outermarker

-

Posts

246 -

Joined

-

Last visited

outermarker's Achievements

-

Hi, sorry about the troubles. I usually tire talc the inside of the tire, insert the tube into the tire with the valve stem facing the red dot side of the tire, insert both wheel halves, put some air into the tube, start the tie bolts so they hold the wheels together, move the tube/tire to confirm that the tube is not pinched and then torque the tie bolts. Align the stem with the red dot and inflate the tube. I normally go to 40psi on the mains.

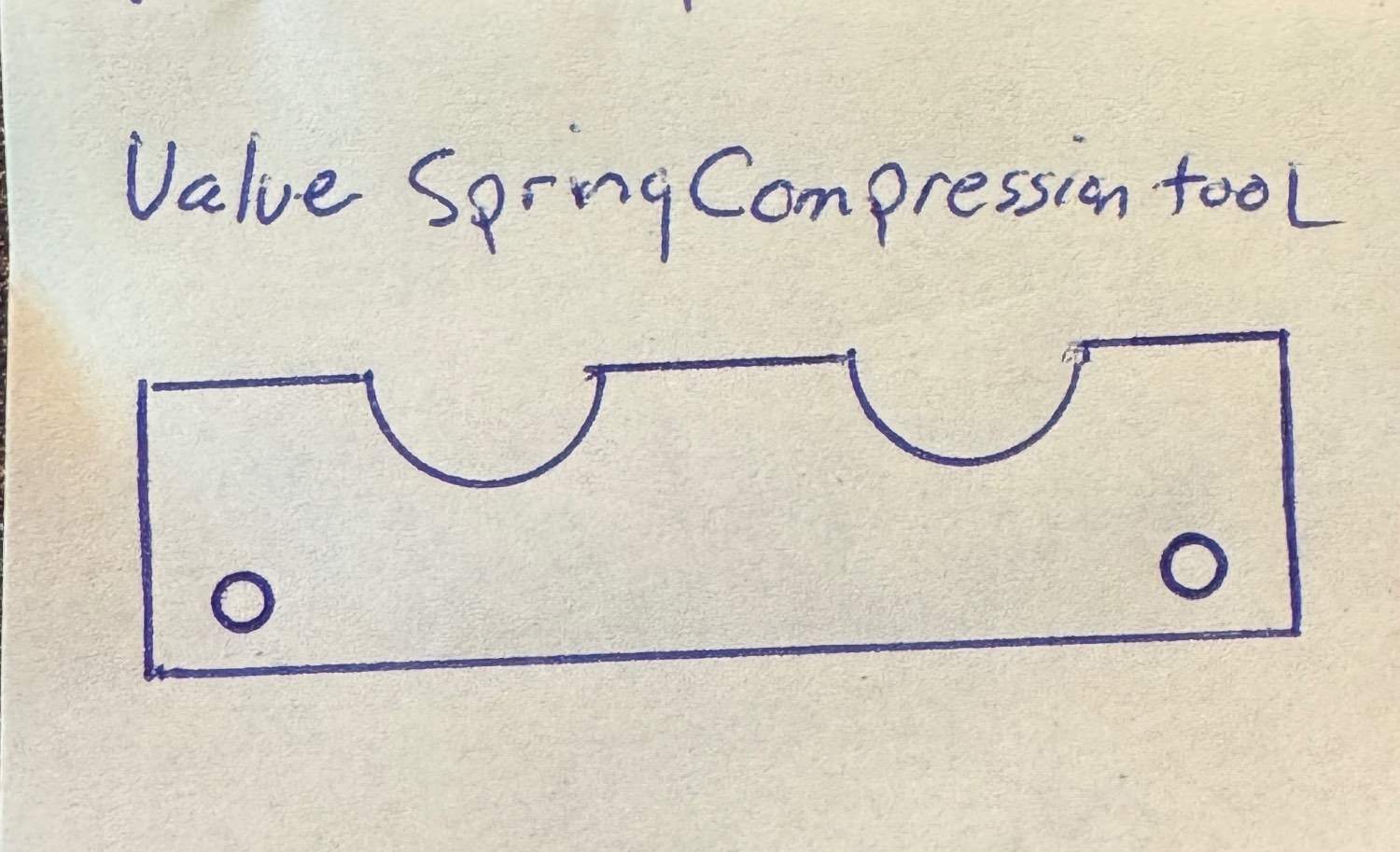

I made a basic install tool that allows me to run some all thread through the bearing hole and gets trapped with washers through some 2x4's. As I tighten the nuts on the all thread the wheel halves are drawn together making the tie bolt part of the job a breeze. Hope this helps. If not can I see some pics?