-

Posts

1,822 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Posts posted by mooniac15u

-

-

15 hours ago, M20Doc said:

We’re you in my shop last week when I was installing one for @ohdub

Where were you able to find one?

-

-

1 hour ago, PT20J said:

I've never seen one with high backs and no headrests and the IPC doesn't show that on any models. Also, I cannot see how the seat would fold down if it was made with high backs. Do you have a picture?

-

2

2

-

-

That’s a routine SAIB announcement. It has nothing to do with your plane or your flight yesterday.

-

6

6

-

-

On 8/15/2022 at 12:13 AM, MooneyMitch said:

My experience...... gear unlocked ( mechanical linkage failure), asphalt runway, flaps fully extended, approximately 65 mph approach speed, calm winds, minimal floating prior to ground contact.....aircraft slid approximately 150 feet before coming to a stop, with only a slight loss of straight forward direction.

This crash is just so heartbreaking. So very sad for the loved ones left behind.

I had a complete extension failure on one main gear and retracted the other two to land gear up. The FAA measured my skid at about 330 feet. They based the starting point on marks and debris on the runway. I wonder if your partially extended gear decreased your skid distance.

-

2 hours ago, ArtVandelay said:

What’s the 50° placard mean?

Looks like a caution against shock cooling. The arrow seems to indicate a movement to the left on the gauge. The full text of the placard isn't visible but it looks like it might read "50°/Min"

-

1

1

-

-

25 minutes ago, 201er said:

Dang that VFR flying... Good reason for going IFR

Perhaps you're familiar with 91.113

"When weather conditions permit, regardless of whether an operation is conducted under instrument flight rules or visual flight rules, vigilance shall be maintained by each person operating an aircraft so as to see and avoid other aircraft."

-

When I'm flying my two favorite entertainment activities are seeing and avoiding. Especially when I'm VFR.

-

1

1

-

-

That doesn't look like an item that should get a lot of stress. Did it break from regular use or did something specific happen to break it? You might try gluing it with a little reinforcement on the back.

-

57 minutes ago, nosky2high said:

FWIW I highly recommend plane power voltage regulators, 2000+ hours behind them and never a problem. Same with their alternators.

Plane Power voltage regulators are part of the STC generator to alternator conversion which doesn't apply to the M20J because they all came from the factory with alternators. Zeftronics is pretty much the only option.

-

-

On 6/11/2022 at 10:00 PM, GEE-BEE AEROPRODUCTS said:

Send me a sample

we stock the Beechcraft tail seal in two versions

standard width if painting

or -3/16 to cover the old cement paint line

I just finished a Cessna tail seal for singles/ vertical

was only made in white rubber , now black gloss silicone

Gee Bee

Do it correctly, not half ass like others do.

It seems like it might not be a good idea to jam a big piece of silicone into that moving part on a Mooney.

-

2

2

-

-

2 minutes ago, bluehighwayflyer said:

No. The opposite. My J was only perhaps 7 or 8 percent faster than my C at max cruise but it was around 20% more efficient if slowed down and flown at C speeds. To me at least that is a greater evolutionary improvement than is the J’s improved top speed that so much is made of. Two sides of the same coin, though, obviously.

I agree. The higher top speed is nice but the efficiency has made a bigger difference for me on long cross country flights by reducing or eliminating fuel stops.

-

2 minutes ago, bluehighwayflyer said:

Fuel flow. And, yes, my J was faster at any fuel flow than my C is as well.

I think I misread your post. I thought you were saying that your C was 20% more efficient.

-

3 hours ago, bluehighwayflyer said:

I have owned both an early J and a lowly C. Both for long periods of time. The J cruised only 10 knots faster but, at the C’s cruise speed, it was remarkably more efficient. Like 20 percent. That is way more impressive than is the paltry 10 knots but no one ever talks about it. Neither have ever made “book” numbers, even after the installation of a factory reman engine. Neither have ever been rigged by a specialist such as @jetdriven, either. I’m sure that that would unlock several more knots from both of them.

That's an interesting observation. What was your metric for efficiency? My J is faster in cruise at any fuel flow than my D was.

-

5 minutes ago, willerjim273 said:

Thanks everyone,

He is asking for copies of certificate, medical, and logbook entry for the light bulb replacement. I have read part 14 CFR Part 43, Maintenance, Preventive Maintenance, Rebuilding, and Alteration enought, I think, to know that I can make log entry and sign off. Any suggested language?

I just renewed my AOPA, will call them as well.

Thanks

Have you already signed the logbook entry? Do you have an A&P who would be willing to sign off your work? I realize that might not be necessary but it wouldn't leave the FAA with anything to complain about.

-

1

1

-

-

Is there going to be a potential issue with flying home with the landing gear light inop?

Before the typical Mooneyspace pile-on starts, I'm not saying it's dangerous or should be a problem but once the FAA is involved could they see it that way.

-

Have you listened for the noise with the squelch turned off on the intercom? If not, is it possible both the ignition and gear motor are making noise and it only breaks the squelch with the cumulative noise?

Have you tried turning off the intercom and seeing if the noise persists? Usually there's a failsafe mode or second set of jacks that bypasses the intercom and connects straight to your com radio. Do you hear the noise there also?

