druidjaidan

Verified Member-

Posts

172 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by druidjaidan

-

We looked at that plane (not in person). I spoke to the seller. He was clueless about what he was selling and I helped him correct a few important points, notably that the engine had indeed been overhauled at some point, but there is still a lot wrong in the ad. Our reasons are not your reasons, but we passed on the plane without traveling to see it in person. A lot of that had to do with changing directions a bit and buying more plane than before. However, I will share my reasons for passing on this plane. In my mind, the strengths of the F are its higher usable load than most and simpler systems (J-Bar, manual flaps). If (and we did go this way to be honest) we are going to take on additional features like electric gear/flaps etc we're going to buy a J/K model. This Had a lot of mods, electric gear, flaps, wing tips, bladders I think?, not to mention the silly throttle quadrant that was installed. I does have a lot of desirable mods as well, notably the 201 windscreen and the enclosed cowl. However, most of the rest of the mods I consider undesirable in an F. I didn't want bladders (heavy and less fuel). Wing tips look nice, but add little besides weight really. Electric gear/flaps are just more complicated and heavy. Worst IMO, was the throttle quadrant, just a bad decision. Almost all of this is cosmetic or personal choice. If it fits you, it fits you so don't let my personal tastes influence you if you disagree. Every F model is a unique snowflake at this point with various owners prioritizing different things and every bird being it's own thing. It's a big part of the reason we jumped up to a K model. They are still all unique a bit, but significantly less so. I can't speak for the condition, which is the most important part, other than to exercise care since the seller knows next to nothing about the plane. It's been sitting a bit. Not terribly long, but long enough that I would expect some issues. The first annual is likely to suck (but that's par for the course when buying a plane in my experience).

-

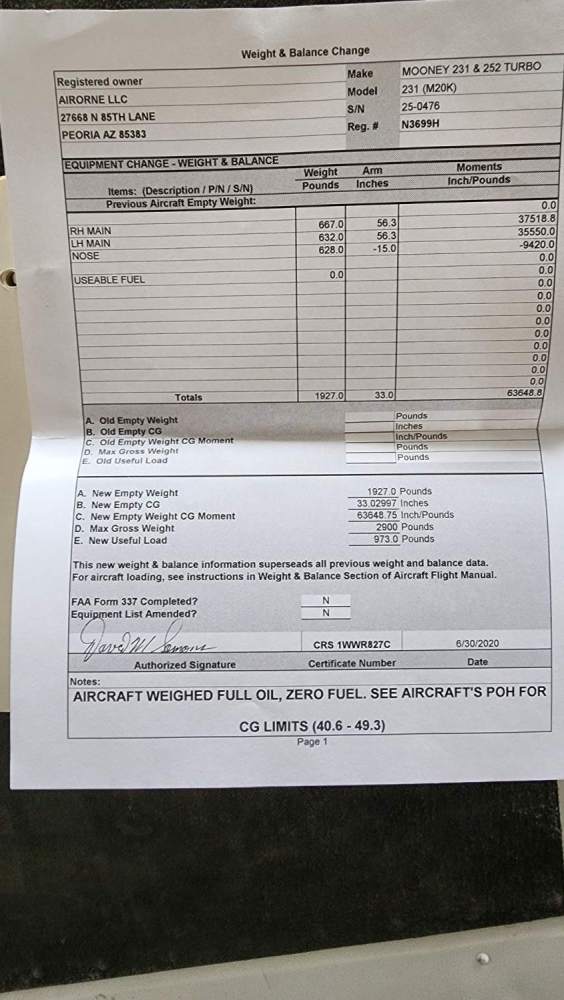

I think you're on the right track, and I think I know what's happened now. I'm not an expert in this so I could be wrong (and I'm using a 252 POH rather than a 231 POH, but I figure it's got to be close). The nose gear should be negative, it's in front of the datum. However, it should be a 5in arm, not 15in. And the main gear arm is measured from the nose gear as a reference, so I think it should be 66in not 56in. Changing the arms out for my guesses gives a 43in empty CG, which is perfect and makes WAY more sense. I think we're still not going to buy this particular one, but I'll let the broker/seller know that they should get their paperwork fixed.

-

I just can't believe I have this right tbh. This plane appears to be totally unflyable currently and would need a ridiculous amount of charlie weights to make it usable just to fly solo. If that's right and common I need to abandon shopping for a K. I don't want to carry around a 100lbs of lead shot to out in the cargo anytime I want to go flying and the family needs more usable weight than I can afford to put 100lbs of Charlie weights in.

