-

Posts

58 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by AZOutlaw

-

I finally made it back to the hangar with my voltmeter. The #1 battery was totally dead, like 0v dead, while in the plane. (#2 was at 25v) I took it out of the plane and it slowly started to come back to life. It had about 6v in it when I left. It will go on a charger. The NO relay was also closed all the time with no power. It also had 2 blown 5a fuses connected to it. I'm fairly certain it's a bad relay. My mechanic and I decided what to order and now we wait a few days until it comes in. I'll post a final update later. Thanks for all the help and happy flying!

-

I have dual batteries in an Ovation. Each battery has a relay mounted near it. Went to fire up today and all was dead, switched to battery #2 and all was normal. I'm going to assume that the #1/#2 battery selector on the panel energizes (closes) the called relay selecting that battery. Has anyone had one of those relays go out? While running, #2 shows a normal amp charge rate. Switching to #1, the amp rate goes to zero like nothing is connected.

-

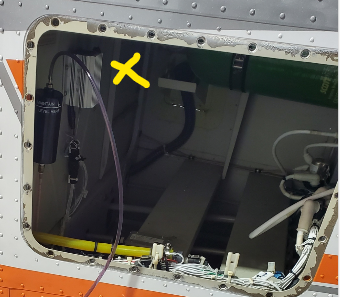

Hi All, thanks for the feedback. I realize I don't need the rear tail position light but I have it built in so why not turn it on. I was really just asking if anyone knows if the Nav light wiring ran through this area where the strobe light power does. We removed the old strobe power supply (where the X is) and connected the wiring for the 650 strobe/Navs. The tail strobe had a power supply in the tail but only one 28v power line off the strobe switch. There's a lot of bundled wire down below and just wondered if anyone had found a Nav circuit there.

-

Recently replaced the old Whelan tail strobe with the Orion 500. There was no "Nav" 28v wire in the tail as the position lights are on the rear of the wingtip on the Ovation. Has anyone found a location to connect that position light lead on the Orion to the Nav circuit? Does the Nav wiring go through the bay with the batteries/oxygen like the strobe wiring does? I have a bundle of zip tied wire in there but we didn't want to cut it all loose unless we knew the Nav Circuit was there.

-

I had the same issue earlier this week. I was doing the pressure feed from the top, then the pump/hold/bleed thing with my wife. I was told to feed the pressure up from the bottom so thought I would try that. I then got to thinking that I would get air back in the line when switching sides. Took another trip to Ace and I hooked my pressure pot to both sides, pumped it up, opened the bleed valves. The fluid moved slowly but after fluid started flowing here came the bubbles. Closed the bleed valves, tested the brakes and they were rock solid on the first try.

-

There are a few locals in the area who will do owner assist annuals if you want to save a ton of money. Been flying a Mooney based just over the hill from Prescott for over 10 years and never had trouble finding a guy. When you get closer, I could round up some names or see if the guy I know is interested in going over there. Welcome To AZ!

-

Thanks for the feedback. It turned out to be a torque issue. I took a few pictures of the new pads and they have very minimal clearance from the rotor. (like none!) The specs called for 75 to 90 in lbs. I'm always a more is better guy so I set the wrench at 90, and the wheels wouldn't turn. Today I backed the bolts off and the wheels spun freely. I then tightened to 75 in lbs and the wheels just started to stop free wheeling but would still roll. All seems good and a couple of trips down a runway will have them free again. I realize I change pads more than most of you, but an Ovation is quite a bit heavier than many of the planes out there too. (my last plane was a D) My pads are typically good when I swap them out, but with some oil leaking they were not this year. As I mentioned before it's inexpensive and easy to do, so why not. Thanks again for the help!

-

Thanks Guys, Pads are correct (but the Rapco Version) and calipers were removed to get new O-rings, and thus, compressed all the way in. I don't replace pads every annual but most of the time as they are inexpensive and easy to do. This year the seals leaked when it got cold so the pads were a mess and it needed a thorough cleaning/replacement. The only thing I can think to look at is the rods ( I think the call them anchor bolts) I'll pull them off and make sure they are shiny smooth and slide easily.

-

I have the dual puck brake system and typically replace brake linings every year at annual. Each time we put the new brakes back on the plane, they are "locked up." I can turn the wheel some (with great effort) but they are tight! We looked this over and can't figure out why. Anyone have this issue? Do I need the shim insulators between the two plates? One question on bleeding. I did the pressure pot thing on my previous D model. That system still work on an Ovation?

