Stephan Kablitz

Verified Member-

Posts

14 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Germany

-

Reg #

D-EJSA

-

Model

M20J

-

Base

EDEP

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Stephan Kablitz's Achievements

-

Landing flap setting for "normal" landings in a J

Stephan Kablitz replied to Ftrdave's topic in Modern Mooney Discussion

Dear Dave, less important that the flap setting is speed control. And in the above mentioned article from Wayne Fischer he emphasizes on the influence of the actual weight at landing. To me, this combined is all the „mystery“ to landing a Mooney there is. Know your weight and the associated speeds and than control the respective speed. This will lead usually (landing weight is most of the times a lot lower than max. weight) to seemingly low speeds over the fence. But surprisingly the landings will make a lot more sense. However, you need to know your numbers also when you are at max. gross weight. Once you are behind the power curve at MGW the ship starts sinking fast, pitching up won‘t help. I dinged a gear door once when there would be no energy left to flare. Cheers, Stephan -

Unable to make maximum RPM a few hours post overhaul...

Stephan Kablitz replied to Tito22's topic in Modern Mooney Discussion

Dear Tito22, your M20J should put through about 17 gph at full power, full rich. In your video I see fuel flow below 10 gph or do I get the display wrong? -

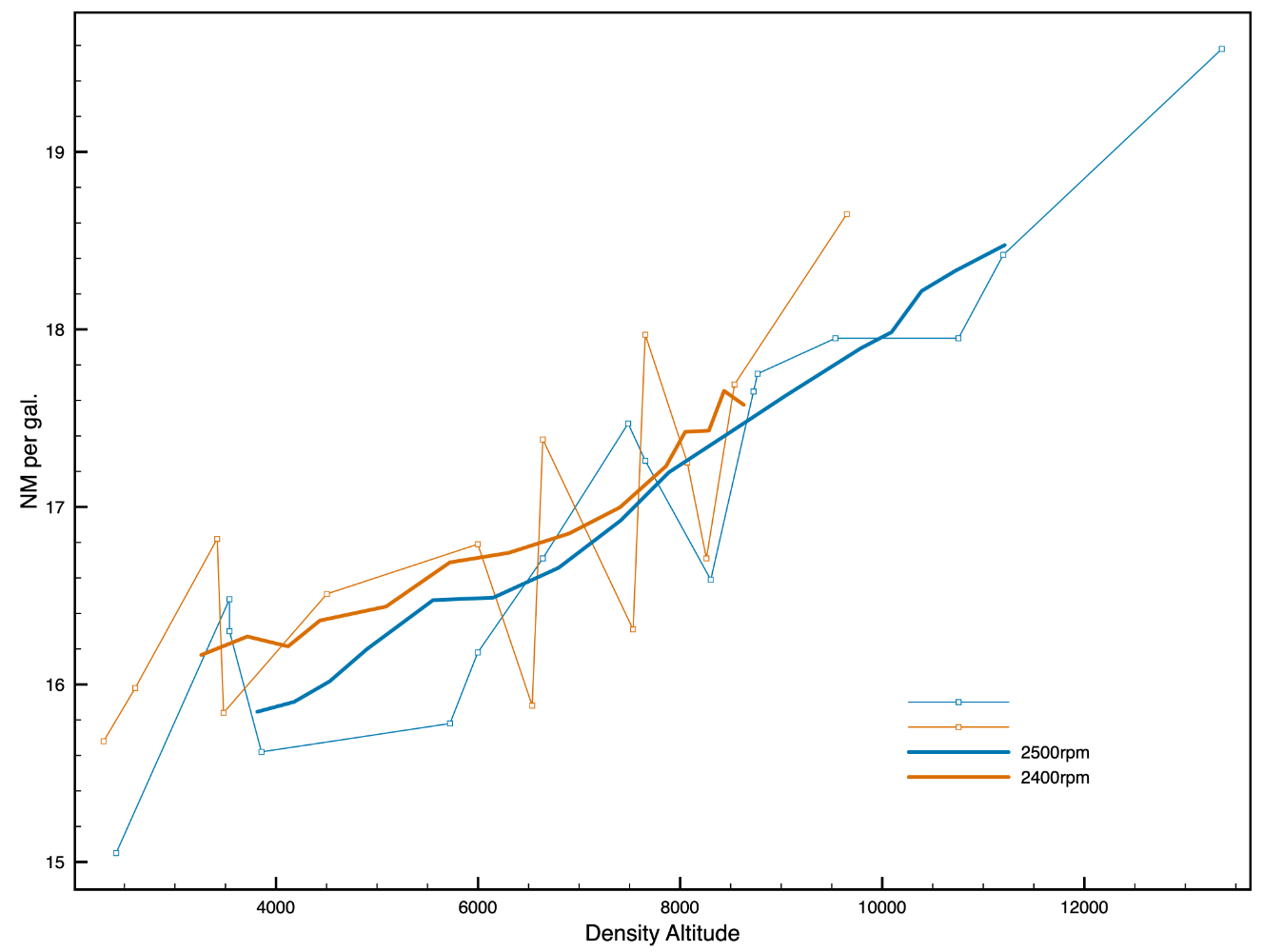

Dear Scott, we have the original McCauley 2-blade prop. And it seems that in the battle between running at optimum prop rpm and optimum engine rpm, 2400rpm has a very very slight edge. But then again, to really prove this, one would have to take a ton more measurements, preferably always in the same flights one 2500rpm data point and directly after that a 2400rpm data point to exclude other effects as far as possible. Some of the data points in my list are twin points - and not in every case the 2400rpm point has the higher NM/gal value. And in other cases the gross weight might have been different etc. Brgds, Stephan

-

I regularly take cruise readings from all engine related parameters and put them in a spreadsheet when I have time on a rainy night. When I plot NM/gal vs. Density Altitude I can see running at 2400rpm ist ever so slightly more efficient than running at 2500rpm (NA IO360 in our J). It's not much, but after some smoothing of the slightly erratic raw data shown in the thin lines (I can not always lean exactly to the same ° LOP and the especially the TAS is always fluctuating a little and there is of course some error in all the readings) it still is measurable and it s not the other way around.

