-

Posts

700 -

Joined

-

Last visited

-

Days Won

5

Z W last won the day on March 1

Z W had the most liked content!

Profile Information

-

Gender

Male

-

Location

Lake of the Ozarks, Missouri

-

Model

1982 M20K 231/262

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Z W's Achievements

-

Looking to see if I fit in a m20c

Z W replied to Quantum Blueberry's topic in Vintage Mooneys (pre-J models)

My recollection is the M20C would climb pretty comfortably to 10k and cruise there pretty well. To get to 12k, you had to accelerate for a while, then climb a few hundred feet, then repeat. It didn't want to sustain a climb. And once you were up there, true airspeed really decayed to where it was much slower. A big driver in switching to the turbo we have now was a trip across Texas and New Mexico on a hot day with moderate turbulence up to 12,500 feet in the C model. I couldn't get higher, and I thought my wife was going to open the door and jump out. The density altitude may well have been 15k or more. I took the C model to Sante Fe which you can access without getting too high, and Denver, but was never comfortable heading through true mountain areas. A few hundred feet per minute of downdraft and you're unable to climb at all. Not a good feeling when trying to cross a mountain pass. Turbo vs. non-turbo is a whole different topic with lots of threads here. I'm in the turbo camp. But, your cost numbers are a little outdated. I spent $13k overhauling a M20K turbo this year. Mine was completely worn out and they couldn't re-use any parts, so that's about a worst case scenario in 2025 numbers, but that's what it cost. Spread over 20 years and almost 1400 hours, it's not an unreasonable cost, but that's what it was. I should have done a preventative overhaul at 1,000 hours and it probably would have been much cheaper. I'd still rather have it than not. -

The spot welded clamp part number for the TSIO-360-MB was 653337. It is now superseded by this new riveted clamp, 670105, in the Continental parts catalog. I tried to buy a new 653337 and they were also unavailable anywhere. I even put in an order on Air Power for one and they emailed and said it was discontinued and they weren't going to sell them any more and never charged me for it. This is what my old spot-welded V-band clamp looks like, for reference.

-

WOW!! Very Bad interaction with Don Maxwell

Z W replied to mooneybuilder's topic in General Mooney Talk

When I picked my plane up from annual at Maxwell last summer, I met with Don and Paul both who answered all of my questions and couldn't have been kinder or more responsive. I did a thorough inspection of the plane on their ramp which they encouraged. We had a discussion about how it's surprising how many pilots roll in, grab the keys, and blast off without even looking the plane over, sometimes at night or into IMC. We then had a discussion that occasionally my panel was throwing an alert for high fuel pressure during full power climbs over about 15,000 feet which was not a problem but annoying. Paul pulled one of their avionics guys out of the shop who adjusted the settings for the alert while I waited. This was after I had paid for the annual, and they didn't charge me any more. On the way home, my gear warning was sounding at much higher manifold pressure than it should (something like 22 inches). I called Don, asked if they had changed it, and he said no, but then took the time to look up and send me the parts diagram for where the switch was. I started looking at it (which required a mirror and flashlight) and found it attached by old, loose, and non-standard hardware that had clearly been there for years. Probably got bumped during annual. Got it all fixed and re-adjusted. Don didn't charge me anything for his help. Several months later, I had oil leaking out of my turbo and was having trouble sourcing a V-band clamp. I called and talked to Don who unfortunately didn't have any clamps to sell me, but was gracious with his time and expertise and didn't charge me anything for the conversation. Sorry you had a bad experience. Just relaying mine in the last 12 months. I've been very happy with them and am glad they're there help me keep my plane flying. -

This is apparently what a $850 exhaust clamp looks like. Posting because when trying to figure out if I had a riveted clamp or not, I never was able to find a picture of one for my part number, though it was pretty obvious mine was spot welded once I got the cowling off and figured out where it was. At least it's a nice looking clamp and comes in a nice box... I hope you all get yours soon.

-

Looking to see if I fit in a m20c

Z W replied to Quantum Blueberry's topic in Vintage Mooneys (pre-J models)

All sounds like a good plan. Since you mentioned wanting to get higher - My M20C really didn't like to climb much above 10,000 feet of density altitude. I was not comfortable doing a lot of mountain flying with it. The carbureted engine really notices the lack of air. It sounds like it would do better than your Cherokee 140, but if regular mountain trips are in your future, you might look for an M20E model, which I've heard with the extra 20 horsepower and fuel injection, performs much better at altitude. Sometimes they come up available for comparable money to the M20C's. -

Just got an email from Air Power - my 670105 Clamp ordered 12/27/2024 shipped today. Their website currently shows 3 in stock. @Ragsf15e

-

My old one had been repaired with what looked like liquid firesleeve: https://www.abthermal.com/firesleeve-open-end-liquid-dip-paste-sealant-rtv-contamination-protection.html It might also have just been orange RTV. It didn't look great, but may have been functional for a while. It had been worked down into the cloth material and seemed to be a decent patch. Sorry to hear the boot has become hard to get. I did talk to the parts department directly at Mooney about it before I got mine. He told me they had some (4 I think?) in stock at the time but that I had to order it through a MSC. You could try calling them direct and see if you get a different answer today.

-

When I needed one a couple years ago, Maxwell was able to order it from Mooney. He direct shipped it to me, and then I put it in a box in the plane to take to him to install during annual. I'd recommend putting your order in now. My old one had been patched, re-patched, and added on to over the years. It's a unique 252 part and can't be obtained anywhere else.

