Flymac

Basic Member-

Posts

67 -

Joined

-

Last visited

Flymac's Achievements

-

IO-550 Complete Ignition/Magnetos Package

Flymac replied to Flymac's topic in Avionics / Parts Classifieds

These mags/harness/plugs are still available, updated final hours as I was delayed in removing them: also dropping price to $2000 shipped. Emailing mackenzie.brian@gmail.com is best. TCM / BENDIX S-20 Magnetos, 10-500556-1, S6RSC-25 356 Hrs SNEW 147 HRs Since 500Hr Inspection – See Service Sheet, were found as essentially new, sent to premier Aircraft Magneto Service shop. Left Harness: 10-423674-19 Rev “A”, K20H “Left” Right Harness: 10-823674-1 Rev “D”, K20H “Right” -

IO-550 Complete Ignition/Magnetos Package

Flymac replied to Flymac's topic in Avionics / Parts Classifieds

I was too late to reply back to Jerry so these are all still available! Please email if interested, thanks, happy new year! -

IO-550 Complete Ignition/Magnetos Package

Flymac replied to Flymac's topic in Avionics / Parts Classifieds

Still available, email mackenzie.brian@gmail.com any questions/details needed! -

Airwolf Remote Oil Filter Mount/Kit K008-F for IO-550

Flymac replied to Flymac's topic in Avionics / Parts Classifieds

Still available, make an offer, email mackenzie.brian@gmail.com -

IO-550 Complete Ignition Package with practically NEW magentos. Removed from IO-550N and running perfectly, upgrading to electronic ignition. $3500 shipped for all, not separating at this time. TCM / BENDIX S-20 Magnetos, 10-500556-1, S6RSC-25 265 Hrs SNEW 78 HRs Since 500Hr Inspection – See Service Sheet, were found as essentially new, sent to premier Aircraft Magneto Service shop. Left Harness: 10-423674-19 Rev “A”, K20H “Left” Right Harness: 10-823674-1 Rev “D”, K20H “Right” Tempest Massive Plugs: URHB-32E, Qty 12 with 149 Hrs SNEW, 2 Brand new/spares Mag Sale.pdf

-

Airwolf Remote Oil Filter Mount K008-F Complete remote oil filter mounting kit, less the mounting hardware for the bracket(AN3 Bolts). Screws right on to the stock IO-550 oil filter pad, remote mount where you like. Size 10 lines included, was mounted on a IO550N. New for $595 on ACS without hoses, posting for $450 shipped with hoses. Paypal. Email mackenzie.brian@gmail.com

-

Engine slightly Rough/Stumble when LOP?

Flymac replied to Flymac's topic in Modern Mooney Discussion

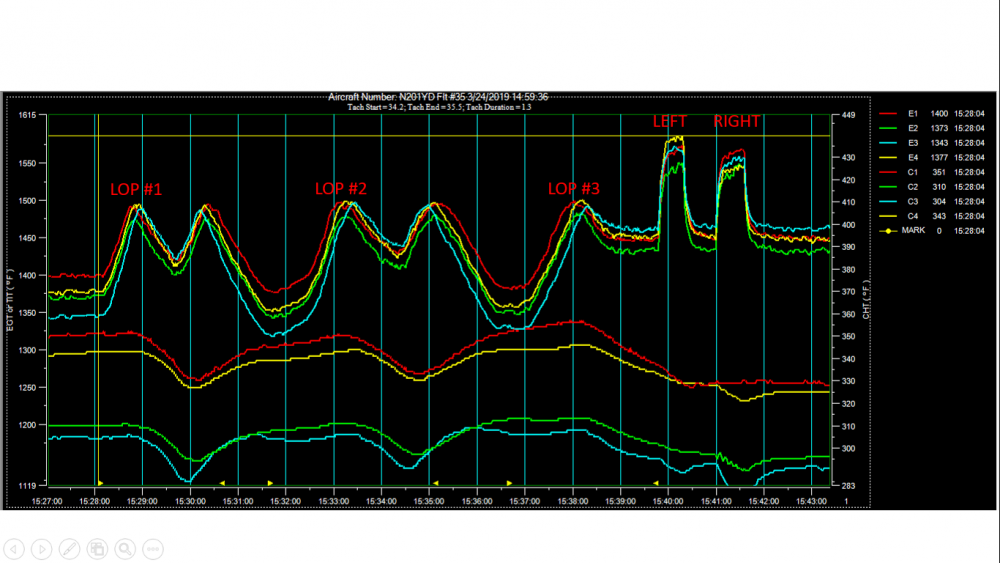

Posted to Savvy: https://www.savvyanalysis.com/flight/3059779/d58d1342-106c-4897-9a76-4896a17e41ac I put all the labels on the posted picture just to help see what happened when, but I know its harder not to be able to freely zoom/scroll, so for the savvy graph: 29min: LOP #1, 33min: LOP #2, 38min LOP #3 with the LOP mag test right after from 40-42min. Per the other questions: all are fine wire plugs, pretty new with only ~130hrs on all of them. -

