments of fast fwd, slow play, stills, etc...which seemed to be from a long flight that also would have been broken into multiple files.

-

What type of metal is the outer sheet made out of? Is it a specific aluminum grade and thickness I assume...say if one wanted to make a flush mounted patch or at least make the patch out of the same material. How does one determine this when the parts bulletin is always in Mooney Part numbers? I know in the Service Manual they list many of the outer skins and such like 2024 T3...but didnt see it on all items like these doors.