BKlott

Basic Member-

Posts

557 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by BKlott

-

I wouldn’t be so hard on the 182 with regards to cross country travels. My wife and I left West Central Florida one Sunday morning and enjoyed an early dinner on the Riverwalk in San Antonio that afternoon. We accomplished that in a 150 hp 172M without the benefit of a tailwind. A 182 would be much faster. The other advantages to a late model 182T would include a factory corrosion proofed airframe, a Lycoming engine that gets you away from Continental cylinders but does give you the Lycoming camshaft issue, fixed gear, a modern panel and the more crashworthy seats. Takeoff and climb performance make trips out West and the high density altitude departures more feasible. The 182 is no Mooney but it is a very viable candidate for private ownership. With Insurance premiums increasing on RGs and Insurance Companies tightening availability for older pilots, I wouldn’t be so quick to overlook a late model 182.

-

Best Airport/FBO for Visiting St. Louis, MO?

BKlott replied to 1001001's topic in Miscellaneous Aviation Talk

You might take a look at Creve Coeur (1H0). There is a great GA museum on the field, self serve fuel and they did have rental car availability the last time I was there...but that was pre-COVID and probably 7-8 years ago. -

Monday, May 10th My new hose set arrived this morning. I had expected an email to let me know that they had shipped but that didn’t happen. These are the Teflon hoses with the integral firesleeve protection. Total cost was $671.23 ($651.23 for the set plus $20 for shipping). This brings our total project cost up to $16,847.72 and counting...

-

If you fly in to ZPH you can taxi right over to the engine shop. Their shop is located on the Southwest corner of the field, easily accessible from the Runway 5 taxiway. I do not know if they offer engine removal and installation services. There is enough space in one building to house an aircraft. A J-3 is sitting in there right now. I have seen both a Cirrus and a Warrior/Archer parked outside on occasion. You would probably just need to call and ask to speak with “LJ”, who runs the operation, to see if they can accommodate your needs.

-

Friday, May 7th Today I received my oil cooler back from Pacific Oil Cooler Service. They found some cracks in the mounting bracket and repaired them. The cost for their services was $298.13 ($216 for the overhaul, $50 for the labor in repairing the cracks and $32.13 for the freight charge). The cooler sure looks nice. It was very well packaged for the trip home. Beats the cost of $700+ for a new one. I also received the new Alcor EGT probe that was back ordered. Still have not made a decision on the engine monitor but I have 8 to 9 weeks wait on the engine. No need to rush on that. I called AWI to follow up on the engine mount. Found out that they are in the process of moving this week. The engine mount section is supposed to be in place at their new facility on Monday. Maybe I’ll hear something early next week. Neglected to account for the postage charge for returning the vacuum pump core of $12.80. New fuel and oil hoses are on order from Aero Aviation Hose Shop in Granite City, IL. I ordered the Teflon hoses with the integral fire sleeve option. They are a bit pricey compared to the standard hose materials used but given the overall cost of this project, the added cost is insignificant. Our total project cost to date is now $16,176.49.

-

That is great advice. I have to admit that I am thoroughly uninformed when it comes to the modern engine monitors that are available. Fortunately I am not quite two weeks in to a ten to twelve week wait for my engine so, I have plenty of time to get educated.

-

Friday, April 30th Today I received a complete new set of powder coated engine baffles from Airforms, Inc. in Wasilla, Alaska. They look absolutely beautiful and are far nicer than the worn out original baffles that were left on my airplane. You can see the difference in the pictures below. I’ve also ordered the two air filters that are used in my vacuum system. One of these is a wraparound foam filter. Both of these should be replaced when the vacuum pump is replaced, if not sooner. Ordered some new SCAT, or in this case, SCEET ducting as well. This added $107.37 to the bill. Still waiting for a report on my engine mount. I don’t believe this is a “no news is good news” type of thing. My project total to date is now $15,838.15. I guess I can now say that I am truly baffled.

-

Wednesday, April 28th Today I have an update on my exhaust system. As you’ll recall, I had sent my exhaust to Aerospace Welding, Inc. to be overhauled. Shortly after it arrived, I received a call from them verifying it had arrived and that they would start working on it. It got overhauled all right. After inspection, they “hauled” it “over” to their dumpster and tossed it in. It was in such bad shape that none of it was salvageable. In hindsight, I should have evaluated the condition of my exhaust system more carefully before sending it off. Had I done so, I could have elected to simply purchase the new system and would have saved myself $470.01 in packing and shipping charges on the old one. Given it’s age and condition, that would have been the sensible thing to do. Since when are light aircraft owners known for making sensible financial decisions?! Today I received a brand spanking new exhaust system for $1,909.50 ($1,855.90 + $53.60 shipping). This brings our project total to $15,730.78 to date.

