-

Posts

50 -

Joined

-

Last visited

-

Days Won

1

vance.k last won the day on May 31 2018

vance.k had the most liked content!

Profile Information

-

Location

KAEG

-

Model

1979 M20K 231

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

vance.k's Achievements

-

Fuel Sender Difference between 610242-1 and 610242-3?

vance.k replied to vance.k's topic in Modern Mooney Discussion

I suspect you are right. But to clarify, this isn't an inboard vs outboard swap. The outboard is a different 'main' part altogether (610243 vs 610242). The one in question is a 610242-001 vs 610242-003. Or maybe I'm just more confused than normal. Vance -

Fuel Sender Difference between 610242-1 and 610242-3?

vance.k replied to vance.k's topic in Modern Mooney Discussion

Thanks Clarence. To clarify, I'm talking about the LH inboard transmitter specifically. There is currently a 610242-001 installed. I incorrectly stated -1 because that is what is stamped on the part. We were working to calibrate it by 'tweaking' the metal arm, but we were struggling to get it far enough to read correctly at 5 or 10 gal. Then the brittle metal (aluminum?) snapped, unfortunately. Then we discovered it was the wrong part number to begin with. It's probably a moot point as I'll have to get it replaced, but I'm mostly curious if anyone knows specifically what the differences are or how to tell (cad drawings?). It seems most Mooneys use the -001, except for maybe the K and the M and there are almost no mention of them on MS or elsewhere. Mostly just my curiosity. Thanks! Vance -

Hi MSers, Just as the title says, I’m curious if anyone knows the difference between fuel sender part numbers 610242-1 and 610242-3? I have a M20K and the parts book calls for the -3. A shop replaced one of the senders with the -1 and failed to calibrate it (long story). I’m working with a mechanic now and working through it, but I would swear the 610242-1 wire arm isn’t long enough to get ‘low enough’ in the tank to properly read it. Any guidance greatly appreciated! Vance

-

@JRHogancamp, curious how this ended up? Did you find someone good to help with training? I've got a K based in KAEG and always on the lookout for a good instructor. Cheers! Vance

-

FWIW, I traded messages with Bruce. Sounds like he is doing well, it is just time to pass the torch on the Spatial Interior STC. He is still involved on a consulting and training basis for awhile, so it appears there is a plan for a smooth transition. It really isn't that complicated to install, so I'm confident any shop or individual DIYer for that matter, that has any attention to detail can produce a good finished product. Especially if Bruce is available for guidance. Good luck @JLindi.

-

No O2 on mine, but I seem to recall that was one of the questions he asked. I’m sure he’s got a solution for it.

-

I would add my recommendation for the Jaeger system. I did the install myself and I'm very happy with the system, pricing, etc. Bruce is wonderful to work with. I'm happy with my results, but I can only imagine how much better it would be if Bruce did the install. My plastics were pretty brittle and were breaking down. His method for backing and repairing the plastics is good. In hindsight, I wish I would have used fiberglass reinforcement as the backing for all of the window frames and the weaker areas as I believe it is more durable. Here's a couple photos. Really can't say enough good things about Bruce.

-

Recommendations on oil consumption next steps

vance.k replied to vance.k's topic in Modern Mooney Discussion

Hi Everyone, Just a quick update. @M20Doc, we were able to do the pressure test using an ASI according to the TCM SB. At full power, with or without the breather system attached, we'd get fluctuations between 95 and 105 mph. So, according to the SB, that is above the 'ground limit'. So, stands to reason that is related. I'm curious, though, does anyone know what the 'normal' value is for a healthy TSIO-360? I imagine most people don't do this test until troubleshooting a problem. The SB doesn't really provide guidance, just that 90 is the limit on the ground. Ultimately trying to understand if that is 'the' smoking gun or if those values are 'marginally out of bounds' but may not be the whole issue. Someone asked which cylinders are oily. To my eye, I believe 4 out of the 6 are oily. I'd say they go in order from worst to best like this; 6, 2, 4, 1, 3, 5. I'd say 5 has no oil, 3 maybe a touch. Any idea if there is any significance to all the evens being the worst ones. We didn't pull the bottom plugs, except cylinder 1. We were getting decent enough borescope photos to be able tell the plugs were oily. Also curious about another oddity, although I suspect it is a red herring. When the ASI was connected but the breather system was still attached (including the oil/air separator), when the engine started, the airspeed would jump between 20-40, but then at idle, would setting around 5. Once I started applying power, it would pull to 0 and stay there, as if there was a vacuum applied. We did it a couple times thinking something wasn't connected right before finally just going full power and as the power got past maybe 30", the ASI jumped to life. When we disconnected the breather and reran the test, it didn't do that. It stayed around 40mph at idle, but once I went full power, it had the same 95-105 range. So, based on this, what next? Re-ring (all cylinders?), top overhaul, IRAN the whole engine? Thanks, really appreciate the help! Vance -

