-

Posts

1,056 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Posts posted by Greg Ellis

-

-

It is amazing that after 17 years of ownership, there are still things to learn about my airplane. My 1963 C model has the 3 pin external power receptacle. I just thought that it was standard and not some option. I found no where in all the logs any entry for its installation. Interesting.

-

1

1

-

-

Just an FYI, I just received a notice that an AD for the Garmin GFC 500 will become effective August 20, 2024. I apologize to anyone if this is old news. The AD says that within 12 months of the effective date you must update the software to something newer that 8.01 for the G5, newer than 9.01 for the G3X Touch and newer than 2.59 for the GI 275. It is for Mooney models C-S and goes along with the Garmin Mandatory STC service Bulletin 22123, REV A, dated Jan 3rd, 2023.

It apparently is for the runaway trim issue.

-

-

On 7/12/2024 at 2:32 PM, ArtVandelay said:

These seem to be Windows only issues, the Mac version has been pretty good, it required reformatting the sdcard after a update a few months ago but otherwise it seems ok.

My experience as well. Updated the Database manager on a windows machine at my house and could not download anything to a card. The Database manager would not even start up. I didn't have the time to troubleshoot with Garmin so I went to my Macbook and it worked with no issues. I dread every time I open up the windows version of the Database manager and it says there is an update. I wonder what else will go wrong. It happened today. A different windows machine, the manager updated, went to download the database and it would stall out part way through the download. I had to shut down the computer and reboot everything then it worked. it had already done its own shut down after updating the database manager. It seems these updates are put out to the public before they are really ready for primetime.

-

I am going to admit to something that maybe I shouldn't. The world of Dentistry is much like that of aviation. If the product is for medical or dental uses, the price gets jacked up 10 fold or more. Same thing in aviation. If it is for a certified aircraft then the price sky rockets compared to homebuilt/experimental.

One year I was walking around Fly Market and saw they were selling hemostats at about 2-3 bucks a piece. They were the exact same that I use in my office. So I bought a bunch. Why? They get bent, beat up and abused over years of use and sterilizing them. A good pair of hemostats from a dental supply company can run anywhere from $20 on the low end up into the $60 and $70 range. These two dollar hemostats have worked well and lasted longer than their expensive counterparts. They take the abuse of use and sterilization better than the high dollar ones.

Not sure if anyone needs to emulate this but does that count?

-

5

5

-

1

1

-

-

10 minutes ago, 47U said:

The 1965-1967 IPC shows the pn as 740019. I’m pretty sure it’s the same part as the ‘63C. As far as fixing it… LASAR used to have the capability to rework Bowden cables, they made up a new flap retract cable for me 10 or 12 years ago. Or, you could call your favorite MSC and get a quote for the price for a new one. I’m sure the factory could make one up, with a few weeks lead time. I’m sure McFarland could make you a new cable under the Owner Produced Parts program if you wanted to go that route. Or, search for a used one from the salvage yards.

