-

Posts

34 -

Joined

-

Last visited

About EchoMax

- Birthday 07/31/1959

Profile Information

-

Gender

Male

-

Location

KBLF

-

Reg #

N943RW

-

Model

M20E

Recent Profile Visitors

2,350 profile views

EchoMax's Achievements

-

I have reached out to Rip Quinby on BeechTalk. Apparently, his company, or at least this product, is no more. The Alpha Systems AOA was suggested by some as a replacement.

-

EchoMax changed their profile photo

-

EchoMax started following Oxygen: Extravagant, Optional, or Essential? , AOA Malfunction , GFC 500 autopilot: down the rabbit hole. and 4 others

-

We inherited N943RW "The Gypsy Rose", a beautifully maintained and equipped 1966 E, from the late Bob Belville. Bob installed a CYA100 AOA indicator and was enthusiatic about it. It is a mechanical windvane type, but it no longer works reliably. Is there some lubricant that would free it up, because I think it is a mechanical problem, or would a replacement do the trick, if I can find one? For any AOA haters out there, yes, it lands just fine without one.

-

'Tis true, and I love her like my wife, though they're both getting kind of old. Exactly so. 1980Mooney, you have really nailed it! Your reasoning is clear, logical, and convincing: I should wait until the STEC-50 fails, and then and only then, upgrade the AP. That keeps me from falling down a 30 AMU rabbit hole, at least for now. Still, it's fun to dream, and window shopping is free (like spending OPM). Should I swap out the Garmin GMA 340 audio panel for the PS Engineering PMA450B? What about upgrading the Garmin GTN 750 to 750xi? Gypsy needs some new rings on her fingers and bells on her toes, but maybe not a new autopilot at this time. T-

-

Please forgive my ignorant questions: I'm here to learn. 1. What is the advantage of the G3X/G5 combo vs two GI 275s? 2. I have a perfectly good (but old) KX 155 Nav/com. What would be the advantage of the Garmin 255 Nav/com?