-

4 minutes ago, Jocbay said:

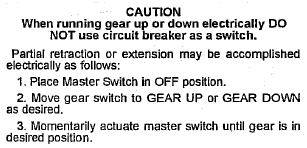

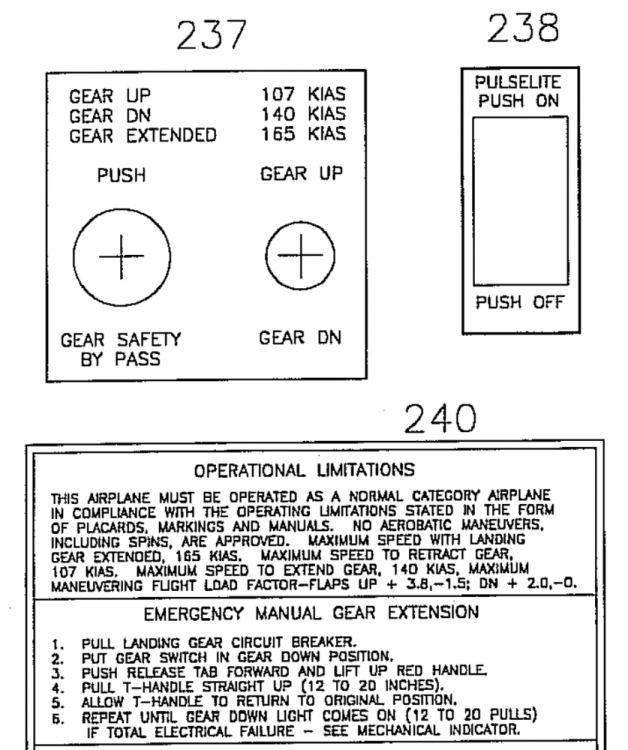

I've searched this topic, but not found an answer to my specific question.

My POH and placard (shown below) both have the same instructions regarding the emergency procedure; however, neither mention the red button that resides next to the gear switch on my 78J. The red button is labeled "gear safety bypass". Where does this undocumented and most mysterious bypass fit into the emergency procedure? Is it a push, a pull; hell, it could be a rotate for all I know.

Also, my "gear circuit breaker" is labeled "gear cont". I know this because I have had to use it. Long story short. Putting gear down, unsafe light goes off but no gear down indicator lights up on floor and the gear cont. circuit breaker popped - pushed in breaker and it pops again. Went through emergency procedure and handle moves 4-5" but jams. Flexed the airplane abit, reset breaker (it holds), reset latch, tried gear again (nada), no green light on floor. Raise a friend, fly over his place and get gear down conformation. Land without incident. Emergency cable still jammed. Pulled actuator assembly and off it goes to Lasar, they go through it, we replace the no back spring (which I sold to another MSr in need) and a couple three AMUs later all's well. EXCEPT I don't remember if I included the red button in my ordeal, though at some point I'm sure I did.

So if y'all can clue me in on the red button...

That button isn't related to the emergency gear extension. It allows you to override the squat or airspeed switch to retract the gear.

-

2

2

-

-

There's a procedure for partial retraction in the maintenance manual (section 32-60-01). It specifically cautions against using the circuit breaker as a switch.

-

2

2

-

1

1

-

-

15 hours ago, 65eTurbo said:

My E is a little unique in that it has the back seat relocated rearward. If I want to carry back seat passengers I wind up at the aft CG limit and bags have to be positioned in the back seat. For example, flying 2 kids to camp or Airventue with camping gear. This will let me put a bag behind the seat.

How do you relocate the rear seats rearward? The structure below them can't be moved. Does the front of the seat no longer align with the structure? Do you have a picture of this?

-

5 minutes ago, bluehighwayflyer said:

My previous 1978 J had the doubler from the factory. But I admit that I didn’t look up the timing prior to posting. Thanks for the correction if that is the case. Regardless, though, apply the service bulletin that was issued over 40 years ago and aft spar cracking is no longer an issue.

Agreed. I wasn't trying to make the case for electric over manual. I've had both types and although I do like my electric gear and flaps it's not because I think they are inherently better mechanisms.

Of course it may be a challenge to source a doubler right now.

-

53 minutes ago, bluehighwayflyer said:

There is a service bulletin to add a doubler to the aft spar to eliminate the cracking problem. This doubler was subsequently incorporated into new production. The cracking problem has nothing whatsoever to do with the flaps’ means of actuation. It has everything to do with the presence or lack thereof of this doubler.

I don't think that's true. SB 217 for the doubler wasn't issued until 1979 which is long after they had switched to only electric flaps. If they had known about the problem in the late 60's and started adding doublers for new airframes the SB would have been issued at that time.

Also, the mechanisms function differently and attach to the spar differently and the SB clearly states that it's only for planes with hydraulic flaps.

-

On 4/2/2017 at 1:49 AM, Herlihy Brother said:

Correction, Manufactured in Fall of 1963, Sold as a 1964 Year model, like they do with cars. This is Serial #101.

The FAA says this is serial #111. Serial #101 would have been the very first M20E.

Klixon Breaker Switches FS

in Avionics / Parts Classifieds

Posted

Romulans.