SpamPilot

Verified Member-

Posts

72 -

Joined

-

Last visited

Profile Information

-

Model

M20K Rocket 305

Recent Profile Visitors

3,305 profile views

SpamPilot's Achievements

-

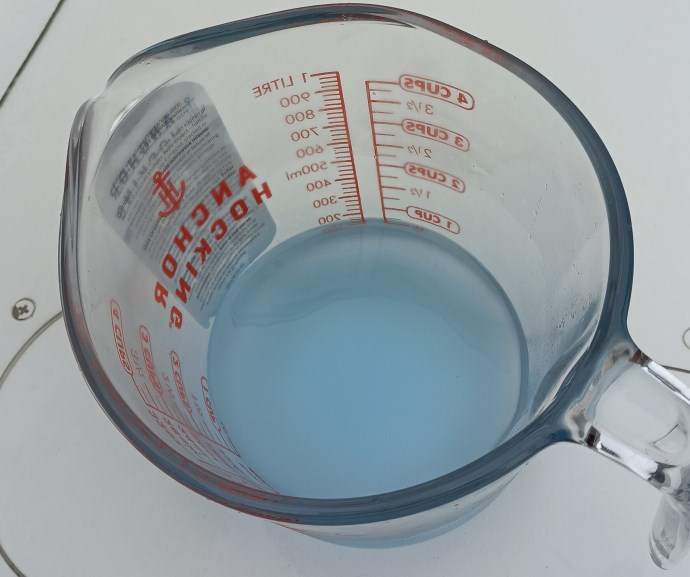

I previously reported the one encounter I have had to date with fuel system icing, causing the engine to sputter, briefly, due to fuel starvation, despite having sumped the tanks and found no water in them. Since then I have remained vigilant about checking my fuel for water and using 99.9% isopropyl alcohol prophylactically, particularly during winter months. This weekend I found water in my fuel and thought I should share my experience. When removing my fuel tank caps, I am careful to dump any water that has accumulated under the cap lever away from the tank opening. I do see occasional drops or blobs of water on the tank flap under the cap. By some magic of surface tension, water does not seep past the flap and instead collects on top of it, allowing me to remove it with a paper towel. Fuel drains right past the flap, so the flap acts as a sort of fuel/bulk water separator. I use silicone gaskets for the fuel cap. I have never seen any more than a drop of water at most in my sample cup when I sump the tanks, and even that's rare. This weekend I drained several cups of fuel and all I saw was this: The fuel was an opaque milky blue. Adding a small amount of isopropyl alcohol turned it clear, confirming the presence of entrained water. This was a surprise, as I had added about 12 ounces of 99.9% isopropanol to each tank the previous evening before getting a fillup from the FBO fuel truck. I reported it to the line guy, who affirmed he had personally checked the fuel in the truck for water and found none (my suspicion is that he only checked for bulk water; if there is a water absorber on the truck to pull suspended/dissolved water out of the fuel, it probably needs to be changed) . Unfortunately, I was not as prepared as I should have been for the trip and had just used the last of the isopropanol I normally carry in my airplane. I get 99.9% "medical-grade" isopropanol off of Amazon (e.g. https://www.amazon.com/gp/product/B08HX5VCYJ). It's currently $10/quart, which I consider a good value. Local drugstores carried only 91% isopropanol, which I elect not to use since I assume the remaining 9% is water and that seems like too much. I found this discussion on MooneySpace where people mentioned using ISO-HEET (red bottle) successfully. I ran out to an auto parts store and bought every bottle on the shelf. Here are my thoughts and observations about ISO-HEET: - In the discussion mentioned above, neilpilot stated that ISO-HEET is "100% alcohol" and kortopates stated that ISO-HEET "is 99& alcohol and 1% proprietary". Neither cited a reference, so I was cautious in interpreting those claims. I found two MSDS for ISO-HEET, and they have potentially conflicting information: https://www.in.gov/fssa/thehub/files/heet-antifreeze-iso-gas-line.pdf, dated 2010, supports kortopates' claim that it is 99% isopropyl alcohol and 1% "proprietary". https://media.napaonline.com/is/content/GenuinePartsCompany/136832608pdf?$PDF$, dated 2019, says something different. It says that ISO-HEET is >=75% isopropyl alcohol and 0.075-0.15% ethylbenzene. Ethylbenzene is apparently a normal component of aviation fuel, so perhaps it's nothing to worry about, especially in such a low concentration. What worries me is the up to ~25% that isn't mentioned. An MSDS "must list the chemical name of all hazardous ingredients", so apparently up to ~25% of ISO-HEET could be non-hazardous chemicals. Not sure what that could be other than (mostly) water... Not knowing what it is doesn't give me any comfort. - neilpilot stated, without reference, that "One bottle [of ISO-HEET] is the perfect size for one tank". Even assuming that ISO-HEET is 99% isopropanol, my previous experiences using isopropanol suggested that a mere 12 oz bottle of it might not be enough. So here for everyone's benefit is the result of my original research. You see from the image above that I had a full tank (40 gallons) of milky blue-white 100LL (at