-

Posts

35 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by N811SS

-

M20F Mooney – 201 CLONE but even Better with all the Upgrades

N811SS replied to N811SS's topic in Aircraft Classifieds

Roger that. -

M20F Mooney – 201 CLONE but even Better with all the Upgrades

N811SS replied to N811SS's topic in Aircraft Classifieds

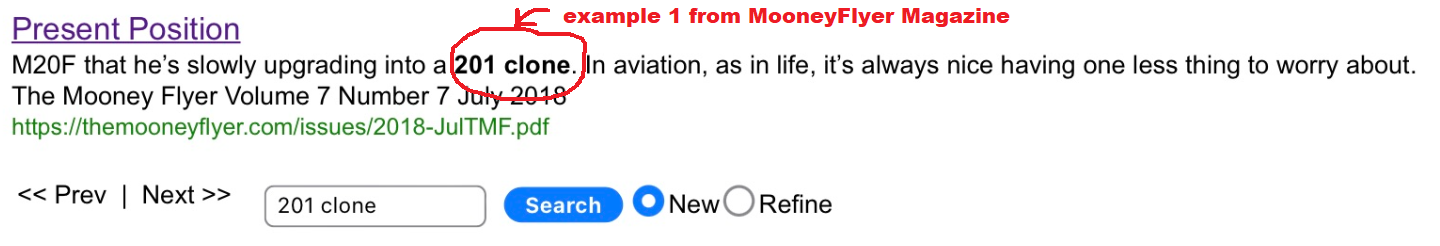

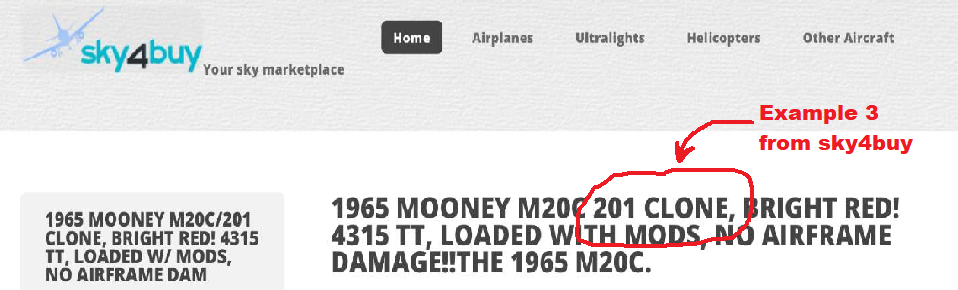

ZuluZulu --> Thanks for the well written/reasoned response above. I am still at a bit of a loss understanding where ArtVandelay is coming from and why he thinks he needs to come to the rescue of any potentially interested buyers that he implies I am attempting to bamboozle. I feel my classified ad for N811SS is not False Advertising nor Deceptive Marketing and is an Honest Representation of a very good machine. I have been flying Mooney's for 40+ years (i got my PPL at age 17) and have owned several over the years...the term "201 Clone" is not something I invented but rather a commonly used term to describe extensive 201"J" alterations to a longbody F model or short body "C/E" model (including electric gear which was a big deal back in the 1980's). A quick search of the internet shows the verbiage "201 clone" being used in the exact same way for several other Mooneys (see attachments below) and has been so for many decades now. If an expert (i.e. the folks at MooneyFlyer.com) tell me the term has fallen out of favor for a valid reason then I will change the language of my classified ad accordingly. I suppose saying the N811SS is '..even better because of all the upgrades..." could be viewed as more SUBJECTIVE rather than OBJECTIVE (i.e. is a 3-blade prop better than 2-blade? is a tuned exhaust better? is Electronic Ignition better? is having a GEM better than not having one?). For me I feel these are important enhancements and increase the airplanes value/resell. However, by way of total transparency to any interested buyer, I provided a list below of my cost ($-parts + $-labor) for some of the upgrades I have applied since acquiring N811SS in 2009 and a link to the mfg describing the features/advantages of these upgrades (fyi - these are the mfg'rs words NOT mine ArtVandelay): * PowerFlow Systems (Tuned exhaust) - part $4,700 + $520 install labor = $5,220 https://www.powerflowsystems.com/products/mooney/mooney-200210hp-io360 * ElectroAire EIS-41000 (Electronic ignition) - part $1,950 + $570 install labor = $2,520 http://www.electroair.net/ourHistory.html * Insight G2 GEM (graphic Engine Monitor) - part $1,600 + $1,000 install labor = $2,600 http://www.insightavionics.com/bestg2.htm * N811SS came with a three blade prop when I purchased it but normally it would be about a $3k upgrade. Here is a link to a robust discussion on MooneySpace between 3 vs 2 blade props: -

