Allen_D

Verified Member-

Posts

12 -

Joined

-

Last visited

-

Days Won

1

Allen_D last won the day on March 17 2024

Allen_D had the most liked content!

Profile Information

-

Reg #

N9426V

-

Model

M20F

Recent Profile Visitors

2,675 profile views

Allen_D's Achievements

-

Nathaniel_H started following Allen_D

-

Are you at Willow Run?

-

I believe the stiffness of the flanges is currently sufficient. The lower pressure inside the duct should assist it in sealing. With that said, I do intend to make the flanges thicker on the next iteration. EDIT: Also the flanges on the new part are a little too thin because I used a heavy layer of Vaseline as a mold release.

-

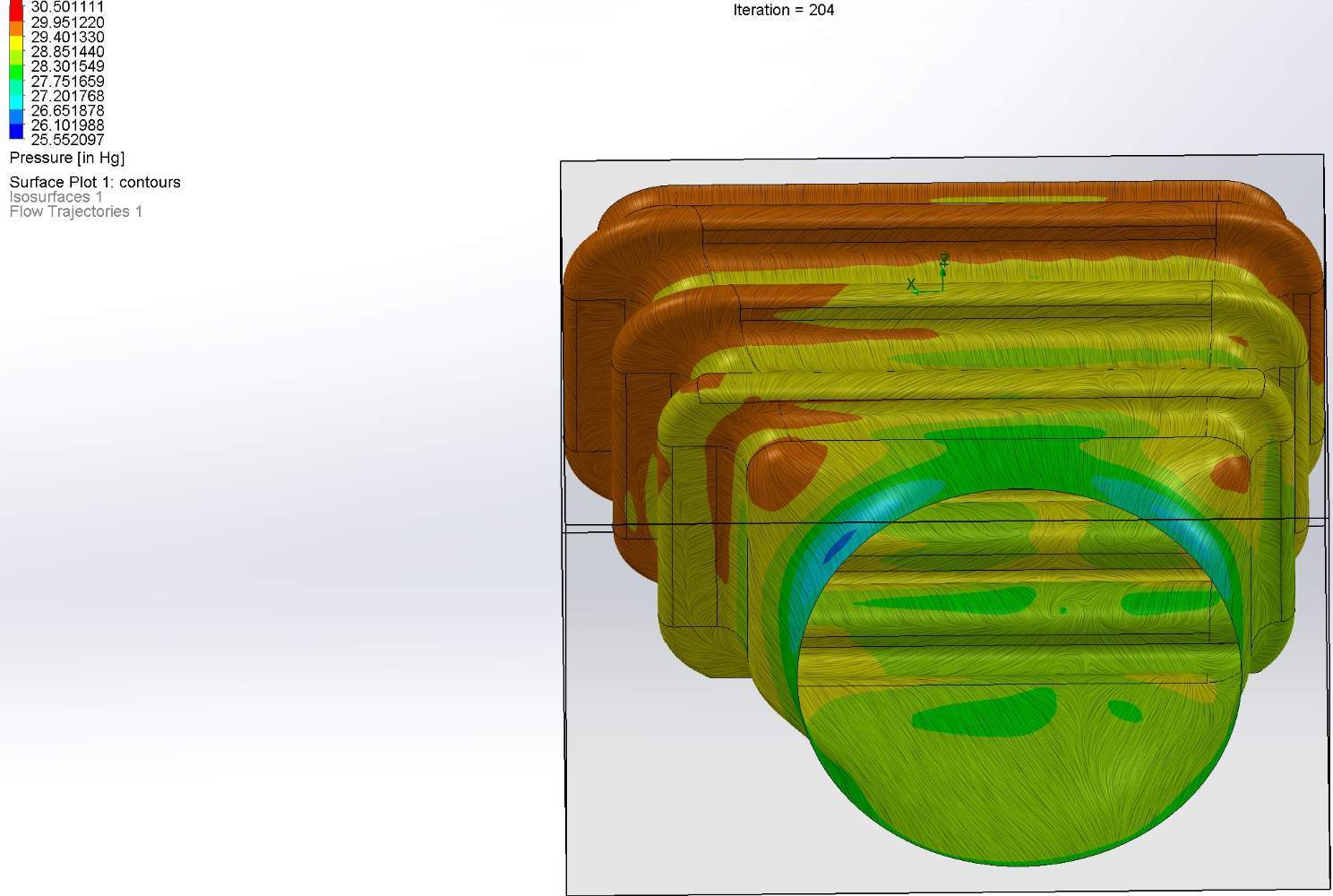

Thank you for your feedback and concern. It's worth noting that the original design for the E/F models does not incorporate any wire in the ribs. To address potential concerns about the induction coupler collapsing, I've conducted a Computational Fluid Dynamics (CFD) study and subsequent Finite Element Analysis (FEA) at twice the expected volumetric flow rate. This allowed me to estimate the aerodynamic loads and predict a maximum deflection of approximately 1 mm for the chosen material. Additionally, in the event of inadvertent flight into icing conditions, the air filter bypass valve is designed to automatically open, preventing engine starvation. I also plan to monitor the part's deflection during ground operations, particularly during full power run-ups, to ensure structural integrity.

