-

Posts

639 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Blue on Top

-

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

Not sure that it is FAR 33 certificated in the US. It is EASA-certified through CS-E, but I'm not sure to what level. 141 Hp (with turbocharging) is a unique power output. Turbocharging is not for turbo-normalizing like the Acclaim; it is there to get rated horsepower. Not sure what happens to power when the turbo fails (in diesels it's really bad). There is/was a Rotax Service bulletin (which leads me to believe that the engine is for LSA airplanes (not certificated airplanes) or EASA VLA aircraft ... US Ultralights to a higher gross weight), which has grounded all the engines (sulfur-filled exhaust valves are failing). Mating two engines to a single propeller has been tried by many and been successful by none. The C337 is a better idea, but the configuration has its pros and cons. A new TC airplane is VERY expensive. -

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

... and the diesel program failed miserably. -

Technically, they don't work with flat plates because of the aileron balance weights, BUT ... They do work when the balance weights are changed to the later style balance weights that are all internal to the OML wing surface. So, bottom line: @PhateX1337Your bank account just got a little smaller, but the sex appeal of your airplane just soared! PS. Aileron effectiveness and forces will go up slightly, too.

-

I sooooooooooo want something like this! It's just money ... right?

-

I think Joe will protect it well and make sure it is always protected. ... but I am in Wichita, KS now.

-

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

Diesels are heavier for several reasons: 1) The compression ratio is significantly higher than a spark ignition engine. 2) Because of 1) they are typically water-cooled. 3) Because of 1) and 2) there must be heavier structure to support those items. 4) The fuel itself is 10%+ heavier; hence the name "heavy fuel" engines. -

@MooneyMitch Joe's son is in town, too.

-

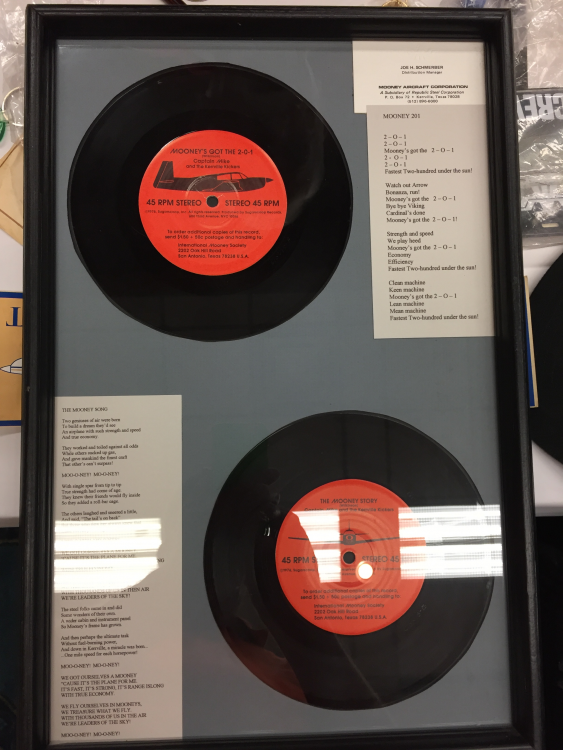

Joe Schmber in Kerrville has a lot of Mooney memorabilia. He's an awesome gentleman. Someone should get in touch with him and make sure everything is preserved.

-

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

I know the website weight of the CD-155 is low by more than 100 lbs. Just sayin'. I got a little experience with it. -

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

Please compare apples to apples and oranges to oranges. IO-550 at 445 lbs. and 300+ horsepower versus Austro at 410 lbs. and 180 horsepower. Airplane comparisons are much more difficult as there are many more factors to consider. -

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

The article where Tom is quoted has lots of errors ... whether misquoted or not. Kerrville and Chino had issues (to say the least). Towards the end Kerrville made a lot of metal parts for us (bailed us out from local California businesses overcharging us). An outside vendor designed the M20 composite shell. We put it in CATIA. It is NOT structural ... and takes many MORE manhours to build. -

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

@RobertGary1 I probably did not say it clearly enough. As you have stated, "if you lose a coil, you lose that cylinder." I actually, intentionally, lose 3 of 6 cylinders in my Pilot every time it goes into "eco" mode using VCM (Variable Cylinder Management). Thanks for the clarification. -

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

@N201MKTurbo I agree with what you are saying, but I believe that the LS series is a little different in that respect. In other words, it was designed for a higher continuous HP than a normal automobile engine. Yes, marine engines have unlimited water coolant. I'm not saying that there are not challenges. Cooling a water-cooled engine in an airplane is a huge challenge for many reasons, especially weight and drag. Air-cooled engines have a much, much easier heat transfer equation as CHTs are significantly higher than the cooling airflow (300-400F). On the other hand, water/liquid-cooled engines have a very small temperature delta (<90F) to transfer all that heat. This requires lots of radiator area and slow airflow ... adding to weight and drag. With that said, though, I would rather fly behind an engine that is nearly an order of magnitude less expensive, is more thermally efficient, will keep running with the loss of a coil/plug or two (unlike a magneto), and runs on fuel that I can get around the corner. -

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

@cliffy Exactly. -

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

1) Optimum propeller efficiency determines propeller RPM and torque required. Number of blades can be changed to optimize horsepower consumed. The gear box is there for one reason: to put the propeller at the right RPM. Single point design ... off point design is not relevant. 2) Sorry, proprietary. When will an IO-550G (Ovation) or TSIO-550G (Acclaim) output 430 horsepower? and for how long? LS3s can be made to output over 750 horsepower ... but they don't last long. 3) Again, proprietary. Cooling on the ground and cooling airborne is apples and oranges. Rarely does it get to -25C with the wind blowing at 180 knots on the ground. 4) Yes. You assumed all plugs were still being fired. My 2007 car (old, but I love her) uses 3 of the six cylinders at highway speeds. Hope this helps. -Ron PS. I agree that most auto conversions are poor. -