Engine slightly Rough/Stumble when LOP?

Flymac replied to Flymac's topic in Modern Mooney Discussion

Yep, see 2nd graph i had posted above right after the ground mag check graph -

Engine slightly Rough/Stumble when LOP?

Flymac replied to Flymac's topic in Modern Mooney Discussion

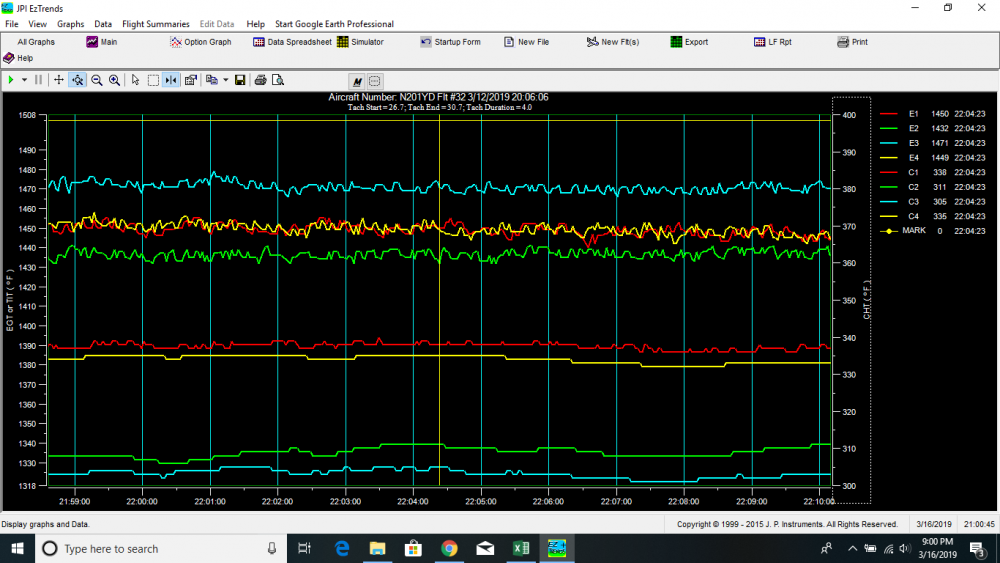

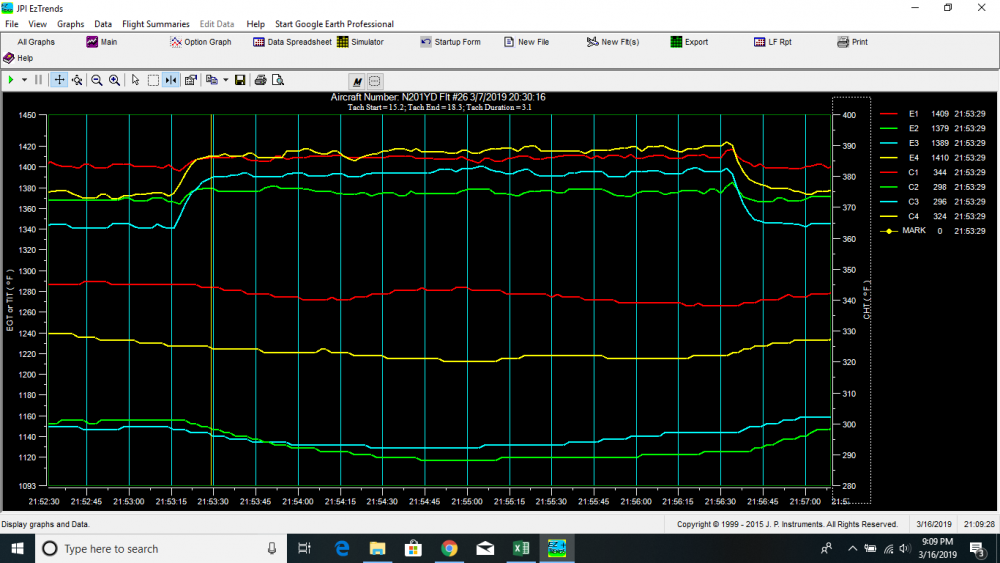

Following up with more data after getting to do the detailed Savvy inflight test today finally, and the LOP mag test I had originally forgotten to do before my last flight and posting all of the original data... Runup to usual 1900RPM, 30 Sec Both, 30 Left, 30 Both, 30 Right...if we're able to nitpick 30 seconds worth of data and only 20 degrees...I see here that L mag E2/Green is alittle cool compared to others...until on R mag, where in general all EGTs are much closer together..apart from E4/Yellow. What this means...not sure! Ha. I have the dual mag, so the balance between the 2 overall EGT temps is in line as expected...possibly clean plugs on #2/#4 is all I get here... LOP/ROP sweeps, 7500 0 Deg C, LOP Mag Check The JPI data taking the time to do the seeps much much slower revealed a spread of closer to 0.6-0.8 Gami spread...so maybe that is part of my issue vs all by prior data, even with pretty