an ambient temperature of 45F) to which about 12 ounces of 99.9% "medical grade" isopropanol had already been added, and it obviously wasn't enough to clear up the fuel. First, I added a small amount of ISO-HEET to the sample shown in the picture and it turned clear, which I interpreted to mean that the entrained water was now successfully dissolved into the fuel, so the ISO-HEET was "doing its job". Then I added not one but three 12 oz bottles of ISO-HEET to the 40 gallon tank and sloshed it around for several minutes by pushing on the wing. I then sampled the fuel and it was still milky blue-white. Ultimately I had to add eight bottles of ISO-HEET and slosh it around before the fuel cleared up. That's 3 quarts, and that's on top of the ~0.375 quarts of 99.9% isopropanol I had already added. Note that Mooney SIM20-64 permits up to 3% isopropyl alcohol by volume for the M20K 231 (and 1% for other models, based on the respective engine manufacturer's recommendations). 3% by volume is 4.8 quarts in a 40 gallon tank. I flew the airplane home and the engine ran fine. - I want to say something about the difference between the (certified) airplane world and the automotive world. ISO-HEET isn't made for the airplane world. I'm sure its manufacturer would completely disown any claim to be a suitable fuel system de-icer for aircraft. More to the point, there is no legal requirement, beyond stating certain broad ranges on an MSDS, to confirm that the product is guaranteed to have a specific composition or achieve a specific result. There is no legal requirement that it even be the same thing from year to year or production lot to production lot. The bottle itself doesn't make any specific claims about the composition of what's inside it, only that it "helps prevent fuel line freeze-ups" (this is a meaningless marketing claim, not a performance claim) and that it does contain at least some isopropyl alcohol. When I was pouring out all those ISO-HEET bottles into my tank, I noticed that some of the product was colorless water-clear and some was almost urine-yellow. I take that to mean that different ISO-HEET mixtures could have significant compositional differences and still be sold as ISO-HEET. That's not comforting when airborne and your life is on the line, but it's perfectly acceptable for the automotive world (and typical of so many aftermarket automotive chemical products that are marketed based on little more than snake oil claims). As such, you should definitely not interpret my successful flight home as an indication of ISO-HEET's suitability for this application. - Somewhere I saw a comment that, instead of ISO-HEET, one pilot advocated using E85. I considered E85 briefly until I looked up its composition. E85 can have as little as 51% alcohol and still meet the ASTM-5798 spec. E85 octane rating is determined by a much different method than 100LL, and again it's an automotive product, not an aviation product, so not subject to the same rules. Whether or not it works, I suspect both manufacturers and the FAA would argue you are crossing the line between using a recognized fuel system additive and fueling your airplane with an unapproved fuel. - I'm going to stick with 99.9% "medical grade" isopropanol. It's not an aviation product and isn't sold through a distribution network that can guarantee traceability, conformance with standards, and accountability for problems (like aviation fuel is). But it is a recognized fuel system additive for this purpose, it's a nearly pure chemical, and the product I buy is from an established supplier (assuming it's not counterfeit). It's also marketed under a very specific compositional claim that would expose the supplier to a certain level of legal jeopardy if they intentionally or unintentionally violated that claim. One more thing to mention for completeness: Both tanks had milky blue-white fuel, but one tank required only about a quart of ISO-HEET to clear up. That was the tank that got less fuel from the FBO truck. The aircraft did sit through rain, but it sits through rain all the time at my home airport year-round and I have never had entrained water as a result.

