AlexLev

Supporter-

Posts

416 -

Joined

-

Last visited

-

Days Won

3

AlexLev last won the day on May 20 2019

AlexLev had the most liked content!

Profile Information

-

Gender

Male

-

Location

Carlsbad, CA

-

Model

M20G

Recent Profile Visitors

4,204 profile views

AlexLev's Achievements

-

Still available and actively flying. About to go in for annual. As far as the anti-skid on the flap, yeah - it takes a little extra briefing to let people know not to step there. Not sure why it ended up on the flap...

-

-

Price lowered to $79,000. If seriously interested, feel free to contact for full logs and any other information. Reason for sale: started flying a jet full time for work this year, love this plane too much to only find time to fly it once a month; selling it out of love because she wants to be up in the air, not stuck in a hangar (I've always kept it hangared in 8 years of ownership).

-

Current location of plane: San Diego, CA. Logs available upon request.

-

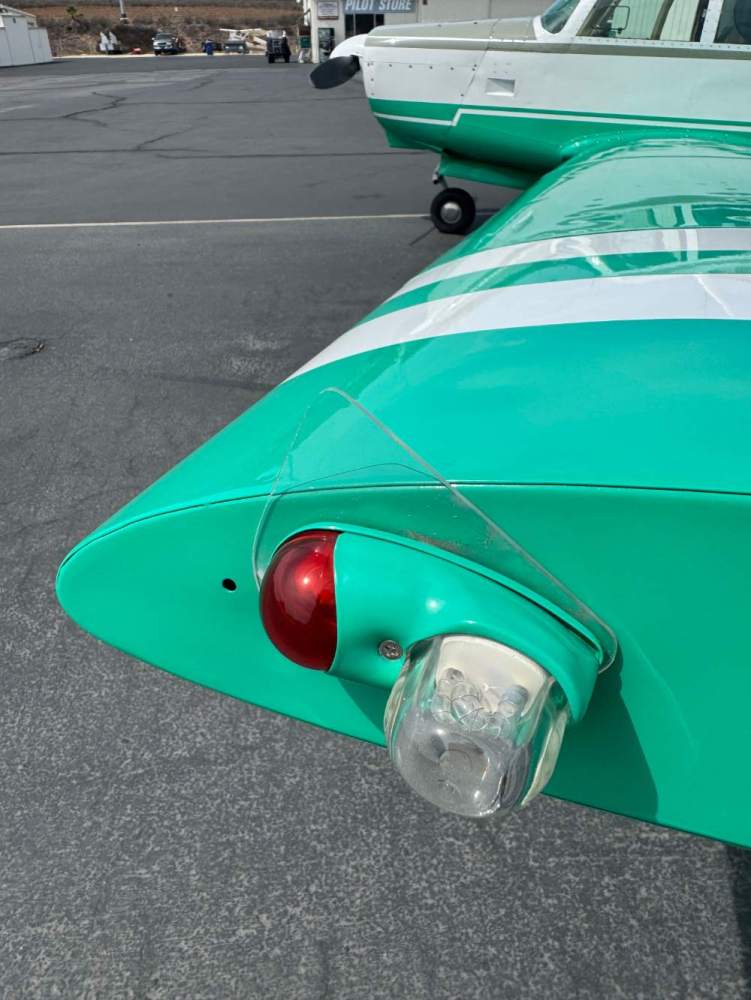

Well loved 1968 Mooney M20G. Dependable 136TAS on a 180hp engine sipping 9-10GPH. Have flown this bird all over the US with multiple CA>NY>CA crossings. She's dependable, clean, and will serve you well. - Engine overhauled in 2018 by Jewell Aviation (1022 hours on engine in 7 years, averaging 146hrs/yr of flying). - Shock discs recently replaced by Don Maxwell (2024) - No AD on prop - Whelen Strobes - PlanePower Alternator Conversion - Skytec Starter (2023 replaced) - 430W, ADS-B 330 transponder - Pathfinder P2A Autopilot with nav mode/heading mode (works), no altitude - Paint is in decent shape and gets lot of compliments on the ramp - Interior is OK, some rips/tears. Feel free to message on MooneySpace with any questions.

-

Practicality of purchasing someone's Aspen 1000?

AlexLev replied to AlexLev's topic in Avionics/Panel Discussion

Thanks! This one has a AOA and Synthetic Vision as well. He's pretty much offering it for free if I want it, which is really why I'm even considering this project (what can I say, I'm a fan of the steampunk feel of this panel). Currently the single-axis A/P runs from the turn coordinator and 430W. It also does interface with the heading indicator for HDG mode, so yeah - I'm curious if it would continue to work with the Aspen. You're saying I'd need to purchase the EA-100 potentially and it's not that reliable? In which case, maybe it's best to walk away while I still have a flying airplane -

Practicality of purchasing someone's Aspen 1000?

AlexLev replied to AlexLev's topic in Avionics/Panel Discussion

Thanks for all this info! I'll have to dig to see about the Pathfinder, since I wouldn't want to change anything if it stops working. It's run off the TC and interfaces with the Garmin currently, so I wonder if I would just keep the TC and AI around on the new panel if going this route. And yeah, I know the right side is a mess, but who doesn't need an ADF and all those fancy instruments to make everything look that much more complicated and impressive...just in case?! -

Practicality of purchasing someone's Aspen 1000?

