-

Posts

38 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by jcolgan

-

I have done owner assisted in the hanger and would do it again if that was necessary but would prefer to pay somebody else. Time is precious and I am slow.

-

The shop on the field I have used for over 10 years has changed hands. The new shop may well turn out to be fine, but it is un-nerving to put my plane in for an annual as they have told me they have limited Mooney experience. I am in north Alabama, just about dead center. Airport is KDCU. Anyone know of Mooney savvy shops or individuals near me? My annual is not due for 9 months, but it is never to early to start worrying about the next one. I am in a private hangar and have jacks and tools, will just need a qualified inspector.

-

Thanks, but I found and bought a remanufactured unit just about an hour ago.

-

My Delco-Remy starter, part number 1109519, has failed. The leading bushing (by the flywheel) failed and deeply scored the shaft before giving any sign of a problem. That was easily accessible, probably should have put a drop of oil on it once a month. Anyone have a serviceable replacement? Parts manual says it is a 1109689.

-

Dive tanks are filled with compressed air, not pure oxygen.

-

Found the reference to M20-345A, it is in the AD. “Service Bulletin M20-345A, dated December 13, 2022”

-

Thanks for the rapid reply. I had seen somewhere that the SB had a Revision A that mentioned the magnet test to avoid paint removal. That may not be the case. Strong rare earth magnets are not attracted to my weights, just trying to verify that is a satisfactory test method. Thought it was mentioned in the Revision if it actually exists. Magnet I used is so strong it is almost impossible to remove them from a refrigerator, I keep it wrapped in a rag so I can pull it off objects.

-

Having a rough morning (had to give up coffee!) I can’t seem to find a printable version of the revision of the service bulletin, or the actual AD. I find copies of the rule implementing the AD, but not the AD itself. Could anyone give me the web address or are these documents already here somewhere?

-

Disagree. Granted, good tools make a job go quicker and are less likely to fail during use, so less likely to round a bolt or damage a part. But to say quality work can not be accomplished by a financially struggling but conscientious mechanic is not realistic. Everyone has to start somewhere and some of the finest mechanics I know started off in a barn with old rusted tools and worked their way up over the years to Snap Ons as they progressed. Start off sloppy, usually going to produce bad results. Start off cheap, can go either way. With the proper motivation it can be just fine.

-

Temporary Low fuel pressure fluctuations

jcolgan replied to ArtVandelay's topic in General Mooney Talk

how long has it been since the fuel system was last opened? Like the gasculator being cleaned and inspected during annual. Could it possibly be some air that was entrained somewhere in the system shaking loose and going through the pump.? -

I recently ran across a YouTube video which touched on the topic of runway separation. I am based at a non-Tower airport and have always believed that you did not take off or land on a runway with another plane on it. Do the regulations about runway separation apply at uncontrolled airports? Our runway is a little over 6000 feet long and has a little hump to it, so if I can’t see another plane on the runway when I’m on the ground, they are beyond the hump and therefore beyond 3000 feet, so I shouldn’t need to wait to depart for landing traffic to exit. if I can’t see them (they are past the hump) there is enough room to safely depart, and it appears to be within regulations. I often thought that it would be safe, but I’ve never done it because I thought it was not allowed. There are several commercial operators who try to save their brakes by slowly rolling all the way to the end of the runway before exiting. I just want to make sure I’m not violating any rules because some of them might not respond well to my departure announcement.

-

iPad Mini 7 introduced 10/15/2024

jcolgan replied to LANCECASPER's topic in Avionics/Panel Discussion

I have a 6 and probably won’t upgrade until they make a mini with facial recognition and/or a brighter screen. -

When I had mine painted I was told I would have it back in 6 weeks which is longer than I like to let it sit idle, but I didn’t take any preservation actions. They actually didn’t get my plane finished for a few days 5 MONTHS. I was livid (and they didn’t do a particularly good job to add insult to injury). It has been 9 years ago and no metal in the oil filter or rust seen as cylinders 3 and 4 were pulled years later for non corrosion issues. I was using Camguard during the paint job and still do now. This is all with the humidity we have here in Alabama.

-

Where is this cotter pin? I am ready to start this project and would love to be able to open the door further. 1964 M20C. Parts manual is no help and visual inspection has not yielded a way to disengage the door slide, but I haven’t looked under any of the interior or door trim\fabric.

-

this is my iPad Pro 11 ram EZ roller mount. I drilled as many ventilation holes as I thought I could get away with and not interfere with structural integrity. I have also modified the bend at the top to accommodate an iPad Pro 11 2024 version as they have not yet put out a ram mount for it. This was originally for a 2016 iPad Pro 11. the 2024 version is approximately 66% brighter in direct sunlight, but is also approximately 1/10 of an inch taller.

