Grant_Waite

Supporter-

Posts

216 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Grant_Waite

-

I concur with this, 2 doors makes a huge difference for getting in and out. Diamonds are beautiful planes but also on the pricey side. The only diamond that’s comparable to a Mooney is the new da50rg which is a 1.5million dollar plane. I’ve also heard that the complexity of the whole fadec can make diamonds quite problematic but that was in the flight school environment.

-

I look at the options like this. If money is no concern go get a g36 bonanza. Cheaper to maintain than 350 has the same amount of seats and good load with speed. If you solely want to go fast with 2 people the Mooney is the best plane there is. And lastly the cirrus is just a good all around. Comfortable, cheaper maintenance but the parachute makes up for not having retract. I’ve never flown one but can’t imagine they are that bad. Bonanzas seating position is so natural and go decently fast, not to mention a high load for most 36 series. The mooneys are the pilots plane. They handle the best out of any plane but have heavy control forces in return. They are hands down the fastest but lack in useful load and options. Go fly all of them, roll around in the interior and take whoever is going to fly with you the most.

-

Mooney, are great planes don’t get me wrong but there’s quite a few parts that are impossible to get. Mooney doesn’t offer much anymore in terms of support or service. Lasar is hands down the best but they are working with a culmination of years of parts hoarding. The Mooney seating position is probably the most uncomfortable position of any of your choices. It’s unbearable but also not great. You can pick up a gen3 sr22T for about the same, most times less than a Mooney with nxi. Cirrus being in business is a huge deal but you need to plan ahead for parts. I love bonanzas but unless you need 6 seats I wouldn’t pay what a modern g36 cost. If you want to get places fast then a Mooney is the best choice. Just be ready for a limited selection of parts that’s steadily declining.

-

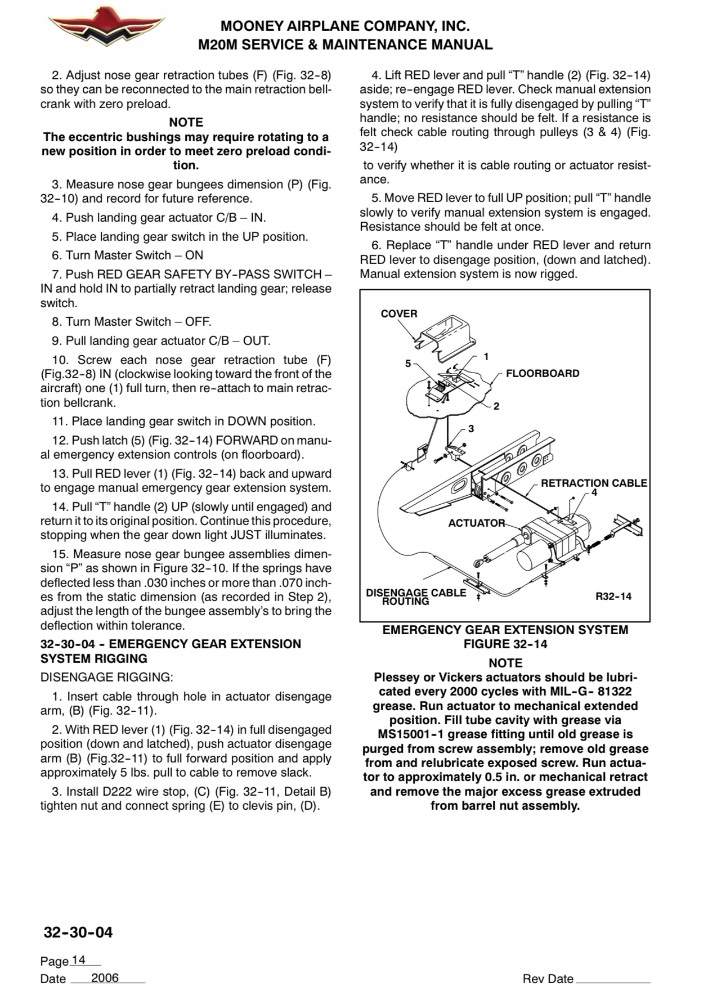

Hence, why whenever people talk about the lever being accidentally unlatched when the gear is down, the gear ceases to function because you’ve essentially disengaged it from its electrical function. Basically, the gear won’t come up when the lever is unlatched because it is not engaged.