-

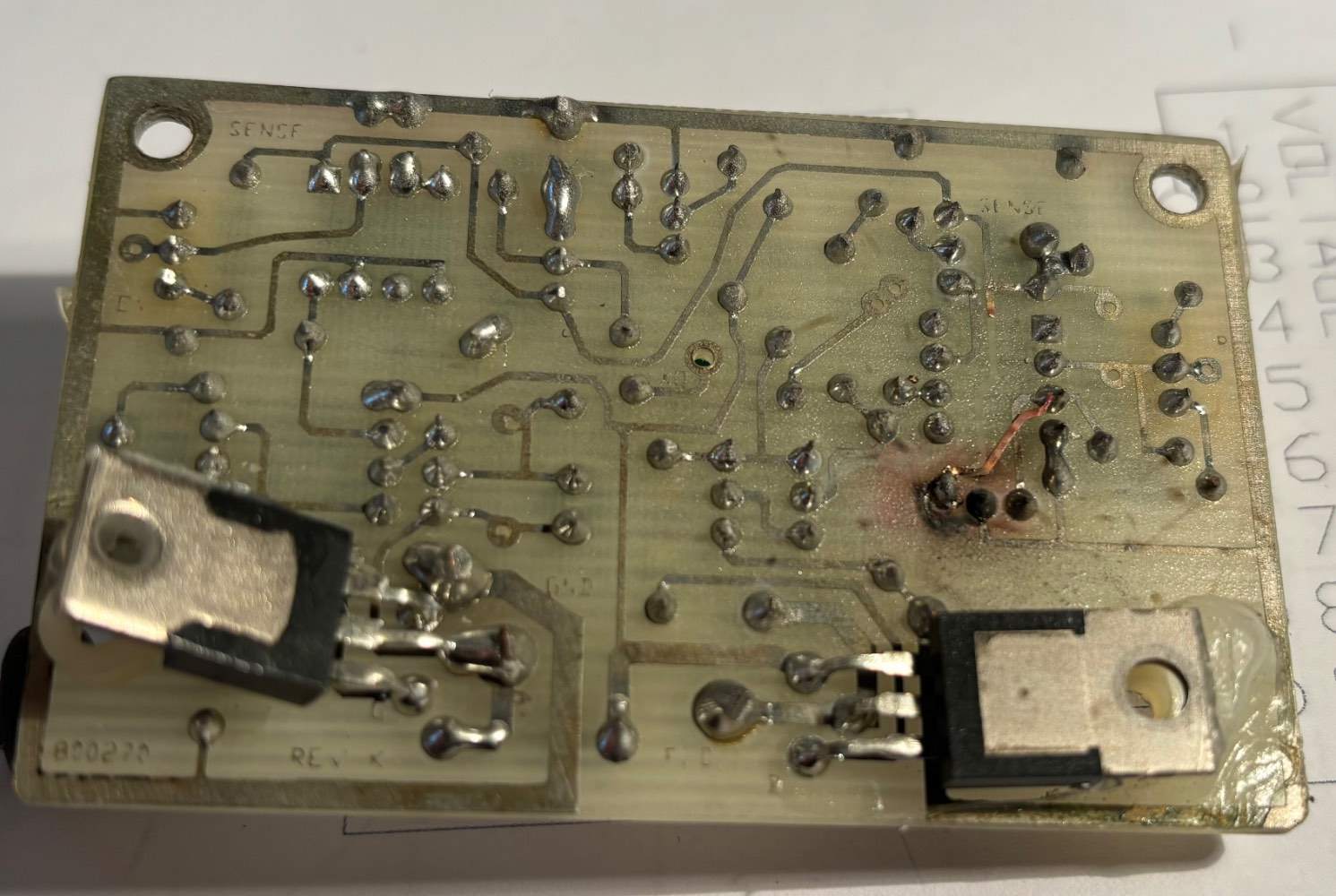

HI Larry, we had the exact same behaviour. Until this spring (fortunately 15 minutes out of the home airfield) it culminated in an alternator failure. We identified the voltage regulator as the villain (black spots on the PCB), sent it to the Don Maxwell correction facility and now we have no more Field CB trips. Brgds, Stephan

-

Just in a day's work for a 252

Stephan Kablitz replied to Aerodon's topic in Modern Mooney Discussion

I can offer some advice from my long years of flying sailplanes. On long cross-country flights I tend to drink very little and try to take on water through food: tomatoes, cucumber, watermelon etc. There is a physiological reason to this. When you drink, the water will take a „shortcut“ from your stomach to the kidneys and end up in the bladder much faster. The food will (at least partially) take the „long“ route. That way you can stay hydrated and keep the pressure from the bladder longer. I never found the above mentioned practices very attractive… -

Advice on first steps after buying an older J?

Stephan Kablitz replied to BlueSky247's topic in Modern Mooney Discussion

Hello BlueSky247, We all fly behind one single engine and you should make sure you see bad things coming before they actually happen. So I can strongly second the recommendation to install an engine monitor. With temperature readings on all cylinders and measured fuel flow you can adjust performance parameters precisely. If you want to run specific power settings, the injection system must be as balanced as possible and you will never know if that is the case without those sensors. If you find out it is not balanced (which is a game of luck) you should get GAMIjectors. Despite all the dark themed emails they mass produce, I have found Savvy Aviation to be a great resource. You can upload the data from your engine monitor and they will alert you to trends. You should get yourself a borescope (or make sure your mechanic has one and know how to use it) and regularly upload borescope images, which they will analyse as well. You should send oil samples to Blackstone to build a history to also be alerted to trends from that angle. Most other trouble with some part or system of the aircraft will not be nearly so severe in consequence as losing the Olympic Fire in flight. -

How long should a Concord RG35a last?