Recommendations on oil consumption next steps

vance.k replied to vance.k's topic in Modern Mooney Discussion

Thanks everyone for the great pointers! @M20Doc, thanks for the link. I'm meeting the new mechanic out there this afternoon with an ASI and we are going to give it a shot! As @takair mentioned, I had read repeatedly before that with blow by, the oil gets dark really fast. I don't know that I've ever seen that quantified, but I will say I haven't noticed a dramatic increase. I'd say it starts to get dark by 25 hours and I've been on a 50 hour interval when I'm flying a lot and closer to 35 when the bird has been sitting. Will update once/if we are able to get the ASI testing to work. Thanks again! -

Recommendations on oil consumption next steps

vance.k replied to vance.k's topic in Modern Mooney Discussion

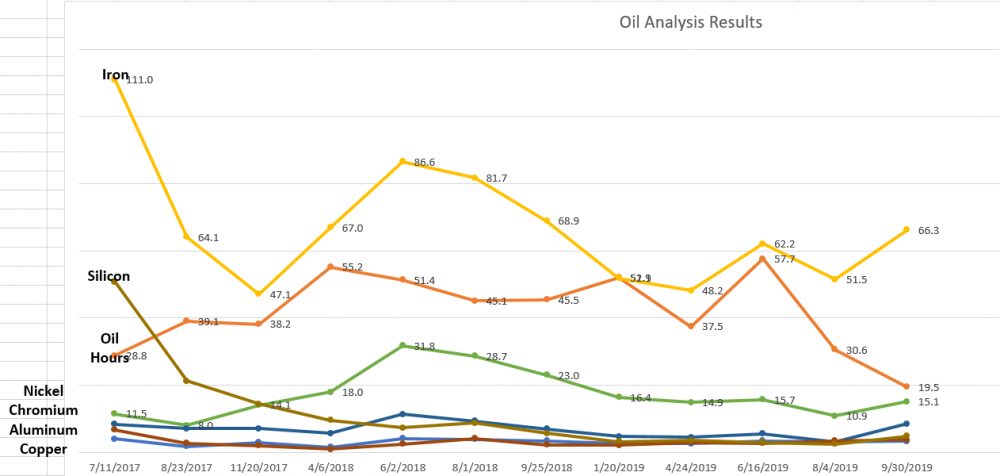

Hi Eric, Forgot to mention it, but did attach a trend line chart from the analysis. I do oil analysis on every oil change, although totally spaced it on this one I just did. Got busy with the new mechanic and forgot to grab it. Bottom line, nothing significant. No metal in the filter either. Thanks! Vance -

Hey MS, Would love to get some advice from the collective. Have a 231 with a TSIO-360-LB1B. It has 1,250TSN (2006). I've put the last 600 hours on it over the last 2.5 years. Until about 9 months ago, I would generally get between 8-12 hours per quart. Starting around April, the consumption started increasing. It increased rapidly and has fluctuated between 4-6 hours per quart. Right when it started happening, my mechanic went through it, compressions, bore scope, etc. Did not find a proverbial smoking gun. Did the annual in August looked at everything again. Compressions 78, 72, 77, 77, 70, 72. Performance is consistent and hasn't changed at all. Each time, there was some oil in several of the cylinders and the bottom plugs were dark, but the tail pipe is not oily. There is a powdery trail on the belly behind the tail pipe. In September, I had an issue where the turbo seized. It happened on the takeoff roll (out of Austin) and there were no indications of issues on the flight in or previously. Coincidence? I had hoped the rebuilt turbo would solve the mystery, but alas, no change. There is some oil leaking from the pushrod tubes, the quick drain was leaking a bit (just replaced it), and there is some oil on the belly out the breather (and maybe 1 or 2 drips after shutdown). I've had 4 different mechanics / IAs look at it while doing different work and everyone kind of shrugs and says none of them are bad enough to worry about, yet. Kind of a keep an eye on it and keep flying. I'm working with a new mechanic (my previous one retired) and we changed the oil last week (and replaced the quick change to fix that leak). We pulled the top plugs and grabbed some photos. I wanted to get some additional opinions on these photos and recommended next steps. Unfortunately, I didn't get any photos of the cylinder walls. Thanks! Vance