-

Having previously educated myself on the supposed non-event of the cabin door opening in flight, both as the POH describes and as Mooney lore across the Web discusses, I was quite surprised at my reaction both times it happened to me in my M20K. I found it difficult to control the panic reflex and avoid distraction, despite forcing myself to continually repeat "Aviation, Navigate, Communicate!" and "Use your checklists!" and "Keep your speed up!" and "The aircraft is still flying, relax!". Your reaction may vary; you are a better man and a far better pilot than I if you have ice water for blood and remain calm, cool, and unperturbed throughout the event. The first time was at cruise altitude, with a passenger. We couldn't get the door closed, so I instructed the passenger to just hold it as closed as possible and we landed at the nearest airport. Having a passenger there to hold the door closed did help me to focus, but honestly it was much harder than I expected. The second time was solo, a few minutes after takeoff, at about 2000 AGL. Both times the cockpit got very loud, which I found terrifying even though intellectually I knew better. At first I thought the turbo had fallen off and I was about to become a fireball - it's not as if the door just obviously swings wide open. I didn't try too hard to close the door - that involves briefly giving up on flying the aircraft as well as giving up on seeing and avoiding, so I elected not to prioritize that at 2000 AGL. I returned to the airport "normally", but again I have to emphasize that it was a major effort to overcome the adrenaline and fear in order to make a "normal" approach and landing. Yes, given the noise in the cockpit, talking to Tower was a challenge, not impossible but it's one more layer of difficulty and uncertainty that was working to panic and distract me. The aircraft was also fairly new to me - I got the door sorted out later - but even with a thousand hours in a previous Mooney, it was another layer of uncertainty I had to force myself to mentally suppress. What got me through to safe landings both times was recognizing that fear could overcome me if I didn't follow my training, minute-by-minute acknowledgement that the airplane was still flying just fine, rigorously using my checklists, and repeating my airspeed mantra throughout the approach. Another time I found the baggage door open at runup. Flying with a buddy that day (who also flies a Mooney) was just enough of a distraction that neither of us noticed that the baggage door was still open until we had already taxied to the runup area, even though we weren't complacent and were following checklists all along and not chit-chatting about random stuff. On that day it wasn't enough that I'm the only person allowed to close the baggage door. I missed the opportunity to instruct the other person (who didn't even need to be a pilot) how to check to make sure I closed and latched the baggage door. Now knowing how much risk an open baggage door presents in flight (not to airworthiness of the aircraft, but to flightworthiness of my brain), I have added checking that the baggage door is closed to my checklist at three separate points. I do wish there were a way to check that the baggage door latch is latched from the pilot's seat. This new accident has me thinking how I might accomplish that. Maybe just a small plastic mirror mounted to the inside of the cabin door would do the trick, allowing me to open the door (while on the ground) and angle it just enough to visually confirm the state of the baggage door and latch.

-

BTW, thanks to goodyFAB for posting a few months back about the turbine inlet gasket, with pictures: https://mooneyspace.com/topic/43361-rocket-parts I see I am going to need a TCM 640877, in stock at Spruce. I'm also going to need a Cessna wastegate gasket 9910306-1, also in stock.

-

Yeah, it has become increasingly difficult to get a response from Rocket. Their answering machine said "send us a detailed email to rocket@icehouse.net", so I have done that and am awaiting a response. Was hoping someone here might have gone through this already and know the drill for repair vs. rebuild vs. replace.

-

During annual, my A&P found a crack in the exhaust transition tube in my Rocket 305 by pressurizing the system and applying soapy water. The bubbling was undeniable. I asked for a dye penetrant inspection so we could get a good picture of it: It's right there next to and parallel to the weld. This is the weld on the pipe headed off to the wastegate. No CO has been observed in the cabin on the digital CO meter. This is the Rev D transition tube. It was installed in 1995 to comply with AD 95-17-06. It's the beefier tube that permits lengthing the inspection interval to 100 hours. Has anyone had to deal with this? Is the transition tube repairable or rebuildable?

-

Why does my Rocket have a dent in its exhaust?

SpamPilot replied to SpamPilot's topic in Modern Mooney Discussion

Thanks to everyone who replied on this thread. I figured I'd provide an update. Four years and ~400 hours later, there has been no change in the condition of this dent, and no evidence of cracking or leaking. My A&P is unconcerned about it, so we'll just continue to monitor it. I suppose one thing going for it is that this is after the turbocharger turbine, so you'd expect temperatures to be a few hundred degrees less than TIT at high power settings. This would help with respect to both strength and creep resistance of the exhaust pipe material. -

