-

Posts

58 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by AZOutlaw

-

GNS 530/430 WAAS loss of GPS Signal

AZOutlaw replied to AZOutlaw's topic in Modern Mooney Discussion

It's very likely a communist plot. I am close to Sedona though and we get some of that Vortex activity and Harmonic Convergence over here too!! That's the only way to explain the end of my flight. My landing was 14100 above the runway at 183 mph -

GNS 530/430 WAAS loss of GPS Signal

AZOutlaw replied to AZOutlaw's topic in Modern Mooney Discussion

Thanks guys. I'm leaning towards an antenna issue. I updated the data card and went to the airport to see if that cleared. It did and both radios started up with good GPS. Second attempt, they did not and I got the same no GPS message. The next 5 starts resulted in GPS reception but it was really slow and seem to struggle to find the satellites. The status bars sat blank for awhile until one or two would start to show something I tried them with the 796 on and off and it didn't seem to matter. I'll get with an Avionics shop nearby, probably after the holidays, and report back. Thanks again and Happy New Year (and Happy Flying) to all. -

GNS 530/430 WAAS loss of GPS Signal

AZOutlaw replied to AZOutlaw's topic in Modern Mooney Discussion

Could not find any outages and there were none that ATC knew of during the flight. -

I see some old threads on this related to antennas but nothing new. We flew 1.5 hours yesterday and while turning base to land, I got alerts that there was no GPS on either unit. When we headed home, both units would never find a GPS signal. I did a lot of restarts and all and nothing worked. I do have a yoke mounted Garmin 796, and it had GPS the whole time. This did happen for about 20 minutes back in September but they both came back and worked fine so I assumed a short GPS outage. A couple of things to note. While I recently updated the data cards and the Garmin website said they were good, the 430 seemed to have an issue as it said it was referencing true north. As we were flying along and I was looking for issues I did see one note on the 430....Not receiving input data on 232 channel #3. The manual just says it's not getting that data, but not what data it is. Any thoughts?

-

Yes it was Bruce and I agree, he's great! I took the left mag to him yesterday and he tested it out. It appears we got a bad capacitor. He put it on a tester and we could see intermittent sparks. Not a lot but you could sure see a few drop out. He found an old capacitor in a drawer and put that on and it cleared things up. He didn't have a new part to match so I'll get it back next week and update the results.

-

Thanks guys, just a refresher. It's a brand new harness two weeks ago and it was tested, for good measure, last week. Mags were rebuilt this summer and only have 6 hours on them. I'm very familiar with burning off fouling and have done that numerous times. Timing has been checked and re-checked. Fuel injectors were removed and cleaned. I'm leaning towards the fact that my Magneto rebuild didn't get rebuilt properly. We pulled them out and sent them in when this started after first replacing the spark plugs. The problem was there before the rebuild and remains still.

-

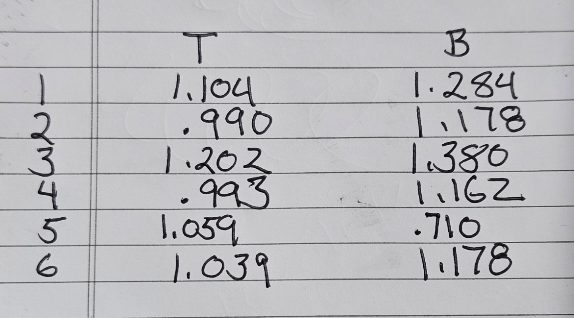

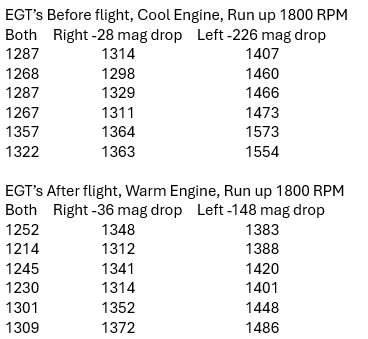

Update: Bottom line, the problem still exists. We checked the timing and did think it was off a little so we adjusted that. Fired it up and first check had the same result. (-150 Left and -40 Right) We shut it down, discussed a few things and decided to try again. This time it was perfect, about a -35 mag drop on each side, or what it always did in the past. Took it up and all seemed good. In flight mag checks were equal and uneventful. Landed and did a check before shut down and got a -65 on the left. Went back a day later and got the same (-150 Left and -40 Right). Borrowed a different timing box, bumped them slightly and felt they were perfect, same result and this time the inflight test was bad on the left, like it was a week ago. Swapped bottom and top plugs thinking the issue might move to the other mag. It did not. Same result, but what is interesting is I did the second start up 30 seconds after shutting down as before, and got perfect mag drops again. This got me thinking heat and resistance was an issue. Pulled all the plugs and did a resistance test, twice, and got these readings. Seems that 5B is reading low and 3B is high but all the rest are really close. I found this online. "Champion Spark Plug Company’s Engineering Manual gives the nominal value for their resistor type of aviation spark plugs as 1000 - 1500 ohms" Anyone have real world experience on what is good and bad readings for a Champion plug?