-

Multi-engine instruction...Mission Impossible?

BKlott replied to BKlott's topic in Miscellaneous Aviation Talk

UPDATE Took my first lesson in the Duchess today. Really enjoyed flying it and like my CFI as well. The Duchess does have a bit more performance than my 172. So far the yaw and roll from simulating losing an engine is a non event. Very little rudder is required. The Duchess appears to be quite docile. We were maintaining altitude at 5,500 ft today with one engine idled and we started with a full fuel load. Another nice feature is the acceleration on takeoff. You accelerate through VMC of 65 knots, wait to rotate at 71 knots and you reach blue line of 85 knots in just a few seconds. Unless you’re executing a short field takeoff over an obstacle and elect to climb out at Vx of 71 knots, you can greatly minimize the amount of time you are airborne at less than blue line airspeed. Not flying out of Orlando, who never did get me on their schedule. -

I believe that is on the engine itself and at the overhaul shop. My plane has a remote, firewall mounted oil cooler. The only components that are being reused as-is are my alternator, which has 458 hours on it and exhibits no indication of any issues and my propellor which was overhauled in March 2016. The prop is still in great shape with 303 hours smoh.

-

Wednesday, April 21st Today was a light day for me and my credit card. I phoned Pacific Oil Cooler Service out in LaVerne, California and spoke with a gentleman there. They sell and service oil coolers. I wanted their opinion as to whether or not I should replace my Stewart Warner Oil Cooler or have them service it instead. They told me that my existing cooler is a good quality piece of equipment and that if it is maintained and used properly, it should give indefinite service. A new one would cost some $400++ more than the cost of their cleaning, inspection, testing and repair service. I had looked at some recent reviews on a new, equivalent cooler, now being manufactured by another firm. Some guys were having problems, including leaks with the newer units. If the guy at Pacific had told me that the new units were significantly “better”, then I would have ordered a new one. I got the impression that I would be better off keeping and servicing what I have. All I did today was to ship the oil cooler to Pacific for servicing. Packaging, shipping and Insurance totaled $33.02. This brings our project total to $13,821.28. Tomorrow, my engine mount and exhaust system are scheduled to be delivered to AWI and I should receive my Aircraft Spruce order as well.

-

I won’t defend what she did in any way, shape or form but I can’t help but notice the disparity between how she has been treated and how motor vehicle operators are treated when they do careless and reckless things with their motor vehicles. I often see drivers running through Stop Signs like they aren’t there, exceeding the speed limit by a wide margin, ignoring Red Lights, tailgating at high speeds, weaving in and out of traffic and making lane changes without signaling. Do they ever receive a letter from a Federal Government or State Government Agency revoking their driving privileges? Of course not. I would argue that their actions are far more likely to result in injury, death and property damage to others than what Martha did.

-

Why won't AWI use powder coating on my engine mount? ANSWER: We strongly advise against powder coating any structural airframe component. This can cause cracks and chafing to go unnoticed. Powder coating is also impossible to remove for future inspections.

-

I believe that the lack of maintenance and upkeep on the existing fleet, coupled with a lack of aircraft production has resulted in fewer viable aircraft being available to meet demand. Sure, you can purchase a plane with a high time engine, lousy paint, worn interior and avionics from the 1970s. Then you can drop $75,000 to $100,000 (or more) into it, to resurrect it into being a nice, up to date airplane again. But how many guys are capable of and willing to do that? The relatively few nice and up to date airplanes that are available will continue to be snapped up when they hit the market because knowledgeable buyers will recognize their value. They’ll also recognize how unlikely it is that they will find a nicer aircraft no matter how long and hard they look.

-

No worries, I’ve got you covered. I am doing the totaling for you!

-

The mount and exhaust system are both on their way to AWI (Aerospace Welding, Inc.) for inspection, repair and refinishing. They do not recommend powder coating the mount but it will be refinished, probably painted white as that helps to identify cracking. The new baffle set will be powder coated, see today’s write-up. I agree with the 182 option. One of, if not “the”, best all around airplanes ever made.

