-

Posts

50 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by vance.k

-

Fuel Sender Difference between 610242-1 and 610242-3?

vance.k replied to vance.k's topic in Modern Mooney Discussion

I suspect you are right. But to clarify, this isn't an inboard vs outboard swap. The outboard is a different 'main' part altogether (610243 vs 610242). The one in question is a 610242-001 vs 610242-003. Or maybe I'm just more confused than normal. Vance -

Fuel Sender Difference between 610242-1 and 610242-3?

vance.k replied to vance.k's topic in Modern Mooney Discussion

Thanks Clarence. To clarify, I'm talking about the LH inboard transmitter specifically. There is currently a 610242-001 installed. I incorrectly stated -1 because that is what is stamped on the part. We were working to calibrate it by 'tweaking' the metal arm, but we were struggling to get it far enough to read correctly at 5 or 10 gal. Then the brittle metal (aluminum?) snapped, unfortunately. Then we discovered it was the wrong part number to begin with. It's probably a moot point as I'll have to get it replaced, but I'm mostly curious if anyone knows specifically what the differences are or how to tell (cad drawings?). It seems most Mooneys use the -001, except for maybe the K and the M and there are almost no mention of them on MS or elsewhere. Mostly just my curiosity. Thanks! Vance -

Hi MSers, Just as the title says, I’m curious if anyone knows the difference between fuel sender part numbers 610242-1 and 610242-3? I have a M20K and the parts book calls for the -3. A shop replaced one of the senders with the -1 and failed to calibrate it (long story). I’m working with a mechanic now and working through it, but I would swear the 610242-1 wire arm isn’t long enough to get ‘low enough’ in the tank to properly read it. Any guidance greatly appreciated! Vance

-

@JRHogancamp, curious how this ended up? Did you find someone good to help with training? I've got a K based in KAEG and always on the lookout for a good instructor. Cheers! Vance

-

FWIW, I traded messages with Bruce. Sounds like he is doing well, it is just time to pass the torch on the Spatial Interior STC. He is still involved on a consulting and training basis for awhile, so it appears there is a plan for a smooth transition. It really isn't that complicated to install, so I'm confident any shop or individual DIYer for that matter, that has any attention to detail can produce a good finished product. Especially if Bruce is available for guidance. Good luck @JLindi.

-

No O2 on mine, but I seem to recall that was one of the questions he asked. I’m sure he’s got a solution for it.

-

I would add my recommendation for the Jaeger system. I did the install myself and I'm very happy with the system, pricing, etc. Bruce is wonderful to work with. I'm happy with my results, but I can only imagine how much better it would be if Bruce did the install. My plastics were pretty brittle and were breaking down. His method for backing and repairing the plastics is good. In hindsight, I wish I would have used fiberglass reinforcement as the backing for all of the window frames and the weaker areas as I believe it is more durable. Here's a couple photos. Really can't say enough good things about Bruce.

-

Recommendations on oil consumption next steps

vance.k replied to vance.k's topic in Modern Mooney Discussion

Hi Everyone, Just a quick update. @M20Doc, we were able to do the pressure test using an ASI according to the TCM SB. At full power, with or without the breather system attached, we'd get fluctuations between 95 and 105 mph. So, according to the SB, that is above the 'ground limit'. So, stands to reason that is related. I'm curious, though, does anyone know what the 'normal' value is for a healthy TSIO-360? I imagine most people don't do this test until troubleshooting a problem. The SB doesn't really provide guidance, just that 90 is the limit on the ground. Ultimately trying to understand if that is 'the' smoking gun or if those values are 'marginally out of bounds' but may not be the whole issue. Someone asked which cylinders are oily. To my eye, I believe 4 out of the 6 are oily. I'd say they go in order from worst to best like this; 6, 2, 4, 1, 3, 5. I'd say 5 has no oil, 3 maybe a touch. Any idea if there is any significance to all the evens being the worst ones. We didn't pull the bottom plugs, except cylinder 1. We were getting decent enough borescope photos to be able tell the plugs were oily. Also curious about another oddity, although I suspect it is a red herring. When the ASI was connected but the breather system was still attached (including the oil/air separator), when the engine started, the airspeed would jump between 20-40, but then at idle, would setting around 5. Once I started applying power, it would pull to 0 and stay there, as if there was a vacuum applied. We did it a couple times thinking something wasn't connected right before finally just going full power and as the power got past maybe 30", the ASI jumped to life. When we disconnected the breather and reran the test, it didn't do that. It stayed around 40mph at idle, but once I went full power, it had the same 95-105 range. So, based on this, what next? Re-ring (all cylinders?), top overhaul, IRAN the whole engine? Thanks, really appreciate the help! Vance -