-

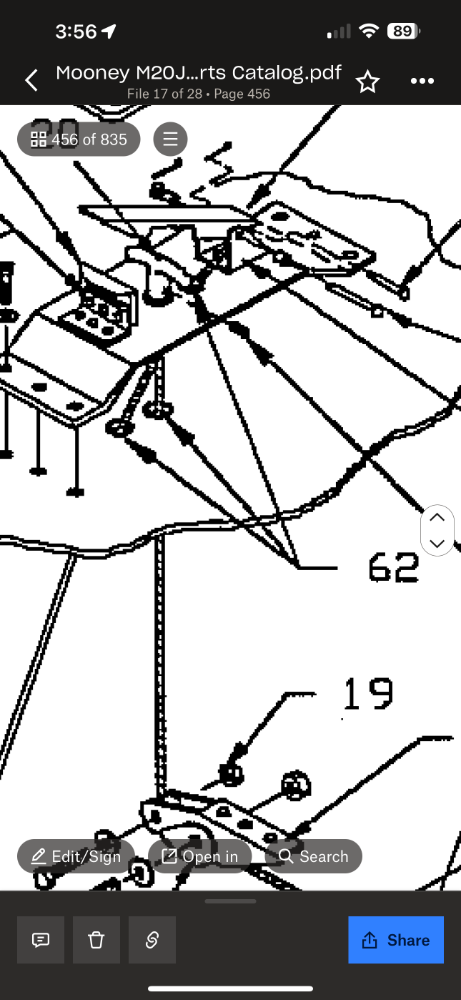

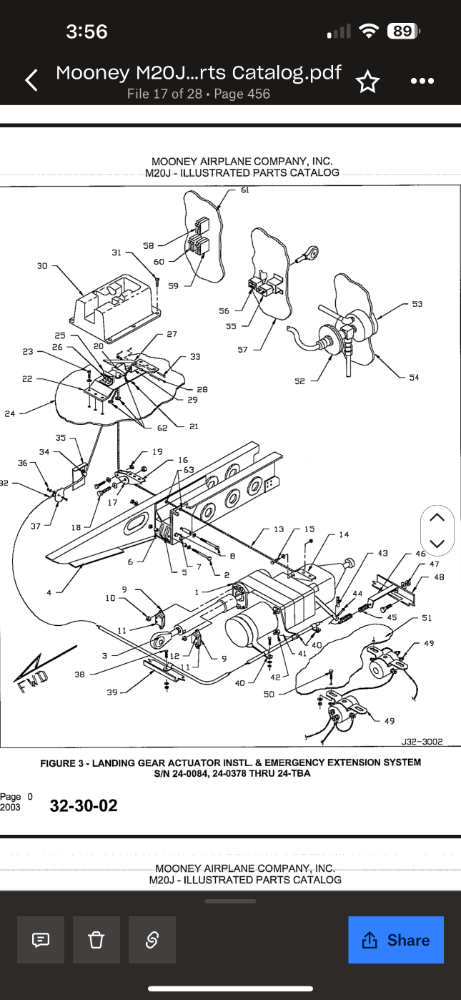

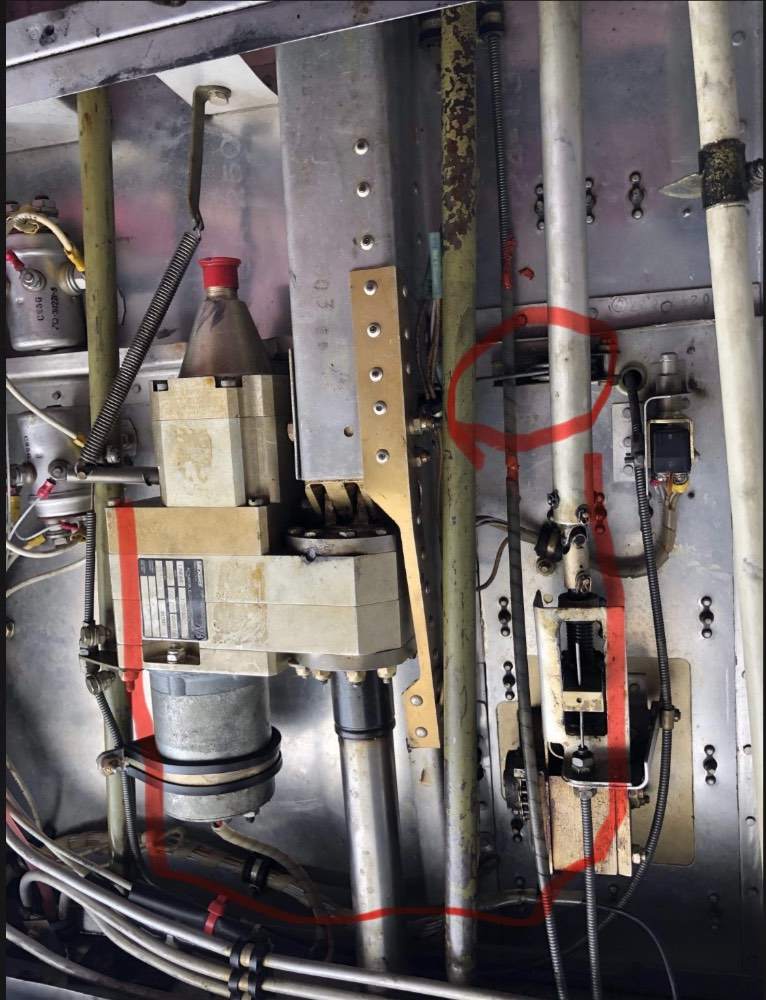

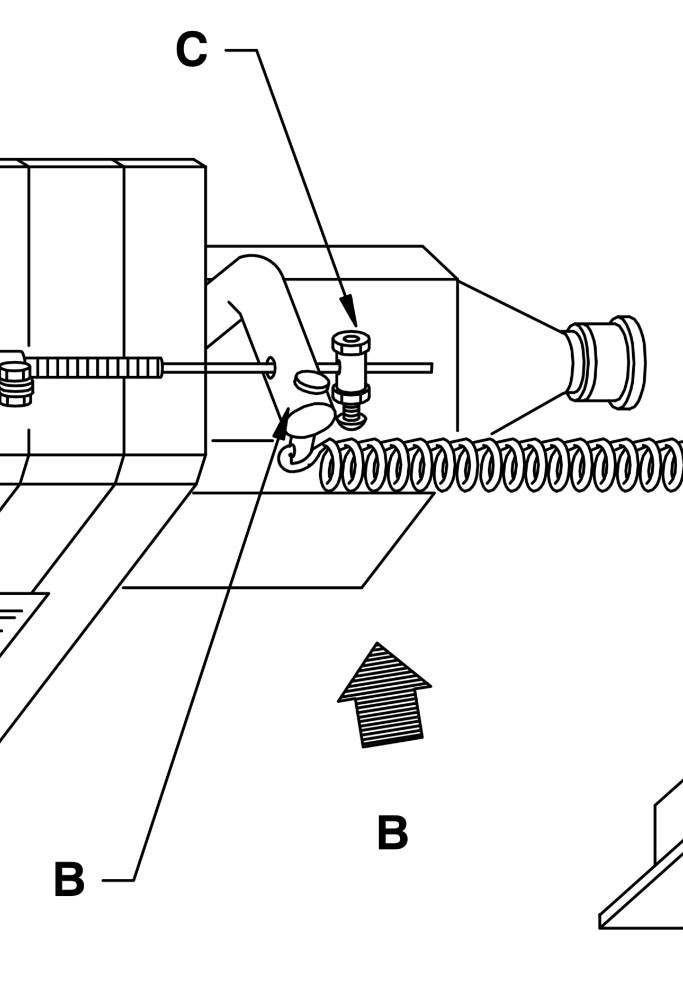

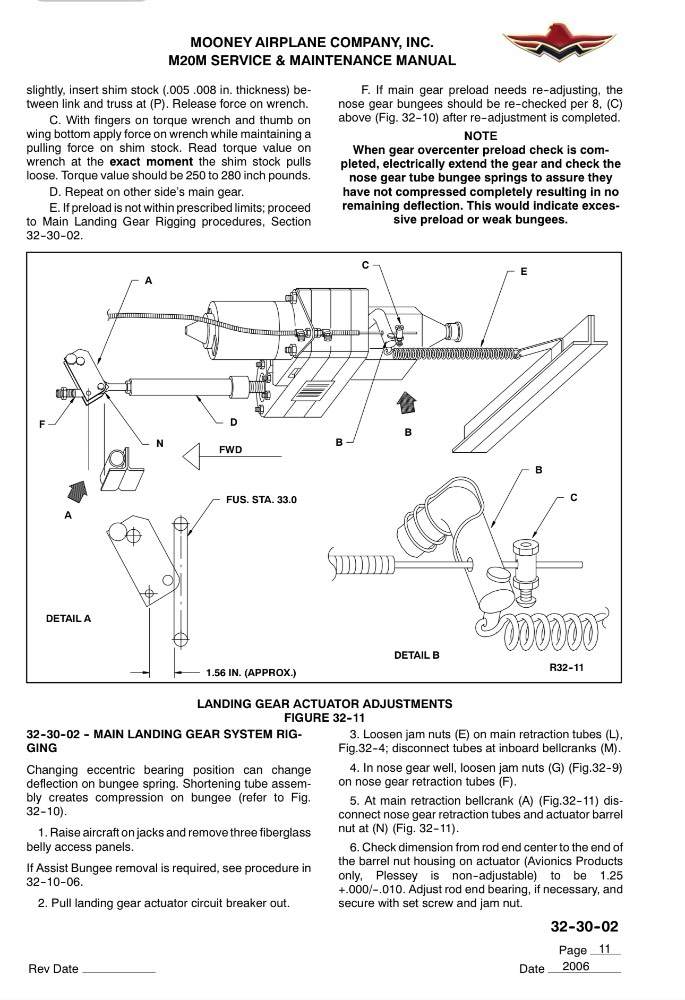

There is 2 cables, one that runs through a pulley to the spindle in the back of the gear motor “the one you’re referencing” and one that runs to the disengage arm of the gear motor. When you pull up on the lever, you are disengaged the gear motor so you can pull on the T handle to have the gear come down essentially. I have circled and highlighted where the 2 cables run. I found the picture on here so it’s not the best. Also you can see both cables in the IPC. Number 32 is the one I’m talking about and 13 is what you’re talking about.

-

Can anyone send a picture of how the cable is attached to the red lever. I know it’s held in place by the rear cotter pin but does the casing that’s around it come all the way up through the floor or is just tue bare cable. I find it hard to see how the cable moves to release the arm but then again I’m just playing around with it not installed.

-

Yeah this one was quite tough. I just received my few parts from BAS that I needed. Still waiting for Lasar to get my gear new and old gear motor

-

Yeah, it drives me nuts trying to search for some of these parts with outdated numbers. Or no number at all.

-

I ordered 2 different types from AS last night. The one you sent me and another type. I figure a cable stop is a cable stop. And one from aircraft spruce should be just as good as what Mooney used right?