-

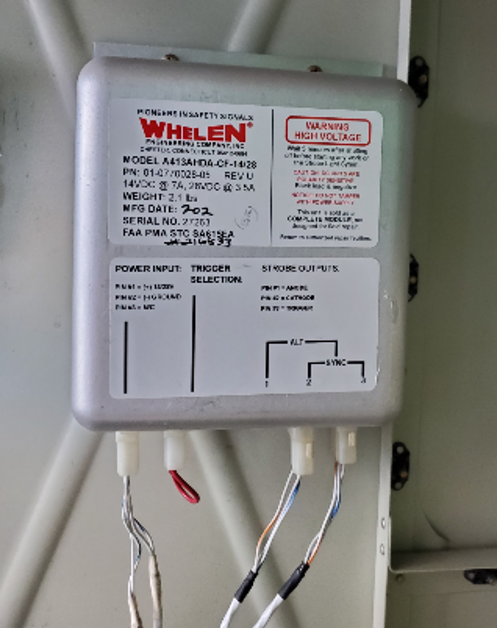

@LANCECASPERI've been told, and you mentioned, that the power supply gets removed when going to LED's. I assume the wiring connects where the Power supply is removed, right? I can't seem to get a wiring diagram but would guess that the + and - inputs connect to the outputs and one of the outputs is the sync, which connect together.

-

Currently doing the annual and we tested the TKS yesterday. I had a low pressure flashing red for a long time and then found fluid leaking from the filter canister in the belly. We removed and inspected and then reinstalled and eventually got the fluid flowing, without the leak. Question is, how often should that filter be replaced, and where do I find one? I'd also be interested in others tricks or ideas to get things flowing. I've learned that the low pressure light will flash forever, and the system won't prime, unless you toggle the windshield switch a few shots to prime. I also get the high pressure light on after the low pressure light quits flashing. Is "high pressure" telling me that all is good or that it's too high?

-

Hi Carusoam, My previous '65 M20D had the push to start and now the '03 Ovation has it too. For some reason they had it.....and then went back to it. We're on the same track as I tried electronic cleaner and also didn't think it could have enough cycles to wear it out. Even after cleaning, I have to turn and push very hard and fast and still only get contact every 3rd try or so. I sent an email to Lasar but with it being the weekend, might not hear back right away.....and I did ask about a rebuild. It looks like an easy fix as on the back of the whole thing there is one screw, give it a 1/4 turn and unplug the connector, and you have it out. Thanks for the response!

-

Thanks Hypertech. That looks more like it. I'll contact Lasar and get the right one, and report back any findings.

-

My Ovation has a L - R - Push to start ignition switch that uses the Medeco key. It's been getting harder to make contact when you turn and push and acts like it's getting worse. I unscrewed the cap and pulled it out of the back of the panel and it looks very different from the Bendix version available at Spruce and Chief. Any ideas what ignition switch I might have?

-

Richard, I hope you enjoy the plane as much as we all did for all these years. I attached a picture I just found from when my brother in law first got it......before he was even my brother in law. Note the date. (I'm also NOT the sharply dressed guy in the Christmas sweatpants!!) Last thing I forget to mention. I always liked the unique N number but there are very few controllers anywhere who get it right. Put a pause in there, Mooney 788...78, and they always get it. Happy Flying!!

-

Thank You Vance. I saw that note but since I didn't have the "fast response" version I had no ferrule to measure off of. I had I call into Electronics Int. and they did call back late yesterday. They told me the end of the probe should be as close as possible to the center of the exhaust pipe. The reason I was asking this is I was still having jumpy readings with the brand new probe. I did some digging under the dash this morning and found more of the fabulous crimp connectors that were loose. I would sure suspect that all will be good when I fire it up this time.

-

I believe the line is called a -4 size which is 1/4" ID and 1/2" OD.

-

I now have great brakes and even a strong parking brake. It was a lot of headaches, maybe a few choice words, but I did contain all tool throwing. I believe we finally tracked it down to the brake lines just above the calipers. There's a 36" flexible piece here and we think it was letting a small amount of air in as we pumped fluid up from the bottom. I just kept pumping, but it was pulling air with it. They never did leak fluid until we removed the calipers and they were dangling by the hose. The lines we took off were old and crusty. I don't know if they were the originals on a '65 but I guess they could have been. Thought they had been replaced not long ago, Learned a lot about the whole system so it's all good. Had a flap pump issue too (in another thread) and flaps are great now as well. A few more parts and repairs and it'll be an Ovation. Thanks to all for the tips and information!!