Recommendations on oil consumption next steps

vance.k replied to vance.k's topic in Modern Mooney Discussion

Thanks everyone for the great pointers! @M20Doc, thanks for the link. I'm meeting the new mechanic out there this afternoon with an ASI and we are going to give it a shot! As @takair mentioned, I had read repeatedly before that with blow by, the oil gets dark really fast. I don't know that I've ever seen that quantified, but I will say I haven't noticed a dramatic increase. I'd say it starts to get dark by 25 hours and I've been on a 50 hour interval when I'm flying a lot and closer to 35 when the bird has been sitting. Will update once/if we are able to get the ASI testing to work. Thanks again! -

Recommendations on oil consumption next steps

vance.k replied to vance.k's topic in Modern Mooney Discussion

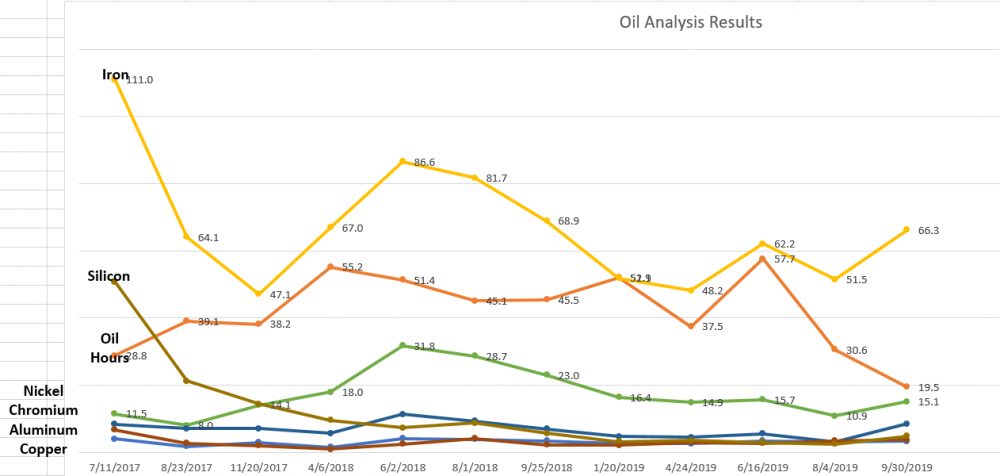

Hi Eric, Forgot to mention it, but did attach a trend line chart from the analysis. I do oil analysis on every oil change, although totally spaced it on this one I just did. Got busy with the new mechanic and forgot to grab it. Bottom line, nothing significant. No metal in the filter either. Thanks! Vance -

