-

Posts

1,378 -

Joined

-

Last visited

-

Days Won

7

Rick Junkin last won the day on April 12

Rick Junkin had the most liked content!

About Rick Junkin

- Birthday 01/30/1961

Contact Methods

-

Yahoo

rickjunkin@yahoo.com

Profile Information

-

Gender

Male

-

Location

Kodak TN

-

Reg #

N1088F

-

Model

M20M TLS/Bravo

-

Base

KGKT

Rick Junkin's Achievements

-

S.2503 Rotor Act - requires ADS-B in AND out !!!

Rick Junkin replied to pmccand123's topic in Miscellaneous Aviation Talk

91.225 is referenced in the legislation and currently excludes these aircraft from ADS-B requirements. However, that's not to say 91.225 won't be rewritten as the result of this legislation. That's probably a good focus for letters to our congressmen. -

As of a couple of years ago I need hearing aids for moderate/severe high frequency loss. All those years of jet noise and Dash 60 power carts had a price. The in-ear offerings could be problematic for me. Bose A20s work great with my hearing aids, so I don't need to worry about taking them out and putting them back in again. Not a huge deal, but I get to avoid the opportunity to damage or loose them. Just one less thing to mess with. Head size plays a major role in comfort - I wear a size 7 3/8 hat. I have no problem with the A20 clamping force, and I've worn them for 4+ hours at a time. As was mentioned by someone else, the passive attenuation is not excellent but the ANR is. And the ear cups are lower profile than the Lightspeeds. I use oxygen on almost every flight and have a Precise Flight boom cannula that mounts to the ear cup, which I like because it lets me easily keep the O2 lines routed out of the way behind me. Having said that, if I needed a new headset I would definitely look at the Lightspeed offerings along with the A30s. I like the cabling on the Lightspeeds better so it would come down to relative comfort and sound quality. The Lightspeeds also boast an equalizer function that could possibly compensate for some of my hearing loss, but I'd have to try them out. If you can't get to a shop that has demo headsets, Sporty's is a good option. They will let you try out a new headset for 30 days. If you don't like it for any reason you can exchange it for a different headset or get a refund.

-

New SAFE/NAFI Foreflight discount policy

Rick Junkin replied to Rick Junkin's topic in Miscellaneous Aviation Talk

Yup, that’s the boat I’m in. I’ve used ForeFlight pretty much from Day 1 when it was released. Over the years I’ve invested a lot of time developing performance profiles, checklists, etc that you had to do manually before the Gucci profiles became available at the higher subscription levels. There are things ForeFlight does really well that Garmin Pilot does adequately, or not at all, and I’ve reached the point of asking myself if I really need those things. I imported my FF logbook into GP and worked up the basic performance profiles for my Bravo. I’ve been using both for about 6 months but found myself falling back on ForeFlight when I really needed something. Time to quit FF cold turkey and rely solely on GP so I force myself to really learn it. I have until July to make a final decision. -

New SAFE/NAFI Foreflight discount policy

Rick Junkin replied to Rick Junkin's topic in Miscellaneous Aviation Talk

This is my viewpoint as well, after thinking pragmatically about the business case. Increased sales and upgraded subscriptions are the drivers for a business like this to offer discounts. There are a lot of folks, like me, who have been getting the NAFI/SAFE discount for years with very few opportunities for eligible referrals. We can still get the same discount, but the company now requires the referrals rather than hoping they will happen. I can’t argue with the discount plan, it’s a solid business case. Unfortunately they will lose subscribers because from the customer perspective ForeFlight is taking 18% away from the 33% discount. The business case no doubt forecasts new subscriptions will exceed dropped subscriptions. NAFI/SAFE members can still get a 15% discount, but if we want more than that we have to work for it as a marketing rep for ForeFlight. We’ll see how it goes. -