Flying my M20K 231/Rocket 305 through eastern Washington this New Years weekend at 14500 MSL in VFR conditions, I felt some light turbulence. After about a minute, it occurred to me that the turbulence was not changing in amplitude like turbulence usually does. I considered whether it could be a small prop imbalance due to icing, but that would be strange since I had been in clear air since takeoff an hour earler. I considered whether it could be a cylinder misfiring, but EGTs were normal on all cylinders, and TIT remained where I had dialed it in. Manifold pressure remained at 30 inches, engine speed was still 2400 RPM, and I wasn't losing airspeed. Then the engine sneezed. That got my attention. I aimed towards the nearest airport, pulled out three inches of manifold pressure, pointed the nose down, and popped the speedbrakes. The engine sneezed one more time on descent, but I stayed focused enough to run all my checklists and grease the landing. Maintenance wasn't available on the weekend, so the aircraft sat on the ramp, shivering ignominiously in sub-20F temps. First thing Monday morning, we brought her into the hangar and immediately pulled a belly pan and opened the gascolator/sump to look at the fuel strainer screen. It was partially coated with what looked like a very thin paste - imagine spreading the thinnest possible layer of white or maybe grey toothpaste over the screen, then wiping it off so you could see through it. Over the next 30 seconds, in the warmish hangar, the paste melted and turned into beads of water. This topic has been covered on the forum in the past (e.g. So whats too cold for the plane and IPA Winter Ops), but I figured a fresh PIREP is always a good PSA. In reading through those topics, I noticed a couple comments that deserve a response. kortopates wrote "I really don't believe there is risk of fuel becoming saturated with water unless there is more moisture than just humid air in the tanks" but then, in a very gentlemanly and helpful way, he retracted his statement and shared Mike Busch's observations: He [MikeB] told me there is a real risk of dissolved (undrainable) water coming out of solution at low temperatures and freezing into ice crystals that can cause engine stoppage. He knows of several emergencies that occurred because of this, although it's definitely not common. Mike says these incidents don't occur in the wintertime as far as he knows. He says the major risk is taking off from a low altitude airport where the temperature and humidity are high and the fuel has become heat-soaked because the aircraft has been sitting in the sun for some hours, then climbing up to the Flight Levels where the OAT is very cold. It takes very hot fuel that can hold a lot more water in a dissolved state (as you pointed out before). The conditions leading to this issue have always been summertime conditions though, not winter. I will simply add that 1) it's winter now, and very very cold for the Pacific Northwest, and 2) I fueled (almost 60 gallons to top off) from an above-ground tank that was at below-freezing temperatures. Thus, I have an existence proof that it can happen in winter with cold fuel. jlunseth wrote of his experience never having this problem: "Fuel gets put on board at ground temps which are warm, and in relatively humid conditions. Then I go to altitude, stay there for 4 hours at -25C, and nothing happens. " Well, this happened to me after only 1 hour at altitude, and yes the OAT at that altitude was -25C (=-13F). I do have many hundreds of trouble-free hours flying this aircraft and another Mooney at temperatures significantly below freezing, though usually never lower than -10C. This happened to be the first time for me in this aircraft flying at -25C. I had done a thorough sump/drain before my flight and there was no evidence of liquid water at all. After observing the ice crystals in the strainer screen, we drained half a gallon from the wings and the sump and there was still no evidence of water. For those who haven't followed the threads, the culprit is water dissolved in the fuel, not free liquid water. 100LL can't dissolve much water, but water is not completely insoluble in fuel, and having tiny amounts of water (on the order of 30 parts per million) dissolved in the fuel is OK so long as it remains dissolved. Sub-freezing temperatures and nucleation sites (perhaps even localized turbulence as fuel flows through a fine mesh) will cause the water to precipitate out as microscopic ice crystals. Once an ice crystal forms, it's going to continue to grow as more fuel flows past it and dissolved water preferentially attaches itself to the crystal structure. These crystals can attach themselves to rough surfaces, get caught in fine mesh screens, or plug tiny injector orifices. For you chemists who are concerned about the proper use of the word "dissolved", I admit I don't know if the water is truly dissolved in the gasoline (= in solution on a molecular scale) or simply finely divided and in suspension (= extremely tiny water droplets that are still orders of magnitude bigger than molecular scale). AC 20-125 discusses "entrained" water and describes it as the latter. I will note that our white bucket test revealed the gasoline in my tanks to be both "clear=clean" and "bright=dry", with no cloudiness that would indicate entrained water. The solutions to the problem, as have been discussed elsewhere on this forum, are: 1) If the fuel is dry, ice can't form. Read AC 20-125 to understand the various ways water can get introduced into fuel. Use fuel from trustworthy tanking/pumping systems that are properly maintained. Make sure your gas cap O-rings are in good shape. Always sump your fuel to check for water. 2) If the fuel has water but remains above freezing as it travels through the aircraft fuel system, then small amounts (30 ppm or less) probably won't have any effect on operation. 3) Adding anhydrous isopropyl alcohol (IPA) to the fuel, in amounts not to exceed Mooney SI M20-64, encourages the water to dissolve into the IPA, which lowers the freezing point of the water, hopefully enough to prevent it from precipitating out as ice. 4) (my recommendation) After taking off from hot and humid conditions, or even cold and dry conditions, when flying for as little as M minutes in temperatures below N degrees C, choose an altitude and a route that give you good descent and landing options in case, like me, you encounter fuel system icing despite all the normal precautions. In my case, M was 60 and N was -25. I am congratulating myself on electing to perform that flight on that day only because it was VMC and, in the event of a problem, I wouldn't have to descend through several thousand feet of icing conditions. I am also considering myself lucky that it didn't happen 30 minutes later over the Cascade mountains.