-

Observed oil temp difference based on probe location

Z W replied to shawnd's topic in General Mooney Talk

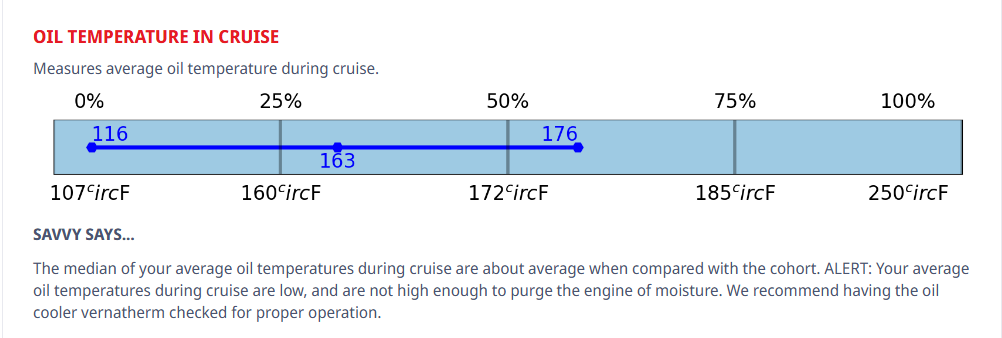

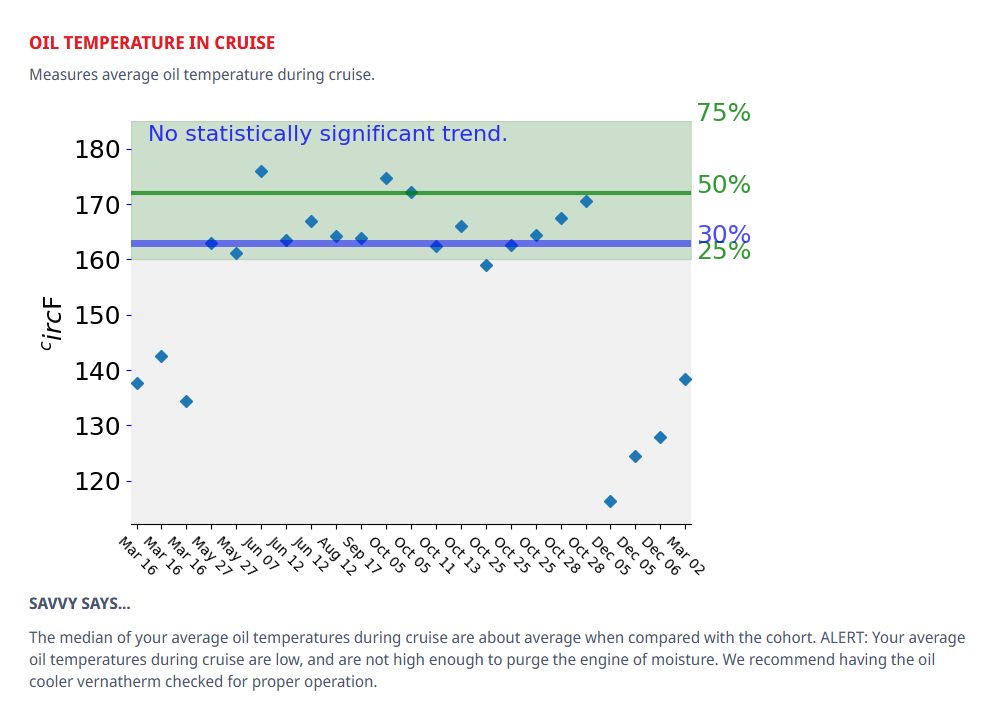

I happened to be looking at my Savvy reports yesterday for the last 12 months. It says my oil temps are about average for M20Ks in their system at 163 dF. They definitely get a lot lower in the winter months. It has always given me the note that they "are not high enough to purge the engine of moisture." For whatever that's worth. I believe my probe is at the base of the oil cooler. This is a TSIO-360-MB2B with a G500Txi EIS. I'll verify the probe location next time I have the cowl off. -

Prop RMPs ~2650 on Takeoff, but can't go above ~2500 in flight

Z W replied to AdamJD's topic in General Mooney Talk

Have you tried increasing the manifold pressure and mixture at the same time you increase the prop to full forward? Or are you leaving manifold pressure low while trying to achieve max RPM? I think I would try that (simulated go-around power settings) at several different altitudes to see if it makes any difference, to help diagnose. -

Didn't need to. Worked fine out of the box. I've had to bleed other hydraulic jacks in the past though and have never had a problem doing that either.

-

Update - Received the Franklin 500lb hydraulic lift from Harbor Freight. Tested it out today. Worked absolutely great. The angle it lifts the cowl at was perfect. Made reinstalling it alone probably easier than with a helper that's never done it before. I used a moving blanket on the table for padding. Not nearly as elegant or cool as the one @JimK made, but I'm not much of a woodworker. And another rolling table to have around the hangar may come in handy for other jobs. Link to the lift table: https://www.harborfreight.com/automotive/lifts-cranes-stands/hydraulic-lifts-carts/500-lb-capacity-hydraulic-table-cart-70726.html

-

-

Yes, related to a poor repair of the air filter housing, which had cracked.

-

Most 252's do 160-165 KTAS and 11-13 GPH at 12,000. Pinecone's seems to run 15 knots faster on 20% less fuel than everyone else's.