-

Posts

38 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by CMMPilot

-

Source for the Ram?

-

Thanks for the info! You guys rock.

-

Just landed after a long cross country trip. (Florida to Edmonton Canada) and noticed a fuel drip when securing the aircraft. I confirmed this is not the sump drain. It is a threaded nozzle in front of that. See photos. any insight is appreciated

-

I am in need of a Turbo Clamp for a 231 (Part# 24540-300). Any help is appreciated!!!!

-

NEED (good) ADVICE on Hard Trim Repair/Mechanic

CMMPilot replied to CMMPilot's topic in General Mooney Talk

Good places to start. Thanks! -

I need a good recommended mechanic or shop to solve a long standing issue I have had with my trim. Has a hard spot that we can't isolate and is causing the Auto Pilot (Century 41) to disengage. I am based in Florida, but am willing to fly just about anywhere to get this done by someone who knows and understands Mooney's. I've been to 2 avionics places in FL and we have done a myriad of tests, servo swaps, reprogramming, lubricating, cleaning, worm gear overhaul, bearing rehab, etc... and still have the issue. Too much money down the drain on all the obvious things and I feel we have to be missing something simple at this point. Or we need to remove the entire tail to check the pivot points... I have a beautiful 1980 M20K 231 Turbo. If you know of anyone who might have experience with this issue, please let me know. I thought about flying it to the San Antonio TX area, as this seems to be the hotbed of Mooney World, I just need recommendations so I can start making some calls. Thanks in advance! Chris

-

I need a good recommended mechanic or shop to solve a long standing issue I have had with my trim. Has a hard spot that we can't isolate and is causing the Auto Pilot (Century 41) to disengage. I am based in Florida, but am willing to fly just about anywhere to get this done by someone who knows and understands Mooney's. I've been to 2 avionics places in FL and we have done a myriad of tests, servo swaps, reprogramming, lubricating, cleaning, worm gear overhaul, bearing rehab, etc... and still have the issue. Too much money down the drain on all the obvious things and I feel we have to be missing something simple at this point. Or we need to remove the entire tail to check the pivot points... I have a beautiful 1980 M20K 231 Turbo. If you know of anyone who might have experience with this issue, please let me know. I thought about flying it to the San Antonio TX area, as this seems to be the hotbed of Mooney World, I just need recommendations so I can start making some calls. Thanks in advance! Chris

- 1 reply

-

- 1

-

-

Can I just say how much I love this forum for this very reason! Someone on here always knows the answer to all things Mooney. It's so cool that so much topic knowledge is available and I just appreciate the opportunity to sit back and learn. Thanks!

-

Where do you mount your fire extinguisher?

CMMPilot replied to RobertGary1's topic in General Mooney Talk

I mounted mine on the wall, about calf level, on the right side of the right seat legwell. It’s a minimal nuisance to the copilot and extremely accessible. I’ve seen several in the backseat which seems difficult to access, especially in a time of emergency. -

As many of you discerned, I was joking about putting the motor in the Mooney. Although I had no idea it would spark such a conversation, I found the comments both entertaining and informative. Truly a group of intellectuals, the Mooney family. I thought I’d share the real reason for the photo. I purchased a new 15hp pump motor for my Orange Grove irrigation system. Unfortunately it was located in Naples FL, about a 3.5 hour drive each way. The OBVIOUS solution was to fly down and pick it up!!! After measuring and weighing in at 255lbs, I determined I could do it. Remove the right seat, adjust the weight and balance and we were on the way. luckily the place was actually located on the airport industrial park so he said he would bring it over to the FBO. You can imagine the looks I got when they saw the Mooney against this seemingly huge motor. With a little help from a strong line guy, we carefully moved it from the pallet to the floor of the aircraft. Strapped it in and we were off again. 2.5 hour round trip! Getting it out at the hangar was even easier with the hoist system I built to hold up my engine when I put the plane on jacks. The overall success of the trip made it that much more fun. I love flying and I love my Mooney!!! Seeing it hanging in front of the plane inspired the joke… Here are some photos.

