-

Posts

114 -

Joined

-

Last visited

About Flybeech21

- Birthday 08/12/1977

Profile Information

-

Gender

Male

-

Location

Concord, GA

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Flybeech21's Achievements

-

I have a PCU on my machine. I changed between the Hartzell governor and the PCU a couple of times for troubleshooting purposes. In my opinion, the PCU is the better governor. It requires a much lower volume of oil to do the job. Also, it is a smaller governor so you won't need to utilize the access hole in the firewall to work on it. The people at PCU have helped me with customer support and troubleshooting from start to finish. It was not a governor problem that I was chasing. It ended up being a crankcase problem. But, PCU never hesitated to help me with technical advise while I "chased the worm down the rabbit hole" for nearly a year. You will be required to change the studs on the adapter plate when you change between PCU and factory governors... So, you will have to remove the adaptor plate and replace studs when you change between the two. It is not a small task to change governor types. It is a pain in the arse and don't attempt it if you are not and A&P. It requires making changes that are not detailed in installation instructions and require the installer to be competent. Either way, go with the PCU.

-

Propeller RPM control issues

Flybeech21 replied to Flybeech21's topic in Vintage Mooneys (pre-J models)

So my engine is reassembled and reinstalled. The prop overspeed issue is officially solved. She works perfect. I am still waiting on word from DIVCO. I spoke to the owner and he basically told me "tuff shit." He distanced his company from the issue by saying "its all on the engine shop who assembles the engine." Then, he tells me that he has had multiple meetings with his workers ensuring this will never happen again. I am pretty sure this proves your gross neglegence sir! He ended the conversation with: have your engine shop call me if there is any follow up to this as there is no need for us to ever talk again. WHAT? I am giving it two more weeks since my engine shop says they can influence some sway. I will reserve presenting my contingency plan for a later post depending on what my engine shop (not the owner) can convince these cronies to do what is right. -

Everyone has weighed in accurately on this one. I will say this: Be very very cautious of A&P engine overhauls. Stick with factory or well known/reputable engine shop overhauls with warranties. My M20E has a 160 TSMOH engine that has been completely disassembled and reassembled twice to find issues with the initial incompetence of the A&P overhauler. there are some super capable A&Ps out there that could do as good a job as an engine shop. However, you should interview, get references, do google searches, and know the blood type of their first born in you decide to go with a field overhaul from an A&P. I will say the M20E is a surprisingly peppy. The 20 extra horsepower on the short body airframe equals full right rudder on takeoff. And, don't even think about lifting off really early in ground effect with a big right crosswind. I noticed the same issue with my 2652W but it is a bigger deal in the E. E vs. C. 2652W was a great machine. I loved it and would love to still have her. I am glad Dave got it. He is a great guy that has improved that airplane beyond belief. I knew this was going to be the case when I delivered the airplane to its new home and it was pushed into the hanger beside a pristine F86 saber and every other warbird we have all dreamed of flying. I mean just damn! However, I must say that the 200HP stock airframe with just the lazar cowl closure performed exactly the same as 2652W when I had her. And, short field performance at max gross weight is definitely improved. 52W is improved now for sure. But, when I sold her, she had just about every speed mod available. I sure do love being able to take those panel off in front of the factory windscreen. The engine monitor would have been a nightmare instal without them. Either way, I still wish I still had 52W. What a great airplane she is.

