Sabremech

-

Posts

2,022 -

Joined

-

Last visited

-

Days Won

26

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Posts posted by Sabremech

-

-

I’m actually thinking of making my new carb air box available with an adapter to the stock C & G model filter. Would like to find a way to not have to do an STC though.

-

2

2

-

-

-

Trimming the cowl flap to clear the tail pipe by 1/2 to 3/4 of an inch will be included in the installation instructions.

-

2

2

-

-

-

No turning back now. Final fit to drill for the firewall camlocs under way. Also fit the new prototype carb air box for the C & G models. Minor adjustment to clear the cowling found during initial fit but looks like this will work well. Also fit the plug to the prop hub for the forward bulkhead to make the carbon fiber spinner. Making some progress.

David-

10

10

-

1

1

-

-

On 4/21/2020 at 7:26 PM, charlesual said:

Thats awesome!! Thank you so much. Looking forward.

Charles Davies

13123 April Circle

Lovettsville, VA 20180

Sent from my iPhone using TapatalkLooks like Monday I can send this your way.

Thanks,

David

-

I got lucky for once. Usually I have to make a couple before it’s just right.

David

-

1

1

-

-

-

Just now, charlesual said:

Definitely want it. I was trying to fabricate one today. Came out pretty botched. If I had a template, it would be so nice.

Sent from my iPhone using TapatalkOk, I’ll try to get mine fabricated this week and then let you know that I’ll be ready to send it out. It’s yours if you cover the shipping.

Thanks,

David

-

-

10 minutes ago, Andy95W said:

I was thinking something more like this, mounted on the flat steel plate above the shock discs. Very thin.

Hi Andy,

I was trying to stay with something FAA/PMA as well as another option for my landing light in the cowling issue I had.

David-

1

1

-

-

As an A&P/IA, I don’t always agree with Mike Busch and have challenged him on a few of his assertions, his writings would be good for you to learn some maintenance fundamentals. Don’t allow yourself to take his words as the maintenance gospel, but allow it to give you the knowledge to know what questions to ask.

-

1

1

-

-

-

23 minutes ago, 67 m20F chump said:

How are you going to attach it to the airplane? Piano hinge or the factory fasteners?

Planning on using factory fasteners and picking up the existing locations.

-

3 hours ago, Hank said:

I'm very happy to see that you put the access panels back on both sides! Makes it so much easier to change the oil! As a 13-year C owner, I've only dropped the lower cowling twice, and my A&P did it once working on the carb.

I lost count the number of times my cowlings have been on and off !

-

1

1

-

2

2

-

-

-

8 hours ago, takair said:

Very nice! What is the squarish inset area? Are you doing louvered cooling there? Apologies if it’s been previously discussed.

Those will be maintenance access panels on both sides. It will also be able to have louvers added in the future by just switching out the panel if needed say for a turbo’d Mooney.

