jkarch

Basic Member-

Posts

179 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by jkarch

-

So a new curve ball-- what if I could get the same engine I have now overhauled by Penn Yan, the IO360-A3B6D with Superior cam and followers and Continental nickel cylinders, but where I don't have to put a bunch of extra money in for the mods, and can probably save 8K as shipping is paid both ways, costs 5K less, includes fuel lines etc, and I don't need to overhaul, just clean and IRAN the governor, oil cooler, and prop?

-

Byron, I appreciate that. I will make sure everything gets done, IRAN /clean at the minimum. I'm trying also to see if I can get the ElectroAir added to one mag while I'm at it too. But then another idea comes to mine. What is a timed out M20J with 2500 hours on the airframe worth with a GTN 750, GDL-88, and Flightstream 210? 85K? I wonder if it might make sense to go to a 231 from here, because I spend most of my time climbing above 10K ft. I like flying around Mt. Rainier at 17K with O2, and while I could usually get up there within 25 minutes or so in winter, the summer performance usually keeps me around 15 when I'm crossing the Cascades and Rockies. Seems like for 130K, which is what the plane might be worth with a fresh engine, I could get an equally nice 231 with a fresh engine, maybe with a 430W instead. Makes me wonder if it's better to let someone else do this, and jump on a turbo instead... But the roller lifters and good fuel economy does sound nice. Plus I've already done WeepNoMore on one tank and the other is still in good shape, and added fresh donuts recently, so it would be a shame to give it up with everything I've done to it.

-

Thanks Takair. Oil analysis interestingly showed no signs, the sign that I was tuned into was the fact that the UBG 16 bar graph showed #1 and #2 peaking much later (1+GPH) than 3 and 4. John Paul of GAMI suggested it because the GAMIjectors never got the flows any closer, but the cam wipe took a really long time. I must have added GAMIs 3 years ago because the engine ran a bit rough in flight. That smoothed it out but never fixed the fuel flow peak issue. At pulling it ran smoothly, just not as strong as I remember it. Only reason it's been pulled is it developed an oil leak out of one of the pins joining the two cases together, so we pulled the cylinder to inspect. I saw it coming, but three mechanics said fly it until the metal gets bad. Well once it was opened for this issue it was too late. I figure the prop can get cleaned, but the governor needs an IRAN and a retune for the new engine gear ratio.

-

Yeah the Lycoming Lead time seems a bit nuts.It may be almost three months. Wow. But I'd assume then my Factory Reman might be closer to a new engine because they have to make all the parts...Good to know about the wiring concerns. I'll have to check. Looks like the governor can be IRANed but has to be reset for the A3B6 model with a different gear ratio... Thank you!

-

Oldguy this is extremely useful! Much appreciated! I called Dan at Lake Aero in CA and he's looking into engine options including getting the correct oil line, governor mounts and a bunch of other things like properly sized oil and fuel lines. He's looking into a kit for me now.It's very much a pain in the butt. I think lead time could prove to be a problem since Lycoming is shutting down for a week in June too.

-

What I was told is they throw away the A3B6D cases when upgrading to the A3B6 and as long as the engine is assembled they will take it as a core but for reman or new only. They are much stricter for overhaul exchanges, with age limitations etc. I don't think I have a crack in the case right now, all I know is the cam's shot.

-

My other concern is what might be causing oil to leak through the through bolts, that might imply issues with the case as a simple press fit keeps oil out. At this point, I'd rather just divest myself of this engine. But I have heard that's a silly thing as the roller tappets taken out of a sudden stoppage engine looked okay and they still had to replace. I'm not sure what that's all about, though I've never so much as removed a cylinder in 800 hours since buying the plane.

-

Question is, what's better, roller tappets, or Diamond coated flat ones? I guess for me the other biggie is no more D2000 mag which was expensive to overhaul a couple of times.

-

I had a thread going on for a few months back in December/January where my EGTs in the front two cylinders were about 80-90F lower than the rear ones, and I suspected the cam (via John Paul of GAMI) but hoped it was a flow divider and fuel line issue. Turns out, while the engine ran reasonably well, the 1&2 intake lobes were wiped. I only found this because the #2 cylinder started leaking oil out of the bolts (and so did the #3 in the rear, which is odd). Fast forward 10 minutes after the cylinder pull: Ok Cam's wiped, but I suspected that already. I want a Lycoming Rebuilt IO-360 with two mags and roller tappets to replace the A3B6D. So, with budget limitations, what do I replace / overhaul? (1) Get a new dry air vacuum pump? It probably has 1000 hours on it and I want to keep doing IFR. I do have a standby vac system. (2) Remove air oil separator system? Do I still need this thing with a factory refurbished engine? (3) Governor's working fine, should I overhaul it? I've found small amounts of metal in the oil filter, but not too much yet. (4) Prop has about 800 hours since overhaul, no grease coming out of prop: reseal it? (5) Lastly, with a cam wiped engine, I was getting 150ish kts out of it, what should I expect from a J at 7500 feet and 2500 RPMs with full MP at standard temperature/pressure, say a standard fall day. (6) New engine mounts? Also looks like some mods were needed with the starter adapter or something to convert the A3B6D to the A3B6.