-

Early M20K. W/B shows it at an empty weight of 1930 and a CG at 33.0in. This doesn’t look like it should be a nose heavy weight champion mind you. 2 blade prop, modern avionics, factory O2 in the tail, not a rocket conversion, doesn’t even have the intercooler. I understand that modern Mooneys have a rep for forward CG, but this can’t be right can it? Even with 120 in the cargo and full fuel to pull the cg as far aft as possible this plane would be well out of CG with a single FAA standard person up front. I couldn’t get this plane into CG in any configuration, I must have something wrong right?

-

Considering making an offer on a 231 in central AZ. I'm based way up in WA and it isn't close enough to really push for LASAR or TopGun that I would if it was a CA plane. There's a MSC at KCHD that will be my default, but I figure I should see if there are any locals that would recommend someone, someplace else? Likely going to be a full annual for the pre-buy given its annual is due soon.

-

N9391M destroyed at KOSH

druidjaidan replied to druidjaidan's topic in Vintage Mooneys (pre-J models)

Fundamentally it's pretty simple. My insured value has nothing to do with the other party's liability. My insurance is only on the hook for the insured value obviously, that is the limit of my insurance's liability to me. If the other party had insurance I could simply file a claim on their insurance and then it becomes a debate toward a settlement. The consultations I've had with attorneys have all basically agreed on the fundamentals of what the party's liability is, who the likely liable parties are, and my roughly estimated value being correct. They also don't believe the value to be significant enough that they would be willing to take the work on contingency and none of them accept hourly at all if we wanted to pursue it. The gap is significant enough to be worth some headache to me. It's worth at least paying for some threatening letters from an attorney and investigating if ELA Gyro's had insurance and was responsible for Bruce's flight. -

N9391M destroyed at KOSH

druidjaidan replied to druidjaidan's topic in Vintage Mooneys (pre-J models)

This is part of the reason I want to get an attorney to advise me. I've read that both Washington (my home state) and Wisconsin (where the incident occurred) both appears to apply something called the "Made whole doctrine". "In Wisconsin, the made whole rule is a legal doctrine that requires an injured party to be made whole before any insurer can recover anything. Garrity v. Rural Mut. Ins. Co., 253 N.W. 2d 512 (Wis. 1977). Thus, in situations where an injured party’s damages exceed the limited pool of funds from which he or she can recover, the injured party is given priority over the subrogated party." I don't know how that works in practice tbh. It seems complicated to say the least, how is my insurance to know what my total claim is or to agree on what my total claim is A lot is somewhat subjective or not strictly determined, what is the actual value of the plane, what will my acquisition costs be, etc. It seems like I'd need to get them to agree to a value, even if that value exceeds my insured amount, and I'm not sure what incentive the insurance company would have to do that at a value higher than my insured value. It may not actually work that way at all, hence wanting to get a lawyer to clearly provide what options we have and push back if we haven't reached the limits of what we should be pushing our insurance to do. So far though I've had very little luck getting a lawyer willing to take hourly work to provide that advise and write some demand letters to see if we can get things moving. In theory, they require all vendors to provide proof of insurance and indemnification. If this was a demo flight I expect that the EAA will try to force ELA gyro's insurance to cooperate at some level. Right now that is kind of the final path to resolving this via a 3rd party insurance settlement rather than via our own (underinsured) insurance and eating the loss. However, I don't know how to navigate to that outcome if it's even possible. But it's an avenue we are looking into. I don't know what stops ELA's insurance from going "nope, ELA didn't authorize Eric as a representative to provide a demo flight so we're not liable" other than litigation. -

N9391M destroyed at KOSH

druidjaidan replied to druidjaidan's topic in Vintage Mooneys (pre-J models)

I don't disagree that I was underinsured, but this argument is just victim blaming. Insurance would have protected me from being "robbed", but it doesn't change the fact that the liable party(ies) will get away with it. -

N9391M destroyed at KOSH

druidjaidan replied to druidjaidan's topic in Vintage Mooneys (pre-J models)

There is no insurance on the rotorcraft . So we're talking about my insurance that wants me to forgo pursuing the rest of the liability. -

N9391M destroyed at KOSH

druidjaidan replied to druidjaidan's topic in Vintage Mooneys (pre-J models)

