Martin S.

Basic Member-

Posts

128 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Martin S.

-

Thanks for sharing ur data gentlemen! @Igor_U Was your case welded, or did you exchange it?

-

Evening everybody, I recently stumbled over this crank case crack thread. Did some research and it indeed turns out that the IO-360s are prone to cracking in this area. Does anybody know whether this holds for all IO-360s or only for specific types e.g. the A3B6D cases? Trying to collect some statistics so that the day my engine goes in for overhaul I can better estimate whether it might from a crank-case point of view be worth upgrading from an A3B6D version of the IO-360. Thanks, Martin

-

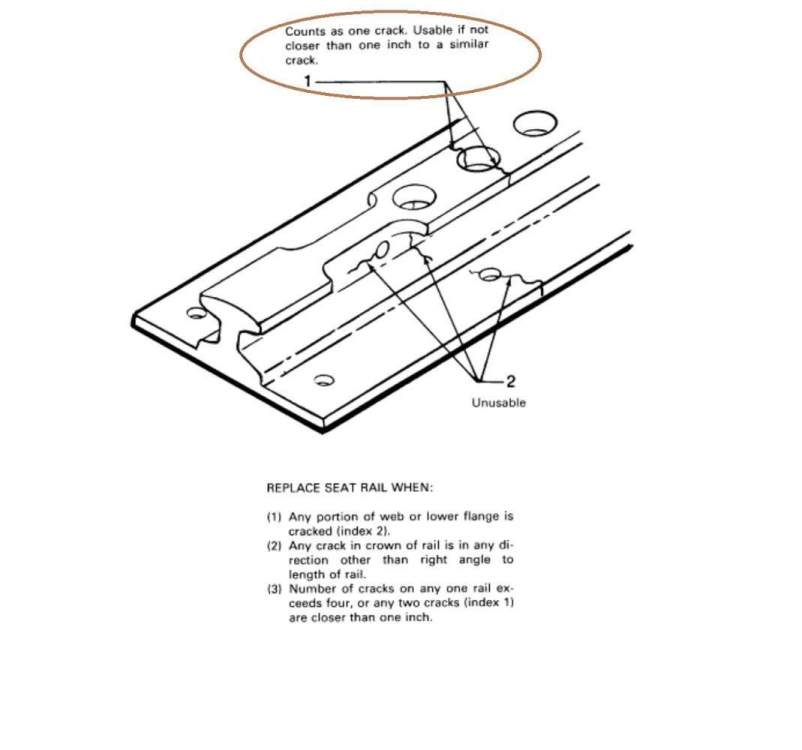

Thanks everybody - really appreciate all your input. Found it interesting to see that the Cessna AD indeed tolerates more than one crack in the rails. Greets, Martin

-

Yes - took a picture. Crack does not go through the entire cross-section of the profile. Question is whether this justifies a replacement of the track? Greets, Martin

-

Evening again, and thanks for the answers so far. One of my rails seems to have a super thin crack. That’s why I was asking. Would you suggest replacing all rails, or just the cracked ones? Sent from my iPhone using Tapatalk

-

Evening gents, anybody an idea if the factory is still selling/producing the seat rails. If no, are there any other companies selling these profiles new for Mooney aircraft? Anybody recently replaced them? Greets from Germany, Martin

-

Thank you Rich and Anthony - that should help! Greets, Martin

-

Good morning, Does anybody know the length of the black pan head screws that hold the Klixon rocker switches to the panel? Should be an MS35215 - but I am not sure with the length and the thread size. I have no access to my plane right now - so I can't measure myself. Did not find them in the IPC. Greets, Martin

-

Thanks everybody. Was already guessing it originates from the intake - but not sure.

-

Evening everybody, Reviving his topic. Can somebody explain me what the small rubber tube in the above photo is for and where it comes from? Thanks in advance, Martin

-

Annunciator panel test function, RIGHT FUEL LOW Lamp

Martin S. replied to Martin S.'s topic in Modern Mooney Discussion

Thanks for the info. Will consider overhauling it. Its not even necessarily the price, more the fact of grounding the bird for moody seventies electronics - haha. -

Annunciator panel test function, RIGHT FUEL LOW Lamp

Martin S. replied to Martin S.'s topic in Modern Mooney Discussion

This little unit has its phases. Went flying yesterday. It worked during the check, with master on and engine off. But I realized the function is quite lazy: It takes like 0.5 sec after pressing the button, until the lights go on. Forgot to test it again though during the flight. -

Annunciator panel test function, RIGHT FUEL LOW Lamp

Martin S. replied to Martin S.'s topic in Modern Mooney Discussion

Roger - will play a little bit more with it and see if I can find an error/failure pattern, before considering to remove/overhaul. -

Annunciator panel test function, RIGHT FUEL LOW Lamp

Martin S. replied to Martin S.'s topic in Modern Mooney Discussion

Yesss - getting rid of 70s electronics/avionics is always good :). I don't see a test function for the gear down lamp in your new setup. Didn't you have to find a replacement for that functionality. Slightly off topic: It looks like you replaced some of the switches/switch covers. If yes, are these 3D printed ones? Very interesed in these - one of mine just broke today - arrrrg. -