Stephan Kablitz replied to Speed Merchant's topic in Modern Mooney Discussion

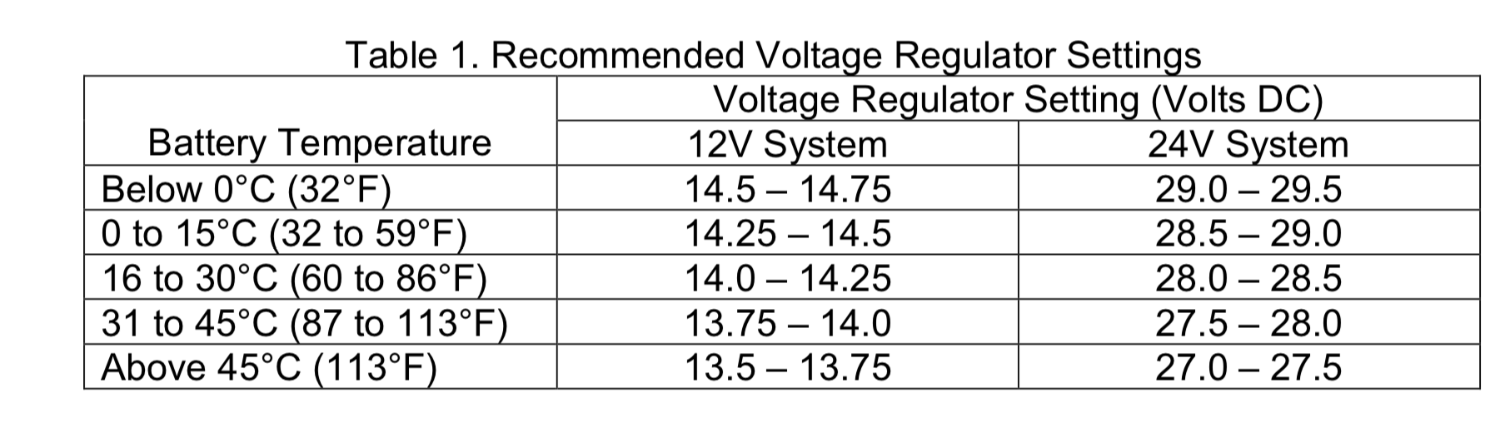

Don Maxwell’s value of 28.8V for the buss voltage seems consistent with Concorde‘s RG Series Owner/Operator Manual: So when the battery sits in the uninsulated tailcone, it will be receiving the charge most of the time below 15°C/59°F and it is also my experience that even when I return from a longer flight and attach the battery to a charger in the hangar, it still will slowly charge for another hour before the charger indicates the battery to be fully charged. So adjusting the battery voltage to a lower value will result in a lower capacity available in case of an alternator failure. Of course the gold-standard would be a voltage regulator that takes the battery temperature into account. -

How long should a Concord RG35a last?

Stephan Kablitz replied to Speed Merchant's topic in Modern Mooney Discussion

Hi Speed Merchant, do you have a readout of the buss voltage? Sometimes voltage regulators go astray and finally fail. We got ours overhauled by Don Maxwell recently and he set the buss voltage to 28.8 for the Concorde AGM type 24V battery. So your VR should regulate to precisely 14.4V. AGM batteries need slightly higher charging voltage than lead-acid types and the VR must be configured accordingly. Having a buss voltage a little to low will result in the final charge to be substantially below maximum. The target buss voltage is unfortunately a function of the battery temperature, so ideally we would have to adjust the VR in winter to an ever so slightly increased buss voltage and readjust when it becomes warmer. If you don't get this right - as probably most people including me do - the trickle charger will help to "fill up" what the VR didn't finish. Otherwise the AGM battery will be tortured at too low charging levels and give up early. -

Dear Yariv, we had a similar problem on our M20J. You could not retract the flaps from full to take-off setting. Retracting completely did work however. We also were quite convinced that it would have to be a limit-switch problem. After changing the switch the problem was unchanged. We then had to learn that a cable was chewed up by a mouse that had lived behind the sidewall lining of the baggage compartment. Wouldn't hurt to have a kook, I think...