-

I re-crimped the terminals with no better luck so I went ahead and ordered a new probe. Does anyone know the correct immersion depth of a Electronics International P-110 EGT probe. There's a real nice instruction sheet with great information, it just doesn't mention how far to put it into the side of the exhaust pipe. By the way....the new probe comes with a much improved mechanical connector. They don't like the crimp-ons either. (I will not call them "cheap" again)

-

Cliffy, they were done a few years back when it had a very extensive annual. I took one apart yesterday when I found the leaky hose fitting. It looked great. I did order new O rings since I need to remove the hose, I might as well replace those 75 cent parts too. My A&P stopped by yesterday with his rivet tool so all good there. I've been working with him but he just hasn't been available a lot. He witnessed the air in the system issue and said he would be back to help when I got the new hoses.

-

I have the old paramount master cylinders and yes on the pressure pot. I noticed that when I go at a slow steady pace I'll get 2 -1/2" air bubbles about every 12" of fluid. Now that my calipers are off and dangling waiting for new pads, I did find a leak in one of the hose fittings. This could surely let air in. Now to order hoses and wait for UPS to carry on.

-

Just wanted to answer a few questions and provide an update. No, I do not have co-pilot brakes. Good for bleeding but potentially bad for my passengers and the aircraft should I pass out. The brake pedals seem good. Firm, near the top, don't bleed down when held. Not sure on the cylinders or hoses but they do not leak. Discs, or rotors, seem good and smooth. Brake Pads....well this is one of my problems. I was told by two people that they looked fine including during my annual. I finally got frustrated enough and pulled them off myself. They are shot. I just started polishing the tops of the rivets but can't see or feel any grooves in the rotors. I think I caught that just in time and will probably solve the problem. Air in the system.....this one I can't figure out. I believe it is a closed system the way I have it plumbed to bleed. I realize there is air, and a vent, at the top of the reservoir, but this is where I'm pushing fluid out of the system. I can push a solid stream of fluid all day long, but as soon as I stop, air bubbles show up as seen in the picture attached. I have no leaks anywhere and I would think if air can get in, fluid must be able to get out. I can only assume that the siphon created by this hose going all the way to the floor is pulling a little air through an O-ring or fitting. Make sense to anyone else? My hope is the new pads will fix all and I'll keep a lookout for leaks and check fluid regularly. Thanks All!

-

Roger that. I still have the original dim, power sucking, inferior bulbs on the shelf and I guess I'll go back to them until this gets resolved. I sure appreciate all your research work on these. I really wanted strobes and when I found these I thought I had a great solution. What I read when buying, and since they are sold by Spruce, sure leads one to believe they are legal. Still a great product and I hope they work it out soon. Thanks again.

-

I installed these and love them. I thought I read where they weren't legal for nightime use in strobe mode. That makes sense as we are supposed to have the steady red/green/white lights at night. (I also still have the rotating belly light that sounds like a coffee grinder) What I do know is a Mooney is a low profile plane which makes it difficult for others to see me. When on flight following I always saw the other traffic that Center calls out before they saw me....if they ever saw me. Using the Navstrobes in the day, others can see me now. With all the uncontrolled airspace out west, and many pilots who simply won't talk on the radio, I feel much safer with the Navstrobes especially during the day.

-

I think I've read every brake thread, worked on mine a lot, and still can't hold in place during a run up. Here's where I'm at. Bled the brakes the old school/pickup truck method with someone pumping and opening and closing the bleed drains. This was a great first step as we got some gunk out of the bottom and didn't push it back through the system. We then noticed a leak on the flap pump and the parking brake valve. Took the flap pump apart and replaced o-rings and did the same with the brake valve. Filled up the reservoir and then started pumping fluid in from the bottom. Pumped some out the "T" by the flap cylinder. I now have great flap movement and no leaks but still can't get the brakes good. We connected a barbed fitting and a long piece of tubing to the top vent hole on the reservoir and ran that into a container on the floor. I could pump from either brake and fill that line with fluid. But here's the strange part. About 15 seconds after stopping the pump and closing the bleeder, air bubbles would start coming out the top of the reservoir into the line. Any idea where this Air would come from? I think it's a sealed up system. The last thing I noticed......the park brake won't hold the plane at even 1000-1200 rpm but with the park brake engaged, my pedal brakes are much stronger. Any ideas? I'm thinking of rebuilding master cylinders next but the brakes don't seem to leak down and feel solid on the pedals.