Annunciator panel test function, RIGHT FUEL LOW Lamp

Martin S. replied to Martin S.'s topic in Modern Mooney Discussion

Thanks - very helpful! Maybe a stupid question but is there any possibility the test function reacts differently, depending on whether the engine is running or not? -

Annunciator panel test function, RIGHT FUEL LOW Lamp

Martin S. replied to Martin S.'s topic in Modern Mooney Discussion

Good point, yes - varied both pressing force and duration. -

Evening everybody, the right tank "low fuel lamp" of my annunciator panel (1978 Model) does only work sporadically when pressing the test button. It mostly works when the tank is really full. Is this a common issue and has anybody an idea of how to repair these units without having them expensively overhauled? If the overhaul is the only solution, has anybody an idea of where to do this and how much it approximately is? Greets from Germany, Martin

-

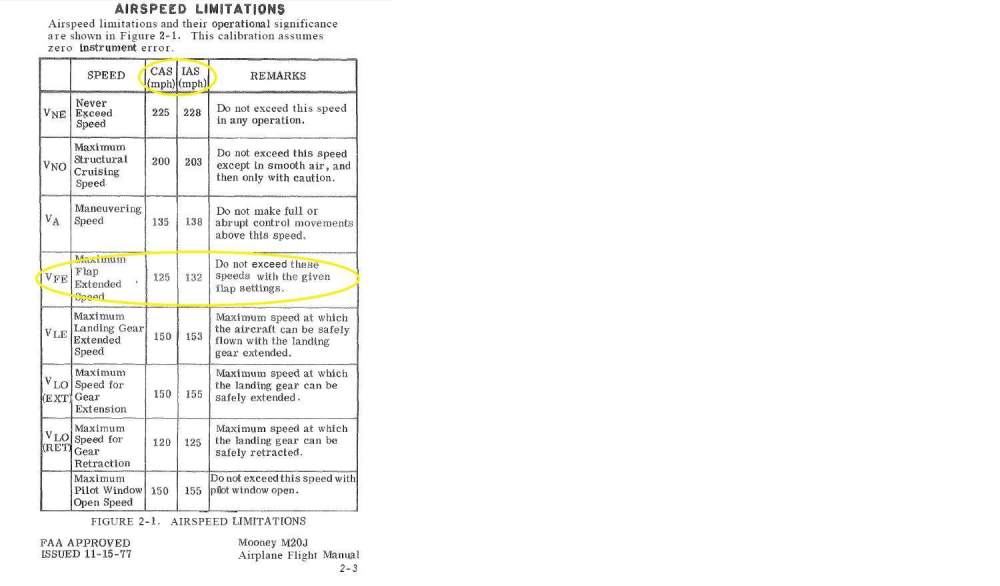

Clarence, I have the POH of a 83J for comparison. It lists the same IAS values as the ones above (originating from a seventies J model). Accordingly, it should be safe to say that there is no mistake in the CAS/IAS table. Greets, Martin

-

Thanks for your thoughts so far. I added fotos of both the ASI and the POH. Take V_FE for an example. It is 125 mph according to the ASI. This corresponds to the POH CAS value for V_FE, but not to the V_FE IAS value of 132 mph that one would expect. I don't understand the FAAs logic from back in those days. If nobody flies according to the IAS, what was the purpose of mentioning it in the POH? Greets, Martin

-

Evening everybody, the M20J POH (section 2-3) shows: Vs0 = 61 MPH CAS & Vs1 = 68 MPH CAS The speed tape of my airspeed indicator (original analogue one) in my cockpit also shows these values, i.e.: Vs0 = 61 MPH & Vs1 = 68 MPH I understand an airspeed indicator shows the indicated airspeed (IAS), not the calibrated airspeed (CAS). Accordingly, there should be a small difference between the the indicated and the calibrated airspeed. Why then are the POH CAS values the same as the speed-tape marked IAS values? Greets and thanks for your thoughts, Martin

-

Skip - I'm impressed, sharp research! I would never have expected this rather "rough" adjusting method.

-

It sounds weird, but maybe they are bent to fit? Clarence, on a different note - did you ever replace one of those? If yes - can you confirm that accessing and mounting the four rivets is possible by inserting a rivet squeezer through the inspection plate? Greets from rainy Munich, Martin

-

Thanks Clarence! That confirms the pattern I have observed. Though I still wonder how such a large torque can be excerted by the small contact between both parts.

-

Evening everybody, Prior to buying my bird, I've seen quite some birds with bent rudder stop brackets (e.g. part 1 in the attached foto - this one is not mine). I understand that when the tow bar is excessively inclined during ground operation, the bracket on the push rod (labelled 2 in the foto) might hit the stop bracket (labelled 1 in the foto) and put some torque on it. However, my engineering guts tell me that's not enough torque (especially because the contact point is so small) to bent the bracket as on the image. As explained, I have seen this on multiple aircraft. It somehow seems to be a pattern. Has anybody a guess for the cause? Would be nice to know. Different question - is this bracket only for stopping - or does it only transports aerodynamic down-forces generated by the horizontal stabilizer? Greets from Munich, Martin

-

Thanks for your comments everybody. I went back to the IPC and it really looks as if I misunderstood something. I'll have to go back to the plane and compare things to the IPC and re-check the whole thing. Will keep you guys in the loop. Greets, Martin