Search the Community

Showing results for tags 'stall'.

-

I have been using my '64 Super 21 to travel between Culpeper VA CJR and Dexter MI 2E8 several times last summer. Because 2E8 is 2100 ft grass with displaced thresholds and has a down slope on RWY 6 in the center third of the runway, it has me working on my short field technique quite a lot. I added a lift indicator and train with it to get better at slow flight and stay safe. This training has helped me to identify a glitch that merits further investigation and I decided to ask you all for some advice. During slow flight practice at safe altitudes I noticed the wings fly well right up to the stall then break quickly and recover quickly causing the airplane to porpoise. At altitude this is not a big deal except the break occurs without warning. When this happens near the ground the results are a hard drop and perhaps a bounce. I would like the stall to be softer with some feel to it, if that is possible without too much difficulty, and without loss of cruise performance and fuel economy. I reread Harry Ribletts book about GA airfoils and he suggests a leading edge modification (page 42) to the 64-212 (and similar 64 series airfoils) but makes no mention of a similar modification to the 63 series. Since the Mooney uses the 63-215 airfoil, would a similar modification be of any benefit? It occurred to me that someone else may have had the same questions and may have done some research in this area. So how about it? Do any of you have any ideas here? Before some comments on my lack of flying skills… I recognize that I can simply adjust my technique to not get so close to the stall during slow landings. And I may be left with just that. But admittedly that will leave some low speed performance on the table, not to mention the added safety margin attainable by softening the stall characteristics of the airplane. So I am investigating to see if it is possible. If you can help I am all ears. Petehdgs@yahoo.com

- 55 replies

-

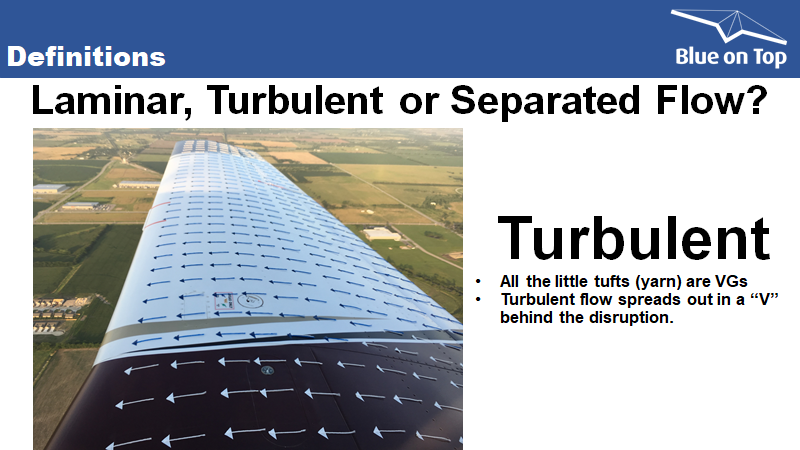

If MS users have aerodynamics questions, I can try to answer them. I know (and hope) others will chime in, too. I plan on giving an Oshkosh Forum this year on this topic. Now that I think about it, would anyone attend if I try one at Sun-N-Fun, too? I'll start with a very controversial topic: the Mooney laminar flow wing. Laminar flow is a very elusive condition. Any bug, dimple, step, etc. will trip the flow from laminar to turbulent. The picture above (of Scott Sellmeyer's beautiful "J") shows beautiful, turbulent flow. People misinterpret separated flow as turbulent flow. We are really talking about the small boundary layer right at the surface. With laminar or turbulent flow, flow velocity on the surface is 0. Hard to believe but true. This is why dust stays on your airplane … even after you fly. Let's have some fun!

- 304 replies

-

- 1

-

-

- aerodynamics

- airflow

-

(and 2 more)

Tagged with:

-

I look forward to being skeward for my various sins.

- 13 replies

-

- 4

-

-

How clean is the stall break in a 201? I had a 67 C model. Stalling it, clean and dirty, resulted in a pretty apparent break which could be followed by a secondary stall if I pulled back too quickly. With my 201, the break doesn't seem nearly as clean. Seems more like a Cherokee stall where I end up mushing along in a 500 fpm descent. I was able to get a sharp break but it involved slowing to the bottom of the arc and then a strong pull on the yoke to induce the stall. Is this typical of the 201? Thx Mark

-

I keep seeing people refer to TKS porous panels as 'Stall Strips'. They are NOT stall strips. They are deicing fluid delivery devices. A stall strip is that short piece of angled aluminum bonded to the leading edge of each wing, on most airplanes, that helps balance the stall characteristics of the wings. Sorry, it just bugs me that people who should know better seem not to... Chuck M.