-

Posts

30 -

Joined

-

Last visited

Profile Information

-

Reg #

N6928N

-

Model

M20C

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

MooneyP87's Achievements

-

What are your CHT's After LASAR Cowl Installation

MooneyP87 replied to C.J.'s topic in Vintage Mooneys (pre-J models)

Also getting 420-430F right after takeoff on initial climb out, especially when it's hot out. Cruise is around 360-380F depending on power %. Like everyone stated previously, I think you do need to have it checked for the idle/taxi temps as those seem abnormally high, even for a C. -

Thanks! The throttle quadrant I purchased earlier this year from eBay, there's a guy who 3d prints them and sells them as plug-n-play. Hindsight, I should have built it myself because getting it to mount into the rest of the vertical column was a pain and I feel like I could have made them a little more precise, but it's done now. The yokes are honeycomb yokes that I have cut up to pieces and rewired lol. This is all a big learning curve but at some point I plan on making my own to have them more realistic, but these will work for now. All of the switches will be wired up to Arduino boards. There are a few options for the software/switch integration, and I am not certain which one I am going to use yet but once I get to the wiring stage I will make that determination. The reason I state this is, I want to find one solution that I can use for X-Plane and MSFS so that I can test and use both flight sims but haven't had the time to test out different switches, potentiometers, and LEDs.

-

Weekend Update: I have the frame put together and am test fitting the panel and left walls. I still have a lot of work to do but the project is coming along nicely.

-

Here's a picture showing the panel with the dash pad attached to it. I've installed and tested the LED lighting strip and I think it will provide adequate lighting, even with the brightness adjusted very low but I won't know for sure until I get everything inside the frame. Now I just need to make the vinyl labels for all buttons and switches and the panel will be ready for wiring.

-

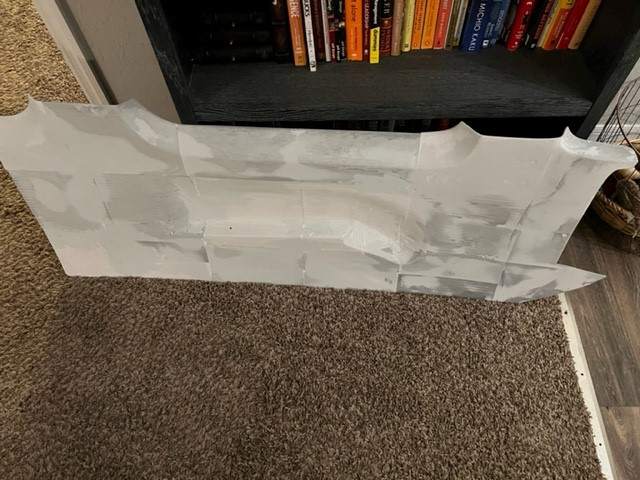

Here's what the pieces actually look like during the process. Picture is the upper left wall I am currently printing. This system seems to be working well for now although I may make a few tweaks to it in the future for additional stability.