AlexLev posted a topic in Avionics/Panel Discussion

A friend of mine is tossing his Aspen 1000 Pro (I think it's the one with some synthetic vision) in his C210 for some G5s so that he can put in a Garmin A/P. He asked me if I was interested in putting the Aspen unit in my 68 M20G that I've owned for close to 8 years now. I've pretty much kept the panel the same since I've purchased it and haven't really contemplated upgrading any avionics up to this point. Attached is roughly what my panel looks like now. Few questions: 1) Do I need to purchase an STC from Aspen to make it paperwork legal if I were to entertain this? I'll give them a call to see, but what would that roughly run? 2) I'll obviously have to get quotes from shops, but what's a project like this run me? I imagine I'd probably need to fab a whole new panel? Probably at least 10k for install (obv depends on shop, but curious on ballpark labor involved). Lastly; would you do this if this was your plane? I'm honestly fine flying the steam gauges and am happy shooting approaches in actual with my current setup, but it would be fun to transition to more glass. Any advice and thoughts appreciated -

Moved to CA from FL, great to be west again!

AlexLev replied to Aerospace's topic in West Coast Mooney Club

Oh hey, I'm based at CPM atm w/my Mooney. Happy to provide mechanic references and help out when I can with tail flights, etc. -

Help me understand my Mooney's electrical system

AlexLev replied to AlexLev's topic in Vintage Mooneys (pre-J models)

This is helpful. Does the alternator just charge the battery or does it supply power to everything electrical? Or does it split the load with the battery? How does that work? -

Dan's story inspired me to buy a Sensorcon which ironically was in Buffalo, NY and I just showed up at their factory and got one. After some flying, it started showing 5-8ppm after turning on heat when normally it would show 0 and it gave me clues to my muffler developing cracks which I was able to prevent thanks to it. Thank you, Dan! Could have saved my life! Side question: for those using the Sensorcon: what do you do after it needs calibration? Can you send it to the factory? Do you have to buy a new one? I think it still works, but it's been a while and it says it needs calibration now.

-

First Time Aircraft Buyer - M20G

AlexLev replied to Semper Mooney's topic in Vintage Mooneys (pre-J models)

I have a G model I've owned for about 7-ish years. Not familiar with that particular plane you're purchasing, but I'd recommend having Airmods or Weber do a prebuy if you can fly it that far. Have you looked through the logs? Have you requested a CD from the FAA with the planes records? -

I own an '68 M20G with a plane-power alternator conversion (instead of the generator). For those technically minded that understand AC vs DC and how the electrical system on the Mooney works, mind helping me understand it? I understand there's a 70A max load for the alternator and it's a 14v alternator. I have a Concorde 12v battery with 33 Ampere hours. The alternator generates AC and converts it back into DC via a rectifier (?) and the buses are fed off DC wires to the battery? Apologies if this is totally wrong, but would love someone's help...also with the battery have 33 Ampere hours - does that mean if the battery dies, and the load I have draws approx 4A, it would take approx 8 (33/4) hours for the battery to die if it's fully charged? How many amp would radios/transponder/GPS draw? Apologies if all these are novice questions, but want to learn/understand the plane and its electrical system better and I figure there's a few more technically minded folks here who could help me shed some light on understanding it.

-

I had my engine done with them and David in Feb of 2018. Since then, I have about 820 hours on their overhaul. No metal in the filter, but it has been seeping quite a bit of oil lately. My A&P tried to address it at annual and said "I believe the majority of the oil leak was the loose oil line return clamps. They're an oddball type (thumb screw, not a hex screw) this engine builder used so I had to improvise to tighten them all but I got them. Checked oil pan bolts and accessory case bolts too. All those were fine." What he did helped for the first few hours of the flight since annual, but the seepage is back now, so I'll have to see about addressing it. I was quite enthusiastic about Jewell's work (on time, budget), but it's disheartening to hear about your experience and it makes me feel a little slightly less confident flying with their overhaul, although it's held up to a lot of flying for the last 5 years.

-

Does anyone have an ITT LA11C2114 landing gear motor I can buy?

AlexLev replied to faridaamar's topic in General Mooney Talk

Any luck finding anything? https://www.ebay.com/itm/275611357824?_trkparms=amclksrc%3DITM%26aid%3D777008%26algo%3DPERSONAL.TOPIC%26ao%3D1%26asc%3D20230105140155%26meid%3Dba951d4ab2574f7dae4de5ebe854a3fb%26pid%3D101666%26rk%3D1%26rkt%3D1%26itm%3D275611357824%26pmt%3D0%26noa%3D1%26pg%3D2380057%26algv%3DRecentlyViewedItemsV2&_trksid=p2380057.c101666.m5481&_trkparms=pageci%3A524419b9-c619-11ed-a27b-223eaf87421d|parentrq%3Af8672fae1860aa71460864e7fffd09e0|iid%3A1 but that seems like a crazy price for a used gear motor...

.jpg.01494e07dae90038cc2a152507369f93.jpg)