Grandmas Flying Couch

Verified Member-

Posts

167 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Grandmas Flying Couch

-

Wrong Belly Panel?!!

Grandmas Flying Couch replied to Grandmas Flying Couch's topic in Vintage Mooneys (pre-J models)

Like two large scoops grabbing air on the high pressure side. Can't be good. Looks like mine were shortened looking in the parts manual they look like they have a version that closes the gap -

Hello, on my M20F these appear to be altered or perhaps wrong, I can't help but think there is extra drag here, what do you all think?

-

Update: Rebuilt both cylinders using new O-rings and keeping the brass valve with original seal that was still pliable. Both breaks work great. Remember that the cotterpin that contacts the fluid inside the cylinder is stainless MS24665-151. Also a piece of safety wire tied in a loop from inlet of the cylinder to rod to keep the cylinder collapsed while installing the snap ring will help you with your sanity.

-

That's how I understood you, I was saying the only way I would know would be to pop in the alternative brass piece and see if it worked. I was replying to jet driven about the statoseal. I was tired and unclear when I posted. I am going to keep the current brass valve as is. Looks like it was available with the seal as a service item but no longer.

-

I don't know, I would have to put the part in and see if it operated as a check valve like this one does. I am going to assemble them tonight using existing washers, they are nice and pliable with no cracking. Even if one were to die 5 years from now I have the other brake and don't use brakes much anyway. It would probably be a progressive failure in the mean time I will look for the parts. I don't think it is a statoseal like seen on the fuel valve as those are incorporated into a washer, perhaps there are variations.

-

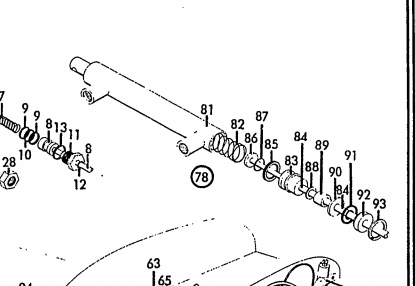

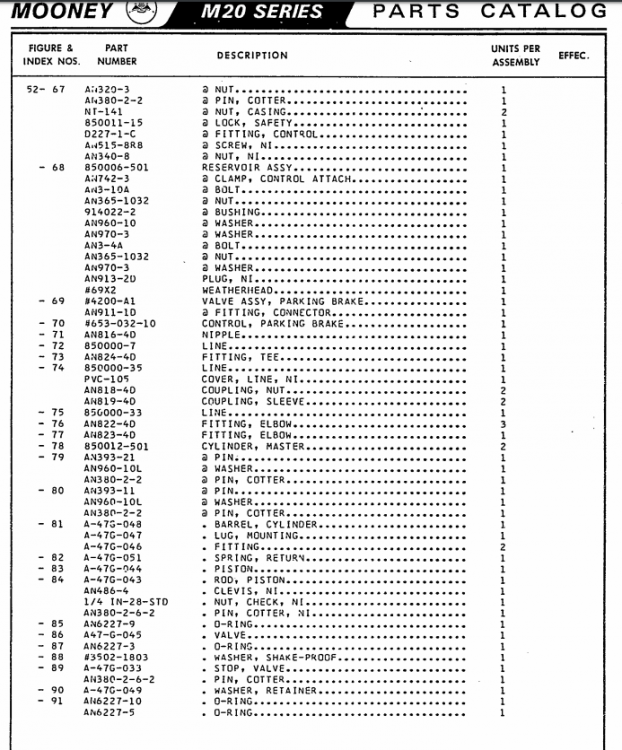

My mechanic and I have taken out the master cylinders when we went to change the 4 O-rings listed in the parts diagram. All the rings match up perfectly except the one on the valve. The parts diagram calls for AN6227-3 (MS28775-008) but the one on the brass valve appears to be a flat washer unless it formed this way over time from the hydraulic pressure. In the parts diagram the O-ring for the valve appears as number 87. O-rings 85 and 91 match up perfectly. In one of the pics I threw the supposed O-ring on the valve for a visual. The rubber on the valve is still soft, I'm tempted to change the other O-rings as they have taken on a square cross section and just leave the rubber washers, what do you all think? Kits provided to rebuild these master cylinders include the same O-rings I have.

-

New brake fluid and grease approved by Mooney

Grandmas Flying Couch replied to KSMooniac's topic in General Mooney Talk

I recently replaced O-rings in wheel cylinders and bled the system from the bottom up with 83282 (Aeroshell 31) instead of 5606. To my surprise the next day both master cylinders were leaking. The fluid was coming from the actuator rods on both cylinders. They did have thickened 5606 fluid on them before I started working on the airplane so they had leaked a little in the past just a weep. Now they are completely shot. I don't know if it was the synthetic fluid ruining what was left of the ancient seals, the fact the system was empty for month or if the thickened ancient 5606 was too thick to leak appreciably. I am picking up new O-rings today and can report back. I don't know if I should fill it back up with Aeroshell 31 or go back to 5606. The wheel cylinders are not leaking now. As a side note, the fluid in the wheel cylinders was thick like pancake syrup (maybe not that bad) change your fluid once in a while! Master cylinder seal numbers for the old black round master cylinders are MS 28775-008, MS 28775-010, MS 28775-111, MS 28775-112. Need one of each for each cylinder. I am picking up 3 of each in-case I damage one during installation. -

