Kesk

Verified Member-

Posts

18 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Kesk's Achievements

-

M20C - hand pump flaps not staying in down position

Kesk replied to rwabdu's topic in Vintage Mooneys (pre-J models)

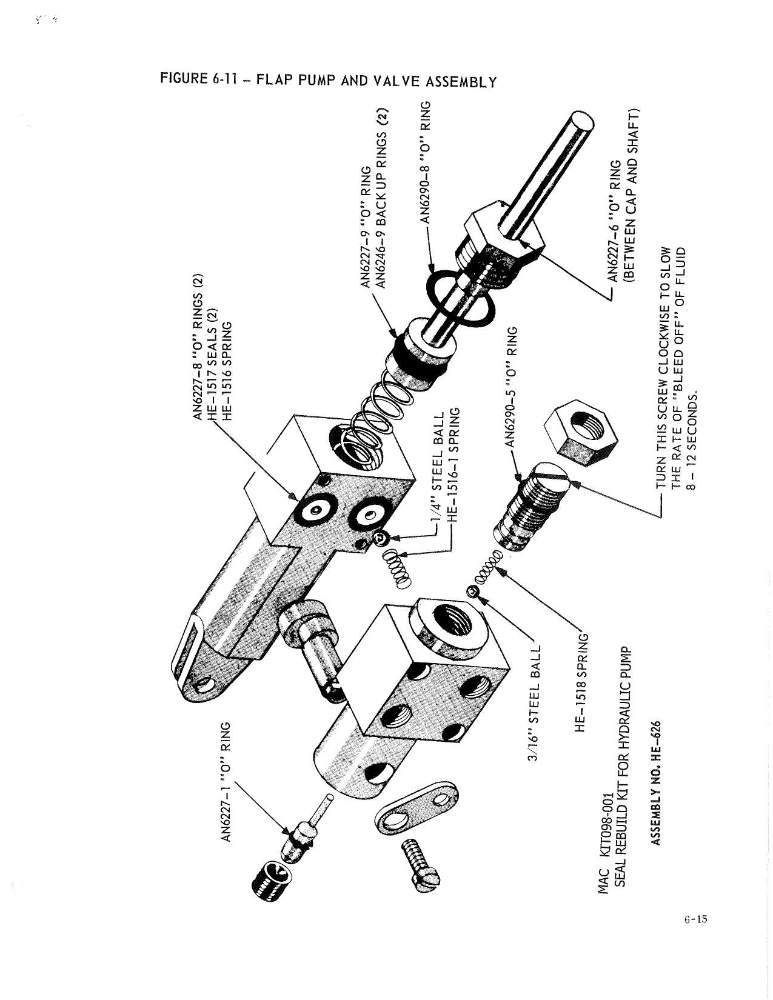

Thanks, I believe I tried with the screw fully bottomed out but not 100% sure. I've messed around with it for hours. It comes up very slowly, you can hear it creak and then it'll allow more pressure after about 30 seconds. You say you just hit the ball valve with a hammer and punch solid? I could not manage to get the needle-like piece with the AN6227-1 o-ring out even with the cam removed, seems like it would just prevent an exterior leak though? Not sure. Everything visually looked fine including the nylon discs and the ball seats. I am not 100% sure I put the springs back properly but usually I am a good boy and keep everything organized, and I had the parts breakdown... Initially I got it just barely adjusted to where they'd come up (I actually watched your video so ~10 seconds), and down would hold after about 30 minutes on the ground. After that work it didn't pass the check flight though so owner has still been flying without flaps in the meantime basically. Not exactly a fan of the idea. The cable itself is an annoying adjustment but I believe this is because the cam isn't sealing right, I assume if it were sealing properly it wouldn't be such a nuisance to adjust. But I've disconnected the cable entirely and moved the arm by hand just to make sure, and it definitely isn't just a cable adjustment. -

M20C - hand pump flaps not staying in down position

Kesk replied to rwabdu's topic in Vintage Mooneys (pre-J models)

Yeah it is a pain. Had a leaking HE625, probably had a solid inch of gunk from leaking for so many years. Resealed it and the HE626, no leaks but now they slowly come up once down, tried manually using the cable to actuate the cam. Sometimes it would seal and stay down, but now it never does it. Slowly comes up no matter how far in the closing direction the cam is pulled. Took it apart and resealed + bled it again, same problem. Think it's a ball valve seat or something else besides an o-ring internally. I'm not aware if it was working before because the owner was not using the flaps as the leakage at the HE625 was so bad they just plain didn't work. -

Well, update on the brakes. Some nice people on Facebook informed us the brass valves are a real PITA. We replaced them with some A114s as ours had o-rings and not stat-o-seals. After doing a normal bleed they got okay, not great, but acceptable. Tried all the tricks we could and they pretty much just ended up passable, about what most Pipers feel like in fleets. Shook the hell out of the cylinders while doing slow pumps with the nose jacked up, did the same after putting it on the ground. Definitely got a lot of air out but even a tiny bit can keep it from feeling super firm. Had no luck with vacuum from the reservoir vent line with the plug closed, not exactly sure so just did a bottom up pressure bleed. Getting the bleeder screw adapter instead of the whole ATS bleeder kit helped. This would be a lot easier with flexible lines I think.

-

If only all Mooneys had flexible lines. You can't move the cylinders around when the lines are hard. This is the trick to get Pipers bled.