-

Thank you and that's where we are headed. Just wondering if there is a better way to time a Mooney than with an antiquated sundial attached to the spinner? Surely technology has caught up to that too.

-

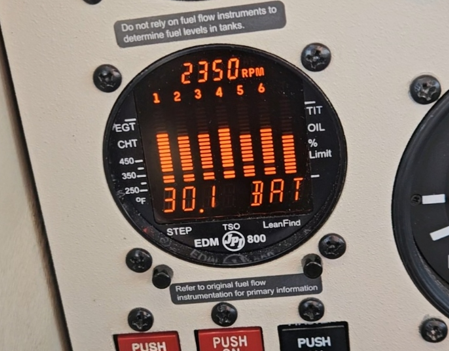

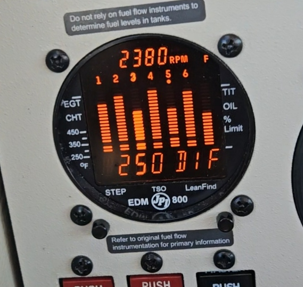

Here's some info I got today. The Left mag side is definitely hotter. I did the inflight mag check as well. At first I ran it out to LOP and it was in the high 1400's. When I did the Left check, everything immediately went off the scale. The ships single EGT gauge went way past redline so I quickly backed out of that. I went richer with the mixture and got a lower base EGT and ran the same check. The right side was smooth and normal. All EGTS rose some but nothing drastic and the engine was still smooth. The Left EGTs took off in different directions and the engine got rough. I had video and at the bottom is a screen shot just before the mag check, the second screen shot is 4 seconds after turning the key.

-

Everything leads to timing I guess. It started in JAN and we changed the plugs. We then sent the MAGS out for rebuild and after a lot of delays got them back and installed with the same result. After that is was the injector clean out and then yesterday, a new wiring harness. Waiting for the rain to clear out and then I plan to test it more today while watching EGT's closer.

-

Probably 8 hours on the plugs. 25 minutes on the wires and the clean injectors. 6 hours on the rebuilt mags. Plugs are Champion RHB32E, massive and yes, we checked resistance. I honestly can't remember if he checked them all though.

-

-

Thank you Marc, I have a JPI EDM 800 but I can look at the EGT's closer tomorrow. I thought I would put bottom plugs on top too, and tops to bottom, and see if the problem switched to the R mag.....then it's a bad plug.

-

Thanks Hank, but I have brand new wiring as of today. I think they're good.

-

It started before the mags were serviced.

-

We've been chasing an uneven mag drop for a few months now on an Ovation with IO 550 G. On the run up, the Left mag will drop and 120 to 145 and Right seems to always be between 40 and 50. They both used to be in the 40 to 50 range, for years. We have replaced the spark plugs, rebuilt the magnetos, cleaned the injectors and replaced the ignition leads. We also did the annual during this and all compressions were good. Any thoughts on what to look at next? Ignition switch is best guess.

-

Problem solved. I was trading emails with Jason at CAV ice and after disconnecting the TKS lines to the switch, we still had a high pressure light. Jason said we could send it in for a rebuild so we went to figure out where to cut or disconnect the wiring. I was a little confusing as the wire diagram shows 2 wires, the switch has three. I'm going to assume the NO wire just dead ends in there somewhere. Long story but we pulled on one of the wires and it came right out. Pretty sure it was chewed up as I probably got a hitchhiking mouse sometime during my travels this summer. I bet that was one hell of a ride!! I connected the two ends and the light is off. Now just need to go back and solder together. Thanks for all the help and comments. A big thanks to CAV. They really are an exceptional resource!! Happy Flying, Sonny