I think keep cht below 400F, lean below 75% power and call it a day. If I say a bridge is good for 10 tons, people will say running 10 ton trucks across it is the worst possible way to use it, so use 8 ton trucks. However the bridge is probably good to 16 tons with a safety factor. The red box might be peak pressures, great, need pressure to push the piston down and the engine was designed to handle these pressures with a safety margin. You can operate your car at 45 mph to save the engine and transmission. I say 50 degrees LOP at at 22 inches and 2600 rpm is way worse than 19 squared. But what fun is that? I'm going to 100 deg rop unless I need range, then I'm going up high 7k plus and rich of rough. I dont think I caused this at all. Thanks for all the input, operate your engine as you will, I think the red box is the worst possible place to operate WITHIN the design limits. I will be going with a monitor just so I can get a heads up if stuff is crapping out in flight next time. Give me an extra 15 minutes notice to a dying cylinder, yes please. Or let me know a clogged injector is heating a cylinder on takeoff? Also yes.

-

Results are back, stuck oil ring. Compression rings gunked up shortly after. Mech wants to send in cyclinder and piston for at least IRAN. I don't know if I could have caused this, plane sat for two years before I bought it. Oil was 7 hours per quart when I for it. Stuck oil ring may have been from heat, fluke, or was partially stuck and getting worse since I had the plane.

-

I agree, I believe these engines are designed to make TBO at best power settings. I think avoiding the red box just puts LESS strain but I do not think best power kills engine as long as chts are in check. Another words engine might go 2200 hours best power or 2800 hours lop, but I want to fly fast. I will experiment once I have my g2 and use lop or rop depending on mission of the day as PT20J says

-

I appreciate all the feedback, I still haven't heard back from Mechanic. I am going to install a g2 as soon as I get plane back. Its 3.5 hours away by car. I fly over nasty terrain, would like to have cht and egt on all 4 cyl. I fly full throttle from takeoff to landing leaning above 5 or 6 k. At about 2550 RPM (I adjust to smoothest RPM above harmonic no go region).

-

After losing this cylinder and thinking I may have cooked it (I don't know cause yet), I'm paranoid, will probably run rich of peak but want to monitor chts. I like the extra speed from ROP. I feel like I cooked that cylinder, it's number 4 I have the factory probe on cyl 3 so that one never got too hot, hopefully the other two being up front in the cool air means they never got cooked. I feel like there is a 75% chance I could have prevented this crap with an Engine monitor. Do you know if the alarm points can be changed to 400F for the cht or is it stuck at the factory 415?

-

Looks like the rings are leaking and pressuring the case. Mechanic came out and everybody is mid 70s/80 except cylinder 4 which was "Really Low" and with air rushing out of the crank case vent. I don't know how low is low but I believe it. They are going to bore scope it today and send pictures. Hey Ross, hope you and your family had a fun outing in the E

-

It's Been awhile! I bought my 67F two years ago the engine was overhauled 10 years ago and has about 450 hours since OH, I put 150 of the hours on it since purchase. This last weekend I flew for 1 hour 15 minutes from Goodyear AZ to Bisbee AZ and went from 6 quarts to 3.5 quarts. I suspect a bad cylinder as the exhaust was coked up and the breather had pooped oil all over the belly. Plane was down on power upon landing. I have a channel changer EGT, gami injectors and have usally ran 100 degree ROP. There have been a couple occasions where I tried lean of peak at 7500+ feet. I would run it rich of rough by a few turns on the mixture knob, did I cause the damage to the cylinder(s)? I usually get bored at LOP and go ROP for the extra power. I don't lean down low. If climbing out of a high altitude airport I will lean to get the egt needle off the bottom peg (noticeable increase in power). Mechanic is coming out today to check it out. Before all this oil was 1qt for 5 or 6 hours compression in the mid 70s. Should I just fix the offending cylinder and be on my way? Has this happened to others as a bad ring or a fluke, or did I do this?, I hate to think I was stupid enough to ruin a 25k engine.

-

How to change the oil?

Grandmas Flying Couch replied to TheTurtle's topic in Vintage Mooneys (pre-J models)

I started doing this after seeing Oil Filter Bib product. I thought Gallon zip lock bag! Funny. Works great, put around lip on engine case pull up on back to form seal, remove filter. -

Thanks @M20Doc, I will have it done, unfortunately I'm waiting for new cables for the mixture and prop, I sent pics to McFarlane of the behavior of the two cables, the mixture skips when turning it and the prop cable is bent so that it orbits as you turn the knob. The prop cable has pleir marks on the shaft when you pull the knob that grind inside the mech. McFarlane says they wouldn't trust the cables as the installer has damaged them.

-

I was wondering if any of you had good mixture cable routing, my old mixture cable was routed in such a way that the yoke linkage under the panel pushed on the cable pretty bad, I had a new mixture cable installed and it also Interferes, although routed differently. If anyone has pics, I would really appreciate the help.