-

Yes I agree. If you take a syringe and fill it with water and air you can easily replicate how annoying it is to get air out when horizontal. Air is hard to move when the cylinder is right side up but when upside down the air moves easily since it's lighter (it's different on a piper which has inverted cylinders because unlike a syringe there is a little nook air can get trapped in because the elbow is not directly at the bottom of the cylinder but like an inch up). Horizontal good luck ever getting that air out. I'd love to have a transparent cylinder just to see what happens on the plane.

-

Was one of the master cylinders leaking? We're trying a vacuum bleed which some users on here recommended since we got barely passable results through traditional methods (pressure bleed bottom-up 20-30 PSI, constant shaking of the cylinders, gallons of fluid, bench bleeding cylinders with caps on to just have the line off for a split second while fluid was pumped from below so minimal air was introduced). Not a big fan of the Paramount cylinders in general, but since it bench bled fine I still don't think it's the seals. If it's getting worse over time it's probably something in the system, but I've only ever had air introduced from bad cylinders, never seen any problems even from very leaky calipers since they're at the bottom of the system.

-

I've bled many aircraft and it is rarely simple. I've bled Pipers by disconnecting the cylinders, inverting them, and actuating them while pressure is pushed through. That's about all you can do and even then they'll just feel okay. I've only ever needed a hand pump on a Cessna. I bleed Diamonds very frequently and it takes a lot of finesse on some. Any time you install a new brake cylinder it can be a huge pain, shaking, actuating, tapping, depressing the pedal during bleed, you just have to try and try and try until you get enough air out. Bleeding aircraft brakes can be maddening at times and take hours. For instance a few quarts for the flap pump worked fine. I'm sure there's air left in it but 5-6 pumps and it works because each builds pressure consecutively. That's good in my book. But brakes are very unforgiving and the cylinders are often just poorly designed or oriented in general aviation aircraft. Even at work sometimes I get bubbles for 2 minutes in Diamonds and sometimes I get bubbles for 15 minutes...

-

Okay, I now understand that there's the pump and then the actuator. We're resealing both. The HE-625 was horrific. Here's the setup. The fittings are Aeroquip and Speedway, the hose is Aeroquip 306-4 but any 1/4" ID hose should work, got it off Aircraft Spruce. The nipple on the bleeder is 5/16" but I figured 1/4" would work and it does. The overflow line is just a 1/4" NPT thread and some random tubing my workplace had, got the fitting from Ace Hardware.

-

Need advice / sharing my concerns with someone

Kesk replied to redbaron1982's topic in General Mooney Talk

I think it really depends on the plane and who you have to prebuy. No doubt a lot of guys out there want free money with no strings attached, you want someone truly experienced for a prebuy or it aint worth a whole lot. However on a 60s or 70s aircraft...might be worth it. You can possibly negotiate down just looking over it yourself so it's an easier sale. -

Need advice / sharing my concerns with someone

Kesk replied to redbaron1982's topic in General Mooney Talk

Checking for corrosion is something that should absolutely be covered by a prebuy. That's probably the most important thing because it can scrap the airplane. Even an engine overhaul is minor compared to that. Especially on Mooneys as they are generally a bit older. If I had to prebuy a Diamond DA20, I could do it in a few hours and tell you everything wrong with it, the only unknown would be wing attach bearings and even those you can feel out by moving the wing. Mooneys are closer to Pipers than 172s or other planes to me, there's a lot more to look at. We had a shop out in Florida do a prebuy for one of our PA-28s. I don't know exactly what the report was but it seemed like nothing major. Plane came in full of mold in the interior and with the middle bolt on the nose gear torque link not even tightened down. They sued the place but I don't know what came of it. Also, at some point a 100 hour found large damage on the RH wing internally and it had to be fixed by Straight Flight. We've also had a prebuy miss a crumpled firewall from a hard landing. It really is a crapshoot and if you are not basically performing an annual you really don't know what state an aircraft is in. I'm talking seats pulled, every panel opened, every system checked, thorough check-flight, just the whole nine yards. Even when you do, people miss stuff. In cases like yours though the MSC really should accept some form of responsibility, although of course they won't. -

Thanks, I think an automotive one would work better here then possibly. If not I believe the ATS hosing can come off for tubing that connects to a flared fitting similar to the drain overflow. If I get exact part numbers I'll post them here once the job is done.

-

I know there are many threads out there for bleeding the flaps but I'm wondering what people have used to pump fluid when doing a bottom-up bleed. I assume top-down will not get them good enough. I've only ever bled brakes and either used a hand pump with vinyl tubing or the ATS bleeder that has a connection for the caliper bleeder screws. When people say they are using a pressure pot, what are they actually connecting to on the actuator and how?

-

Necroposting but...does anyone have a part number for the AN fitting that screws into the reservoir? We use these at work but I don't know for personal use. I'll report back if I find out from the parts clerk. I'm also wondering if the ATS brake pressure pot will connect to the bleeder valve on the HE-626. That might have to be found out the hard way.

-

Thanks for all the replies. Obviously going to do a full AD compliance, SB-208 sounds pretty similar to the Piper spar inspection. I expect to have to do some gear work by the sounds of it.

-

AD 77-17-04 Control Wheel Inspection

Kesk replied to Dreamlifter's topic in Vintage Mooneys (pre-J models)

Old post but this magnaflux kit is what we use on our DA20s for their nose gear dye pen check. Good stuff.