-

Looking to see if anyone knows where I can find this part? It’s listed as D222 Stop, Wire in the IPC. I can’t find anything when I look for the name. It’s number 43 on the landing gear actuator and emergency extension page. Here’s some better pictures I found in the service manual of what it looks like

-

My plane has been down since late June so I haven’t been using it. When I did use it, it was just as hot then as now and I was pleased with it for how much it cost. Not to mention there isn’t any alternative other than it for a portable solution. Everything else is a permanent fixture or semi permanent and cost a lot more. If I had a long body that I planned on keeping forever, I could see investing in the 30k A/C system as the only way to go. There’s no doubt it’s the only thing comparable to a cars A/C. I’ve yet to be in any plane with a true A/C so I’m just speaking of what I’ve read and heard. You can’t go wrong with the Eco Flow. It requires little modification and can easily be installed and removed. Not to mention the add on battery has plenty of power to run the unit for a good hour plus on max. I typically run mine for probably 35-45 minutes cumulatively each flight. It’s perfect for me, since I fly alone 97% of the time. It works with 2 people, I just swap the duct back and forth. 74° air feels great when it’s 145° on the black top and 100° ambient. I’d imagine that it would work even better in a less humid climate than here in Florida.

-

I’ve seen the kit on there list of retrofit parts but as you can guess that kit is long gone. So I’m getting the motor from Lasar and the parts from a salvage place in Tennessee

-

I’m looking to see if anyone would be willing to take some pictures of the their emergency gear extension install. I’m only looking for those that have the later version with the T handle pull, that’s behind the trim wheel. I would like to see under the plane, where the one pulley is and how the 2 cables are run through the floor and to the gear motor itself. I’ve looked at the IPC extensively, but would like to see how to it compares on the actual plane. Thanks!

-

That picture, is quite old. I stripped the paint around the selector and had the black valve painted red with a white stripe pointing to what tank I’m on. Still have yet to get the trim piece on. Any advice on how to get the holes drilled for the screws? I guess using some butcher paper and tracing it? I have a place near me that makes decals for aircraft and is the oem supplier for piper, making me all new decals for the plane. I’m thinking about having the auto upholstery shop near me, redo my seats and cushioning. The seats bottom out when I sit in it, and I don’t weigh all that much. It would only be 1000 per front seat and probably a little less for the back bench. I got a quote to redo the whole interior from an aircraft interior place and it was 22k. Yeah no thanks, not on this plane.