That would definitely be the least stressfull way to handle it. We'd likely be out of flying for a few years at least due to the gap in insurance vs actual loss. The emotional part of me has a hard time swallowing that I just got robbed for ~$35k because someone else crashed. Honestly, I'd probably already have taken that route if the insurance release didn't require us to forgo any additional claims against the 3rd parties in the future. That requirement also makes me disinclined to help the insurance company at all -

N9391M destroyed at KOSH

druidjaidan replied to druidjaidan's topic in Vintage Mooneys (pre-J models)

Right about now I'd take any attorney to help advise us, let alone an aggressive one. We've been turned down by all 5 attorneys we've reached out to after the consultation reviewing our options (from simply helping ensure we don't sign something we shouldn't, up to could we litigate). Roughly the answer has been basically: "we don't do hourly only contingency, and your claim doesn't have injuries so no matter the viability we won't help" -

N9391M destroyed at KOSH

druidjaidan replied to druidjaidan's topic in Vintage Mooneys (pre-J models)

My experience so far with the 3 lawyers I've spoken to (and 2 more that haven't replied I suppose) that property only claims aren't financially viable to litigate. Too low of value. Maybe I'm just talking to the wrong lawyers. Did he tell you it was a demo or are you assuming it? If he was doing a demo that's useful information to have confirmed. -

Engine won’t start. KOXI airport.

druidjaidan replied to billy hellcat's topic in Vintage Mooneys (pre-J models)

Is the prop turning and it's just not starting? If so it's not the starter and likely the SoS. Also it's a hot start, that can be a pain if done incorrectly, not sure his experience level. Beeping on the speaker makes very little sense, it isn't like our planes have any digital controls that would do that. Edit: Saw that tapping the solenoid got it going again. And the starter is new? Warranty it. -

Vintage Mooney current market value?

druidjaidan replied to Immelman's topic in Vintage Mooneys (pre-J models)

Depends on your willingness/ability to pay out of pocket for when a Gyroplane falls on it. Real answer, the only way is to look at the market and figure out how much you'd have to spend to get a comparable plane. Then add all expenses you would incur to actually complete that transaction. Add some buffer for things you might have in the plane that could be destroyed. Given my recent experience my current thought process that if the insurance company doesn't balk at the value I likely didn't go high enough. That will cost you in premiums though and maybe you won't care when the gyroplane falls =) -

N9391M destroyed at KOSH

druidjaidan replied to druidjaidan's topic in Vintage Mooneys (pre-J models)

We don't know for a fact that he doesn't have insurance, he isn't talking. His not having insurance is conjecture based on an aviation attorney who said "most" gryocopters are uninsured. He could be wrong, or maybe this one is an exception since it's being used for demo flights. We won't know until the pilot starts talking. As of right now I only know who the pilot is only because social media has leaked it. The EAA hasn't told us, our insurance hasn't penetrated past the anonymous LLC that the gyro is registered to, the pilot hasn't come forward. Imagine that this pilot tries to hide behind his LLC with inevitably no assets except the gyrocopter itself. Yeah, there's a reason I haven't been sleeping well for the past week. -

N9391M destroyed at KOSH

druidjaidan replied to druidjaidan's topic in Vintage Mooneys (pre-J models)