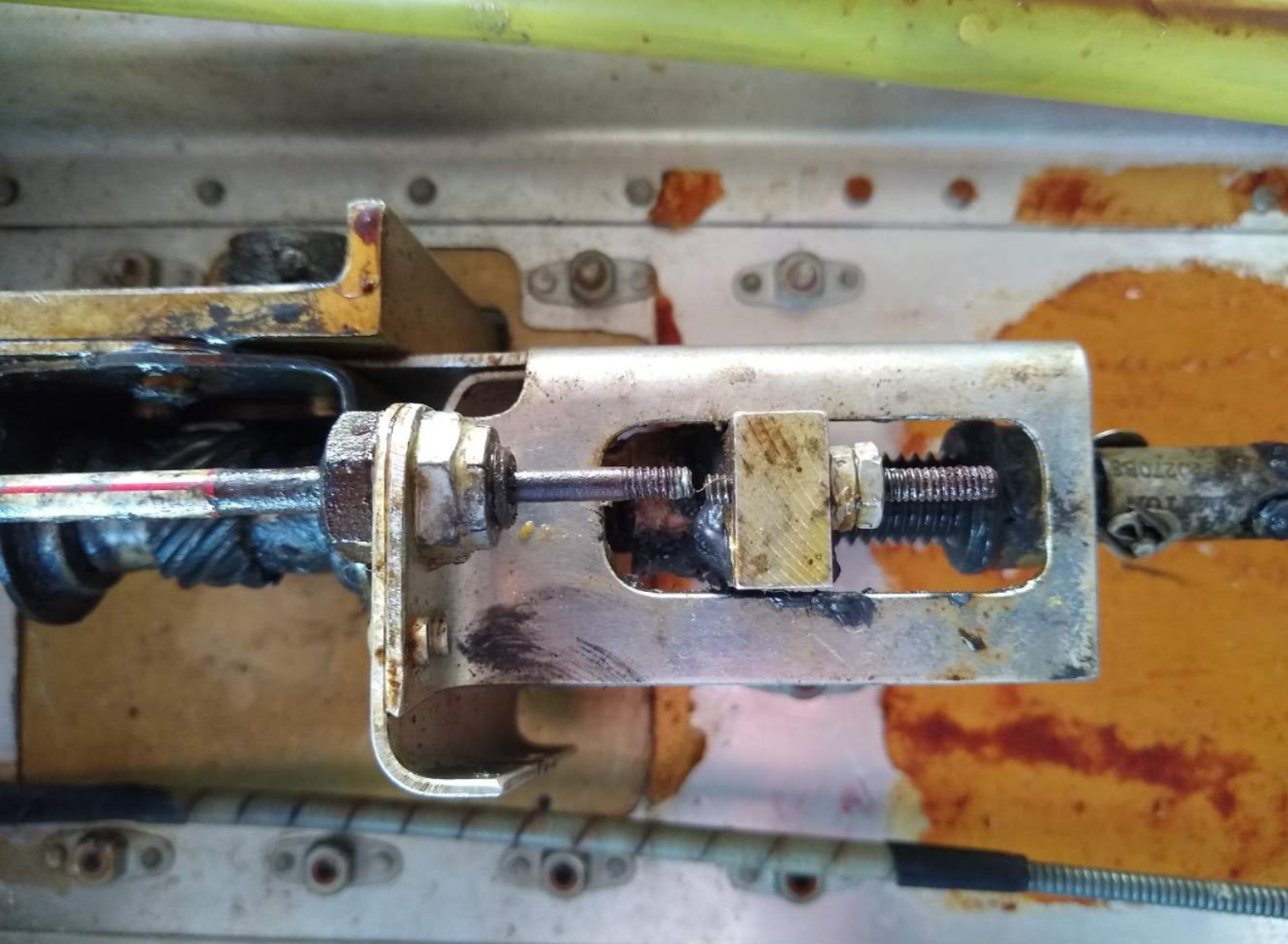

You’ve got quite a bit of threaded rod aft of the lock nuts. You might effect a (temproary?) repair by splicing the two broken ends together using a threaded ferrule (like the one in the pic below, from McMaster Carr). That would generate excess wire at the other and require readjustment of the piano wire under the indicator cover housing. Which, if it’s like mine, has a ring terminal on the end of the piano wire. You’d have to cut the wire and put on a new ring terminal.

One last observation, (if permitted, I’m not sure whose correct here, the IPC graphic is inconclusive) but you have both jam nuts on one side of the block, whereas I have one jam nut each on either side of the block. (The block isn’t threaded, is it?)

Anyway, let us know how it turns out… good luck!

Here’s mine…

Thanks for the response. There is a jam nut in the other side. I removed it to get the photo since it broke right at the nut. I had two on one side and one on the other. Thanks again.

-

1

1

-

-

2 minutes ago, N201MKTurbo said:

The easiest way to figure out the thread size is to remove one of the jamb nuts and find the screw that fits it. Take it to the ACE hardware store. They will help you out. They may have the threaded spacer you need too.

Thank you.

-

2 minutes ago, PT20J said:

Later models had a piano wire. It looks like the bracket and the moveable part on the trim screw don't line up and this put a side load on the threaded portion which eventually caused a stress fracture. Since there are threads left on both ends of the broken part, I would try to find a female threaded barrel with the same thread dimensions and use it to reconnect the two ends after bending the bracket slightly to align them. You should probably use a die to clean up the threads before trying to screw on the barrel.

Thanks for that. I thought about it as well and found some at McMaster Carr but I am unsure of the thread size. Any easy way to measure that? Also, there is not an alignment problem. The stop block has some play in it and can be move slightly side to side to realign the cable pieces.

-

I have a 63 C model. As you can see in the photos, the trim indicator cable broke at the threaded part near the stop block (left side of the block). Anyone have a creative way to fix this? I called an MSC but I don’t think they understood what happened. They said just pull out the wire and thread in new wire. They gave me a Mooney part number but said it was just piano wire. That does not look like piano wire to me. Any thoughts? Thanks. I looked in the parts catalog and the maintenance manual but could not see this cable in there anywhere.

-

That is pretty cool. You'll put the rubber band companies out of business.

-

2

2

-

-

47 minutes ago, Sabremech said:

I was chasing an oil leak on a J model last fall and thought of UV dye until I saw the price. If memory serves me right, the minimum quantity was a gallon and I’d never use that in my life time. I didn’t search for every possible source so maybe it could be found cheaper and in a smaller quantity.

ultimately, we found it using Magnaflux developer.

David

They have lots on Amazon at very small quantities. This one for instance... Amazon.com: InterDynamics Certified Auto Pro Oil and Fuel System UV Dye Leak Detection for Cars & Trucks & More, 1 Oz, 374CS, Universal : Automotive

As well as others in small quantities.

-

@00-Negative On another thread on Mooneyspace, someone mentioned that planexhaust.com (They said PlaneExhaust.net but that does not seem to exist) was able to make them a down pipe in an hour and get it to them the next day. Maybe they can do something for you and still help you make it to the Bahamas. Although with July 4th upon us, that may be difficult.

