-

Posts

1,828 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Posts posted by mooniac15u

-

-

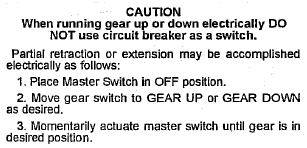

There's a procedure for partial retraction in the maintenance manual (section 32-60-01). It specifically cautions against using the circuit breaker as a switch.

-

2

2

-

1

1

-

-

15 hours ago, 65eTurbo said:

My E is a little unique in that it has the back seat relocated rearward. If I want to carry back seat passengers I wind up at the aft CG limit and bags have to be positioned in the back seat. For example, flying 2 kids to camp or Airventue with camping gear. This will let me put a bag behind the seat.

How do you relocate the rear seats rearward? The structure below them can't be moved. Does the front of the seat no longer align with the structure? Do you have a picture of this?

-

5 minutes ago, bluehighwayflyer said:

My previous 1978 J had the doubler from the factory. But I admit that I didn’t look up the timing prior to posting. Thanks for the correction if that is the case. Regardless, though, apply the service bulletin that was issued over 40 years ago and aft spar cracking is no longer an issue.

Agreed. I wasn't trying to make the case for electric over manual. I've had both types and although I do like my electric gear and flaps it's not because I think they are inherently better mechanisms.

Of course it may be a challenge to source a doubler right now.

-

53 minutes ago, bluehighwayflyer said:

There is a service bulletin to add a doubler to the aft spar to eliminate the cracking problem. This doubler was subsequently incorporated into new production. The cracking problem has nothing whatsoever to do with the flaps’ means of actuation. It has everything to do with the presence or lack thereof of this doubler.

I don't think that's true. SB 217 for the doubler wasn't issued until 1979 which is long after they had switched to only electric flaps. If they had known about the problem in the late 60's and started adding doublers for new airframes the SB would have been issued at that time.

Also, the mechanisms function differently and attach to the spar differently and the SB clearly states that it's only for planes with hydraulic flaps.

-

On 4/2/2017 at 1:49 AM, Herlihy Brother said:

Correction, Manufactured in Fall of 1963, Sold as a 1964 Year model, like they do with cars. This is Serial #101.

The FAA says this is serial #111. Serial #101 would have been the very first M20E.

-

11 hours ago, AerostarDriver said:

Fuel pump was on and constant 36 PSI was maintained the whole time. I will check the vents and I am going to go ahead and do all new hoses firewall forward. Thank yoou

My E has so many power and RPM restrictions it is hard to keep track of them all. I was informed when I did my transition training that you were to not maintain full power and RPM for more than 5 minutes. Then on top of that with the top prop, Hartzel says no continuous operations above 24" at greater then 2350 rpm while preserving the existing RPM restriction of 2000-2350 rpm. The guidance has been unclear to me from Hartzel as to what "continuous" means, I have heard everything from 5 minutes to 90 seconds. Am I missing something? I would very much like to not to have to make so many power changes. In theory, there is no reason I would not be able to make it to pattern altitude on the downwind in 90 seconds so I am likely making this way more complicated than it should be.

I think you need to verify these restrictions. The only full-power time restriction I've heard of in Mooneys is with an IO-390. If you have an IO-360 you should be able to run it at full power for more than 5 minutes.

The Top Prop brochure says this about continuous operations:

"Placard – “No cont. ops. Above 24” manifold pressure between 2350 to 2550 rpm” (M20E, M20F only)"

https://hartzellprop.com/wp-content/uploads/Mooney-Combined-PrcSht-Order.pdf

Which again allows you to remain at full power. The limitation should be documented in the STC paperwork.

-

1

1

-

-

Oil Temp on the left and Cyl Temp on the right. Those scales look right to me. What do you think is incorrect?

-

The voltage regulators all seem to have overvoltage protection built in. Is there a separate relay somewhere else?

-

1 hour ago, Hank said:

Didn't someone buy a scrap J to update his own Quadrant to Push-Pull? Seems he used a lot of parts from the panel, nose gear well, etc., but had many many parts left over. @scottfromiowa? Wonder whatever happened to the leftovers?

I think you're talking about @KSMooniac.