So let me explain further. I think it is likely that EAA has some blame in this accident. I think it's obvious the pilots flying, probably the gyro have the majority of the fault, but also likely the helicopter pilot has some as well even if minority. I'm pretty sure I have 0 responsibility in the incident considering I was parked. So what happens now? In theory, my insurance would make me whole, but they won't come close in reality. Hopefully, the pilot(s) insurance will come through, but we don't even know if the gyro pilot has insurance. He's not talking to anyone, or at least not anyone who we have contact with or our own insurance. Apparently gyrocopter insurance is "prohibitively expensive". I think blaming EAA for the accident is pretty unsavory, but let me pose a few thoughts where I think EAA could end up shouldering some fault. Apparently, the gyro pilot had been warned about unauthorized procedures in the pattern. Why wasn't he removed from the approved list if that is true? Some people are claiming the 360 maneuver for spacing is permitted in the safety briefing, if so that seems very short-sighted and likely implicates EAA in the procedure design. Finally, if this was indeed demo flights on the part of a manufacturer (that is what it looks like) I would hope that EAA would require adequate liability insurance, and if they didn't or they failed to verify I believe that ends up with them bearing some responsibility. Also, if this was a demo flight I would think that makes the manufacturer liable. So much about the incident is still unknown that I think it's unreasonable to rule in or out who had how much accountability I think we all agree the pilot's are primarily responsible, but I also think it's likely they are not alone in the responsibility. I don't view this like the other cases where totally unrelated inculpable parties are being mentioned. My insurance is inadequate to restore my full loss. Even considering that it is my fault for not upping my hull coverage fast enough to keep up with the market rates that isn't the end of our losses. Maybe this will serve as a lesson for everyone reading about how much insurance they should carry. We have so far account for almost $4,000 in destroyed personal property, we might be able to claim against our homeowners for this. We have accounted for roughly $13,000 in uninsured losses to expenses relating to the accident so far. The majority of that is sales tax on a theoretical replacement plane, but the rest is travel expenses related to the accident. And we haven't yet accounted for the other new purchase costs: pre-buy inspections, travel to/from planes to view them, and the travel costs to return the plane to our home base. That could easily be thousands: 2-3 prebuys, 2-3 two way airfare and a one way ticket to bring the plane back + a trip back that could feasibly be as long as Florida to Washington. I'm sure I'm missing things even then. None of this is even in the realm of "pain and suffering", it's all real money losses. -

N9391M destroyed at KOSH

druidjaidan replied to druidjaidan's topic in Vintage Mooneys (pre-J models)

I guess that means you volunteer your plane as the landing pad next time? Or are you only talking about the actual pilots that were flying? I'm not particularly rich. What I'm looking at losing right now may be enough to keep me from owning a plane again. All because I was parked in an unfortunate spot. I'm very glad my family is ok, I'm glad the two occupants of the gyro were saved. I also firmly believe I am owned full compensation for my loss. This isn't some "guy runs out of fuel and dies, family sues Cessna because the plane didn't stop him from killing himself" -

N9391M destroyed at KOSH

druidjaidan replied to druidjaidan's topic in Vintage Mooneys (pre-J models)

It's unlikely to be completely binary, but who knows yet. That said we saw some details. The helicopter did not fall into the camping, it fell on the road. There exists a rotorcraft forum where more witnesses are discussing the accident. The only detail there worth sharing is that if what they say is true the collision very well could have happened over the road. -

N9391M destroyed at KOSH

druidjaidan replied to druidjaidan's topic in Vintage Mooneys (pre-J models)

I'm having a hard time with it. On one hand I'm glad that my plane was able to minimize the loss of life and wasn't just destroyed. On the other hand it's eating me up a bit that the evidence is pointing at the gyro, the people it saved, being at fault for disobeying the safety procedures. It just doesn't feel right. -

N9391M destroyed at KOSH

druidjaidan replied to druidjaidan's topic in Vintage Mooneys (pre-J models)

I was in row 123 -

N9391M destroyed at KOSH

druidjaidan replied to druidjaidan's topic in Vintage Mooneys (pre-J models)

The kids are upset, I'm upset. I don't think it impacts our future flying with them. We likely will seek out legal advice regardless. At a minimum to ensure we are treated correctly for all incidental losses involved (we had personal electronics and equipment in the plane), and partially because we've already received advice to be mindful of the impact of a claim on our insurance and that we should seek out the other parties insurance. Regardless of right or wrong I'm not a huge fan of going after eaa for this. I would bet they will never allow the ultralights to fly right over the campsites again and that procedure will get revamped or that section of parking closed. -

N9391M destroyed at KOSH

druidjaidan replied to druidjaidan's topic in Vintage Mooneys (pre-J models)

The news on the pilots is not good. The one that didn't land on my money was not survivable. The one that did, I met one of the people first on scene who pulled them from the plane. They were alive at the time. -

My plane for the past 6 years was destroyed today. Two ultralights collided on approach and one of the planes came down on top of my plane. We were on our way back from the seaplane base, had we decided to take the South 40 bus instead of main gate we, and my children, likely would have been at the tent when it happened.

- 203 replies

-

- 20

-

-

-

Surefly is an interesting option, but I'm a bit nervous about going electronic ignition. f you look through my post history you'll learn why I'm leary about going to electronic ignition. It's just a one off, obviously, but My 2016 trip to Oshkosh would have been significantly more painful had I had Surefly