-

I've made some progress, and the urethane part is slightly stiffer than the original using a shore 90A material. I am considering switching to shore 80A as might be a closer match. Currently I'm using amber urethane to spot air bubbles. Once bubble elimination method is sorted, transitioning to black. Seeking feedback on this progress.

-

@cliffy The flow rate employed for the CFD analysis mirrors that of our IO-360s at 5400 RPM. This intentional setup is designed to generate loads higher than actual, incorporating a safety factor into the analysis. This safety factor proves crucial in scenarios involving a restricted air filter, as the air filter bypass door activates, preventing pressure from dropping to levels that could cause the induction coupler to collapse. Ensuring that the new part matches the strength of the original is pivotal for meeting the requirements of the type certificate. On the topic of "approved data," it's worth noting that attempts were made to obtain the engineering drawing from Mooney, but unfortunately, they declined to share this information, rendering "approved data" unavailable. Recognizing the legitimate concern surrounding A&P sign-off, the local FSDO is conveniently located less than a quarter mile from my hangar. I plan to seek their advice once I have a tangible prototype. Their endorsement could prove influential in persuading any hesitant A&P. I want to emphasize that I welcome and take no offense to any comments. The purpose of my post is to gather feedback comprehensively, ensuring a safe and well-considered solution. I share the belief that taking no action could lead to more accidents. The unavailability and exorbitant cost of the part contribute to individuals using aging induction couplers beyond their safe operational lifespan. We all have a stake in this matter. I appreciate everyone's engagement in this discussion.

-

@Shadrach Let me finish this before I start something else.

-

@EricJ If we can establish that the new part is at least as strong as the original – and even stronger – it should inherently be capable of withstanding conditions such as a backfire. The aim is to not just meet but surpass the standards set by the original design.

-

Thank you for sharing your concerns and suggesting a potential testing approach. I completely agree that demonstrating the safety and reliability of the design under various failure modes is crucial. I'm considering the development of a test fixture with a significant pressure difference, as you've outlined. This fixture would simulate real-world conditions, inducing anticipated failure modes to ensure the induction coupler doesn't lead to an intake obstruction. Your suggestion aligns well with building confidence among potential users and obtaining necessary approvals. Regarding the pressure difference, it's important to note that the maximum pressure differential pre-throttle body is about 5 inHg, and this occurs at an unreasonable 5400 rpm.

-

@MikeOH I've been searching for information on whether a cloth mesh has additional impacts beyond what I've mentioned, but unfortunately, I haven't found anything yet. If you come across any sources that show it prevents fragmentation, I'd greatly appreciate it if you could share them with me. Your input is crucial, and I'm open to any ideas or questions you might have.

-

I appreciate your insightful question and would like to emphasize that my design choices take into account significant advancements in engineering tools and materials since the original part was conceived in the 1960s. In the original design, a cloth mesh was integrated into the butyl rubber to augment tear resistance and enhance dimensional stability. However, with the evolution of materials, my revised approach opts for a urethane rubber without the cloth mesh. The advancements in materials and engineering tools have allowed for a more refined solution that doesn't require the additional reinforcement provided by the cloth mesh. This decision is made with confidence in the improved properties of the selected urethane rubber. To address safety concerns, thorough ground tests at full RPM and regular inspections will be conducted if the induction coupler is installed on my plane. Your keen interest and question are highly appreciated, and your feedback is invaluable to the continual improvement of the project.

-

David, I appreciate your contribution of the old duct for my project. I've been conducting thorough analyses using Finite Element Analysis (FEA) to assess the performance of my version of the induction coupler under various loads. The primary goal is to ensure it won't collapse and adversely affect the engine. Considering the potential for backfire in its location, I've decided on using a flame-retardant material with high tear strength. In examining worst-case scenarios, such as full RPM at 0 knots, I introduced a safety factor by increasing the maximum RPM by 20%. The latest test involved running the coupler at 3,240 RPM, utilizing a Shore 60A urethane. The results indicate minimal deflection, with approximately 2mm on the bottom surfaces and 1mm on the top. Notably, I conducted a case at an exaggerated 2x the RPM, resulting in only 6mm of deflection. Responding proactively, I reinforced the design to ensure robustness under extreme conditions. Moving forward, my next step involves creating the mold and experimenting with various urethanes to refine the manufacturing process. I plan to document these practices meticulously to verify and build upon my findings. If successful, I'll certainly send you a usable product. I'll keep you informed of my progress. - Allen

-

Would you be willing to share your drawings of this part? Or is someone willing to send me an old unserviceable part? I would like to analyze the deformation/stress/strain of this part using different materials.

-

Hi MooneyJohn.

I saw you post about the intake duct. I was considering experimenting with producing this part myself. My current intake duct is still in use and difficult to measure. Do you have a drawing of this part that I can use to replicate it in SolidWorks? I would like to do a stress analysis on it to see how a TPU version would hold up.

You can email me at m.allen.dutton@gmail.com.

Thank you,

Allen Dutton