-

Thank you, for that informations. I was going over in my head all the stuff you mentioned as necessary items. Just need a drill brush, a lot of acetone, knee pads, and the will. I have to wait a while till I get my plane back. I did as you did, in the baggage compartment and rattle canned zinc phosphate primer. Not sure why they don’t come that way from the factory. Not sure if I’ll do the main cabin. I have my ac in the back so I didn’t want any chance of water causing corrosion. Here’s what my floor looks like. It’s a picture of something else with the floor in the back ground

-

Good to know! I was leaning towards doing nothing and just seeing how it works out. Right now I have nothing holding my carpet in place and it stays alright. I have mats over the carpet and those things stay great, because of the left over adhesive on the back of them. It was an absolute mess when I took them out. Should I really worry that much about cleaning the floor until it’s bare aluminum or just make sure all the old adhesive it gone? Not like one sees the floor when the carpet is down. I just want to clean the seat rails real good, since that’s all you see. I got them pretty clean from last time.

-

That’s exactly what I was planning on doing. I think the idea of having the foam backing to help with vibration and sound dampening.

-

I was thinking about just doing the hook and loop on the bottom. Snaps are quite the labor extensive thing aren’t they? I don’t disagree I think snaps are far superior and look good. Just not sure if I want to do it to this plane. It seems Airtex and SCS are the only 2 options for kits. I’d like to hear from people who have used both.

-

I’m thinking about getting the nylon carpet kit for my 77J while it’s down for maintenance. I ordered some samples but wanted to see what others have to say. Good quality final product, easy to install, fitment? How did you clean and get all the old gunk off the floor from the old stuff? I’ve already removed my existing carpet and cleaned it up some. But it could still use some love. I want ti get the floor like it’s bare aluminum just don’t know how yet. Also I’ve tried but didn’t get very far with removing the rear seat in my plane. It’s the one piece bench so I don’t how it comes out. I was possibly thinking about replacing all the old insulation with a kit from Soundex. Anyone have any experience with it?

-

The plane is not anywhere close to me, so I can’t go easily look at it. Hopefully the motor didn’t get all messed up but who knows. I’m sure this has happened to others before but I find it odd that it does happen. I guess nothing is fool proof. Hopefully Mcfarlane can make a new one. The one post stated it only cost 225 in 21 which isn’t bad.

-

Flew my plane to the mechanics yesterday, apparently the cable connecting the emergency gear crank to the back of the motor is destroyed. He said the gear must have actuated with it engaged. Not sure how the hell it happened. Could be vibration, my leg hit it just a little, not sure. It was doing it before the heat swing so I didn’t do it then. Just a fluke thing I suppose. So I’m going to see if McFarlane can make me a new emergency gear extension cable, since Dan at Lasar said they don’t exist new. Someone on here said they had one made by them in 21. I’m going to the motor to Lasar and have the 200hr ad done and look to see if anything got damaged. If it did, I’ll weigh the cost to fix it and if the parts are even available. If they aren’t I’m going to have Lasar build me an Eaton motor core than will work with my older style crank extension. That’s what the guy Lasar said he does.

-

This is correct information, our part numbers don’t match the ones in the AD. So does this mean our motors don’t suffer from the same gear tooth wear as described?

-

So I called Maxwell and the A&P, the previous owner used. They both said the identical thing. They don’t think it’s the motor because no circuit breaker is popping and the motor continues to run when the gear stops retracting. They said it’s possibly the rubber coupling that goes between the motor and transmission or the shock disc are too worn. The shock disc are 12 years old, so they could be an issue. I planned to replace this annual. Maxwell said that the dukes is a good motor and mine has had good maintenance. He also said they are in R&R of a solution to fix all this mess. That’s all the detail he’d give me on that. I’d rather pay 5k to remove, clean, paint, and put new hardware on the gear trusses than pay 11k for a new motor. Idk why but having the gear trusses look like crap really takes away from it looking nice.

-

Yeah, I wish I had the one piece belly. Right now I have the first 2 panels off. It seems that I would need the red latch, and trim for the Eaton emergency extension if I go that route. Not sure if either of those things are available to get. I want the meat down time possible but also don’t want to cheap out on anything either. I know how important the gear is so I don’t want to mess around. It’s great building all this retractable time but it comes at a cost.

-

The fact that it has to be removed every 200 hours is a huge turn off and pia for me. I’ve flown almost 200 hours in less than 6months but the cost of the Eatons are high. So I’m not sure what I’ll do. I’m definitely not throwing out the old motor. I would probably end up sending it to Lasar if I do go the Eaton route.