-

-

Adding an Audible Alarm to my EDM900

CMMPilot replied to CMMPilot's topic in Engine Monitor Discussion

This is great information! I already noticed the relationship between FF and TIT when LOP. All of this makes sense, especially when considering how old this tech really is. I stress a lot about running the turbo too hard or causing some sort of failure because I let the TIT or MP get too high. Thats why (and the original reason for my post) the Audible alarm was a nifty addition (I thought) to help me prevent those situations. Hope the new engine treats you right! -

Adding an Audible Alarm to my EDM900

CMMPilot replied to CMMPilot's topic in Engine Monitor Discussion

I wish I had 30 years behind the yoke! I do have a Merlyn so you’re telling me it may not be working correctly? On the recent XC trip, I had to make minor adjustments to the mixture at least every 20-30 minutes on a 3 hour flight. I would set the TIT at 1590 (about 50° LOP) ,with a smooth running engine. It would remain relatively stable for a while, but then would start either climbing (richer) or descending (leaner) in Temp on its own, and I would have to make a small adjustment back. it was definitely not as stable as when I run ROP. Should I have someone look at the Merlyn? -

Adding an Audible Alarm to my EDM900

CMMPilot replied to CMMPilot's topic in Engine Monitor Discussion

Okay guys…I’m the first to admit I’m naïve about many aspects of Flying, still relatively new and wanting/willing to learn so constructive feedback is always humbly appreciated. -

Mooney Service Center Recommendations in South Carolina?

CMMPilot replied to TommyFlies's topic in General Mooney Talk

+1 Cole Aviation in Dalton,GA (KDNN). I lost a cylinder over KCHA and had an emergency landing. Nobody on the field knew how to work on pistons…. Finally connected with Joe Cole who made the drive and got me back in the air. Really stand up guy. Make the call. -

Adding an Audible Alarm to my EDM900

CMMPilot replied to CMMPilot's topic in Engine Monitor Discussion

No science here, just experience. I was traveling east with a 30kt quartering tailwind that changed to a 35kt direct headwind in less than 30 miles and although I made no power or mixture adjustments the TIT started dropping another 30° LOP. My guess is the change in wind resulted in a change in pressure. But maybe you’re right, it was probably the other way around… -

Adding an Audible Alarm to my EDM900

CMMPilot replied to CMMPilot's topic in Engine Monitor Discussion

I just completed a cross country trip from Florida to Colorado, over the Mountains to tour the Grand Canyon, and back home via Indiana. I spent a lot of this trip at altitude running LOP. If you have a Turbo Mooney, you know that the TIT can start to runaway as the pressure changes or if relative wind changes dramatically. My point is that the audible alarm was great for alerting me when the TIT started to climb without me touching a single control other than the yoke. Especially in the mountains when I was busy outside the airplane a lot of the time. Now letting the TIT get above 1620 never lasted more than a few seconds. I’m very happy with this added layer of safety. there are other obvious advantages for all types of notifications, but this one was most poignant during my recent (30 hours of flying in 4 days) Cross Country trip. -

