-

Posts

1,453 -

Joined

-

Last visited

-

Days Won

12

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Bennett

-

Thanks to everyone who replied. It would seem that my ailerons are set too high, and I will have the good folks at LASAR re-rig them at the next annual. When I had the airplane repainted a few months ago all control surfaces were removed to be painted separately, and perhaps there was some changes made in re-installation, although I noted the "high" ailerons before painting. I know LASAR has the templates, tools, and expertise to do the re-rigging. The airplane is in such good trim, I almost hate to have any work done on them.

-

A couple of us are using battery powered Robotows. Mine has no problem with pushing N335BB up a slight incline to the hangar, over the hangar door baseplates, and a futher slight incline in the hangar floor. Good unit. In another thread on Mooneyspace.com there was a posting that suggested adding wheels to a Robotow. Great suggestion, and very easy to accomplish. Makes using the Robotow all that much more pleasurable.

-

In level flight my M20J tracks true, with no tendency to drop a wing, or turn, but I note that both ailerons are about 3-4 degrees higher at their inboard ends than the flaps, or one could say both the flaps are about 3-4 degrees lower than the inboard ends of the ailerons. What is the proper rigging? I hate to fool much with having them adjsuted, unless there is really something wrong with the current setup. My prior aircraft had the ability to reflex the flaps up almost 10 degrees in level flight, and I did pick up a couple of knots by doing so, (just like the designer said it would). I never heard of reflexing ailerons upwards, and I am curious what the effect would be. I believe that the Columbia 400 (now Cessna ...400) can reflex her flaps upwards to gain speed in level flight. Any aerodynamists on the forum that would venture an opinion?

-

Thanks for the great idea. I've gotten tired off carrying the Robotow out to the airplane to bring her back into the hangar. After reading your posting I went out and bought the 3" wheels at Lowes for about $6.50 per unit. I suggest that you get the longest cable ties you can find. I had to join 14" ones to make it work. Also, I didn't bother with the tubing. I tried rolling the Robotow over asphalt outside the hangar, across the hangar door floor plates, and on the carpet in my hangar. Works fine in all cases. .

-

Just a couple more recommendations: Fire extinguishers have been mentioned, and I totally concur, but I suggest that there be at least two in the hanger, and one close by outside. The outside and one inside can be dry chemical (with one preferabley CO2), both of good size - 20 lb, and I recommend the third one be a Halon extinguisher, again of good size - 20lb, wall hung, and well marked as Halon, just inside the hangar door area. Halon leases no residue, and is the preferred type for panel, or aircraft interior fires. Halon is expensive, but not as expensive as your aircraft. There are several formulations marketed as Halon, and I suggest you talk to a local fire extinguisher servicing company for their recommendations. I also recommend a well stocked industrial type first aid kit, again wall mounted, and well marked for anyone to see within the hangar. Some form of eyewash should be included. This might seem excessive to some, but I am a long time risk management consultant that works with our clientle on catastrophe planning. The unexpected, and unplanned, does happen. We recently had a hangar fire at my home airport, and even with a full time fire truck on the premises, three hangars were damaged, one severely, and there was damage to all three housed aircraft. Without our fire truck, this could have been a huge disaster. Since then, new rules as to what can be done in hangars have been implemented (surprise!), and many more extinguishers were mounted on the outside of hangars. Fires are tough to put out, and the more tools to fight them the better.

-

All good ideas. I have a long painted centerline strip outside the hangar, and since I carpeted my hangar floor (indoor/outdoor carpeting is easy to lay, and cheap - the concrete was badly craked and broken, and carpet covers the defects very well, and is pleasant when you have to crawl under the plane), I have mailwheel stripes in contarsting color as a sort of runway. San Carlos, CA is in earthquake country, and so I use, and recommend, at least nose wheel wheel chocks. i've always used wheel chocks in any hangar I have rented and leased, and with little clearence between the spinner and hangar door, it just seems prudent. Also I suggest as much lighting as you can add. Overhead is terrific, but I have a potrtable stand with really bright lights to work on the airplane. My unit folds up, and has a adetachable light bar so it doesn't take up much room when put away. Don't forget a decent capacity battery charger. I assume you have a built-in power inlet on your Mooney. Sportys sells a neat plug that fits Mooneys, and has round lugs (+ and -) on the outside that can accommodate a standard set of battery cables.

-

Great job. Glad it turned out so well. Some years ago, in another Mooney, this one with a vernier throttle, I had a situation that could have had serious consequences. I was taking off at Little River (CA), with a 5,200' runway when the throttle knob came off in my hand. I had just lifted off, about 1500' down the runway, when I noticed the turbo was slightly overboosting manifold pressure. When I dialed it back, (and I estimate I was about 100'-150' above the runway), the vernier section just seperated from the control cable (broken weldment). This left me at full throttle. Since I had so much runway left, I popped the speed brakes, pulled the mixture to stop the engine, bled off as much speed as I could, and got her back on the runway - used just about all of it. I couldn't have done that at my home airport - San Carlos, CA - 2,500' Had that been the situation, I would have flown to a longer runway, and when I was sure I could make it, I would have dead sticked her in, using the speed brakes, flaps, and cowl flaps, and slips. I did this once in another airplane, and it wasn't exactly fun, but it did work out just fine. While I like verniers for the mixture and prop, I now use a simple push-pull for the throttle. Also I never retract the gear until I'm certain I couldn't put it back on the runway. Lessons learned.