Rick Junkin started following New SAFE/NAFI Foreflight discount policy

-

Here's the answer to what's happening with the NAFI/SAFE Foreflight discounts. I cut and pasted from the email I just received this morning. TLDR: Basic discount is reduced from 33% to 15%. If you want to market Foreflight to your students you can increase your CFI discount all the way up to 100% if you refer enough students; 20% for the first "eligible" referral and 5% for each additional referral (that's 4 referrals to get about the equivalent discount to the current 33%, 17 referrals to get to 100%). But you can't add the referral discount on top of the basic discount, they are mutually exclusive. The only "eligible" referrals are for people who have never had a paid subscription to Foreflight. Details below. From the email: Greetings Pilot, We wanted to let you know about some changes to the ForeFlight subscription discounts offered to members of the Society of Aviation and Flight Educators (SAFE) and National Association of Flight Instructors (NAFI). What’s changing? As of today, the SAFE/NAFI discounts now provide 15% off the price of your ForeFlight subscription plan (excluding any add-on products or regions). Additionally, these discounts may no longer be applied to purchases of the Starter subscription plan and can only be used with the Essential or Premium plans for first-time purchases, upgrades, and renewals. How can I increase my discount? Our recently-announced ForeFlight CFI Referral Program allows you to earn up to 100% off the price of your subscription plan simply by introducing eligible* students to ForeFlight, with 20% off for just the first referral and an additional 5% off for each subsequent one. Note that discounts earned through the CFI Referral Program are mutually exclusive with your SAFE/NAFI discount, so both cannot be applied to the same purchase. What do I need to do? No immediate action is required. Your ForeFlight account will continue to be eligible for the SAFE/NAFI discount (15% off) as long as you remain a member of either organization. You can also refer eligible* students to ForeFlight to build your discount as part of the CFI Referral Program, then follow the in-app instructions to apply these discounts to a purchase in lieu of your SAFE/NAFI discount. Visit foreflight.com/cfi-referral to learn how to get started with the ForeFlight CFI Referral Program. Blue skies, Team ForeFlight *Only students who have never had a paid ForeFlight subscription before are eligible for the CFI Referral Program.

-

FS: Sidewinder Tug and 28V GPU

Rick Junkin replied to KSMooniac's topic in Avionics / Parts Classifieds

My Sidewinder is still fairly effective on a wet ramp with enough down pressure on the Sidewinder wheel, but not in snow if the nose wheel is picking up the snow. The drive wheel gets packed with snow/ice and won't turn the nose wheel. Nose tire pressure is important for the Sidewinder-type tow bars. If the tire is low the drive wheel can't get a good friction grip and will slip more easily. All that said, $1,000 is a great price for a used Sidewinder and if I didn't already have one I would buy it! -