-

I don’t recall it ever happening. I have an EZ roller Ram mount on the yoke. I did modify the mount to allow air to circulate on the back while in the mount. Took a step drill bit and perforated the back of the Ram cradle. Holes of varying sizes to expose as much of the back as possible. I have done this with mini iPad and iPad pro 11. I supply external power continuously.

-

Weigh the seat and enter the negative of that weight in the calculation.

-

I am going to pick mine up from Eddie at Wet-wingologist this Thursday. Flying down on Delta in just a few hours. Had to have my drain AD done and some issues caused by a previous owners patch job corrected which drove the price up from the original quote. Does anyone know the punch code for the walkthrough gate at the corner of the Wet-wingologist hangar?

-

I’ve taken out a significant scratch with Aeroglaze and a lot of elbow grease. It was deep enough there is a little light distortion in that spot, but you only notice it if you know where to look.

-

My Foreflight subscription is set to auto renew soon. They kindly sent a push notification about it at 13 minutes after midnight last night. I have notifications from the program turned on for fuel timers and such, so I don’t want to turn it off, but I find that their timing was less than optimal for that particular non-urgent notice. Does anyone know of any subscription discount codes that are in effect at this time? Or perhaps a way to get a veterans discount?

-

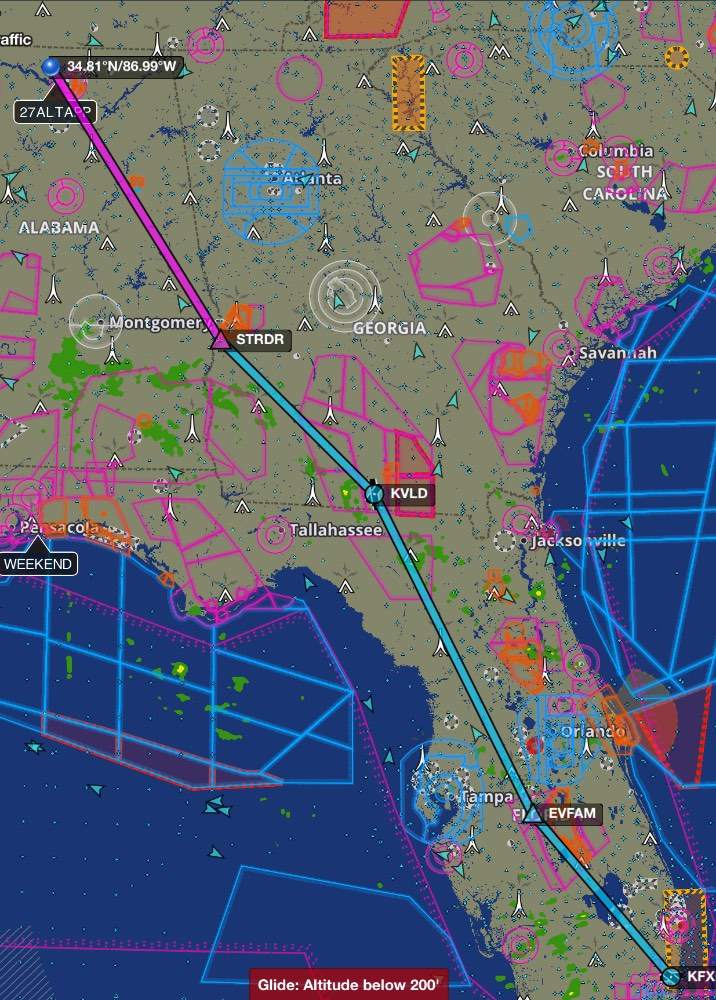

My plan. Just occurred to me that there might be quite a bit of traffic squeezing between those two bravo class air spaces.

-

I’m VFR and planning on flying right down the center of the state. Considering making it an early flight, around 6 AM to enjoy reduced traffic. Using airways never occurred to me.

-

The flight through A-292 was a non-event. Didn’t see any traffic until hitting the C airspace, which was quite busy. next adventure is flying down to Wet Wingologist in Ft Lauderdale for my July tank reseal. That looks to be busy airspace. plan on trying for an 8 AM arrival before things get crazy busy.

-

I am planning a VFR flight from North Alabama down to KPNS, Pensacola, which means I have to fly through Alert Area 292. Thursday around noon. No way to avoid it. Never been in an alert area before, other than flight following and keeping my head on a swivel any words of wisdom?

-

When I transmit the feedback I hear of myself has considerable noise/static if the engine is under load. I have been told the noise is not being broadcast, so it is an annoyance to me but not an actual communications problem. I still have a generator which has what I believe is a small old capacitor attached. The electrical drawings don’t seem to show this capacitor and so I have no part number. Any thoughts, drawings or information would be appreciated. 1964 M20C.