-

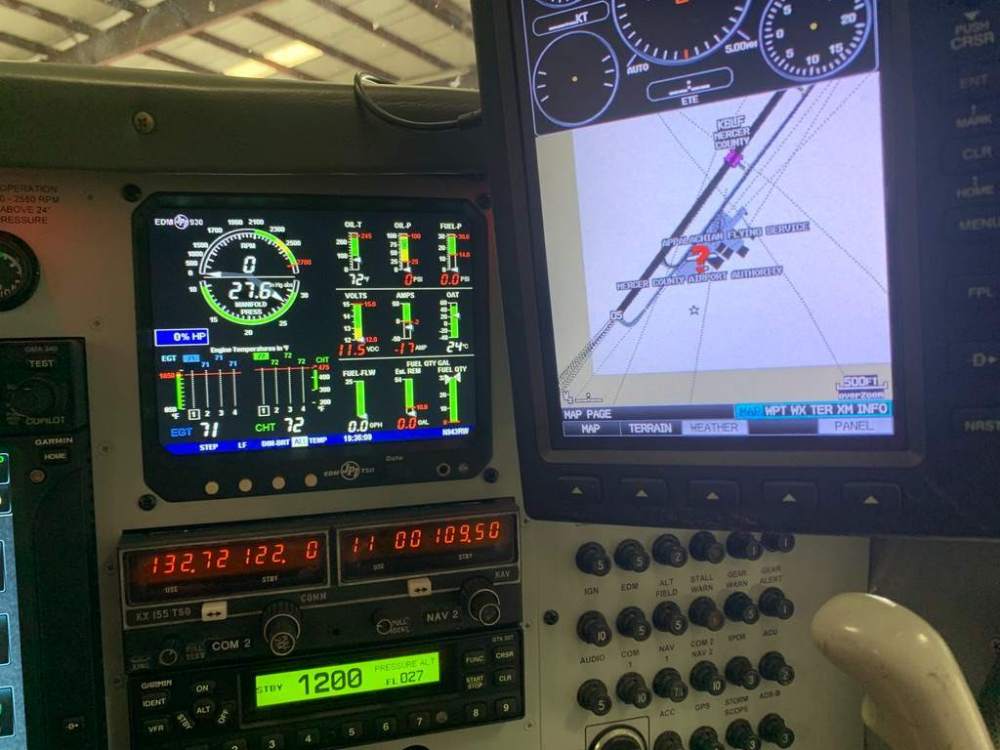

I have a 1966 M20E with a functional STEC-50 with Alt-hold. Nevertheless, I have a hankering for a modern autopilot. The decision tree starts out simply enough: there is only one AP available at this time for the E, the Garmin GFC 500. It's a reasonably priced, reportedly excellent AP. So far, so good, but then we go down the rabbit hole. The Aspen won't drive the GFC 500. Will it be of any use? Should I remove it? I'll need a G5 to drive the GFC 500. But hey! The GI 275 is only a little more and is much better so let's make that a GI 275. Now I'll need a backup for IFR, so add a backup G5. Oh, what the heck! Let's just make that two GI 275s. But don't two GI 275s present a possible single-point failure, as has been recently discussed? So maybe I should keep the vacuum AI. Or if I want to ditch the vacuum system, I could convert the step from vacuum to electric and add a Lifesaver electric attitude indicator. (Oh, and while we're at it, let's upgrade the GTN 750 to the 750xi.) Have I left anything out? What would you do? Standing pat may ultimately prove to be the best option; it is certainly the most cost-effective. But that would make for a rather dull discussion. Tom- My current panel includes: STEC 50 w Alt Hld Stormscope - WX-900 Aspen PFD 1000 MAX GTN 750 FS 510 JPI 930 GDL 88 GPS 696 GMA 340 GTX 327 CYA100 AOA

-

I found this by perusing old posts: Bob_Belville, Posted September 23, 2017 << Aeroshell W-100 with CamGuard year round. (Preheat engine in NC winter.) Target to change @ 25-35 hours, New spin on filter and check screen, sample to Blackstone Labs. (sample report attached) Tempest oil filter - AA48110-2 torque per filter instruction 16-18 ftlb. (New style spin on filters do not get DC4 lube.) ... I went to a fine engineering school that offered degrees in chemistry, chemical engineering, and mechanical engineering. But I did not follow those paths, they all had afternoon labs that interfered with my golf game. (I studied math - no labs since that was pre-computer science.) So I do not know much about oil, oil additives, or metallurgy. 2 prop strikes occasioned 2 IRAN tear downs, less than 100 hours apart. Both inspections revealed deteriorating cam/lifters. (The first engine shop had recommended Phillips multi-grade.) I'm probably smart enough but I'm definitely not educated enough to know what goes on to cause premature cam/lifter failures. So reinforced by @jetdriven's much more informed disdain for what we're working with I've followed Busch's preference for single weight, non-synthetic oil. And having heard CamGuard's presentation a couple of times at Summit, I returned to Aeroshell W100 with CamGuard and believe that combo gives me the best chance is this lottery since I fly only about 75 hours per year and sometimes the plane goes several weeks without flying. (I send a sample to Blackstone at every oil change and personally examine the screen and cut and inspect the oil filter. ... CB admission, I have about a half a case of Phillips 20W-50 and AeroShell W100 straight mineral oil (break in oil). When I think about it I'll use one of those quarts when I add oil, just one per oil change. I'm assured all oils approved for a given engine can be safely mixed. >> *** According to the aircraft listing: ~ 780 SMOH Triad It seems unlikely that CamGuard was used during break-in, but what about the mixing of Phillips 20W-50 and AeroShell W100?

-

It's just a theory, with no real evidence, that Camguard was added during break-in. The previous owner has passed on, and he is unavailable for comment at this time, but he was reportedly very meticulous, and I find it hard to believe that he did something so stupid. So we're left with the mystery of the four glazed cylinders.

-

All four cylinders were glazed. We had three options: rehone, new cylinders, or reconditioned cylinders. We opted for reconditioned based on the advice of our mechanic. The theory is that the previous owner (now deceased) used Camguard during the initial break-in. Our MSC mechanic spoke to another highly-respected MSC mechanic who said that he's seen a few cases of Camguard-related glazing.

-

A year ago we bought a well-equipped, well-maintained 1966 M20E, frequently flown except in the last year of the previous owner’s final illness. The PPI was perhaps unduly cursory, given the sterling reputation of the previous owner. Our first indications of trouble were mag-check failure, fouled plugs, and excessive oil consumption. We replaced the spark plugs, magnetos, and the fuel diverter, but nothing changed. We were advised to just keep adding oil. We ignored this advice. After further investigation, it was found that the cylinders were glazed. The cylinders have now been replaced, and meticulous break-in with mineral oil is underway. The engine is running great now: all previous problems solved and slightly increased power output. Camguard, reportedly beloved by the previous owner, has been blamed for the cylinder glazing.

-

Considering a Mooney as my first airplane...

EchoMax replied to AKEllsworth's topic in General Mooney Talk

We bought a Sundowner four years ago. It’s a nice aircraft, and for some people it may be the ideal aircraft, but it didn’t suit our mission because it was simply too slow. The significant other in the right seat didn’t appreciate lagging behind freeway traffic with 40 knot headwinds. We recently bought a 1966 M20E and sold our 1983 Sundowner. Res ipsa loquitur. [Latin for “The thing speaks for itself.”] -

As anecdotal evidence, we recently put our Sundowner on the market (after buying our M20E), and within two or three days we had several serious buyers that devolved into a two-buyer bidding war. It is now under contract, and we got our asking price, which is more than we would have expected six months ago.

-

Here are two videos that demonstrate my preferred tiedown knot: I’m not sure what the name of this knot is. I couldn’t find it in my copy of “The Ashley Book of Knots”, but it is a variant of the bowline knot. The method of tying while tensioning is as important as the knot itself. The West Valley Flying Club in Palo Alto calls its version "The West Valley Knot", so I guess it was invented in California. Most of the so-called “aircraft tiedown knots” I've seen are actually insecure “slip knots” and should be avoided. It’s also important to position the wing tiedown rings even with or slightly behind the ground anchors.