- 37 replies

-

- 13

-

-

-

- fuel system icing

- ipa

-

(and 1 more)

Tagged with:

-

So it turns out that we *did* use an incorrect procedure to set up the weight and balance. You need to read the Service Manual very carefully, not just the POH. The A&P had not done that, and I had to do my own research and ask a few questions to uncover this. But the biggest problem was the scales turned out to be uncalibrated. You can't trust any numbers from uncalibrated scales, and you can't use uncalibrated scales for an official W&B. Having no calibrated scales, the A&P went with the "by calculation" method, after visually confirming the absence of any unaccounted equipment and having performed an excruciatingly detailed review of all the W&B changes going back to when the aircraft was new. The weight and CG now appear to be in family with the other 231 Rockets that have modern avionics and end up with a UL of 1050+- and CG > 43". We had removed about the same weight of avionics and wiring from behind the panel as was removed from the tailcone, but because the arm is so long to the tailcone, this means the CG shifted forward about half an inch in the process. That's not great news for a Rocket, but it's manageable. Flying with two modern-sized people in the front and full fuel requires at least 50 lbs of baggage to stay within the W&B envelope. I already fly with ~25 lbs of tools, oil, random gear I will probably never need, and tiedown ropes. On any trip I'm likely to take with one other person, we'll easily add another 25+ lbs of bags. When I fly locally with a CFI for training, I have some lead weights I put in the back. Charlie weights are a must-have for the Rocket. Interestingly, I can see in my logs that the Charlie weights were not installed back when the Rocket STC was performed, but were added just a couple months later. I do want to say that, while I am often near the front edge of the W&B envelope on takeoff (because I'm operating in the narrow "doghouse" area at the top of the Rocket W&B envelope), the aircraft is *not* nose-heavy. With correct trim, it flies itself off the runway with no back pressure on the yoke. It never slams its nose on landing, even those rare times when I (oops) drop it. I've seen lots of comments saying "it's nose-heavy", but that's not my experience. The big TSIO-520-NB up front is statically balanced by the two batteries way back in the tail, plus the Charlie weights. Odd that everyone focuses on the big engine and concludes "nose heavy" without considering all the added weight and moment arm at the rear which, by the same line of thinking, should give it a "tail heavy" reputation. With my O2 bottle in the tailcone, my CG is within 0.1" of the CG when the aircraft was born as a 231. Anyone who is experiencing a heavy nose flying a Rocket is, I'm guessing, probably not actually inside the W&B envelope, or is landing overweight, or both. If you are flying two modern males, full fuel, and no baggage, and especially if you don't have Charlie weights, you are probably forward of the CG envelope, at least with a 231-based Rocket. You also need to burn off fuel before you land to get below the landing weight limit. Load and fly it according to the CG envelope and it flies and lands just fine.

- 5 replies

-

- 1

-

-

- rocket 305

- weight and balance

-

(and 2 more)

Tagged with:

-

I've been enjoying my Rocket 305 for three years now. I've made a few upgrades along the way, always dutifully tracking the changes in the Weight and Balance log. I have also corrected a couple major mistakes in the math made long ago. Starting from the original factory Basic Empty Weight of 1923 lbs @ 43.4", 290 pounds of new equipment have been added to the aircraft (mainly the Rocket 305 conversion, built-in O2, and Charlie weights, plus a new COM radio and two G5s). 90 pounds of old equipment originally delivered with the aircraft have been removed (KFC 200, KCS 55A system, BX2000 system, and associated wiring). Q: How much *should* the aircraft weigh now? (Basic Empty Weight, including 10 gallons unusable fuel for the Rocket 305) A: 2123 lbs (@ 43.5") Q: How much does the aircraft actually weigh? A: 2273 lbs (!!!!!!!!) (@ 36.5") (!!!!!!!!!!!!!!!) Obviously, I'm freaking out. That's a 150 lb increase and a 7 inch forward CG shift that are unaccounted for. I've been all through the airplane with my A&P. There's nothing we can find that comes anywhere near explaining even a 15 pound difference, much less a 150 pound difference. The panel looks like a ghost town with all of the ancient avionics gone. I've got 20 lbs of wiring alone that was just removed. There are no errors remaining in the historical W&B entries. I read with great interest Rspencer612's topic Mooney Missile CG. I read about the possibly incorrect arm for the main and nose axles. Even if I can justify ignoring the actual measurements we made, adjusting to the referenced numbers still leaves the CG off by at least 3" from where I expect it to be, and where other Rocket 305s are. I also read that Rspencer612 appears to have resolved his problem by installing the Charlie weights that had never been installed when the Missile conversion was performed. In my case, though, the Charlie weights are definitely installed. I also have a heavy O2 bottle that should be biasing the CG well rearward. We tried this with two different scale sets, and they agreed to within 0.2%. Yes, we followed the correct leveling procedure, twice. We weighed with full tanks and subtracted the weight of 70 gallons usable fuel, per the POH weighing instructions. Has anyone seen a ~150 lb weight increase *and* been able to explain it? I read some comments on this forum and elsewhere about significant weight gains in aircraft as they age, but I haven't found anyone that was actually able to confirm the source of the gain (as opposed to just guessing that it might be dirt and oil, etc.).

- 5 replies

-

- rocket 305

- weight and balance

-

(and 2 more)

Tagged with:

-

Gentle Mooniacs, In the face of an upcoming official reweighing of my M20K (after wholesale replacement of my old avionics with newer, lighter, better equipment), I have been pondering the collective wisdom on how one is supposed to determine unusable fuel, both for W&B purposes as well as flight planning. I'm pretty sure the collective wisdom is wrong. I read in these pages some who advocate using the fuel pump to drain the tanks, and then weigh the aircraft on that basis. Even my A&P, who has done this hundreds of times, was going to follow that very same procedure on the basis of "I've never seen it done another way" until I explained why it was wrong, or at least incomplete. I also read in these pages some who advocate establishing their minimum usable fuel level by running one tank "dry" in cruise flight, landing on the other tank, and then filling the "empty" tank to determine maximum usable fuel volume. This is more for flight planning purposes than measuring aircraft weight, but it's basically the same approach and result. The thing is, neither approach respects the intent of "unusable fuel". It turns out "unusable fuel" is a formal term defined by the regulations that govern the design of certificated aircraft. The regulation is 14 CFR 23.959, which reads, in relevant part: "The unusable fuel supply for each tank must be established as not less than that quantity at which the first evidence of malfunctioning occurs under the most adverse fuel feed condition occurring under each intended operation and flight maneuver involving that tank." My translation of this is: don't think about level flight, think about approaches and go-arounds. I believe you are at increased risk and not in compliance with regulations if you determine unusable fuel/minimum usable fuel by the common techniques of running a tank "dry" or pumping fuel until the flow stops. In both of these cases, you are not measuring the "most adverse fuel feed condition occurring under each intended operation and flight maneuver involving that tank". The most adverse condition of intended operation is neither level flight, nor sitting on the ground in a near-level-flight attitude. The most adverse condition is probably a steep descent, but it could also be a steep ascent, and maybe one should consider a smallish amount of uncoordinated flight at the same time. It would depend on the fuel tank geometry vs. fuel pickup location. Some aircraft (not Mooneys, except maybe the Mite) use header tanks to manage fuel flow under adverse feed conditions. Forward slips are also an adverse feed condition on the tank in the downhill wing, but there is an operating limitation warning you not to perform forward slips with low fuel in the downhill wing, so it's not an "intended" operation for the tank in question. In any event, you should want to ensure you have enough fuel in the tanks so you do not unport the fuel pickup during any normal maneuver (including unplanned maneuvers) you might need to perform in order to ensure the continued safety of flight, which includes go-arounds and steep approaches to landing. (certification nerds will point out that most Mooneys are largely certfied under CAR 3 and not Part 23; I did not check CAR 3 for similar language, but regardless, I think Part 23 expresses the correct requirement) The "optional" Mooney weighing procedure, which has you pump the fuel out and then add back in the specified unusable fuel, appears to take this into account. The standard Mooney weighing procedure, which has you weigh with full tanks and then subtract the weight of the specified amount of unusable fuel, also appears to take this into account, though it has more opportunity for inaccuracy due to the fact that a tank being "full" is a function of at least ground slope, uneven tire pressure, fuel temperature, and filling technique.