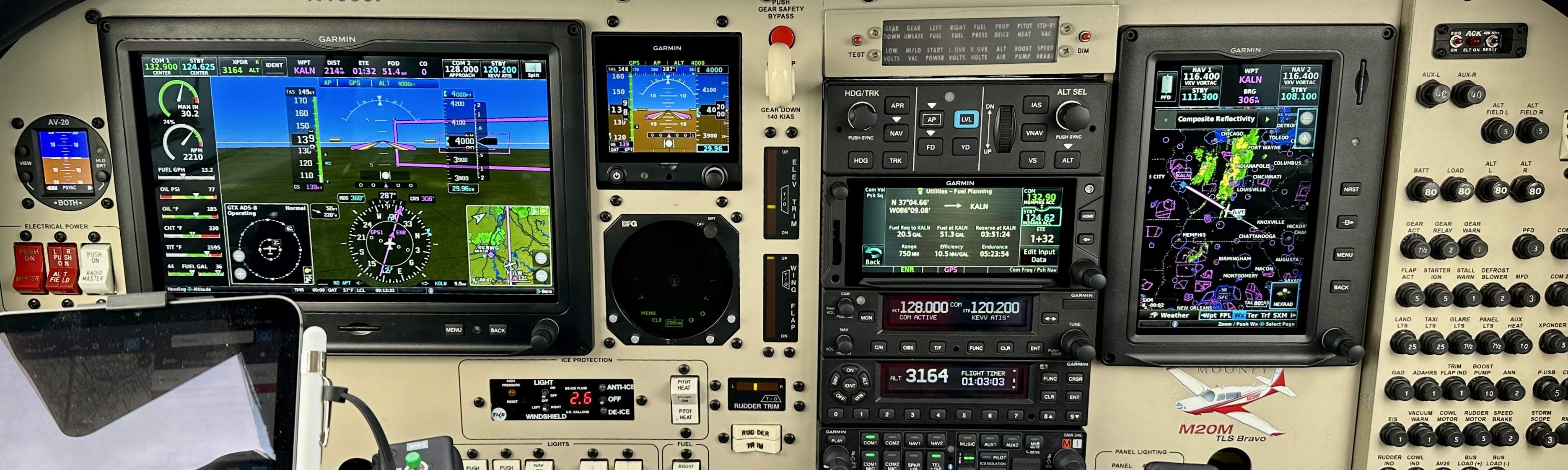

Today's flight was my first flight of the year in my Mooney. It was glorious! I've been down for numerous health issues (removing and replacing a worn part, removing some other sick parts all together) starting last December, and the airplane was down for parts past the start of the runway rebuild project here at GKT. I kept both of us in flyable storage throughout. Me in the books and on X-plane, my baby in a climate controlled hangar with an engine dehydrator and dehydrator plugs for good measure. The runway opened a couple of weeks ago. I got a flight review in a 172 last week so I'd be legal to do the hour of post-maintenance orbits over and around the field solo. I exercised just about everything and collected enough data to confirm the engine, airplane and avionics are operating 4.0. After the GAMI sweeps I captured a couple of screen shots of the performance ROP and LOP at 30/2200, my preferred power setting. It was a good day.

-

Landing Clearance Reminder Technique

Rick Junkin replied to Lax291's topic in Miscellaneous Aviation Talk

I read something similar a number of years ago and incorporated it into my flow. The taxi light comes on when cleared for the approach, landing light comes on when cleared to land. In fact when I replaced my panel I moved the taxi and landing light switches next to the boost pump switch and use them as a physical “checklist” before landing. Works for me. I do the same kind of thing when VFR into a non-towered field. Taxi light on with first CTAF call, landing light on when entering the pattern. It keeps the habit pattern consistent. -

I know this isn't practical for everyone, but my practice is to fuel and preflight the airplane and avionics at home the day before departure, and then do another exterior walk-around and sump the tanks the day of. I essentially do the same at the destination by fueling on arrival and performing a jaundiced-eye post flight inspection after I put her to bed. Mama doesn't mind the arrival delay because she knows it helps ensure there won't be extensive waiting at the airport when we're ready to go home. Plus it cuts down on my, "Gee, I hope the airplane's ok and we'll be able to get fuel" blank stares during our stay

-

In the "how have you improved your process" category, the last thing I do before climbing into the airplane is go stand 20-30 feet off the nose and give everything a last big picture look. I caught a low tire once that had looked fine in the hangar so it catches more than the obvious stuff with flags and such.

-

"2"

-

You're correct, we need to adjust for GW. Roughly 1kt per 100 pounds in my M20M. If you're using Foreflight Performance subscription and you have your airplane performance set up you can get the approach speed for your projected landing weight from the Flights page. I don't have a J POH to reference, but the approach speeds for different weights are at the top of the Landing Distance chart in the M POH. Those speeds are also only computed for full flaps at the various GWs. If nothing else you can do what I did and use the Stall Speed chart, assuming there is one in your POH, and do the math for the approach speeds for no flaps, approach flaps and full flaps at the weights listed in the Stall Speed chart. My rules of thumb for empty weight plus fuel, just like we did in the jet (BAW + ordnance + fuel), as I said is 1kt per 100# (I use 15g of fuel as roughly right to make the math easier) but not sure that's appropriate for a J. Probably? "Better" and more familiar answer for you is to target the book approach value and then adjust with reference to AOA, but that requires installing a reliable AOA indicator. Now THERE'S an open Pandora's box!

-

Tit probes. Have two which one do I really read.

Rick Junkin replied to warrenehc's topic in Mooney Bravo Owners

How do your individual EGTs compare to the TITs from the two probes? My TIT, as measured from the OEM location, is about 75-100Fº higher than the average of my EGTs. From your pictures it appears the OEM location probe is fairly new, while the other one shows signs of erosion at the tip and buildup at the base. I would expect, as @LANCECASPER pointed out, that the worn probe would be reading lower than actual. The fact that they are reverse of this, with the newer probe reading lower, is puzzling. This is a guess, but it may be possible that the buildup of gunk at the base of the second probe is retaining heat and causing the probe to read high. I agree with Lance, installing new probes at both locations would provide a more accurate basis for comparison. If the OEM probe is indeed fairly new you may only need to replace the secondary probe, which is looking a little worse for wear. I'm not a mechanic, just a maintenance-involved owner. -

Is this an emergent problem or has it always been this way? Are you always re-trimming in the same direction? Are you seeing the trim "drift" in smooth air? The first things that come to mind are either hysteresis/backlash or friction in the rudder control system. Have you looked at the condition and security of the pushrods and linkages? Were they lubricated recently?