-

M20J cylinder temps and baffling

Stephan Kablitz replied to Kirch56H's topic in Modern Mooney Discussion

Since you didn't mention it, you are positive that all you 4 JPI probes are the primaries and the probably previously existing ex-factory single CHT probe was removed? If your installer for some reason did not remove it but "piggybacked" the #2 JPI probe in the way it is done with the non-primary installations that could explain exactly the 30° that you see. -

Dear milotron, if you talk about rubber, you mean the baffle seals. I have never seen precut seals. You can buy „stripes“ in various widths or larger mats e.g. From Aircraft Spruce. Then you can use the old seals as templates for the new ones. It does pay to be super thorough because cooling air is a precious commodity and you don‘t want to waste a single molecule through leaking/warped baffle seals. Brgds, Stephan

-

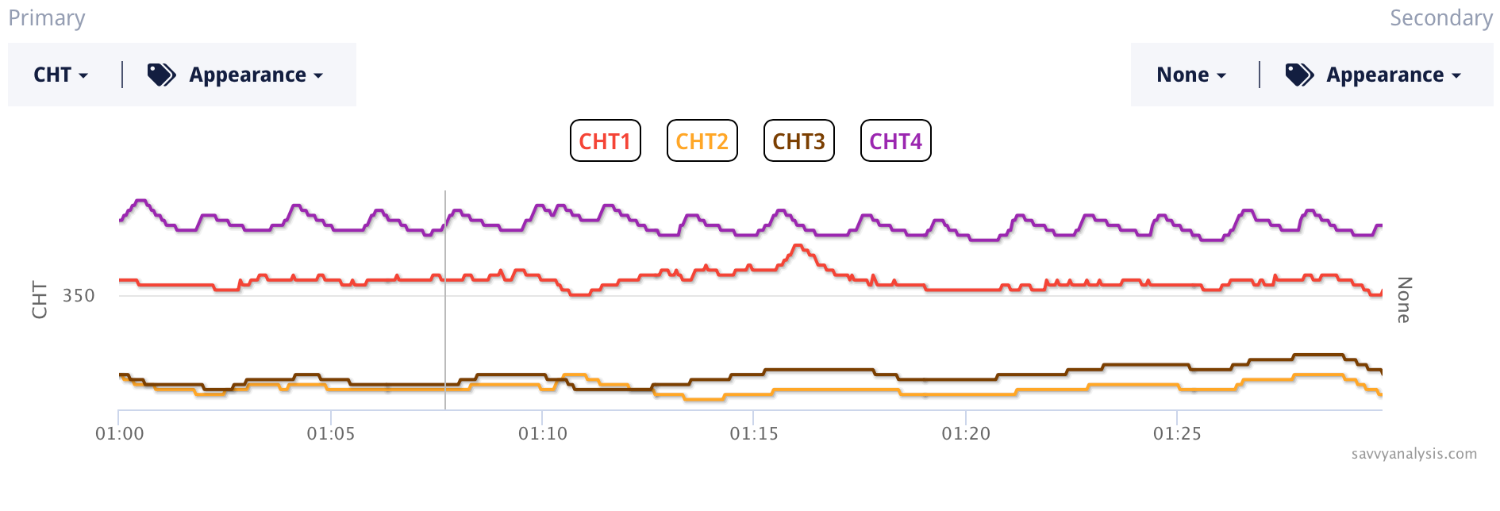

The frequency of the oscillation suggests, it has something to do with the exhaust valve. And we do have a slight leakage at the exhaust valve at TDC, however no leakage at all at BDC. And since the leakage occurs only when the engine is warm, we believe the root cause to be the hydraulic tappet. I am still puzzled however, that we see the oscillating signal at the CHT#4 probe but not at all at the EGT#4 probe.

-

HI, OR75! We recently have dicsovered a similar pattern om our IO-360-A3B6D. Did you ever find out the cause of your oscillating CHT#4? Brgds, Stephan