-

Tuesday, April 20th. Big order day... I started today with placing an order for a new set of baffles from Airforms in Alaska. A number of years ago our right front baffle assembly fell apart. The metal was so thin at that point that my IA said it would be best to replace it as he didn’t think he could even repair it. The baffles were just bare metal that had some black paint sprayed on them without any evidence of priming. The paint was just flaking off and it looked terrible. I ordered the three front pieces of the baffle set from Airforms and elected to pay extra for the powder coating option. These looked so much nicer. My thinking at that time was that if we had to get the engine done, I would just order the remaining pieces to complete the set. Well....insert laughter here....it turns out that the base price for the needed pieces totals $1,231.86 but you can buy the complete set for a discounted price of $1,255.79. In other words, for $23.93 more I can get the entire set brand new. Add in the powder coating charge for a total of $1,425.42 + $75 shipping = $1,500.42. These photos show the difference between the Airforms powder coated baffles and the original baffles. My next order for today was with Aircraft Spruce. Four new Lord mounts to replace the Barry mounts that were installed back in June 1996, new hardware for connecting the engine mount to the firewall, new hardware for the new Lord mounts, a new Alcor EGT probe as the existing one looks cruddy, an overhauled Rapco Vacuum Pump as the existing one was installed in September 2013 and has 448 hours on it and a new Lycoming Alternator belt. It would be silly to not replace this since the prop is off the engine. Aircraft Spruce was able to supply all the hardware needed for this order except for the self locking nuts and two types of washers needed. I had to go to two other suppliers to get the three remaining pieces of hardware needed. Aircraft Spruce should be quite happy with my $1,388.75 order which did qualify for free shipping. Next stop was Spencer Aircraft to order 8 nuts of two different types. The nuts cost $10.08 and the shipping cost $10.90 for a total of $20.98. Maybe I am the third kind of nut.... Finally, my last transaction of the day was with Cessnaparts.Com to get 4 washers. These look like pretty special washers as they cost $36.64 plus shipping and handling. This brings today’s total to $2,946.79 and our project total to date is now $13,788.26.

-

There are STCs available to go from the 150 hp to either 160 hp or 180 hp. Some of these require that the flap travel be limited to thirty degrees, instead of my forty. Additionally, the higher horsepower increases fuel burn and my airplane only has the 42 gallon / 38 gallon useable fuel tanks. The more modern 172s have 50 gallon tanks. Another reason that I’ve elected to retain the 150 hp engine is that, if 100LL does go away, theoretically I could use the UL 94 AVGAS from Swift Fuels without issue. Can’t do that with the 160 hp or 180 hp engines. I think that if you really want the 180 hp engine, there are real benefits to getting one of the newer 172S or SP models. These have corrosion proof airframes, 50 gallon fuel capacity, more modern seats, instrument panels and avionics. It’s tough and expensive to try to upgrade a legacy 172 into a modern 172.

-

Mine does have the 40 degree flaps but with infinite settings available from 0 to 40 degrees. I prefer that to the pre-select flap positions.

-

Wouldn’t be much trade-in value at this point.

-

It has the O-320-E2D 150 hp Lycoming.

-

The engine will receive brand new cylinders from either Lycoming or Superior, depending upon whether or not the Lycoming cylinders will be available. The engine shop advised that Lycoming is experiencing supply chain issues and that may drive the decision. The existing cylinders have been previously overhauled once already. I want new cylinders and that is what Zephyr recommends. It is nice to be hangared on the airport where one of the top engine shops in the business is based right on the field. Estimated time to complete the engine is “10 to 12 weeks”.