slow sweeps, was showing 0.5gph spread every time.. -Funny E4 on this one is much higher on that others on the L mag vs the R mag on the runup above.... -LOP order is consistent...E4/Yellow and E3/Blue still rising significantly and crossing others j -

Double Check your Batteries are Secured after Annual

Flymac replied to Mooney_Allegro's topic in Modern Mooney Discussion

back to the battery topic, if thats now on your personal list to check the tie-downs...I'd add checking the water levels (if not sealed)...that was my learning this year (always heavily involved in owner assisted every year, but always learning more to check, and what to check earliest in)...my battery levels were extremely low, probably added 2oz per compartment...just one more item thats on my personal list to "trust but verify" the shops...easy item to help maintain. -

Engine slightly Rough/Stumble when LOP?

Flymac replied to Flymac's topic in Modern Mooney Discussion

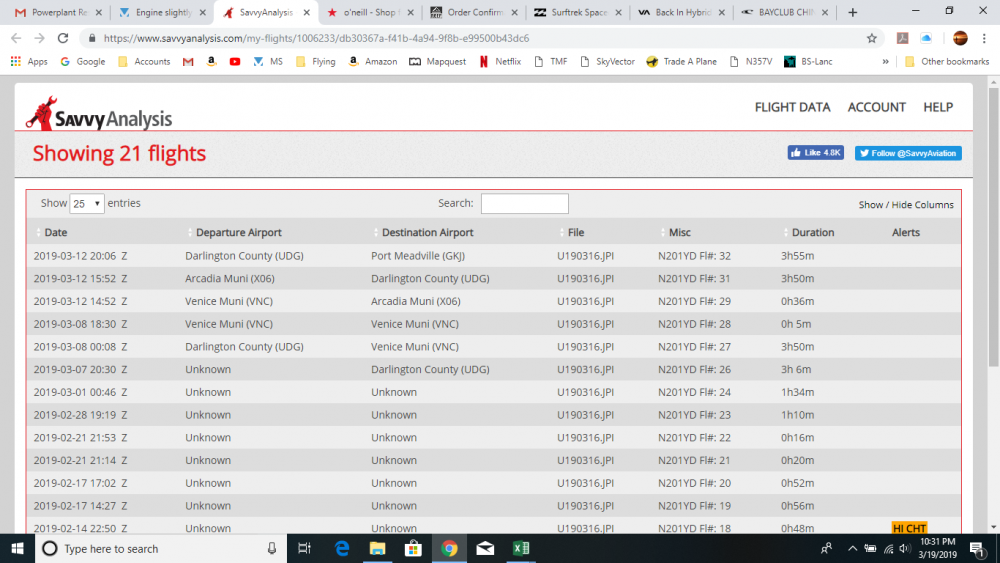

I get this view/web when I click the link...but maybe its different to others, see the "Misc" column is the Flight numbers I was referring to in the notes above. Thank you much for taking the time to check it out and all your feedback! -

Engine slightly Rough/Stumble when LOP?