-

10 hours ago, Skates97 said:

Never had that happen, but I do have this tiny nagging fear of picking up a little pebble with my shoes, having it fall in the selector recess, and jam it. I make a habit of running a finger inside the recess before switching tanks just to make sure there's nothing there. Once in about 900 hours I found a tiny pebble, no idea if it would have caused a problem.

Just giving all of you one more thing to worry about.

Added to my checklist...."Check Fuel Selector for Rocks"

-

1

1

-

-

If your concern is with Beryl then go to the National Hurricane Center website. They have the storm tracking much farther south than Galveston and it will hit more towards Corpus Christi, South Padre and northern Mexico. You may get some rain and wind but according to the NHC it is not going to hit Galveston. Although that could change because landfall isn’t predicted until Sunday.

If your concern is generally for any hurricane that may hit Galveston, head up to DFW. When the Texas Coast gets a hurricane, we barely get a rise in wind and maybe a drop or two.

-

I think I would transition into something that allowed me access to remote airstrips and mountain airstrips to visit places in the US that are not accessible by Mooney due to unimproved runways, etc..

-

Don Maxwell at KGGG is only about an hour to hour and a half away (depending on wind and model of Mooney) from Little Rock as the Mooney flies.

-

If any of you guys with a Pre-201 Mooney, have not had a chance to read this Valuation Guide, it is worth the read. Just full of a ton of information that I was not aware of about my Mooney. Mr. Garrison really put a lot of effort and time into this and the research effort shows. It is a great read and worth the time. I suggest getting one if you can.

-

If your new airplane is a Mooney, congratulations and let us know what year and model so people on the forum know what you may be looking for. However, if your new airplane is the 182Q Skylane that you have on your avatar then you may want to check out a different forum for parts.

-

1

1

-

-

23 hours ago, Sue Bon said:

I don't understand anything you guys have said,

I feel this way with just about every thread on Mooneyspace....

-

5

5

-

-

8 minutes ago, Jim Peace said:

Just saw this thread. I get high pressure while taxing and on final...maybe a few times here and there as well in my 64C.

How much was that fuel pump you bought and the model number.

This is the one I ordered. Tempest Lycoming Fuel Pumps New | Aircraft Spruce

It was about $300 less than the Lycoming Brand pump.

-

3 hours ago, Yetti said:

still sounds like wiring. Would still check the grounds and such. All connections should be shiny bright. Try jumping the solenoid from battery hot to contact.

in my parts spreadsheet I have this.

here is some info: http://mooneyspace.com/topic/3437-spec-sheet-for-cutler-hammer-6041h231/

and if you can get your mechanic to agree it is a "standard part" (It has no TSO, PMA, or Milspec) and the 6041H105 meets or exceeds the original specs, then the 6041H105 may work.

Master Relay eaton "6041h105"

Oh look when I search the Eaton part number I find this. https://www.aircraftspruce.com/catalog/elpages/solenoid_6041H105.php?gad_source=1&gclid=CjwKCAjwmrqzBhAoEiwAXVpgokHVB0I9c-9YozfNvSmlGTZJzP5fLZNCXGUuRe-E-QhAfqTq_vYQoBoClf4QAvD_BwE

Thank you. I will check this out next weekend. That Eaton part, however, looks nothing like what is on the plane right now. However it is the correct part number according to the IPC.

-

55 minutes ago, 47U said:

It’s the intermittent stuff that drives me nuts. What does the ‘action’ feel like on the master switch? Is it… snappy? Otherwise, Yetti has good advice, check all the terminal connections on the master switch and master solenoid. Including grounds.

Please let us know what you find out.

The switch itself feels fine. I will troubleshoot a little more next weekend. Thanks for the advice from everyone.

-

19 minutes ago, 47U said:

Mx manual 106 (‘68C model) shows the master solenoid (relay) as a Cutler Hammer pn 6041 H 231. Several available used searching on controller.com… or new FAA-PMA Sky-Tec on Aircraft Spruce.

Thanks. I saw that same part number in the IPC but could not find an updated number for it. Thanks for the info.

-

50 minutes ago, Yetti said:

Master solenoids are constant duty for the mooney usually 200 amp. They would be a better starter solenoid than an intermittent duty starter ones. So not part of the problem. As far as "going out" Not sure how that is being determined. solenoids are pretty binary. So the battery could be getting weak or a ground is failing would be a better bet.

as far as a replacement any starter solenoid should do. The originals were usually a Cutler and Hammer brand. At one point I found the Master solenoid for my 75 at McMaster Carr, but have not seen it recently. Oh look there is one on ebay. https://www.ebay.com/itm/325655658606

There is no way I would buy the ebay one.

But you might find the part number and cross reference to DgiKey and or McMaster Carr.

So, it started when I would turn on the master switch and the solenoid would click on and off multiple times. I would turn the switch off then immediately back on and all is good. A flight last Friday revealed no issues and it seemed to work fine. Yesterday, turned on the master switch and nothing. No power at all. No clicking no nothing. Turned it back off then back on again and it was fine. Worked like nothing was wrong. So I thought it was the master solenoid going bad.

M20J minimum hours to be insurable

in General Mooney Talk

Posted

So this thread has made me read over my entire policy which I have never done. Is it bad that I am two pages into it and am already confused?