Hey MS, Would love to get some advice from the collective. Have a 231 with a TSIO-360-LB1B. It has 1,250TSN (2006). I've put the last 600 hours on it over the last 2.5 years. Until about 9 months ago, I would generally get between 8-12 hours per quart. Starting around April, the consumption started increasing. It increased rapidly and has fluctuated between 4-6 hours per quart. Right when it started happening, my mechanic went through it, compressions, bore scope, etc. Did not find a proverbial smoking gun. Did the annual in August looked at everything again. Compressions 78, 72, 77, 77, 70, 72. Performance is consistent and hasn't changed at all. Each time, there was some oil in several of the cylinders and the bottom plugs were dark, but the tail pipe is not oily. There is a powdery trail on the belly behind the tail pipe. In September, I had an issue where the turbo seized. It happened on the takeoff roll (out of Austin) and there were no indications of issues on the flight in or previously. Coincidence? I had hoped the rebuilt turbo would solve the mystery, but alas, no change. There is some oil leaking from the pushrod tubes, the quick drain was leaking a bit (just replaced it), and there is some oil on the belly out the breather (and maybe 1 or 2 drips after shutdown). I've had 4 different mechanics / IAs look at it while doing different work and everyone kind of shrugs and says none of them are bad enough to worry about, yet. Kind of a keep an eye on it and keep flying. I'm working with a new mechanic (my previous one retired) and we changed the oil last week (and replaced the quick change to fix that leak). We pulled the top plugs and grabbed some photos. I wanted to get some additional opinions on these photos and recommended next steps. Unfortunately, I didn't get any photos of the cylinder walls. Thanks! Vance

-

I had the same problem and found the wrong probe and a miswire. The replacement part was 880006-501 and I got it from Lasar, as an earlier poster mentioned. I’m also attaching a copy of the gauge spec sheet / drawing that helped me sort out the wiring and troubleshoot the readings. Good luck! 880000.pdf

-

Log Review - Knoxville/Crossville, TN

vance.k replied to ValkyrieRider's topic in General Mooney Talk

I had the same problem when I was looking at a plane. Older seller who was unable/unwilling to scan them. I was pretty interested and traveled to the plane, bought a scanner and took a couple hours at the hotel room getting scans of everything. It had everything back to the beginning of time, so took a few hours. L It would have been impractical to get all of that with a phone (although not all was needed either). I’m glad I took the time to do real scans. I ended up buying that plane and I now refer to the scans more than the digging through the log books when looking for something. V— -

Thanks everyone! The hours did add up much more quickly than I expected and frankly, the utility of flying surprised me. The freedom of not worrying about missing a flight or what the security lines will be like, or unexpected delays, is huge! I know I'm preaching to the choir. In my mind, I expected some of that, but it surprised me nonetheless. I love when people ask 'what time is your flight' and I think, 'whenever I get there'. Of course, I usually give some time that works with the schedule as to not get into it. People's reactions and perceptions are funny, so sometimes it is best to keep my little hobby among family and friends. @carusoam - I'll work on the wife and see if she would do something like that. I'd say not too likely, but worth a try. Thanks again everyone, what a great community! Vance

-

Hello MS'ers, Wanted to take this time to commemorate the 1 year anniversary of my first flight in my Mooney. Picked up N231CK from the shop a year ago, after some post purchase work and upgrades, and have been flying every chance I get. I logged 276 hours with 160 landings in those 12 months and have enjoyed the heck out of it. I've learned that I don't like flying at night; it is really dark out there and any off airport landing will likely hit something very hard. And my night landings are usually my worst..but hey, I can usually get my night currency in one trip down the runway (3 bounces count, right?). Conversely, I got my IFR and really enjoy flying in IMC and the utility that it brings. It is still nerve racking and exciting. But, my actual IMC has all been departures and en route with no approaches yet. This past year, I traveled to Denver (~20x), Chicago Area (2x), Kansas (3x), Nebraska (2x), Arizona (3x), Nevada (4x), Texas (3x), and Utah (2x), as well as a host of other places across NM and CO too numerous to mention. I've scrubbed a couple flights, delayed a couple, but have benefited from a remarkably good dispatch record, considering. These Mooney's are travelling machines for sure. I have an opportunity to fly to Orlando (~1,400NM) for a conference in 2 weeks, but after my last trip back from Chicago where I was bucking headwinds the whole way, I'm rethinking that potential 10 hour (probably 2 day) return trip from Orlando. While I'd love to say I did it, I may sit in the back and have a drink for that trip. I've benefited tremendously from the knowledge and resources provided by the community here at MS and for that, I am very thankful. I hope to be able to collect enough in the experience bucket to be able to contribute meaningfully some day. Thanks again for everything! Vance ps. Attaching a photo of the panel and of the family. The family trip was last September on the way to Salt Lake City for labor day. My wife hates flying, but she was a trooper and the trip up was super smooth. Not so on the way back and it was the last time she's been in the plane. Glad a took a photo as proof.