-

I too would like to find a source for rudder pedal extensions. I have them on the pilot's side (M20J), but everyone who sits in the co-pilot seat complains that they are too far away. If someone does manufacture them from the Mooney drawings, I would be interested in purchasing a set.

-

Much like boat brokers. Some really great ones, but far too many are more than a bit shady. I've been lucky in both circumstances, but much of that comes from being extremely wary. When I decided to sell my LSA (long story) and get back to Mooneys, I negotiated a flat fee with a broker I know for the Mooney research, pre-buy advice, title search, etc. and I retained the broker to act as my negotiator when we found the right airplane. We both combed as many sources as we could find - some obsure, and some on dealer only networks. After many, many phone calls by the broker checking out the specifics of various aircraft, and conversations with me with pros and cons about each aircraft, we settled on a couple to get serious about. The broker knew aircraft - not just Mooneys, but enough about them to check with his profesional sources to make sure we were asking the right questions. We agreed that a certain private sale M20J met my requirements. The pre-buy was done by LASAR, a firm I've worked with for over twenty years. I asked them to be thorough - more than the usual pre-buy, and they were. A number of items showed up that were surprises (at least to me and my broker), and I was ready to prove the adage:"The best money you will ever spend is on a survey (pre-buy) that reveals that this is not a boat (airplane) that you want to buy". I was ready to have the airplane ferried back to the would be seller, when conversations with my broker, and Robert at LASAR convinced me that repairs could be done to make the plane absolutely right, if the seller would agree to reduce his price to cover what proved to be very expensive and, in my opinion, extensive repairs. My broker had already negotiated a price well below asking, and I was certain that the seller would not agree to a VERY substantial further reduction. My broker persisted (rember he is working on a flat fee from me, buy or not buy, and there was no financial incentive to push the sale), and to my surprise (I'm not that good a negotiator) the seller agreed to the new price which made the whole project worthwhile. Then an old bank loan turned up that had not been cleared, although the loan was paid off. The bank in question had been sold to another bank, and it was a mess. In three days my broker managed to have the successor bank clear title. Anyway, I highly recommend Craig Vincent at SkyView Aviation in Tracy, CA as a buyer's broker. He is really a good guy, and I would definitely work with him again if I were looking for another airplane, but it is hard to believe that I would give up N335BB.

-

I promised to post photos of the infamous articulating seat bottom mechanism when I received it. It was due a couple of days ago, but (surprise) Mooney's factory inventory is wrong. I have now received an email from Mooney to that effect. They really don't have two of them in stock in spite of their electronic records. They did agree, however, to build one for me, and said they will send it to me in 3 to 4 weeks. We shall see. Nothing easy (or inexpensive, except for free advice) in aviation.

-

Way too many AMUs! The list price is $3,035.00, and that is just for the seat bottom assembly. The seat backs are the same as the regular co-pilot seat, and can be easily mated to the new bottom. Of course I will now have to have the uphosteror do some work in removing the seat and changing the seat bottom assembly. This is a minor task as compared with all the other work he has done. When I receive the assembly I will phtograph it, top, side, and bottom, and post the photos to this thread.

-

As expected, Mooney will not release the drawings for the articulating seats. They say these drawings and design are proprietary to Mooney. They did say that they were in the regular parts supply for Mooney, and available through Mooney Service Centers. I was surprised to hear that, as I had been told otherwise. In response, I ordered and paid for one of two then available. Should have it in a few days, and I will have the co-pilot uphostery transfered to the new frame. Not inexpensive, (I cant't beleive how much mark-up there must be in this unit), but for a variety of reasons I do not want unauthorized parts in my aircraft . I know that others have had local weldments made to raise the seat, but its not for me. Mooney engineered some safety factors for pilots and passengers in the seat design and construction, and I would not feel comfortable in bypassing these safeguards.

-

From the album: #Bennett's album

-

New Interior - leather has now shrunk to tightness

Bennett posted a gallery image in Old MooneySpace.com Images

From the album: #Bennett's album

-

Pilot side arm rest recessed into aviation honeycomb side panel

Bennett posted a gallery image in Old MooneySpace.com Images

From the album: #Bennett's album

-

From the album: #Bennett's album

-

Interior (4) Perforated and smooth leather

Bennett posted a gallery image in Old MooneySpace.com Images

From the album: #Bennett's album

-

From the album: #Bennett's album

-

From the album: #Bennett's album

-

From the album: #Bennett's album

-

From the album: #Bennett's album

-

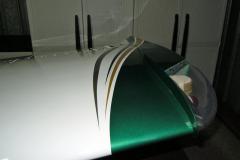

Wingtip 2. Prior to airbrushing of stripes

Bennett posted a gallery image in Old MooneySpace.com Images

From the album: #Bennett's album

-

From the album: #Bennett's album