-

I’ll start a new thread on the “what next” section. I know there are some mods to upgrade to the true dual mag version with roller tappets.

-

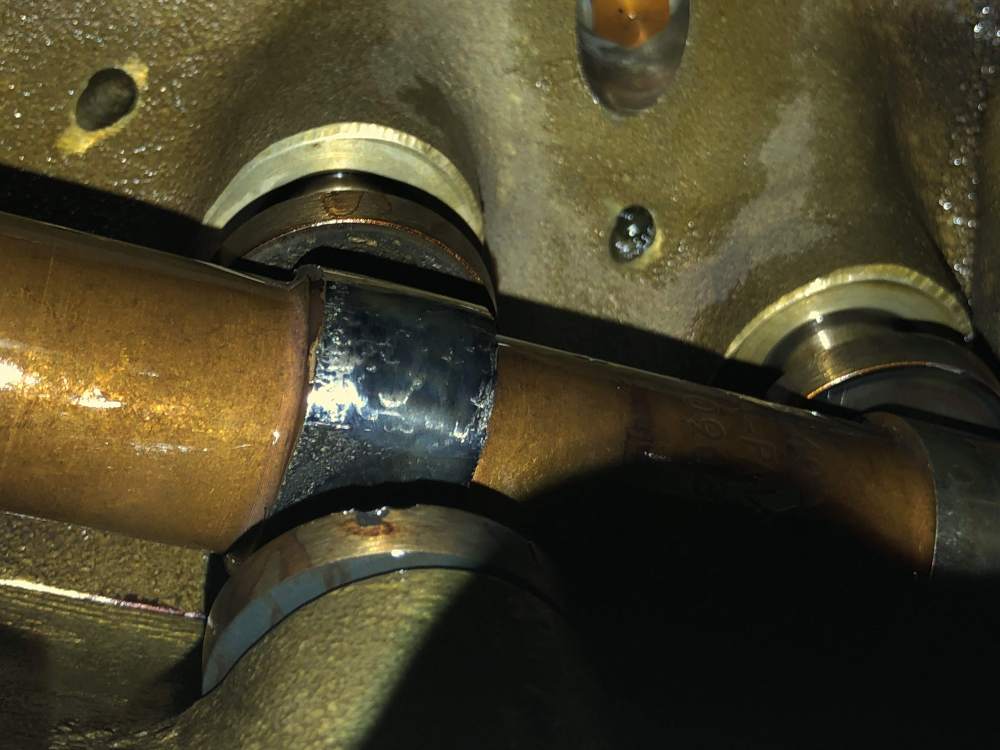

Yup, looks pretty worn down. 1&2. I wonder if I would get back a few kts with the new engine. I have been slowly going down to about 150 kts over a long time. It was closer to 154-155 when I got it although the cause may be related to sitting for five months outside before I bought it, or when removed from service for avionics upgrade which took six weeks about 4 years ago.

-

So now that the dirty deed is done, what should be redone along with the remanufacture? New vacuum pump, prop governor overhaul(or IRAN), and prop reseal and new mounts? I assume it makes sense to clean the gunk out of the prop and governor.

-

What’s rather strange is what precipitated the cylinder pull. It wasn’t related to the cam. Oil was weeping out of the cylinder to crankcase seal on front #2 and rear #3. I will be getting a factory rebuilt from AirPower so I probably won’t know what becomes of this single dual mag engine ... even better, the roller tappets will preempt this from causing overhaul in the future, and I will have a dual mag setup. I may even be able to eventually go 50 hours between oil changes now, as I usually do 28 between changes. While the new fuel lines actually smoothed out engine operation, it did not fix the GAMI spread too. Exhaust lobe looked good comparatively. Just as expected and predicted! And just prior compressions were all in the 70s so exhaust lobes were likely ok.

-

Well here’s an update. No surprise here. Started leaking oil out of front and rear cylinders. So finally had no excuse but to pull the cylinder I expected was a victim of a bad cam. Engine still ran great other than the annoying egt indications. But when front cylinder was pulled the answer was clear. Yup, John Paul nailed it. The damn cam and lifters. Time for a reman. -Josh

-

Much appreciated! I was checking the bank accounts to get ready and calling overhaul shops. Even if I’m 2-300 hours plus out it’s good to take stock.

-

I’ll have my mechanic do that tomorrow. Is there a particular document we should use for the procedure? I asked him to grab a dial indicator. I’ll check this and the screen tomorrow when I do the oil change. Isn’t any amount of magnetic material long past the initial break in a sign that a failure is within sight?

-

So this is what I found in the last filter. I’ll see if I can get my mechanic tomorrow to measure lift while we drain the oil. Does this seem like a lot of ferrous material? This is from 30 hours. -J