-

7

7

-

-

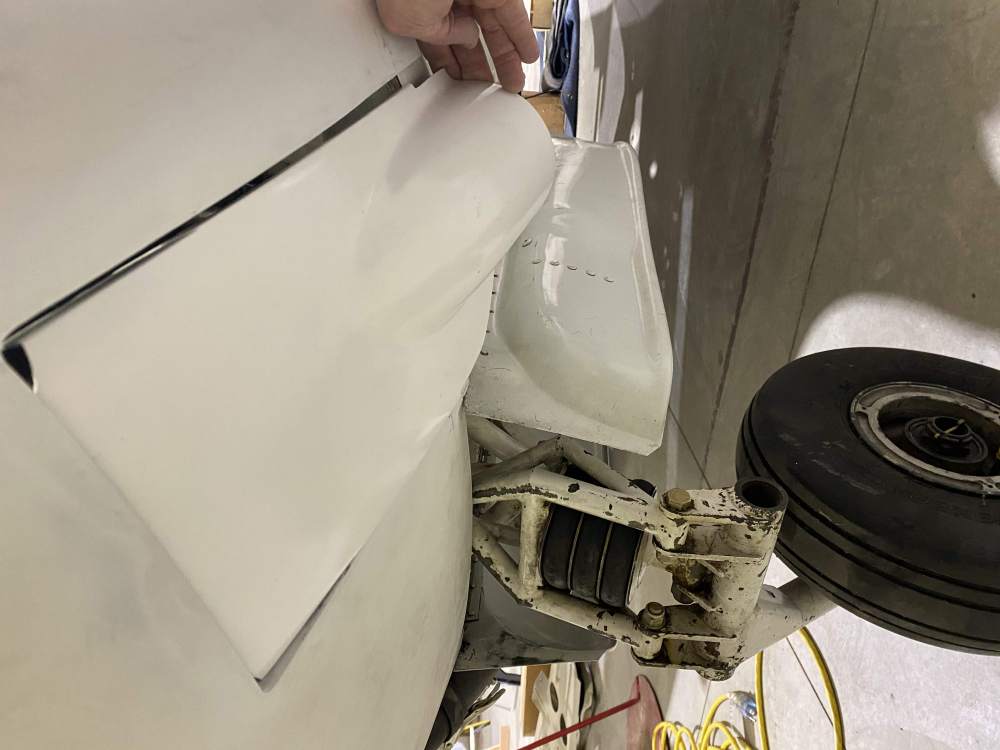

Working on fitting the lower cowling. I expected to have an issue with the carb air box and that is a definite need to redesign. The much more sloped cowling is going to require a new lower profile carb air box. What I didn’t expect was an issue with the landing light. I found that the O-360 muffler hits it. I now understand why as the difference with the fuel injected O-360’s moves the muffler down and aft. O-360 is up and forward due to the carb. I will have to move the landing light to the center on the carbureted Mooneys. I’m also thinking I will need to move one of the air fittings on the muffler shroud. I did manage to get it on today and do some initial fitting to verify if I’ll have any other issues.

-

9

9

-

1

1

-

-

Just now, jamesm said:

Awe you beat me with the photos, but I will say this though admits all this stupid covid crisis that we are in. Other than sun in the pnw which can be rare this time of year.... receiving Down and up lock blocks was the next brightest thing.

Is it wise to powder coat the down lock block? I wanted to match the panel.

Thanks again to Dave and Anders and others that made this happen.

James '67C

Hi James,

I think LASAR powder coats their blocks as the ones I have from them are powder coated. I personally don’t care for it as its chipping off in the contact areas. I think the anodizing will be better in the long run as it won’t chip but will show where it contacts and wears over time.

Just my .02 bit you can powder coat if you choose.Thanks,

David

-

1

1

-

-

Hi ReconJon,

There were no extras made as that would fall outside the owner produced rules.

I could make some for you but you’d need to supply me with at least the raw materials in order to qualify for owner produced and they would be pricey for a single set.

I’m told LASAR has stock again on theirs. You might try them and if they are out of stock, I can see what the pricing would be.Thank you,

David

-

1

1

-

-

1 hour ago, hammdo said:

Question, is there tracking info?

-Don

Hi Don,

There is tracking information but I wasn’t going to try and send out all 23 orders tracking info. If you don’t have yours by Wednesday, let me know and I’ll track it.

Thanks,David

-

6 minutes ago, N201MKTurbo said:

All the sealed bearings in the ones I’ve worked on were easily disassembled. There is large circlip holding the shield on the side of the bearings. It can be removed with a very sharp poker. The races actually have a cutout that allows the balls to be removed. You can do this without pressing the the inner races off the shaft.

I suspected that was the case as I had one blow up in the press and then saw the cutout. I typically don’t disassemble a sealed bearing and decided it was much better to go new as my airplane has 7600 hours on it. Bearings were $200 for a pair. No worries now for a long time.

-

2

2

-

-

12 hours ago, DEGWS said:

Hey,

I want to check the jackscrew at me Mooney tomorrow.

Plan is to remove bearings, disassemble, clean, grease and reassemble. Really good post here. Only question is... where I have to disconnect the trim rod that I can remove the bearing block? Is there enough free play to disconnect in the rear or is it necessary to disconnect the U-joint below trim wheel?

thanks!

You won’t be able to remove the bearings from the shaft without a press and a bearing plate to hold the inner race. I took mine to a machine shop to have them removed and the new bearings pressed back on. The bearings are sealed so you won’t be able to disassemble them to clean and grease.

David -

Good morning to the group. The parts shipped this morning. I have one set left to ship to Clarence (for Ned) that I will work on this afternoon. Hopefully no issues shipping to Canada.

Thank you all,David

-

7

7

-

2

2

-

It’s finally time (cowling)

in General Mooney Talk

Posted

More progress today. Lower cowling has been fit to the airplane and camlocs installed. All is good except for the left cowl flap does not fit as well as it should on the inner flange. I will need to cut it and modify it to make another mold. All in all, that’s not too bad considering the size of the project. I also made a modification to the prototype carb air box and it fits great now. That can be finished and I’ll call it final for this cowling. Tomorrow, it’s time to fit the upper cowling and get it trimmed to fit.