-

Posts

66 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Moonbat

-

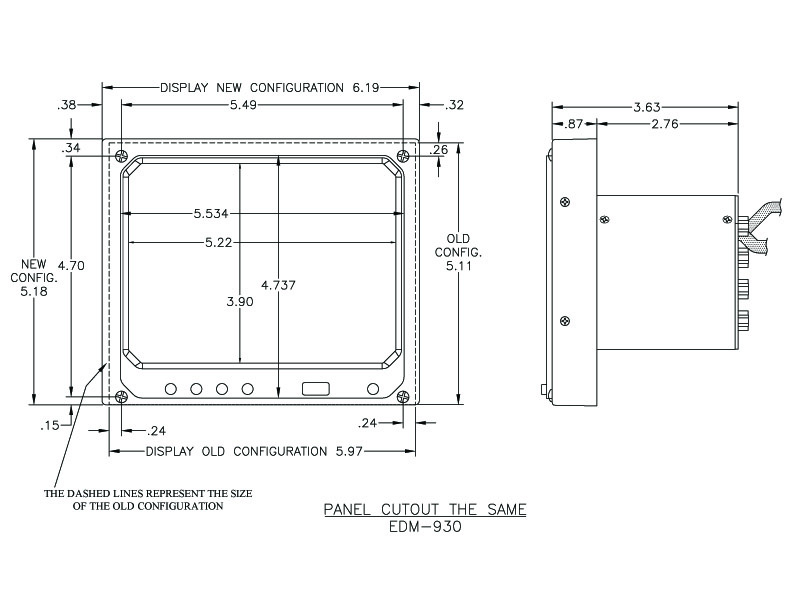

1. I am not concerned over the $500 upgrade from a JPI EDM930 (early serial number) to a JPI EDM930 (newer serial number). That seems very reasonable. 2. For those who are *really* into this, note that even the older firmware goes into a higher sample rate mode of 1 sps (up from 1 sample per 6 seconds) during LeanFind operations. 3. The upgraded unit does have better color display, updated firmware and a higher sample rate capability... along with the increase in dimensions of the frame. The upgraded display is what causes the small increase in dimension. 4. It is just my bad luck that the JPI EDM unit in my panel layout is right up against the structural member of the aircraft frame. The “201 style” windshield mods, cowling mods, turbo mods, etc., all come into play. 5. Below are pictures of Casper’s (N3215F) panel. I really love it as is! I suspect moving the Avionics switch, the autopilot and the EDM930 downward in a new layout would solve the dimensional problem with the EDM930 “upgrade”, but I do not judge it to be worthwhile... yet. Especially after gaining a “0 SMOH” entry in my engine log book less than a year ago! 6. My experiences with Tech Support at JPI is not the worst I have experienced in the industry. (I reserve that title for a vacuum-powered HSI manufacturer.) Definitely “mid-range” though. ‘Nuf said, as I am sure they are trying their best. 7. I should stop whining... life is pretty darn good as is. panel.

-

I know it is hard to believe, but I have gone beyond "knee deep" into this with the tech support person at JPI. For certain serial numbers and older, there is no feature in the firmware to do this AND there is no upgrade to the firmware to fix this problem, presumably because the firmware memory is not large enough to absorb the newer firmware releases. The older firmware versions of the EDM930, like the one I have, sample and store once per six seconds normally, and once per second during Lean Find operation. To get the newer firmware releases, one must do the $500 upgrade and turn in the old unit, BUT the upgrade unit is dimensionally different enough that I can't use it.

-

Truly a shot in the dark. Perhaps someone wants company for a long x-c trip, a lot of under the hood time, etc. I am going to be in Dubois, WY and need to get back east to VT. I can meet you at any airport in the vicinity, say Jackson Hole to the west or Casper to the east for example. Even further if necessary.

-

My EDM 930 is p/n: 790000-C-624, s/n: 01834. The newer EDM930 units obviously have newer firmware and feature a much faster sample rate than the 1 sample every 6 seconds that mine has. The newer units are also the tiniest bit larger than the old units and simply can't fit into my panel without cutting into structural tubes! See the attached drawing for the gory details. The last few times I have tried to download data from my EDM930, after happily doing this same thing for many years, the EDM930 unit began behaving differently. For example, when I plug in the memory stick to the USB port on the front of the unit, the unit detects that event as before and asks if I want to download the new data only, or change the settings. I usually select new data only. Instead of downloading the data file as it has for many years, the screen displays “Syncing… “ and then a countdown of sync files from about 50 or so down to 1 is displayed, then a very abbreviated download occurs. It produces only a tiny 3-4KB file on the memory stick. I can see that the file contains only some header information and contains no real engine data at all. I can tell this is the case, because I compared the abbreviated download file to some previous downloads. When I try to read that small data file in EZ Trends, the EZ Trends software can’t even load the data file, complaining that there is “No Flight Data in Download”. Indeed that is the case. Tech Support at JPI is... well, not helpful. I'd happily pay the $500 upgrade and move up to the newer EDM930 units BUT IT WILL NOT FIT INTO MY PANEL WITHOUT MAJOR CHANGES TO THE PANEL. The Tech Support guy there just keeps repeating, "we don't support the older units any longer..." rather than giving some real help. JPI will "upgrade" an older EDM930 to a newer EDM930 for $500 plus your old unit as a "core". If any of you folks are planning to do this upgrade with JPI, AND your old EDM930 is still working 100% properly including data downloads to a memory stick, I would like your old EDM930 and will give you mine plus $100 if you give me your working unit. You can then send in my unit for the exchange core for an effective $400 exchange, and I will use your old unit, and, with luck, have the data downloads working properly once again.