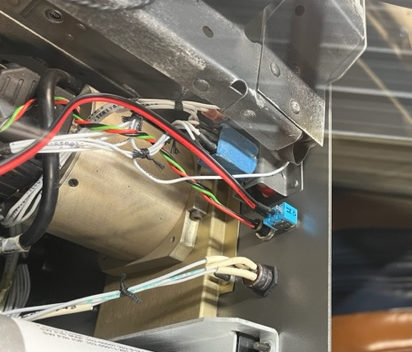

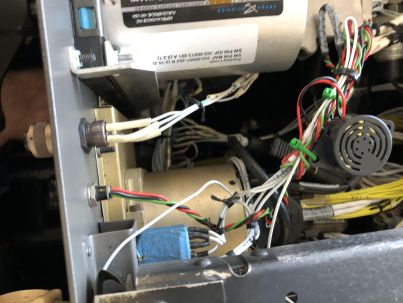

I do a lot of Cross Country flying which includes a fair amount of Auto Pilot. My trip from Florida (KINF) to DC (KVKX) takes approximately 4 hours, if the wind is right. I love my EDM 900 and it gives me a level of comfort I didn't have in my previous aircraft without an Engine Monitor. It has saved my on at least 2 occasions where engine trouble caused me to declare an emergency. On a recent flight I was reading a magazine and when I put it down to change frequencies, I noticed the yellow warning light was blinking. A quick scan of the EDM 900 indicated "Low Fuel" which was not a big deal as the alarm is set for 10 gallons (almost an hour of gas) and I still had 20 in the other tank. Although this situation was not a big deal, I started to think about how long the light could've been flashing without me knowing. I'm sure I was reading for over 5 minutes... I contacted JPI to see if they had a terminal connection for an audible output. NOPE. Just the LED light alarm output. I asked about adding an audible alarm and he agreed that it wouldn't make any difference if I wired it into the light circuit. The EDM 900 has a 3 wire alarm circuit where the Black wire provides power and the Red (Red Light) and Green (Yellow Light) wires provide ground to complete the appropriate circuit. So if I wired a small speaker with the hot side from the circuit breaker and the ground tied into the red or green wire, I would get an audible alarm when the light was lit. That became my plan, so I wanted to share how I did it. First, I installed the audible alarm by connecting it to the Red Alarm Light. Unfortunately I chose a beeper that was the same sound as my gear alarm, but at least the gear alarm is intermittent and the EDM alarm is continuous, so I know the difference. Second, I added a second alarm for the Warning (Yellow) circuit. I could have used the same but found a "buzzer" rather than a "beeper" that I liked and it would give me an audible difference for Red (Beeper) and Yellow (Buzzer) alarms. Third, I considered my last Emergency situation where I lost a cylinder at 15,500' and had a 20 minute descent to the closest airport. I think the continuous audible alarm for 20 minutes might ADD to my STRESS rather than help the situation. After all, I am mainly concerned about not noticing an alarm on a long cross country, when I might be reading or watching a movie and only glancing at the panel from time to time. I don't want a "YELLOW" to go unnoticed until it becomes a "RED" or worse. The audible alert solves this issue, but creates another one with extended situations where it may add to the stress. I realize I can "clear" warnings but they do come back after a few minutes and it's one more thing to worry about. For this I decided to simply install a switch that I can use to silence the audible alarm, but will have no effect on the visual LED alarm. This was an easy add-on and took me longer to label the panel than it did to install the switch. Ultimately, it works like a charm and as I designed it so I'm super happy with the results. I feel I have added an additional layer of safety that makes me feel more comfortable on long XC trips. Piezo Beeper Buzzer 12V-85dB VONVOFF Toggle Switch 12V I will go over the simple steps I used to complete the task and try to reference the photos. Step 1: Remove the Glare Shield Step 2: Locate the Circuit Breaker for the Engine Monitor and Disconnect Step 3 Connect a wire to the "cold" side of the circuit breaker Step 4: Run the wire to the center of the console, behind the Remote Engine Alarm Light Step 5: From the Beeper, Connect the Red Wire to the wire coming from the Circuit Breaker and connect the Black Wire to the Red Wire on the Remote Engine Alarm Light. (The circuit is completed by the EDM 900 connecting the light to ground, therefore, the wire from the circuit breaker represents a "hot" lead and is connected to the Red Wire on the Audible Alarm Beeper. The Black Wire from the Beeper is connected to the Red Wire from the EDM 900 (which drives the Red Warning Light). This is done with an in-line connection, so when the EDM 900 completes the circuit to illuminate the Red Light on the Remote Engine Alarm Light, it also completes the circuit for the Audible Alarm Beeper.) Step 6: Repeat Step 5 for the Buzzer on the Green Wire (Yellow Light Circuit) Step 7: Wire the switch between the circuit breaker and the hot wire used for both speakers. In this case I used a white wire from the Circuit Breaker and it connected to the Red Wire for each speaker. Opening the switch will disconnect the power to each speaker, so it will not sound when the LED light circuit is grounded. Step 8: Drill a 1/4" hole in the panel to mount the switch and label properly. Step 9: Install the Switch into the panel. Step 10: Make sure all connections are soldered and protected with shrink wrap tubing. Step 11: Zip Tie all loose wires and the Buzzers to the wire loom to avoid entanglement in the controls. Step 12: Turn on the Circuit Breaker and Test Step 13: Replace the Circuit Breaker in the Panel Step 14: Replace the Glare Shield ***Alarms sound during the initial boot up for the EDM 900, along with the warning lights. Well that's it! It took less than an hour to complete. Of course, everything was overseen and inspected by my A&P IA. Ultimately, it works like a charm and as I designed it so I'm super happy with the results. I feel I have added an additional layer of safety that makes me feel more comfortable on long XC trips. I'll include a couple of images for you to see. Let me know your thoughts and if you would do anything different. Thanks, Chris N231JY