-

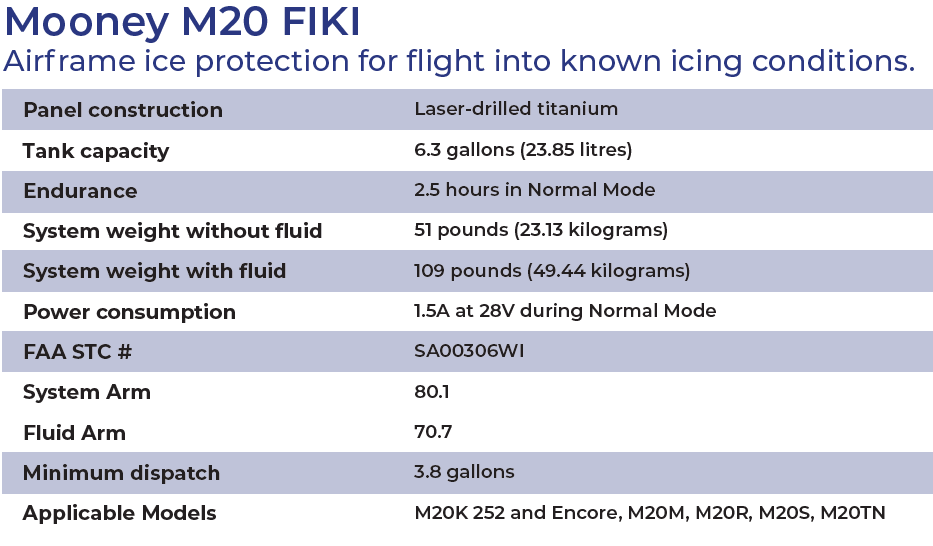

It's been around awhile but I only buy the 2.5 Gal bottles so I don't have a big drum of it. I live in AZ and we rarely see ice!! I dumped in a new bottle the other day and ran a good portion of that out on the ground thinking that might be the case. The stuff in the tank has been in there a couple of years but it was down to about 3 gallons. I'll admit, I don't run it monthly as CAV suggests as I hate the clean up and the dripping in the hangar for the next 2 weeks. Anyone know what "Minimum Dispatch" refers to?

-

I have a continuous High Pressure light on the TKS panel. CAV Ice's recommendation is to change the filter, which we did, with the same result. I have tried the reset button and it does shut the light off occasionally, but not always. If it does go off, it comes back on soon. I've run a couple of gallons of fluid through the system recently as well. Any thoughts on what to check next? I'm guessing it's a bad pressure switch, but while I do have wiring diagrams for what seems to be all Ovations, I can't find anything that has the TKS wiring included.

-

Update......We got a new gear up limit switch and the Ovation version is about 7 times more expensive than the M20J version noted above. After removal I tested the 1-2 and 4-5 NC contacts on the old switch. The 4-5 set didn't ring out, unless I tapped on the switch. Fairly certain that was the problem. We're heading back today to jack the plane and swing the gear just to be certain all is in the right place. We did measure the exact location of the old switch before removal, but seems best to be sure as it could activate and shut down the motor sooner, or later. Thanks for the help Skip!

-

Hi Skip, Just to refresh, I've had a gear retraction failure 4 times now and each time it was on very bumpy runways. Each time, it eventually does come up. After we cleaned, lubed, and adjusted the emergency gear lever all seemed good for a few months. I then found another bumpy runway yesterday and the gear didn't retract. The override doesn't do anything so I would assume it's not the airspeed sensor. I would guess that microswitch, mentioned above, could bounce to a closed position, and then release to its open position a little later, allowing the gear to retract. That make sense to you? Sonny

-

I agree completely, it does not match the symptoms. If there was a prox switch indicating the Emergency gear lever was disengaged, then maybe, but I see no wiring or indication that exists. We will get it back on the jacks and test it out. As mentioned, both times it did not retract was due to a big bump on take off. My home runway has a dip about 1000 feet down and the second was on the worst concrete runway in Iowa. Not sure what a big jar would do in take off, and why it would then go away. Thanks for the help!

-

Thanks jetdriven and PT20J. It does appear that the cable clamp had slid down the cable and the emergency gear was engaged, even when the handle was down and locked. When I released the handle, there was 1/2" "slack" between that and the arm it is meant to engage and the cable clamp (pic). Not sure if that was the issue as no breakers ever popped so it didn't really seem to care that the emergency clutch was activated all the time.

-

I have a 03 Ovation and on 2 occasions ( oth real bumpy runways) my gear would not retract until 5+ min of flight. No breakers popped. Assume up limit switch but could be emergency gear actuator. Upon inspection, it appears the red handle down and locked does not pull the lever forward (on the actuator, under the bottom panel) Am I correct that forward is Unlocked and backwards, with the spring pulling back is locked?

-

Yesterday I thought I was walking home. After dropping a guy off in San Diego, I went to start and heard the started spin, but it wouldn't engage. Removed the cowling and noticed the solenoid mounted to the top could be slightly twisted and moved by hand. Not where it's bolted on, the back end where the cables are connected. After jiggling that around, I tried the key again and it did engage. I hoped it would still be happy when I got the cowling back on, and it was, so I flew home instead of walking. Is this a sign only the Solenoid is bad or is the whole unit going out? I've looked for the solenoid online and can't really find it alone, except for the ebay used parts guys.