-

Propeller RPM control issues

Flybeech21 replied to Flybeech21's topic in Vintage Mooneys (pre-J models)

1CA48BAD-2B61-432A-AC9A-79D51E18461D.heic -

Propeller RPM control issues

Flybeech21 replied to Flybeech21's topic in Vintage Mooneys (pre-J models)

Sorry I have been so absent on the forum. Well folks, my problem still persisted after trying everything known to man to try and solve the issue. I installed the restrictor plate and the problem was a little better. After hagleing with the engine shop for nearly a month, we decided to pull the engine, tear it down and inspect. After a year of throwing money at this issue at the direction of the engine shop we are finally at the point where they say "lets pull it and tear it down." After pulling the engine, we found the problem. The two dowel pins (see photo) in the forward main bearing area were drilled all the way trough and the pins were hollow. The pins reside in the shaft galley for the propeller oil supply. So, oil was being dumped back into the case at a rate determined by the viscosity of the oil. This is the reason when oil temp increased, prop RPM increased. DIVCO is at fault. DIVCO overhauled and yellow tagged this case after performing faulty workmanship. PLAIN AND SIMPLE!!!!!! I have poured countless hours of labor and $12000 into chasing this issue when it was DIVCO's terrible work the whole time. At the present time they are only willing to cover the cost of reoverhauling the case and buying a new set of bearings. The engine shop is handing communications with them for now. Once they are done "getting what they can get" then I will start my part. They should cover a hell of a lot more than fixing the case and buying new bearings. I will keep you guys updated. Sorry for the absence. IMG_0427.HEIC -

Propeller RPM control issues

Flybeech21 replied to Flybeech21's topic in Vintage Mooneys (pre-J models)

It as warm. 35 psi. -

Propeller RPM control issues

Flybeech21 replied to Flybeech21's topic in Vintage Mooneys (pre-J models)

I did the leak down test with the prop installed. -

Propeller RPM control issues

Flybeech21 replied to Flybeech21's topic in Vintage Mooneys (pre-J models)

The previous owner apparently sent the oil cooler off to be flushed. Thats all I know of what has happened with the oil cooler. -

Propeller RPM control issues

Flybeech21 replied to Flybeech21's topic in Vintage Mooneys (pre-J models)

I have been reviewing the data with the engine shop. There is nothing to tie it to anything in particular. I am going to mention this service instruction that installs a plate between the gov and adapter listed above. That sounds very promising. -

Congrats!!! I sold N2652W to Dave years ago. I should have my back side kicked for not buying it back when I had the chance. I am now stuck with a M20E that was perfect on paper that has been trouble every day I have had it... Congrats again. My family and I have some great memories in that bird.

-

Propeller RPM control issues

Flybeech21 replied to Flybeech21's topic in Vintage Mooneys (pre-J models)