-

I had the same problem and found the wrong probe and a miswire. The replacement part was 880006-501 and I got it from Lasar, as an earlier poster mentioned. I’m also attaching a copy of the gauge spec sheet / drawing that helped me sort out the wiring and troubleshoot the readings. Good luck! 880000.pdf

-

Log Review - Knoxville/Crossville, TN

vance.k replied to ValkyrieRider's topic in General Mooney Talk

I had the same problem when I was looking at a plane. Older seller who was unable/unwilling to scan them. I was pretty interested and traveled to the plane, bought a scanner and took a couple hours at the hotel room getting scans of everything. It had everything back to the beginning of time, so took a few hours. L It would have been impractical to get all of that with a phone (although not all was needed either). I’m glad I took the time to do real scans. I ended up buying that plane and I now refer to the scans more than the digging through the log books when looking for something. V— -

Thanks everyone! The hours did add up much more quickly than I expected and frankly, the utility of flying surprised me. The freedom of not worrying about missing a flight or what the security lines will be like, or unexpected delays, is huge! I know I'm preaching to the choir. In my mind, I expected some of that, but it surprised me nonetheless. I love when people ask 'what time is your flight' and I think, 'whenever I get there'. Of course, I usually give some time that works with the schedule as to not get into it. People's reactions and perceptions are funny, so sometimes it is best to keep my little hobby among family and friends. @carusoam - I'll work on the wife and see if she would do something like that. I'd say not too likely, but worth a try. Thanks again everyone, what a great community! Vance

-

Hello MS'ers, Wanted to take this time to commemorate the 1 year anniversary of my first flight in my Mooney. Picked up N231CK from the shop a year ago, after some post purchase work and upgrades, and have been flying every chance I get. I logged 276 hours with 160 landings in those 12 months and have enjoyed the heck out of it. I've learned that I don't like flying at night; it is really dark out there and any off airport landing will likely hit something very hard. And my night landings are usually my worst..but hey, I can usually get my night currency in one trip down the runway (3 bounces count, right?). Conversely, I got my IFR and really enjoy flying in IMC and the utility that it brings. It is still nerve racking and exciting. But, my actual IMC has all been departures and en route with no approaches yet. This past year, I traveled to Denver (~20x), Chicago Area (2x), Kansas (3x), Nebraska (2x), Arizona (3x), Nevada (4x), Texas (3x), and Utah (2x), as well as a host of other places across NM and CO too numerous to mention. I've scrubbed a couple flights, delayed a couple, but have benefited from a remarkably good dispatch record, considering. These Mooney's are travelling machines for sure. I have an opportunity to fly to Orlando (~1,400NM) for a conference in 2 weeks, but after my last trip back from Chicago where I was bucking headwinds the whole way, I'm rethinking that potential 10 hour (probably 2 day) return trip from Orlando. While I'd love to say I did it, I may sit in the back and have a drink for that trip. I've benefited tremendously from the knowledge and resources provided by the community here at MS and for that, I am very thankful. I hope to be able to collect enough in the experience bucket to be able to contribute meaningfully some day. Thanks again for everything! Vance ps. Attaching a photo of the panel and of the family. The family trip was last September on the way to Salt Lake City for labor day. My wife hates flying, but she was a trooper and the trip up was super smooth. Not so on the way back and it was the last time she's been in the plane. Glad a took a photo as proof.

- 15 replies

-

- 19

-