-

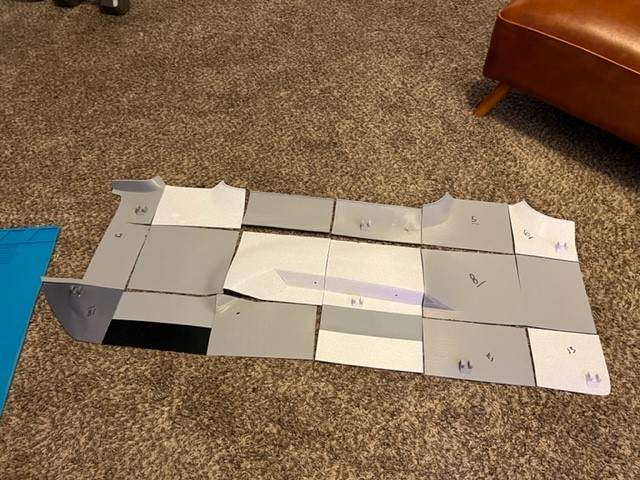

I wish I had a monster printer hiding.. I do have a Prusa XL on pre-order but even once I receive it, it will only print 14" parts; still better than 8-9" though. The answer to the question is the most time consuming part of the project, 3D modeling. I model the main sections and then make cuts every 210-240mm and insert a bracket on the back of the print that will link the parts together with 3mm bolts. See pics for a better explanation. The inside of the cabin looks like one piece, however the rear shows all of the connected brackets that are used when the parts are split so that they can be linked together. The 2nd pic shows the boxes I use to "cut/split" the objects for printing. The large brackets you see on the corners are used to attach the section to the frame of the simulator.

-

Update post: The panel is painted and ready. I am going to give it a few days to fully cure and then I will install the G1000/G5 units along with the switches. I test fit it with the vertical column last night (2nd pic). I still have some work to do on the vertical column but it is close to being ready for paint. I also finished the dashpad this weekend (1st pic) and finished the left (lower) wall but forgot to take a picture of it. Right now I am printing the left upper wall. Should have some major progress pictures coming soon as I am just over half way finished with the printed parts.

-

Sure! The three printers shown are all Prusa MK3S's. I also have an Ender printer but I try to not use it unless I need all the printers running as the quality just isn't the same. The parts are extremely durable. For the heavy use parts like the panel, switches, and dashpad I am printing those using PETG with a larger print nozzle than standard with an additional wall layer (typically 3d parts are printed with 2 solid layers for walls but I am using 3). I've tried to break the dashpad with my hands and was unable. The walls/ceiling are printed at 3mm thick with three layer print seams to make them more durable. I have learned that I need to make connector links for all of the large parts so that they can bolt together with 3mm bolts. This isn't so much of a strength issue, but it will help, but more of an alignment correction. Having 18 printed parts for a wall with no way to connect them except some type of glue makes it a pain for linking them together. So each piece moving forward (upper left wall/ceiling, and right sides) will still be large separate pieces but I will make each large section bolt together. This would also allow someone to not be required to glue them.

-

I have no idea what you're talking about

-

Currently doing it for fun however I have had a few people ask if I was planning on selling some type of kit or making it certified. I don't have any plans as of right now to get it certified (however this may change once I have it completed). I have read briefly on the certification process and I would need to provide a plug and play system for this to happen. I could do this but the price would knock most sim enthusiast out. I am thinking about making replica interior kits that would have the framing, walls, ceiling, and possibly a custom panel depending on what the user wants. The panel is where the hard part comes in because not everyone wants a G1000 setup.

-

The dashpad is printed and I've applied bondo to help smooth it out, it just needs a little more sanding and it will be ready. I modeled a recessed area so that I can install a LED strip into the bottom of it to light the panel.

-

The panel has also been printed and just needs some bondo or CA glue to help hide the seams and it will be ready for paint.

-

Progress on the left wall. I've printed it and touched it up with bondo to help remove the seams. It needs some more sanding and minor corrections and it will be ready for paint. The pictures can be deceiving, this piece is close to 5 feet long.

-

Update on the build since starting over on "Version 2". I've printed the panel, center vertical column that is below the panel, and the lower left side wall. Quite a time consuming project but I am hoping the end results will be well worth it. I had to figure out some type of bracket system to hold the walls and ceiling in place but I have a system now that is fully adjustable which will help tremendously once I start installing the finished pieces into the frame. Below is the latest rendering of the 3D model. All pieces shown are already printed.

-

Wanted to provide a quick update. I’m in the process of starting over on the new build. Currently printing the panel right now. I’ve swapped from using a 2x2 frame to using aluminum extrusion. This will allow me some flexibility on the brackets that will hold the interior in place. Pictures of the model attached are no where near finished but I feel I am making good progress.