M20F Mooney – 201 CLONE but even Better with all the Upgrades

N811SS replied to N811SS's topic in Aircraft Classifieds

Ouch! Not sure where the hostility is coming from but sorry you don’t like my airplane. I think Most owners would consider i) three blade prop, ii) power flow exhaust, iii) electronic ignition, iv) speed brakes, etc, etc….Upgrades to a “J” model. She has been a pretty good machine for me. -

M20F Mooney – 201 CLONE but even Better with all the Upgrades

N811SS replied to N811SS's topic in Aircraft Classifieds

I may have my terminology wrong (STC's vs. 337's). I can tell you that when they turned this M20F into a 201-clone it involved pages-n-pages-pages of Mooney factory parts diagrams and installation instructions involving (but not limited to); cowling, engine compartment, panel, gear, windshield, etc. I think most mechanics view this bird as a 1982 J model instead of 67 F model. For gear and flap extension speeds I just go by the M20F PoH. Stall speed (clean and dirty) is pretty much spot on. -

M20F Mooney – 201 CLONE but even Better with all the Upgrades

N811SS replied to N811SS's topic in Aircraft Classifieds

Some unique upgrades for sure. The ENCO cabin cooler fans and Aileron trim are actually very useful. -

M20F Mooney – 201 CLONE but even Better with all the Upgrades

N811SS replied to N811SS's topic in Aircraft Classifieds

-

M20F Mooney – 201 CLONE but even Better with all the Upgrades

N811SS replied to N811SS's topic in Aircraft Classifieds

Correct, the bracket left passenger window is for the stratus II. It is connect to airplane power via 12v adapter (cigarette lighter). I have tried every possible location and this is best I think. Stays cool, has good reception, is completely out of the way and can be visual checked for lights and rebooted by pilot if necessary. Set it and forget it. -

M20F Mooney – 201 CLONE but even Better with all the Upgrades

N811SS replied to N811SS's topic in Aircraft Classifieds

Asking Price = $121,300 aircraft located at KSEE (El Cajon near San Diego, CA. might consider partnership arrangement if aircraft can stay in KSEE -