-

2

2

-

1

1

-

-

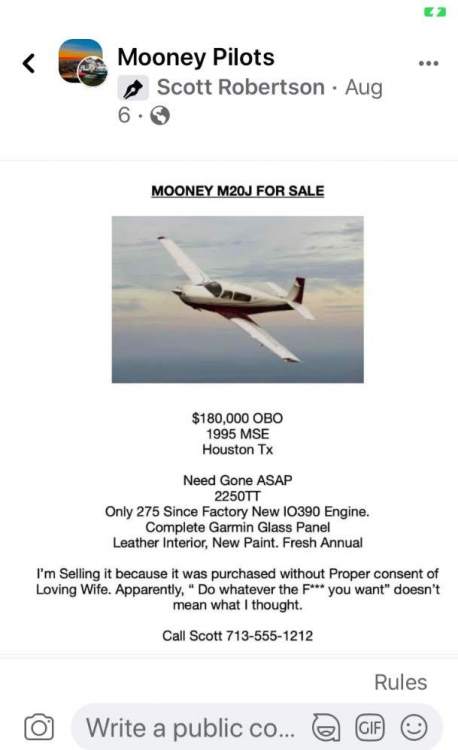

6 minutes ago, MooneyMitch said:

You are an evil person!!!

-

1

1

-

-

That you use an apostrophe when you make Mooney plural.

-

5

5

-

2

2

-

2

2

-

-

-

25 minutes ago, jaylw314 said:

I did some back-of-napkin calculations a while back and a tank of fuel will actually DISSOLVE about half a tablespoon of water in a full tank at room temperature and up to a full tablespoon of water in cold weather, so there COULD be some condensation, but it would be a trivial amount.

Of course, that doesn't account for how much water gasoline could SUSPEND, and I couldn't find a good reference for that

Solubility generally increases with temperature. Less water should dissolve in avgas in cold weather.

-

1

1

-

-

The same thing happened to me on the first long trip after I bought my M20J. The plastic cracked around the metal bracket. I put some tape over it to keep it from getting worse and then repaired it when panel was off during the next annual. I removed the metal part and repaired the crack using some of the solvent-welding techniques described in some other threads here on MS. I reinforced the area behind the bracket by gluing a small piece of ABS to the back of the panel like a doubler. The repair has held up well for 8 years.

-

12 hours ago, Falcon Man said:

Mooniac15U - Please send me your shipping address and I will let you know the $. Jeff

I sent you a PM.

-

On 9/28/2021 at 10:54 PM, Falcon Man said:

I have three David-Clark headsets: H10-13X nose cancelling, H10-13.4 and H10-30. All are in great shape. Just pay for shipping and they are yours.

Thanks, Jeff

I could use a pair for my passenger if they aren't already spoken for.

-

-

3 hours ago, base698 said:

Have tried three different methods to download JPI engine data.

Used this: https://smile.amazon.com/gp/product/B0000VYJRY/ref=ppx_od_dt_b_asin_title_s00?ie=UTF8&psc=1

On the JPI with the plug in: I went into program and hit download all.

First method was EZData program downloaded from JPI site. That was asking about a com port. It says com port not found when I hit start. Was using a serial to USB adapter. assume maybe I need another driver?

Second I used the same USB adapter and an adapter to USBC on an Android phone. That also failed.

Anyone have success?

I use the same Keyspan serial to USB adapter with an older version of EZTrends software. I don't see EZData listed on the JPI website so I'm not sure if that's the same software. It's been a while since I set it up but I recall that it took some configuring of serial ports on my laptop and it seems to matter which USB port I plug the Keyspan adapter into. There's a little bit of black magic required to make it work so I just keep using the same ancient laptop and I don't change anything on it as long as it works.

-

16 minutes ago, A64Pilot said:

No, I didn’t say that I was unaware of any failures of the dual mag, I said I was unaware of failures of the drive shaft, that being the only common item of the dual mag that I knew of, but if there are enough of anything, there will be failures.

But I woud say it’s safe to say that pretty much any item that falls off of the aircraft will cease to function, but being incorrectly torqued or even if the mounting stud broke its not a mag failure, it’s an engine failure, or a human failure. There are innumerable single items on the engine and aircraft that the failure will bring it down.

So if a wheel falls off on landing because the mechanic left the cotter pin out, is it a wheel failure?

You can’t make something idiot proof, there will always be a better idiot, and we all can on occasion be that idiot.

Here's where you said you believed that the only failure that could take out the dual mag that didn't take out independent ones is the failure of the driveshaft..