Well Damn. My problem is still not solved. I have been off of the thread for a long time. But, I have been fighting this issue ever since and it is still not solved. Summary: When the issue returned, I pulled the prop and sent it to the prop shop. It was garbage. Bad blades, bad fork, hadn't been overhauled in decades. I overhauled it to the tune of $6000 and still didn't get rid of the 100 HR AD. Problem solved right? WRONG. On the first flight after prop overhaul, the problem persisted. I was so pissed off that I started installing the Graphic Engine Monitor that I had purchased and figured some eureka moment would happen while I was installing the GEM. On the ground run, I noticed the factory oil pressure gauge was 15- 20 psi less than what the GEM was indicating. After verification, the factory gauge was inaccurate. Problem solved right??? WRONG! I adjusted the oil pressure up to the 80 psi I though I was getting before. I flew it again and then noticed that when the prop gov was in the operating range, the oil pressure plummets to slightly less than 60 psi ( in the yellow arc) and the problem still persisted. I then pulled the prop off and performed the transfer bearing leak down test per Lycoming's service instructions. No defects. The plug in the crank was intact and the test was normal. I then changed the spring and ball with a stiffer spring and a new ball to get up to 90 - 95 psi. I flew it again. This flight I noticed that the oil pressure would steadily decline with the increase in oil temperature and would go below the magical 60 psi at precisely 210 degrees of oil pressure. when I leveled off and kept the throttle low to prevent the persistent overspeed tendency and to allow the oil to cool the propeller system would function completely normal once the temp reduced to below 210 degrees. Partial victory I guess. So this engine is still in it's break in phase. I decided to keep flying it to continue the break in. It operated fine as long as you kept the power back for the first 10 mins of cruise and let the oil temp cool to less than 210 degrees then operated normally. Then I changed over to phillips 20W-50. The issue was back with a vengeance now and twice as persistent. I then decided it was time to send the prop governor in. Aside: This was the second prop governor that was installed on the airplane chasing this issue. After speaking with the previous owner's mechanic, he told me that they had the same squawk and fixed it with a new PCU5000 prop governor. They flew it twice with no issues and put it up for sale. I was the lucky buyer!!! I asked them about the profile of the test flights and they told me that it was pattern altitude type short flights. That is why it didn't show back up. They never got the oil temp above 210. The prop shop said there was nothing wrong with the governor except it was not set per the manual. They reset everything per the manual and sent it back to me. I reinstalled it and - you guessed it - still not fixed! I then decided to remove the PCU5000 and go back with a Hartzell H-1. I decided to do this after speaking with Rich (the chief inspector at PCU prop governors manufacturer). He wanted verification that it was not some compatibility issue with the engine/prop combination that they didn't know about. So, I did that. It was an absolute pain in the neck. The studs on the adapter plate were too long and had to be changed. The Hartzell is huge compared to the PCU and required throwing a couple of wrenches across the hanger and removing the oil filter and P-Lead on the right mag to get it to fit. It literally took me a half of a day to get the H-1 on this airplane. So, time to fly it again! I flew it and the problem still persists. I am beat down and devastated. This flight was this afternoon. I am out of ideas here. I have never had an engine issue beat me. I have always been able to figure out what the issue is. This one has defeated me. I need help. I do see some good ideas posted above. I will forward them to the engine shop as this is now, in my opinion, an engine warranty issue. -

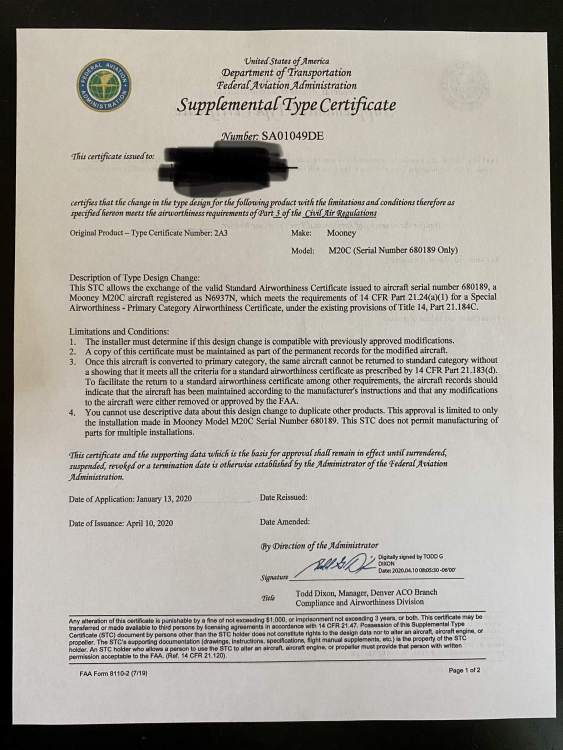

It's my friend's M20C. He just completed the process. I am about to take all of his paperwork and tell them to do the same for me. I think this is the first Mooney that has ever transitioned. If my process goes flawlessly, then it opens the door for all < 2700 lb Mooney owners to do the same.

-

I will be glad to forward everything to you once I complete the process.

-

Update. See the attached STC for the transition. I think I should have my STC within the week or so.

-

So actually, deeper in the fine print there is language that says you must have a valid standard category airworthiness certificate. Of course, when I spoke with my insurance agent he said: "uhhhh, we have never heard of this before." They requested a written explanation and wanted a copy of my certification plan. The result??? The effect on my premium is nil. The only change is that there will be no open pilot clause. All pilots must be named like on most experimental aircraft.