-

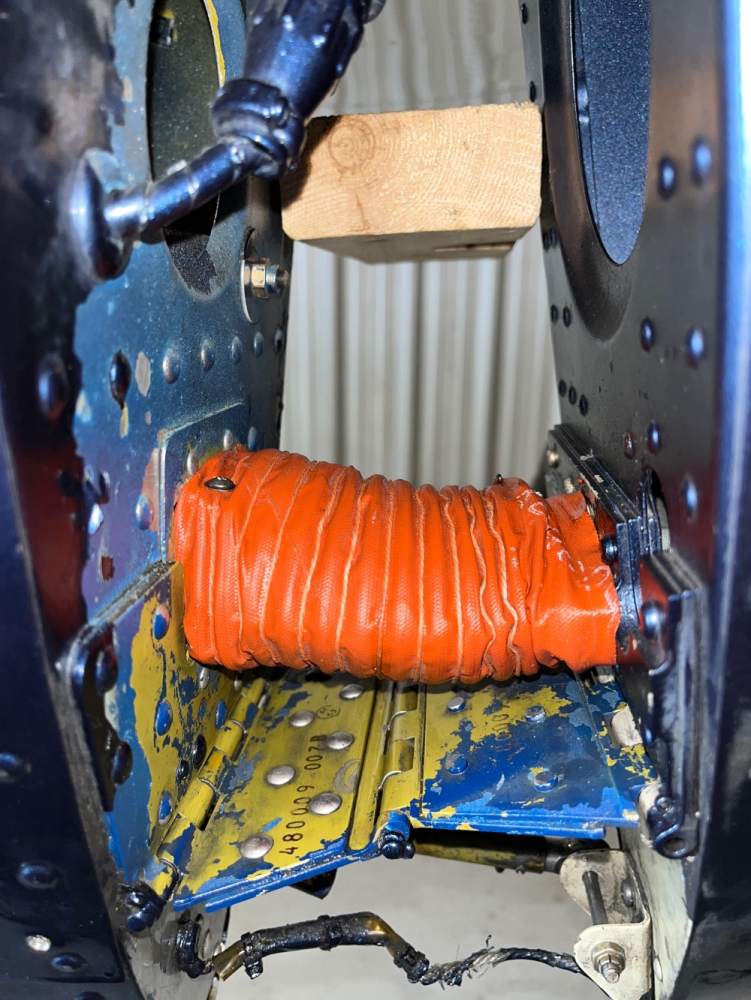

I just serviced my trim jack screw assembly and the original boot was full of gunk/dirt/grease and when I tried to clean it it started shredding. Obviously I jumped onto MS to see what others had done. The scat hose was a great idea, so I grabbed some 2 1/2” hose, cut a 4 1/2” piece, and cut about one ring of wire from each end. Bent the end of the wire and covered it (and the string ends) with a little RTV. I bent the first wire ring on one end into a square so it would rest on the mounting tabs and make it easier to screw on. The other end floats so I squeezed it into an oval so it fit over the bolt better on the tail side. I think it turned out much better than factory. Here are some photos. Chris

-

This is interesting, a Mooney competitor maybe?

CMMPilot replied to bcg's topic in General Mooney Talk

Agreed! -

Hmmmm, Interesting and worth a Saturday to check out. Thanks!

-

I’ll give that a try as well. Thanks to everyone for the advice and helpful information.

-

We have isolated it to the linkage between the trim wheel / servo motor and the worm gear actuator at the tail. We have eliminated any kind of drag at the wheel. There was some slack in the chain and we made a small adjustment to take it out. We disconnected the entire tail section and removed a lot of paint and debris from the hinges and pivot points. All of that is clean and lubricated, and the tail moves freely when not connected to the linkage. we cleaned the jackscrew and lubricated it, so that seems to be working properly. The rod moves freely through the two passes through points with proper bushings intact and plenty of play. I’m down to the century 41. auto pilot. my next step is to disconnect the AP and go from there…