23 hours ago, A64Pilot said:I believe the only failure that could take out the dual mag that didn't take out independent ones is the failure of the driveshaft, and I have never heard of that occurring.

I pointed out a specific, known failure mode. A failure mode that you were unaware of that could affect your aircraft.

Of course anything falling off an aircraft could affect it but not everything has a history of causing accidents to the extent that there is an SAIB about it. To argue otherwise is just being disingenuous.

You now know about the SAIB. You're welcome.

-

14 hours ago, A64Pilot said:

You could make that statement about most anything...

You said you weren't aware of any failures of the dual magneto. I pointed out a known failure mode that was common enough for the the FAA to issue an SAIB and you decided to belittle my choice of words. Nice!

-

3 hours ago, A64Pilot said:

I know your talking about modifying the engine to accept separate magnetos.

However, why do that? I believe the only failure that could take out the dual mag that didn't take out independent ones is the failure of the driveshaft, and I have never heard of that occurring.

I don’t believe there is a failure mode of the accy gearbox that doesn’t take the whole thing down.

‘I believe there may be an electronic alternative for the dual mag, I don’t know anything about it, but I had rather have dual electronic ignitions in one box than dual independent magnetos myself, mostly to get away from the 500 hour maintenance requirement, and if done correctly a much hotter spark, although a higher amp ignition does increase wear on the spark plugs, it out to enable smoother LOP.

Maybe one day we will have dual electronic ignitions triggered off of a crankshaft sensor? Shouldn’t be hard to do, but can you make money with it?

There is a serious risk of failure of the dual magneto if not mounted correctly.

-

14 hours ago, A64Pilot said:

Outstanding, thanks, I remember seeing the red and black on the actuator, but I thought they spliced into aircraft wire, but I will look. If they do maybe I can get the wire number or buzz it out with the multimeter.

I still will likely replace both with the though that they are 41 years old and one is giving problems, how far behind could the other be. But if I can verify which is which I’ll label them for future needs.

I think the schematic indicates that they splice into numbered wires, but I can’t read the numbers

I think you're right that they are spliced into numbered wires. It might be easier to see the numbers in this version.

-

The wires all seem to be labeled. Have you looked at the electrical schematic for your serial number?

-

2

2

-

-

On 4/17/2021 at 6:00 PM, Matt M said:

So I have been chasing a fuel smell in my cabin for about 4 months now. It only happens on climb out and goes away in about a minute. I keep my tanks topped off after every flight. When I climb in the airplane no smell of fuel at all just old airplane. I thought I fixed the problem a few weeks ago when I had the fuel pickup tube gasket replaced as it was a little wet around it and had blue staining. Well the last two flights after smell still occurs. It doesn’t happen on subsequent takeoffs which makes me believe that once some fuel burns off the leak stops. Anyhow today I’m climb out no smell at all, until I make a right turn in the climb. So I thought it must be coming from the left side. I switched to the right tank after 15 min or so I am 3 below full on each side at my destination airport. The next takeoff no smell at all. I go back to my home airport and top off the right and leave the left 3 low. Takeoff again and smell occurs on right climbing turn. I start smelling around and determined it seemed to be stronger toward the right side of cabin. When I landed I pulled off inspection plate under wing leading edge closest to cabin and saw staining on forward part of the tank at the seem where it meets the upper wing skin. It's a 82J with original sealant. It had a repair job about 2 years ago. Different area though. I showed the photo to my mechanic and he thought maybe instead of opening the tank and patching the inside it may be possible to patch on the outside. I am not sure I am too keen on this idea or whether it would even work. I know I probably require a new strip and seal in the future, but it would be nice to get maybe a couple more years. Besides this weep it is dry everywhere else. Thoughts? Also how many gallons low would the tank need to be to reach the top near this seem. It seems like 3 gallons and I have no smell so that is my guess? I think i could live with keeping it 3 low if it buys me more time.

Matt

Have you checked the seal on your fuel caps? When I first got my J one of the caps wasn't sealing tight. When I topped the tank on that side the fuel level would contact the rear part of the cap during a climb and the low pressure on top of the wing would pull fuel out. I could smell fuel when that was happening and during one flight I could actually see the fuel coming out. Once I replaced the o-rings and tightened the cap a bit it stopped doing that.

Emergency Gear Extension Procedure

in Modern Mooney Discussion

Posted

That button isn't related to the emergency gear extension. It allows you to override the squat or airspeed switch to retract the gear.