-

I was amused and bemused by the recent photograph of a "tripod" aircraft in a "tail-dragger" posture due to an ice storm. I guess it's OK to laugh (if it's not on your dime, and no one was hurt). From looking at the photo, I suspect that there was a tie-down failure related to a "slip-knot", a lack of "tensioning", or both. I have always been mystified by the myriad variety of tie-down knots that I see on the tarmac. When I first started in aviation, I thought to myself that there is surely a "best practices" of knot-tying for tie-down. Not so. I see many so-called knots that are actually "slip-knots". I see knots that are more appropriate for monofilament nylon fish-line than for the twisted polypropylene lines that I usually encounter. Most of the aviation tie-down videos that I have seen on YouTube are pathetic, if not ridiculous, although there are exceptions. I'm not a mathematician, topologist, or Boy Scout, and I am not much of a sailor, but it strikes me as strange that, given our seafaring legacy, pilots do not pay more attention to the simple tie-down knot. In the case of this aircraft, the damage repair may cost a few AMU. If there had been a prop strike after a thaw, it could have been much worse. The owner owes thanks to his fellow aviator in kindly restoring the safe posture of the plane. The best tie-down knot should be: 1. Secure (not a slip knot) 2. Appropriate for the "suture material" 3. Easy to tie 4. Easy to untie 5. "Tensionable"--perhaps most relevant for this event 6. Standardized: "Let the best knot win!" What tie-down knots are used by the MS community? (I have one that I prefer, but I do not want to prematurely bias this "survey".)

-

Oxygen: Extravagant, Optional, or Essential?

EchoMax replied to EchoMax's topic in General Mooney Talk

I'm a little bit higher than Bob Belville, and he strongly recommended O2. We're in the mountains.... -

I know, I know! This topic has reappeared on a regular basis, but in a partial perusal of previous posts, I have not found the answer to my question: What is the most cost-effective oxygen solution for a normally aspirated E? Bob Belville used a passive Aerox system with pendant cannulae and a 22 or 24 cu ft aluminum cylinder (not sure which, E or jumbo D), but that has been removed from his former aircraft that we inherited, The Gypsy Rose, or N943RW. I'm planning to install or share a hanger refill station at some point, but I'm not sure what hardware and plumbing I would need. I plan to get two welding O2 tanks from the local AirGas, etc. All that is in the future. In the meantime, thanks for all of your suggestions for upgrading N943RW. As it turns out, the single suggestion that I am most interested in implementing immediately is the one that I originally dismissed the most quickly: oxygen! Striving for what I consider to be the “best value” on the cheap, my budget is simultaneously liberal and frugal. 22 cu ft seems to be the sweet spot. Aluminum is the best value. Kevlar, etc. is ridiculously expensive and has a limited 15-year lifespan...Yuck! Jumbo D is much shorter but slightly thicker and about the same capacity as E (22 vs 24 cu ft), and slightly more expensive, but I like the form factor much better. I don’t have refill yet at my hangar, so I want to have two tanks to swap out. I am considering: https://gascylindersource.com/shop/industrial-cylinders/industrial-oxygen-cylinders/22-cu-ft-aluminum-oxygen-cylinder/ $111 ($95 plus $16 shipping) Vertical valve and gauge: https://gascylindersource.com/shop/gas-cylinder-valves/oxygen-valves/cga540-vertical-outlet-valve-with-gauge/ $50 This is optional, but a gauge is desirable somewhere in the system, and I feel more comfortable with the vertical option: less of a lever arm to break it off. Anyway, all of the “professional” aviation systems that I have seen use a vertical valve. The gauge by itself I have seen from $10-20, assuming the right size (1/8 vs ¼”) and assuming that the existing valve has a gauge port. It’s not always easy to figure out online. Maybe I can reuse the supplied horizontal valve somewhere else, in the hangar perhaps. O2D2: Having read some, but not all, of the voluminous posts on this topic, you guys have convinced me: I will justify it as a health and safety issue for which no justification is necessary. It’s on the order of one AMU, or a pair of Bose headphones. We don’t usually fly with more than two people, so I’m favoring the one-place regulator (for two people with the O2D2) over the four-place regulator (to use with the occasional backseat passenger, generic constant-flow nasal cannula, not O2D2) at a savings of $135. What about… O2D2 System (EDS, Regulator, Cylinder) SKU: 00EDS-2062-02 Compressed Gas Connector Type: CGA540 (USA) Number of Stations: 2P Cylinder Model: AL-647 ($1325) I am looking at: E-Z Breathe-II Boom Cannula for EDS-Pulse Demand (One Touch) connector ($100) https://www.mhoxygen.com/product/cannula-e-z-breathe-ii-eds/ Nice idea, but is it worth it?