-

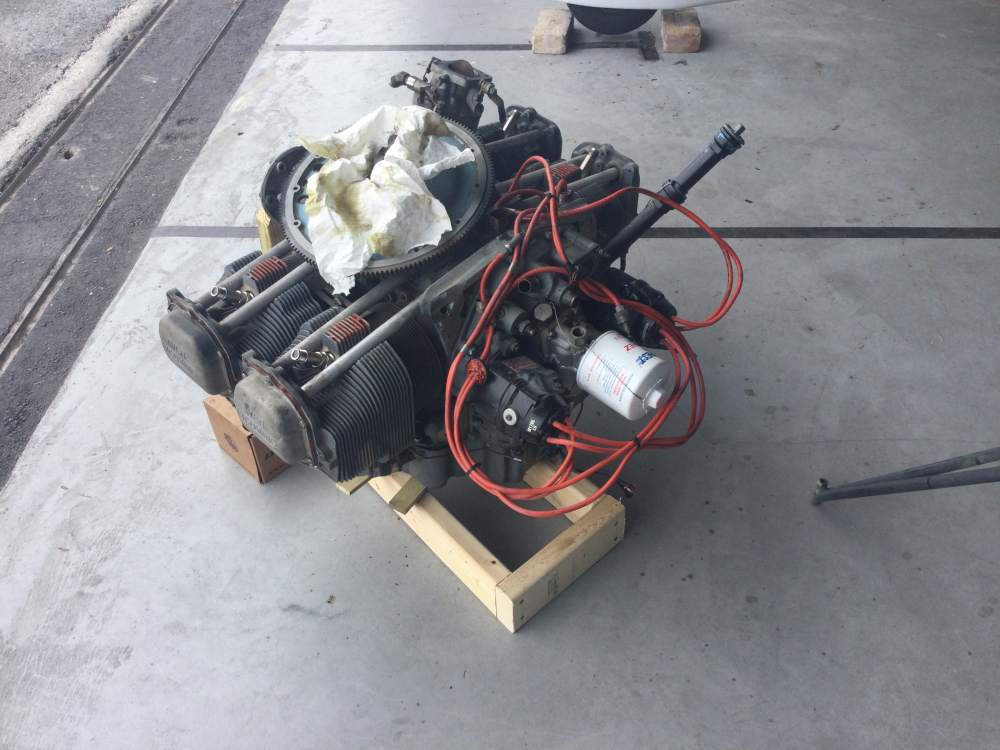

“How much does an overhaul cost?” I have been asked this question twice since last Tuesday so I have been giving this subject a lot of thought. My wife was the first to ask, following our shorter than expected (12 minutes) flight last Tuesday evening, due to an engine issue. Our engine powered up as usual but I noticed our rate of climb was a bit sluggish. It varied between 500 to 600 fpm, instead of our usual 700 fpm initial climb rate. We leveled off at 3,000 and the engine did not seem to turn up like it normally does. I glanced over at the gauges to see a much higher than normal oil temperature reading coupled with a much lower than normal oil pressure reading. Not good! As I reduced power, the engine began running a little rough, making it an easy decision to reverse course and return to the airport. Given that the engine was last overhauled in June 1996, that three of the four original cylinders were consistently showing below 70 compression readings and that we had oil leaks from multiple locations, I knew that our engine was near the end of its life and an overhaul was coming. I had already decided that I was not going to spend money on piecemeal engine repairs trying to avoid the “big bill”. The engine owed me nothing at this point with 1474 hours smoh. As I approach the twilight of my flying days, I want to finish up my adventures flying behind a good engine with new cylinder assemblies instead of a tired, worn out engine. Our son called last night and we broke the news to him by telling him that we would deduct the overhaul costs from his sister’s share of the inheritance instead of his. He liked that and asked “how much does an overhaul cost?” The most honest and truthful answer that I could give him was, chuckling, “nobody ever really knows”. Over the next few months I will attempt to answer that question by sharing my engine overhaul adventure with you. As I incur expenses along the way, I will update this topic, explaining my thinking and keeping a running total along the way. I will tell you right up front, I am NOT a member of the CB Club. I consider myself the temporary Caretaker of N5479R, with the idea that when my flying days are done, this airplane will continue to provide transportation and joy to the next Caretaker. On Sunday, April 18th, the engine and accessories were removed in preparation for this project. Total costs incurred for this step was $385.00 paid to my IA. Monday, April 19th. Today I returned to Zephyrhills Airport to meet the guys from Zephyr Aircraft Engines so that they could pick up my engine and take it to their shop. My engine will receive a major overhaul to factory new limits with all new cylinder assemblies, a new upgraded camshaft, an overhauled carburetor, new starter, new magnetos and wires, plus whatever repairs are needed to the crankcase and crankshaft. Estimated cost is $23,600 and I paid a 40% deposit today in the amount of $9,440.00. I also took my engine mount and exhaust system over to a local pack and ship outfit. These items are being sent to Aerospace Welding in Eagan, Minnesota for inspection and repair. The mount has not been off the airplane since Cessna installed it during the summer of 1974. So it is long overdue for inspection. I am anxious to see how much of it will need to be replaced. The shipping costs for these items, including the custom packaging, Fed-ex Ground and Insurance coverage was $470.01 for the exhaust system and $536.46 for the engine mount. This brings today’s total to $10,446.47. Total overhaul project cost to date: $10,831.47.