- 15 replies

-

- 19

-

-

Got my renewal insurance quote today...

vance.k replied to ragedracer1977's topic in General Mooney Talk

I renewed 3/10 and switched from Starr to XL. 2017 - Starr - $2575: $120k hull / $1m/100k subs - New pilot w/ ~80 hours, 0 complex, 0 Mooney (required 5 hrs transition + 5 solo) 2018 - XL - $2,200: $120k hull / $1M smooth - ~250 hours w/ 160 Mooney time. I pushed really hard for a smooth policy and made that my number one ask for my broker. I had also been told an IR was required and it was my goal, but lost 2 months due to an AOG issue, so didn't get it done in time. XL was the only carrier that offered a smooth policy. BTW, did my IR checkride today, woot! On to commercial.. -

Hi @Randy A, I'm based at Double Eagle and not aware of an MSC around here either. I have a '79 K model that I would be happy to provide some exposure. I believe the F and K are substantially similar from a length/cabin perspective. Shoot me a PM with your details and we can find a time to get together. A couple pieces of unsolicited advice. 1) I would second @carusoam's advice that if you want to see a bunch of them, make a trip down to San Antonio and visit with All American. I did that and sat in at least a dozen different planes; small, mid and long body as well as a Piper 6 and a few others. Probably as close to a car dealership as you can get with their inventory of for sale planes all in one place. And David and Jimmy are super knowledgeable and friendly. No pressure, just good guys and happy to help. 2) I ended up buying a 'good deal' that had been sitting basically idle for the previous 4-5 years. As you've no doubt read by now, be careful of those. Nothing harder on a plane than one that has been sitting, even if in a hangar. If I do the math where I sit today (I don't really want to do the math, though..), I'm probably still ahead, slightly, as some of the issues I had could happen on any plane. The biggie is we found spalled lifters while replacing the push rod gaskets. Luckily, the cam was still within tolerance, so only cost me 12 new lifters. A lot of the rest were just deferred maintenance type things and stuff that could break on any plane. If I were to do it over, I would insist on getting a plane that was flown regularly. I don't know what the bottom limit would be, but it needs to be getting some real flight time regularly. 3) I didn't find this forum until I was under contract and into the pre-buy. I'd recommend posting the details of what you are looking at and let the group here pick at it and provide some good feedback. The knowledge pool here and willingness to help is incredible. I'd highly recommend taking advantage of it. This was probably my biggest miss in the process...I wish I had found and utilized this group more during the process. Cheers! Vance

-

Century 41 AP - Rolls hard right when activated

vance.k replied to vance.k's topic in General Mooney Talk

Hey @DanM20C, Not sure if all C41s had an FD. Although, funny enough, when I was at Century, they had a large background banner system like you would see at a trade show back in the day. It had photos of their older systems, including the C21, C31 and C41 setup. I remember looking at that and thinking my AI doesn't look like the one with the C41 setup. It looks like the C31 AI, but with the C41 control unit and badges. So no, my AI doesn't have the FD button or the command bars. Perhaps it got swapped out somewhere along the way. Maybe I'll dig through the logs at some point, but I don't recall seeing anything about that, at least not in the recent past. Cheers! Vance -

Century 41 AP - Rolls hard right when activated

vance.k replied to vance.k's topic in General Mooney Talk

Hey Dan, Yes, they were definitely great to work with. I'm unsure on whether the Aspen can fully drive the C41 for roll/pitch. Mine definitely isn't connected that way and maybe wasn't considered. I bought the plane with the Aspen already installed, so didn't do any of the research or design decisions on that install. I don't believe my plane has a flight director. Vacuum-less is intriguing. The AI is my only vacuum component at this point. Cheers! Vance -