Flymac replied to Flymac's topic in Modern Mooney Discussion

I've posted my file (was a download all) to Savvy...it says I can share a link for individual flights, but I only see a link to share them all it seems. The 2 focus flight might be #26 and #32, and as described below. I agree on a in flight LOP Mag check, it was my absolute intention before landing, just forgot, certainly hope no ignition issues being a brand new harness and new fine wires with only ~100 hrs. https://www.savvyanalysis.com/my-flights/1006233/db30367a-f41b-4a94-9f8b-e99500b43dc6 #32 Was pretty much all LOP, 5500, a climb at 1:06 to 7500, then right back to LOP rest of flight, was the slight rumbley/stumble as described... #26 Was the "failed attemp" flight of 8500 trying LOP 2 times that was just a tab too rumbly to accept after trying for ~5 min or so, 8500ft...at 29 min and 54min were first 2 LOP attempts for a few minutes -

Engine slightly Rough/Stumble when LOP?

Flymac replied to Flymac's topic in Modern Mooney Discussion

2 seconds -

Engine slightly Rough/Stumble when LOP?

Flymac replied to Flymac's topic in Modern Mooney Discussion

Help me understand your feedback alittle more if you could, and thanks for taking a look...you noted E1/E2, red/green which match up so I dont think a typo, but I dont see these crossing each other, or otherwise why you believe their ill behaved? If I have exhaust temps crossing each other, especially at this small scale, I would actually take this as a good thing that their running so close/consistent together (not take I care vs having the fuel mixtures close rather than temps)..but just want to understand your feedback. It does seem #1 is a tad lean to begin with as I dont get much rise out of it compared to the others...will have to see if I could possibly richen it up with another injector swap... -

Engine slightly Rough/Stumble when LOP?

Flymac replied to Flymac's topic in Modern Mooney Discussion

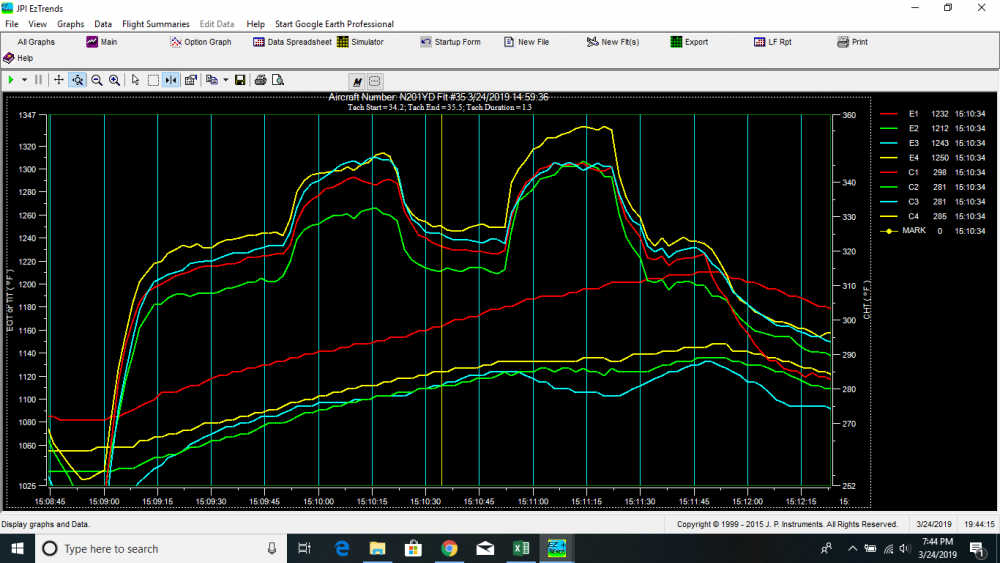

I did try different RPM/MP settings...essentially varying between 2400 to 2550 RPM...my default is/was WOT during the trip, I tried backing that off some with varying RPM, but it didnt seem to have any affect. I just had the prop balanced down to 0.02 as well, so I believe what I'm feeling/hearing is truly this slight stumble-ish behavior of the engine. -When we were swapping injectors around, I believe my mechanic cleaned them with spray/cleaner, no ultrasonic. we started at ~1.2GPH spread post-OH so definitely worked our way forward The JPI EZTrends is still a bit boggling to me how to change the scales, get FF together with the temps..etc...attempting to post... This is 5500Ft running LOP, ~8.8GPH...slightly rumbly as I have described..but was happier than trying at 8500 This was at 8500Ft trying LOP when it was just too unhappy to continue LOP...same WOT, ~2400, was still about 9GPH...as you can see still being 9gph not trying to get excessively deep LOP, just enough to peak all cylinders, still which were still all within ~0.4gph