-

Multi-engine instruction...Mission Impossible?

BKlott replied to BKlott's topic in Miscellaneous Aviation Talk

UPDATE*** Received a call from a CFI at the FBO I contacted. Looks like I am in business after all. I’ll keep you posted. -

It started back in 1990 while I was completing my Commercial ticket training. The FBO at the airport where I based my Grumman Cheetah had acquired a Twin Comanche that had been sitting for some time. They pulled it into the maintenance hangar and started working on it. They even put a couple of remanufactured engines into it and placed it on the rental line. As a reward for passing my check ride, I treated myself to an hour of dual in the twin. Two things stand out from that lesson. First, I was so far behind that thing that we were climbing through 1,100 feet when my CFI suggested that it might be a good time to start our turn to crosswind. Second was the fluctuating fuel pressure gauge on one engine during our pre flight run up. After landing, my Dad commented that when we flew across the field to switch the pattern due to changing winds, “that thing sounded awful”. Maybe that is why we cut the lesson short at .7 and my CFI had me park the plane in front of the maintenance hangar instead of at the fuel pumps as we would normally do. It turns out that the fuel pressure fluctuated and the plane sounded “awful” due to the fact that the intake manifold on one engine was loose. I didn’t fly the plane again before it was sold to a new private owner. Some years later, at the same airport, I watched a Cessna 310 lose it’s right engine at rotation. He elected to continue the takeoff and it did not turn out so well. He killed himself, his wife and their teenage daughter in front of their relatives who they had just spent the weekend with and had delivered them to the airport. I will never forget the woman on the ramp going berserk or the color of that column of smoke rising from behind the tree line West of the field. In 2004 I decided to try to overcome my fear of twins and scheduled a lesson in a Seminole. Had a good lesson, made a good landing for my first try and it didn’t really bother me being in the airplane...once we got the takeoff behind us. I guess the $400+ bill for .9 must have discouraged me from pursuing it further at that time. My log books still reflect a whopping 1.6 hours of multi-engine time. I am retired now, financially secure and starting to work on the bucket list while I still have the ability to do so. The Multi-engine Rating is on my list of “unfinished business”. I started studying again this year, watching videos and getting ready to schedule some lessons, only to find out that scheduling dual in a twin is nearly impossible to do. After thoroughly considering the subject, I decided that I wanted to train in either a Duchess or possibly a Grumman Cougar. They are both known for docile handling characteristics, have upright seating positions which I prefer and would both be candidates for possible future ownership if I liked flying them and decided to go nuts. I tried to contact an out of state school with a Cougar and a great reputation by filling out the contact page on their website. To date I have received no response. Four local flight schools, by local I mean within two hours of driving time, offer training in a Duchess. I visited one school and asked to see their Duchess. The Manager asked the girl working the front desk to walk me out to the plane, which turned out to be beat up looking. While out there, she confided with me that “This plane has problems. Don’t be surprised if it goes down for maintenance during your training.” This was the replacement Duchess for the one that crashed following a power loss on departure during a check ride. The engine failed because the Bendix mag drive fell off the back of the engine. Want to fly there? I checked the three other schools pricing. Two were comparable and one was $75 per hour more. I decided to schedule dual with the one that has two Duchesses available and had won the AOPA Best Flight School Award a few years ago. I called them up last Friday and told them that I was interested in getting my Multi-engine Rating and that I wanted to schedule some dual to get started. Silly me. That is how we used to do it but apparently that is not how you do it anymore. Now you have to leave your name and number because someone is in a meeting and they’ll call you back. Oh, they may not get back to you until Monday. They didn’t call back Friday or Monday so I guess I won’t be flying tomorrow as I had hoped. Then I remembered that I had previously attempted to obtain information from this outfit before by completing their contact page on their website. Like the out of state FBO, they never replied either. Maybe that is why the Leesburg outfit charges $75 per hour more than the others. At their school, you actually can get on the schedule and fly their airplane. That is probably worth $75 per hour right there. The other outfit states that their average time to Rating is 15 hours, which probably is more a comment on the school than the students. They have some unfavorable reviews out there. Of course, they would be the closest and most convenient choice. I have no idea how this story is going to turn out. In the olden days, renting airplanes and obtaining dual was so much easier. I can remember just walking in to the FBO at the old West Pasco Airport and asking if I could get checked out? The CFI was sitting behind the desk, grabbed the keys and off we went. The good old days...