1967 M20F serial number 670064 with TTAF= 6,620 with last annual complete in Nov. 2021, all AD’s complied with. Engine Lycoming IO360-A1A, TSMOH = 780 hours done by Ameritech in 2014. Last prop OH was 300 hours ago. Aircraft painted in 2009 with interior redone in 2003. Right tank strip-n-reseal in 2021. Avionics: · Audio selector – PS Engineering PMA6000 · Garmin GNS430W (WAAS enabled, factory upgraded in 2017) · Second Comm TKM MX-11 (installed 2017) · Second Nav Narco Nav122 centerline VOR localizer & glideslope · Garmin 496 with panel dock · Appareo Stratus II, perfect for using Foreflight on your iPhone and iPad. · Garmin GTX330ES - ADS-B out (Installed 2019) Airplane Equipment & Instrumentation: · Complete 201 M20J factory STC’d retro fit in 1986 (one piece slopped windshield, gear retraction, panel, cowling, oil cooler relo, air filter box, horizontal fairing, flap gap seals, elevator hinge covers, RAM air induction, tanks 64 gallons total) · McCauley 3 bladed Prop with polished Aluminum spinner · Power flow exhaust – tuned exhaust (installed 2020) · Electronic Ignition Electro Aire 41000 (installed 2014) · Insight GEM graphic engine monitor G2 (installed 2021). Perfect for LOP operations. · Brittain Autopilot (Accu-trak B-11 and Accu-flite B12) Heading bug and Nav tracking coupled to Nav 1 or Nav2. No Altitude hold. · Electric gear · Electric elevator trim · Electric aileron trim · Hydraulic flaps · Pneumatic retract step · Precise Flight Speed brakes · Precise Flight Stand-by vacuum system · ACK E-04 ELT (installed 2017) · Davtron 5 function display (Volts, Density Alt, Pressure Alt, Temp F, Temp C) · Airspeed gauge with Ture airspeed indicator · EMCO cabin cooler STC’d – blower motor ventilation located behind hat rack · Enhanced aircraft lighting: o Whelen Aviation 3 position strobe lights o High intensity LED landing light in nose o Wing mounted LED Taxi way lights o Wing mounted collision avoidance Pulse light o Tail illumination lights · Rosen Sun Visors · Bruce’s custom canopy cover (installed 2021) · Fuel tank sight gauges · Quick drain oil coupling · Auxiliary power connection · 4 place intercom Contact ---> Mark Farabaugh at 760-445-8983 (mafarabaugh@sbcglobal.net) M20F Mooney for sale.pdf

-

I have decided to sell my M20F Mooney (201 clone). Here is the link on trade-a-plane: https://www.trade-a-plane.com/search?category_level1=Single+Engine+Piston&make=MOONEY&model=M20F&listing_id=2407870&s-type=aircraft It is a 1967 M20F Mooney but had the factory conversion in the mid 80's to turn it into a 201. Very good IFR machine, tons of upgrades (see attached document). Mark Farabaugh cell: 760 445 8983 M20F Mooney for sale.pdf

-

I have decided to sell my M20F Mooney (201 clone). Here is the link on trade-a-plane: https://www.trade-a-plane.com/search?category_level1=Single+Engine+Piston&make=MOONEY&model=M20F&listing_id=2407870&s-type=aircraft It is a 1967 M20F Mooney but had the factory conversion in the mid 80's to turn it into a 201. Very good IFR machine, tons of upgrades (see attached document). Mark Farabaugh cell: 760 445 8983 M20F Mooney for sale.pdf

-

Hello Adam - I have decided to sell my M20F Mooney (201 clone). Here is the link on trade-a-plane: https://www.trade-a-plane.com/search?category_level1=Single+Engine+Piston&make=MOONEY&model=M20F&listing_id=2407870&s-type=aircraft It is a 1967 M20F Mooney but had the factory conversion in the mid 80's to turn it into a 201. Very good IFR machine, tons of upgrades (see attached document). Mark Farabaugh cell: 760 445 8983 M20F Mooney for sale.pdf

-

One day I showed up to the airplane and there was no pressure on left brake peddle. Mechanic got rid of the bubble by bleeding the brakes and forcing hydraulic fluid up from the bottom of the felt brake caliper. Great, I thought, I have braking action back. However, now I can only barely push the plane back into its parking space and I can hear that left brake screeching as it rolls backwards. Taxi and takeoff require a lot more right rudder because those left brake pads are squeezing the rotor. Mechanic said that’s just the way it is and no adjustments are available. Any suggestions?

