Search the Community

Showing results for tags 'head'.

-

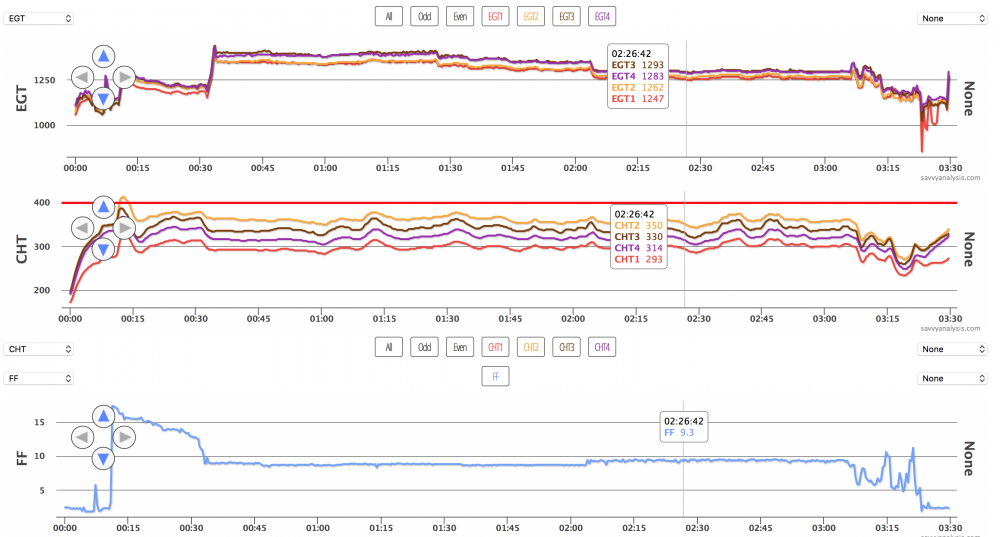

Quick question vintage Mooney officianado's, I've put roughly 35 hours on my new to me 67 M20F since taking ownership and finally was able to download the EDM 700 data. The engine is a Lyc remanufactured IO-360-A1A installed in Feb of this year by prior owners. Normal cowl but it does have the lower cowl cover. I'm seeing a consistent temp split between my #2 (hottest) and #1 (coolest) cylinder of ~70-80 deg F. (attached pic of data from one flight). Engine now running Aeroshell 100+...max fuel flow indicated during takeoff ~15-16 gph She runs smooth, during runup with the JPI Norm mode, all appears to respond as expected. Figured I'd ask if there is a 'normal' or expected temp differential between hottest and coldest cylinder...thoughts ?

- 13 replies

-

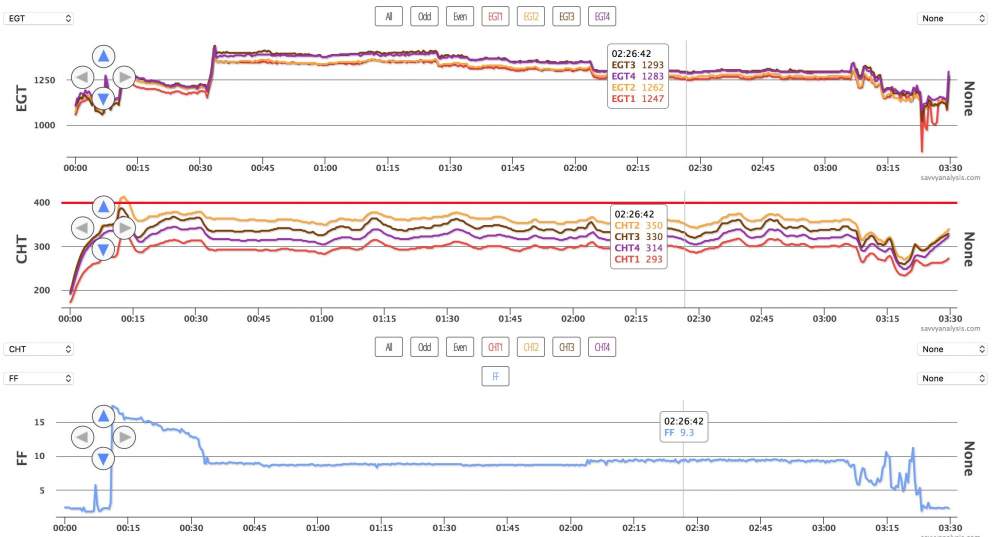

Mooney M20F, Lycoming IO360-A1A I thought would put this out there for some advice & feedback. Recently I had my mechanic examine my engine and he mentioned pooling of oil and possible cylinder glazing. Cylinder glazing is a condition that occurs where oil film left on the bore "glazes" to a hard coating and can prevent optimal sealing of ring to bore. The oil here is the result of cylinder head temperatures, CHT'S, not getting hot enough to burn this oil film and. thus prevent the glazing. Optimally, he says, the CHT'S should run about 360-380 F. My engine is seeing a range of 300-320 deg F with an OAT of around 34 F. This is with cowl flaps completely closed all the way, they are closed and flush with the rest of the cowling. All cylinders are running about within 10-15 degrees of each other & measured by JPI930 engine monitor. Of course, my goal is to get these temps into the suggested range. Just wondering if anyone is running into the same issue? what temps do you typically see? Has anyone found a way for the cowl flaps to create more flow restriction? has anyone done anything with engine baffling as to affect the cooling of the engine? Thanks for any feedback. 04/19/2018 -- ADDITIONAL INFORMATION: Thanks for everyone's feedback! what a great resource! I thought I would share what led to the inspection of the cylinders and a give a clarification of the above statements. On a couple of occasions, a ramp guy took notice of a puff of white smoke when taxiing up the ramp. Curiously, I mounted a go pro camera and focused it on the exhaust to try and observe it myself and of course, it never showed up. Recently, I pulled the cowl to check a few items and noticed oil coming out between the exhaust manifold and tube flange at cylinder#4. I immediately sent it in for service and it ended up being a bad valve guide. With all that said, cylinder#4 has undergone a rebuild and will require break-in, hence, the recommended higher CHT's. After clarification and reading all the great comments, this is why he mentioned the glazing and the importance of running higher CHT's. My fault on the interpretation. Fortunately, I do not have any cylinder glazing as all cylinders. were checked at this time. For those that asked, oil consumption has been in the normal range. I have 2 years of history (about 400hrs worth) and it ranges from 0.10 to 0.15 qt/hr. This looks to be well below even what Lycoming says is normal. I found this formula in their manual Normal Oil Consumption (Qt/hr) =(0.006 * BHP * 4) / 7.4. At a BHP of 0.59, this equates to 0.19 qt / hr. Compressions are all good ranging from 77 to 80. One question I do have for all of you, When do you typically add oil? Do you wait til it gets down below the 6qt mark, or, do you add it when it is hovering just above around the 6qt mark? I have been doing to latter. I have heard that these engines typically find their happy spot and then do not vary much. I may be adding too early as it may stabilize at 6qt. Any thoughts here appreciated.

.thumb.jpg.ed6aafa91f819cec0d83fd72d0471094.jpg)