-

"Dynon supplies the ARINC interface for connecting a certified IFR navigation source. It looks like the 375 is a certified IFR source. I would go along those lines. " Going along those lines puts one in direct conflict with the language of both the STC and the GNX 375 install manual, so one can't simply go along those lines (at least not without getting a Field Approval). Even the Dynon installation manual says you have to comply with both the Dynon and the third party manuals.

-

Thanks to those that have commented so far, I appreciate it. I'm not disputing it will work, but it sure looks like it is not legal. The STC clearly states that the GNX 375 must be installed IAW the installation manual. The installation manual clearly states that any device connected to the GNX 375 not on the compatibility list requires "additional airworthiness approval". The SkyView HDX is not on the compatibility list. Therefore it's not legal to connect the GNX 375 to the HDX without additional airworthiness approval. This means a Field Approval. I am not an A&P (or lawyer), but you don't need an A&P to explain this to you. The language is plain and clear. FWIW, my avionics shop did confirm this explanation. I did talk to Dynon. Their response was friendly, but it didn't clear anything up. Although I asked, they made no claim that connecting an HDX to a GNX 375 was, in fact, legal. I interpret that to mean they are aware of the issue, they (wisely) won't make any claims that it is legal, and they are (appropriately) leaving it up to the purchaser to figure out with the help of their A&P/IA (as anyone should). They provided no guidance on how to obtain a Field Approval. They did provide a wiring diagram, which is helpful, but anyone can draw up a wiring diagram. It does not equate to airworthiness approval. Moreover, the HDX Certified installation manual says: "When connecting to third-party products, refer to the Dynon Avionics instructions as well as the product manufacturer instructions to ensure the products are configured and wired for compatibility with the SkyView HDX System." When you follow these instructions (which is required by the HDX STC), and you consult the GNX 375 IM, you find that the GNX 375 IM contains no instructions that would enable you to configure and wire the GNX 375 to an HDX. Instead, you find that the GNX 375 IM has a compatibility list and is resticted to connecting only to devices on that list, and the HDX is not on it, whereas some other EFISes are. There is no "generic" ARINC 429 installation. The IM does allow connecting to devices not on the compatibility list subject to "additional airworthiness approval", but gives no guidance on how to obtain that approval (and neither does the Dynon IM). It may be that a Field Approval is easy to get for this, in which case it should be straightforward for the GA community to share the data that the FAA accepted, or better yet for Dynon to provide such data since they have a financial interest. With respect and without prejudice, I would say it may also be that a Field Approval is hard to get, or at least an unknown, and hopeful owners are using shops who have overlooked or not researched the plain language of the STC. It did take me a non-trivial amount of time to piece this together. An A&P/IA signing off does not make the installation legal if it was not installed IAW both installation manuals. Since the owner is responsible for airworthiness, accountability in that case points back to the owner. Again, it's totally fine to have both installed, you just can't connect them without obtaining a Field Approval. And I'm not complaining about the fact that the HDX isn't on the GNX 375 compatibility list. Dynon is under no obligation to talk to Garmin and vice versa, it was my choice to buy the GNX 375, and if SkyView compatibility were something I wanted badly, I had the opportunity to discover this issue before making my purchase decision. I would *like* to have an HDX in my panel. I would even consider installing the system without connecting it to the GNX 375 until such time as Dynon and Garmin talk and Garmin updates its compatibility list, or a straightforward process for Field Approval becomes documented. (I'm also willing to consider just going with a G3X, because it's compatible and I don't have to deal with any uncertainty.) My hope was that someone else in the community might say "oh, I've been through this, it was easy to get a Field Approval because the FAA recognized that it's just an ARINC 429 interface between the two" or "Garmin provided me with a letter confirming compatibility and the FAA was good with that" or "hang on, here's chapter and verse from the regs that explain why it is actually legal" or whatever.

-

I'm wondering if anyone can comment on their experience connecting a SkyView HDX to a GPS navigator. I'm specifically interested in the GNX 375, which I already have (maybe 231MJ can comment based on his GNX 175 experience). Here's the thing - SkyView is not on the compatibility list found in the Garmin 375 installation manual (some other EFISes are). The IM specifically says that any equipment not on the compatibility list requires "additional airworthiness approval", which my avionics shop says means a Field Approval. Since the STC for the GNX 375 requires that the GNX 375 be installed IAW the IM, then you are not allowed to connect the GNX 375 to SkyView, at least not without a Field Approval. You would expect a SkyView to be able to talk to the GNX 375 over ARINC with the appropriate interfaces, so that would address at least a part of the concerns you would need to address for a Field Approval. There might also be concerns that the ARINC implementation of the GNX 375 plays well with the ARINC implementation of SkyView. Yes, ARINC 429 is a standard, but SkyView is not TSO'd or otherwise independently evaluated with respect to requirements and standards, so when you have to certify the SkyView+GNX 375 as a system, there's no simple argument that allows you to conclude the combination is airworthy, especially for IFR operations. To be clear, the STCs allow you to install both in your panel, you just can't connect them.