Century 41 AP - Rolls hard right when activated

vance.k replied to vance.k's topic in General Mooney Talk

Bringing back an oldie, but wanted to follow-up and close the loop as I FINALLY got it fixed after 8 months of not having a functional AP. I wasn't in a huge hurry, because I enjoy flying it and the ~180 hours or so of hand flying in that time period has probably been good for me. But, I'm getting ready for my IFR checkride and wanted to have it functional and get some experience with it, in case I really need it some day. After months of trying to get the local avionics shop at my field to troubleshoot it in earnest as well as trying to even get a return call/email from a shop at Centennial where I travel frequently, I finally threw in the towel. I called Century directly on Tuesday and asked if I could just bring the plane to them and get it fixed. They said come on down. I went to Mineral Wells Wed evening and they pulled it into their hangar first thing Thurs while I hung out in their lounge with another gentleman who did the same thing. They spent a few minutes troubleshooting, then pulled the AI and walked it across the street to the factory. A couple hours later, it came back, rebuilt and with a clean bill of health. One of their techs went up with me, calibrated it in the air, then gave me a tutorial on how to use all the functions, followed by programming up and letting the plane fly a full RNAV/LPV approach down to minimums (practice approach) and it worked flawlessly. Left Mineral Wells and was back home in Abq on Thurs night. In my 10 short months of airplane ownership, I seem to have had a pretty constant string of maintenance/repair experiences that were, let's say, 'meh'. Mostly over-promise and under-deliver with a few that just flat out lie to get you off the phone with no intention of actually following through on their promises. This experience, however, was as good as it gets! Truly great people at Century (Matt, the service manager, especially) and the super friendly folks at the FBO, etc. Wish I had done it sooner and for anyone in a similar situation (unable to get qualified local help to fix it), I'd highly recommend this option. Cheers! Vance -

Just realized I hadn't followed up on this thread to close the loop. I ended up buying the PMA'd KSAvionics A002C-30 unit for a little over $200. Installed it and verified it worked correctly with the ship gauge. Then we paralleled the JPI and everything is working correctly. The JPI reads about 25F higher than the ship gauge, but I'm happy with that. So, I guess this is confirmation that there is some technical issue with the JPI probes not being able to drive this particular ship gauge, but the PMA'd units work just fine. And legal...so that's a bonus. Thanks again to all the MSers that pitched in to help with info and guidance. Vance

-

Hey @Northern Mooniac, Congrats on getting it fixed. I'm curious, what all was done for the repair? I basically ended up with a completely rebuilt exhaust. I know they are supposed to keep some portion of the original component in order to 'repair', but I swear each shop basically built a new system. Anyway, I'm back flying with what I would say is a 100% new exhaust, but it cost many multiples of $500 Canadian. Thanks! Vance

-

Maintenance Manual for TSIO-360-LB - X30571?

vance.k replied to vance.k's topic in Modern Mooney Discussion

Thanks everyone. I wasn't able to create any type of account via the portal, that I could figure out. I emailed ATP and they responded that they are no longer free. The cost is $330 for the Continental Engine Library, according to that same email. Vance -

NM, I feel your pain. I'm in the throws of the same issue right now. Found a leak near the #6 (exhaust dust and blistered paint on the engine mount). We pulled the whole left side exhaust and sent it to Knisley. Was supposed to be 2 weeks, but took over 5. Ugh. Then, once we got it back, big leak on the crossover between the new and old. Our mistake for not taking everything off and sending it all together. Good advice above to do that...wish I had known. I actually didn't realize they basically just rebuild everything instead of patching. Works for me...I just didn't know. Knisley basically said it would be another 4+ weeks. Dawley said the same. It is killing me having the plane down (I fly quite a bit and hate taking the 'bus'), so I overnighted everything to Aerospace Welding in MN as they indicated 1-1.5 week turnaround. We will see. Check those v-bands while you have it apart. Found a crack on one of mine. Good luck! Vance

-

Maintenance Manual for TSIO-360-LB - X30571?

vance.k replied to vance.k's topic in Modern Mooney Discussion

Thanks everyone! That explains why I wasn't finding it in the quick search I did...there's good money to be made selling it. I'll give eflightmanuals a shot and see if that fills the need. If not, I'll sign up for ATP. Thanks again! Vance