-

Hello All, here is my update - By God, preliminary/premature results (i.e. after only 5 hours of flight time) do hint at a reduction in oil consumption since I installed the black extension tube (see photo from my original post). Where I used to be a consistent 1qt each 3.5 hours I think I am now seeing about 1qt. every 4.5 hours. Go figure! Perhaps Carusoam is correct when he says: "...case venting --> It is important to have the proper length, diameter, ice / vent hole, bends...this is important because there are so many variables involved..." Now my challenge is figuring out what is the optimal part for my particular aircraft. I can't use history because this machine has had so many changes since it originally rolled off the assembly line over 53 years ago (i.e. 201 cowling, cowl flaps closure amount tweaked, powerflo exhaust, electronic ignition, stand-by vacuum, engine rebuilds, air/oil separator put-on then taken-off, etc.) . I wish I could find specs on what Mooney says it should be for perhaps a "J" model. I walk around the airport and try to take a peek at what other Mooneys have installed and it seems there is no one consistent configuration. I suspect the length of the tube is important because I could see where air pressure rushing out the bottom of a closed cowl flap would be greater and hence creating a low pressure environment. Any advice? What does your exit tube look like? How far back does the exit pipe go? Does to extend beyond the end of the cowl flap? I know this is not the most important thing in the world but would like to take my best shot at getting it as good as it can be.

-

p.s. -- Why is number 3 always the problem child cylinder?

-

Quick question --> Do you have a GEM? If so, did it show high CHT or EGT on #3 before she went tits up?

-

All good questions/responses. Thanks. To provide some more details: Engine Background: * Engine is an IO360-A1A (the original) * Engine rebuild was 700 hours (about 7 years) ago. Re-honed cylinder 2 & 4 at the 125 hour mark. Replaced cylinder 3 at the 400 hour mark due to broken ring. Re-honed cylinder 3 at the 500 hour mark again. Through-out all of this, oil consumption has remained at 1 qtr every 3.5 hours. * The oil gets dark (but not real bad) by 8 to 10 hours after a change....and that's considering that I keep adding a qrt each 3 to 4 hours. * The belly on the left side (behind the breather tube) gets a little bit oily but nothing too bad. * The engine compartment is perfectly clean (no oil drips anywhere). Nor have I ever seen oil drips on the ground after parking. * Have done borescope many times and there is usually a little bit of oil on the bottom of cylinder 3 but nothing too bad according to the mechanic. The hatching on the walls looks good to everyone and no signs of glazing. The compression's are good in all 4 cylinders (76/78/78/77). The bottom plug on cylinder 3 has a little bit of oil in it but I cant say the plug has every been fouled. * Its just weird, I keep feeding oil into this thing and it just disappears...I guess it is getting past the rings and burned in the exhaust...its quite the mystery. Crankcase Pressure (according to the mechanic): The only reason that the wind from the prop blowing past the exit port of the breather tube might be creating a negative pressure in the crankcase is because the mechanic hooked-up a manometer water tube to the dipstick filler. He tried 1000, 1700, 2500 rpms and could not get a positive pressure in the crankcase! He could hear the engine puffing past the rings but at full rpms the crankcase pressure was negative (3" of water in his tube)! The top cowling was off but the bottom cowling was on. I asked if he compared open cowl flap to closed cowl flap and he said no. Then, he disconnected the black crankcase breather hose up near the accessory case and voila all of the sudden he could measure positive crankcase pressure at double the normal range. He surmised that prop wash was creating a venturi effect on the breather tube. I know that sounds like a stretch especially considering that tube is angle-cut such that the opening is facing backwards (see photo below) but I noticed that other Mooneys have the breather tube run toward the tail for about 5" . ...So here is what I did this afternoon. I went and bought a small section of tubing from the auto-parts store with a 90 deg bend and clamped it on the existing (see below). I am doubtful it is going to make a difference but I don't see the harm in giving it a try. I will report back my findings. Here is just a Mooney photo i picked off the internet (its not my plane) showing the breather hose pointed aft:

-

Greetings All - Looking for a little advice. My 1967 M20F (with 201 conversion kit) consumes about 1 qrt of oil every 3.5 hours. The oil gets darker than it should after about 6-8 hours of operation so I know I have ring blow-by issue. I took it to Gibbs (at KMYF) and had them check the crank case pressure with my most recent oil change. Indeed, the pressure was higher than it should be. I have already honed these cylinders twice before (which was after the Ameritech engine rebuild 700 hours ago...which is a very long/depressing/expensive story) so I am not really interested in doing yet another top overhaul. The curious thing was that the mechanic said that there was quite a bit of vacuum pressure happening at the breather tube exit point even with just the plane on the ground and the engine rev'd up. I used to have an airwolfe air/oil separator but took it off awhile back (the oil consumption did not go up or down with its removal) but the metal tube (which has the hole in it for icing protection) is flat, meaning horizontal, and flush with the firewall. I see in these pictures that your breather tube has a 90 deg bend and sweeps aft. Here is my question --> If I change my tubes exit configuration to sweep back towards the tail will that reduce the venture effect and perhaps help draw less oil out the breather tube?