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

Engine (or electric motor for that matter) torque curves are not relevant in an airplane. Torque required is defined by the propeller, and the engine/motor must match it. LS3 engines run as pump motors at full power for 2.5-3 years at a time (stopping only for oil changes and routine maintenance). Yes, I would rather have 8 coils than 16 spark plugs. The LS3 will continue to run on 3 coils. I like that for a huge safety factor. -

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

The LS3 all up with gearbox (and radiator I believe) is slightly under the weight of an all up IO-500. On the GM would still have to sign off part ... well ... that's really not true. GM would have to sign off IF the engine were spec'd from an OEM. This is one BIG reason why airplanes are so expensive today. If OEMs would do a little work and certificate there own designs (or others), airplanes could be affordable again. Generators/Alternators are a great example. Most earlier airplanes used automotive generators. (I'm trying to be PC here). Some companies would buy off the shelf units, test them as required (minimal), put their label on them and sell them at a reasonable cost to the operator. Others, on the other hand, said let's make a spec, give it to a manufacturer, legally bind them to an agreement and a process that if they change their design (which sells millions of units) they have to tell us. And they need to fix their problems ... because we ordered 100 of them! LOL. And people wonder why that $200 automotive generator now costs $3,000? -

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

When I first really got on MooneySpace, I asked a question about certifying the LS3 engine. That is still the shortest path to a long-term solution. Yes, especially for the long bodies ... and every other airplane produced today. The only new engine that Continental makes is the IO-550. As mentioned above, diesels are heavy and lower on power ... and I'll add to that VERY heavy, need to be turbocharged (and failures of the turbo are significant), expensive and hard to cool (and water radiators add a LOT of drag). -

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

Cooling and fuselage drag can be reduced on all M20s. We all play by the same aerodynamic laws. As for electric airplanes, they require the same power as their ICE counterparts. Power required is power required; electric or not. Propeller noise is propeller noise; electric or not. Hybrid is the TEMPORARY solution to lack of electron storage. Electric motors (if cooled properly) are good enough in their current state. Why do I always have to open my BIG mouth? -Ron -

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

The STC route is the way to go! We're definitely not ready yet, as we are waiting on energy density of something to be as good (and as cheap) as 100LL. In the meantime, we should be doing designing and testing on distribution systems (and their failure modes) to be ready when the massive flow of electrons come! -

This thread is fascinating to me (I'm not an EE). Plus, I needed to post something to stay in the loop on this one. Thanks all y'all

-

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

PS. Everyone wants a "J", but that production ended 35 years ago. Account for inflation, labor costs, engine costs and btw, throw out integrated glass, leather interior, engine monitoring, ADS-B, GPS, TCAS, etc. I do think that this is the way to go ... especially now that Garmin (although good) isn't the only player in the game. My lot more than 2 cents -

Technology Today vs the 1960 Mooney Design

Blue on Top replied to cliffy's topic in General Mooney Talk

Thanks for the add @carusoam 1) Al Mooney AND HIS BROTHER ART were great designers and producers. The original M20 would have been as fast as an M20E, but Al was forced into a different engine that had much higher cooling drag. The wood wing is faster, too. But that's a different topic 2) Carbon fiber is heavier than aluminum because the main failure mode of most airplane structural parts is compression or buckling, where composites are poor. Where buckling/pillowing of aluminum is allowed, it is frowned upon in composites (and very difficult to certificate). The SR airplanes are relatively very heavy compared to a comparable aluminum airplane. In addition, where minimum thickness is all that is required (flight controls, flaps, empennage, outboard wing skins, etc.) 0.020 aluminum (or thinner) is MUCH lighter than 2-core-2 carbon. Oh, and add a copper mech (heavy) or aluminum mesh with a fiberglass layer for corrosion protection for all outside surfaces for lightning protection and dissipation if it is carbon fiber. 3) The Starship has a lot of aerodynamic problems (in addition to weight) starting with a canard design that by definition is very draggy. There is over 1,00o lbs. of down force on the inboard main wing due to the canard. Propellers are in the worst place possible, etc. Original Cirrus (and the current ones, too) are fiberglass, which is very heavy. The only carbon in a Cirrus is the spar ... and the name of the paint scheme. A metallic M10 would be a great airplane ... same shape with a better wing ... and MUCH lighter. Mooney can make ANYTHING in aluminum! The raptor ... well it's for a different reason. The B787 is composite solely because composites don't corrode (if designed properly with proper hardware. An aluminum 787 would be lighter ... but might corrode. 4) Because composites are heavier. 5) I won't comment on Boom. I know many very good people that have come and gone from there (almost me, too). Their video is good, though. Why no change? Mooney could advance state of the art, but they are unwilling/unable to do so. There are many, many items in both design and manufacturing that they could improve upon, but ... This is where getting older and hopefully wiser tells me I should stop. -

The evolution/development of the wing design between Al and Art is fascinating, too, with Al being the aerodynamicist and Art being the manufacturer. All of their earlier work, including Culver with slotted wing tips, and culminating in the Mooney wing. Amazing!

-

If I owned them, I would have long ago made MP3 files They are owned by a gentleman in Kerrville, I believe. He had a booth at the last MAPA Homecoming in Kerrville ... 2017 or 2018? I regret not knowing his name. Wonderful gentleman.