-

Answers to some questions: - $1200 for the cert was on the West Coast, using a well-known avionics maintenance chain that typically deals in corporate jets. They diagnosed but did not fix a small static leak (see my post on the static drain leak), which added to the cost. They did get me in very quickly. My preferred shop on the field couldn't get me in for at least a month. - RG-58 has about 50% more loss per unit length at transponder and GPS frequencies than RG-400, but that's not enough to make a noticeable performance difference over the short runs you get in a Mooney (often less than 10 feet). Improperly crimped connectors are a different story, as would be corroded connectors. New question: Why does ATC care so much about Mode C anymore? I naiively thought ADS-B was supposed to provide ATC with the same (and better) information as Mode C. My ADS-B out was still working well, even when ATC couldn't get Mode C. My FlightAware track is pretty clean.

-

My GNX 375 with GAE 12 altitude encoder passed its IFR and VFR certs (91.411 + 91.413) just a few weeks ago. On a subsequent flight, in remote areas, ATC reported they were not receiving my Mode C. At these times, the interrogation indicator on the GNX 375, which should be going off at least once every 12 seconds when ground radar paints and interrogates the airplane, was inactive. My A&P checked it out and found a poorly made crimp on the BNC connector that connected the coax from the antenna to the pigtail at the back of the GNX 375 mounting tray. The connector pulled off easily by hand. He replaced the entire length of 40-year-old RG58 coax with new M17/128-RG400 coax and connectors. Do I need to re-do the recent IFR/VFR certs? (which cost me $1200, BTW; also BTW, I'm inside a Mode C veil, and under Class Bravo) I think not. My A&P is uncertain. I welcome opposing or supporting viewpoints, especially if anyone has direct experience. 14 CFR 91.413 covers transponder tests. It requires transponders to be inspected and tested every 24 months and found to comply with Part 43 Appendix F. Appendix F lists all the various tests that a transponder must pass. It does not require the transponder to be in the aircraft for such testing. You don't even need to connect it to an actual antenna - it's just a test of the transponder itself, not the coax that connects to the antenna. You can bench test a transponder and be in compliance with 91.413. More to the point, this clause doesn't require Appendix F testing to be redone after maintenance; it's only elapsed time that compels new testing. 14 CFR 91.413 and 91.411 also require an integrated system test per Part 43 Appendix E paragraph (c) when you perform maintenance "where data correspondence error could be introduced". "Correspondence" is defined in AC 43.6D. It is "the maximum absolute difference between altimeter display and encoder output for a constant encoder output". This is about making sure that the static system, altimeter, altitude encoder, connection from the encoder to the transponder, and the transponder configuration/interpretation of the data coming from the encoder are all working properly so the altitude reported over Mode C is within 125 feet of the panel altimeter reading. If, for example, you disconnect the altitude encoder from the transponder, or install a new one, you'd have to do the Appendix E paragraph (c) tests. If you opened the static system, other than by using the static drain port, then not only would you have to do Appendix E paragraph (c), you would also have to do Appendix E paragraph (a) per 91.411. So... 1) My 24-month test was done just a few weeks ago, so it's still valid. The 24-month transponder test regulation doesn't require you to re-test when you perform maintenance on the system. 2) You only need to re-test when you perform maintenance "where data correspondence error could be introduced". Replacing the coax between the transponder and the antenna is maintenance that is entirely downstream of the altimeter, altitude encoder, and transponder. It cannot introduce data correspondence error, because it doesn't change any of the subsystems or interfaces that are involved in encoding altitude correctly. 3) We didn't touch the static system, altimeter, or altitude encoder. The connection between the altitude encoder and the GNX 375 was not affected. We never removed the transponder from its mounting tray, and we didn't change its configuration relative to the encoder (or any other configuration item). 4) We did a function check on the ground and confirmed that the new coax to the antenna connection is working. The GNX 375 indicates that it is receiving and responding to Mode C interrogations. It's also getting ADS-B In, which uses the same antenna, and displaying traffic. I conclude that I don't have to redo the IFR cert. Thoughts? Comments?