-

No Cabin Heat with Cowl Flap open

N811SS replied to N811SS's topic in Vintage Mooneys (pre-J models)

Eagle engines used new lycoming cylinders on it as part of the rebuild. I think it was the standard steel barrels (but i am going to double check the color coding on top to see if has a blue strip indicating Nitride hardened). I cannot find in the engine logbooks where it specifies. Eagle went out of the engine business about 6 months after my rebuild. It was a real mistake using them, should have gone directly to Lycoming. -

No Cabin Heat with Cowl Flap open

N811SS replied to N811SS's topic in Vintage Mooneys (pre-J models)

Hello All – Good stuff, thanks for the dialog. Here is an update on N811SS: 1) With the 201 mod on the M20F the air intake for the SCAT tube is just inside the front of the cowling on the pilot side next to the air filter. The oil cooler is relocated to the back of the top cowling on the pilot side. I traced/visual inspect the SCAT tube integrity from the ambient air entry point to the cabin and all was good. In the past I have had a similar situation mentioned above where one of the rods that actuates the cowl flap bangs into the SCAT tubing and rubes a hole in it but have since moved the SCAT tube slightly to provide clearance. I removed the SCAT tube on-top of the heater box (a simple job since all you have to do is unscrew one hose clamp) and watched the flap that diverts the warm air flow between the cabin and the SCAT tube that exits near the cowl flap opening on the bottom. Just as suggested above it was only moving about half-way open. I re-adjusted so that the heater cable open moves it to full-open and diverts all the warm air to the cabin. Eureka, it worked! Now I have the reverse problem in that even with the heater cable closed about ½ the warm air still flows into the cabin! For the winter months it is acceptable/preferable but come spring I am going to be bitching about it being too hot inside the cabin. Eventually I need to get a more permanent fix because it is very hard to move that cable through its full range of travel and the round flap inside that heater box looks pretty rusted. Took a fair amount of lube on that cable and shroud even to get to function. Also, with the number of twists & turns that cable/shroud does it makes it very difficult to push and pull? 2) High CHT's is a bigger issue --> Amen to that! Don't even get me started on all the issues I have had but in a nutshell I did an engine rebuild with Eagle engines 360 hours ago and never got those damn rings to seat correctly. Never got better than a quarter every 3.5 hours, with CHT's running between 375-425 deg and wet plugs. Basically it was a firewall wall forward redo with new cylinders + engine baffles + baffle seals replaced with every possible hole plugged. 50 hours ago I had all cylinders rehonned with new rings at the annual with the hope that this second attempt would get those rings to seat properly. I think I have read everything possible on the correct Lycoming engine break-in procedure and we have literally followed the procedures to the letter. Initial 3 hour break-in with high MP (like 28 inches or greater), low altitudes, no short flights, kept CHT's as cool as possible, do gradual decent using minimum of 21” and speed brakes, still running on mineral oil, etc. Now, 60 hours later I still have the same issue as before the rehonning with burning a qtr. every 3.5-4.0 hrs. Last borescope indicated wet plugs (but not real bad) on all four cylinders. Since I am still supposedly in the "break-in period" I am trying to leave that cowl flap open basically all the time. For the life of me I cannot figure out what I am doing wrong to this poor little IO360-A1A. I have an Insight GEM and basically the CHT's and EGT's for all 4 cylinders are behaving the same. Whatever the issue (glazing cylinders or annealing the rings) I do not think it is a run-of-the-mill problem. My old Mooney does have a fair amount of mods like; electronic ignition in place of the left mag, three blade prop, stand-by vacuum system, airwolfe air-oil separator, modified cowling, relocated oil cooler, etc. but I doubt any of these could be contributing to my break-in problems, right? After $32k for the rebuild and an additional $8k for the rehone-ring replacement I am beyond frustrated. I know I am way-off the original topic but one thing that occurred to me was that perhaps the scat tube the exits the heater box is not long enough. For example, there is about 8 inches of distance from the bottom of the SCAT tube to the opening for the cowl flap. Maybe (and this is a big maybe) with the cowl flap closed the warm air exiting the scat tube from the heater box is helping to heat the space underneath the engine (instead of exiting out the bottom of the engine compartment) and contributing to high CHT’s and thus contributing to the ring seating problem? Can anyone without a high CHT issue give me a sanity check on how close your scat tube exit is to the cowl flap opening? -

No Cabin Heat with Cowl Flap open

N811SS replied to N811SS's topic in Vintage Mooneys (pre-J models)

I thought of that possibility as well. For example, with the cowl flaps closed there is more air pressure under the hood and therefore more airflow through the scat tube air intake next to the air filter. However, i have not really experienced a larger "volume" of air (i.e blowing stronger) coming into the cabin when the cowl flap is closed only that it is much warmer. This weekend I will take the lower cowling off and snaps some photos. Maybe the scat tube plumbing is in some way in correct. thanks for the reply. -

Hello All - Quick question --> My 1967 M20F will only provide cabin heat when the cowl flap is closed. Problem is that on cold days (and nights) I still need to leave the cowl flap open (or at least trailing) to keep the the CHTs below 400 degs. I find myself switching between cowl flap closed so I can get some heat in the cabin to defrost the passengers or half-open to get the CHTs cooled off with the air vent closed to prevent the cold air from rushing in. I checked the SCAT tubes and don’t see any holes/ripes and I checked the movement of the lever in the heater box and it seems okay. With the cowl flap closed it cranks out the cabin heat just fine. Maybe that is just the way these old Mooney's are but it seems like a crazy design...I do have the 201 cowling mod installed on N811SS and there have been all manner of mods/changes done to this machine over the years. Does anyone else have the same issue?

-

West Coast Mooney 2016 Get Together LOCATION PREFFERENCE

N811SS replied to FlyDave's topic in General Mooney Talk

Hello west coast mooney group, N811SS would like to come, did you settle on a date yet? Was it the 10th of January? Middle ground between NorCal and SoCal makes sense but perhaps next meeting the group could go to KCNO ( Chino, ca. ). Flo's airport cafe and the aircraft museums make it an interesting destination but possibly even a tour of mooney international (on the south side of the airfield) could be arranged? Just a thought. -

Hello all- I too have been having problems with my FT-101. The mechanic talked me into replacing the transducer (although the problem was more likely the connections and not the transducer itself). The issue now is that I can not get it to read accurate burn. The totalizer always indicates more fuel consumed then actually burned. He installed a new floscan 201 transducer (serial number 194815). I removed the hoskins ft-101 and noticed that the switch arrangement was set to medium (S1=on, S2 = off) so I changed it to low (S1=on, S2=on). I think this made the accuracy worse, in other words it is now indicating even more fuel used than actually burned. Instead of just trail and error on the switch settings it would be nice if I can figure out what the transducer expects the switch settings to be. Anyone have any ideas? Here is the k-factor options: S1 S2 Low on on Medium on off High off on High/High off off

-

Looks like I have an oil leak in my 1967 M20F that is coming from the prop governor BOX (below the accessory case). The mechanic and I had the cowling off, engine oil warm, engine running about 1500rpm and when the prop was cycled you could see oil seep from the joint holding the two half's of the prop governor together. Tightening the bolts did not seem to solve the issue. Any one have a similar experience? How did you get it fixed? Was it expensive?