-

The “shape” of the EGT #4 curve is indeed different, an outlier, and troublesome. It is hard to believe that there is anything wrong with the injectors themselves. Two different sets, one brand spanking new, both show the same outlier in Cyl #4 regardless of the sizes of the jetting. Nevertheless, I will have another look. Swapping #2 and #4 sensors? Interesting, and what the heck, I’ll probably try that, but... as we all know, the absolute value of the EGTs is not terribly accurate. The fact that there is a peak to the temperatures is the important part, within reason. I expect the flattish shape of the curve to stay with #4 cylinder no matter what probe we put in there. Maybe worthy of a try, just in case though. Easy to do. What a surprise that will be if it follows the probe! As to the time required to do another baby jar test? Only a few hours at my amateur mechanic snail’s pace. Enjoyable few hours... Anecdote: Early on in the break-in process, we found cylinder #2 was taking over the leanest position from #4. I pulled the injector, and the eagle-eyed mechanic spotted the tiniest bit of thread goo across the injector port. Cleaned it out, and it was back to “normal” with cylinder #4 back it the leanest position once again. I can’t even recall how many times I have pulled these injectors - especially #4 - to look for this kind of resolution to the issue. Hope springs eternal.

-

Spider, yes. Fuel lines, no. The fuel lines will be the focus of the next phase of investigation. First by performing a baby jar test. If no significant variation found (again), then mechanical cleaning, reaming and close inspecting for obstructions and/or kinks. A critical piece of the story is that cylinders 1-3 have gotten a little tighter after replacing the motor, injectors, et al. Cylinder #4 was and still is the outlier going back to data collected prior to the change to the new motor. That makes me think it has to be something that is still in common, i.e., the fuel lines from the spider. Or, perhaps, as I initially asked in this post, does this particular turbo-normalized set-up somehow jam more air into cylinder #4, making it the leanest? As for Anthony’s suggestion about contacting Paul K, he is the one at Savvy who is watching over all of this, and he’s looking into the quirk I think I detected with the “share” feature. Thanks for your help to this MS place!

-

I did mean "too lean". Thanks. Corrected now. I will check all your suggestions out soon and report back. As for with and without turbo, I did GAMI sweeps at 6K and 8K at high MP and 10" lower just to eliminate that possibility. Same results.

-

The folks at Savvy are working on it. The only "share" that was possible was one that shared (made public) about 305 flights. Seemed like a bad idea.

-

I’ve shared the data via Savvy’s share feature. https://apps.savvyaviation.com/flights/4533779/a716f153-fd4f-4750-8faa-7dfd77d5add1 --- Flight 2020-11-20 20:12 Z. GAMI sweep #1 from about 22 - 25 minutes into the flight (JPI data time 20:34:00 - 20:38:00) yields a SPREAD of ~.8 gph GAMI sweep #2 from about 29 - 33 minutes into the flight (JPI data time 20:42:30 - 20:45:40) yields a SPREAD of ~.9 gph GAMI sweep #3 from about 38 - 42 minutes into the flight (JPI data time 20:50:00 - 20:54:30) yields a SPREAD of ~.9 gph The data file (*.jpi) is the native format of JPI’s EDM 930. The tool to analyze it in its native format is JPI’s data analysis tool, EZ Trends. Windows only, afaik.

-

Here is the EDM930 data from the most recent flight, including 3 GAMI sweeps, all done with the new set of injectors, at an altitude of 5K. (Special note: Please don't ask for a faster sampling rate for the data. This is as good as it gets for my particular model and firmware. In an attempt to partially compensate for the slower sample rate, I made the adjustments to the mixture knob precisely as follows: 1/2 turn CCW (leaner) every 30 seconds. On my particular unit, it appears to sample 1 time every 6 seconds in "normal" mode, but when I enter LF (Lean Find mode) it changes to 1 sample per 1 second. I believe in newer units, it can sample at 6sps. Not the case with my unit.) U201120.JPI

-

The baby jar test was done about 6 months ago when we were first digging into the problem of a too lean cylinder#4. At that time, the nozzles were E D G H, which is how they were when I acquired the plane. As is the case now, the nozzle in cylinder #4 was the largest. The previous owner had been messing with the GAMI injectors, too, but with a different set of criteria. He was not trying to set things up to fly LOP, he was trying to equalize the EGT's. Don't ask!!! In view of that, and the fact I was worried about the nozzles having been tampered with (reamed out, or damaged in some other way) I asked GAMI to allow me to start over again. And that is how we got started with the current, brand spanking new, roster of nozzles: A A D J. I am going to re-run the baby jar test this week. Two things have been suggested to me by Savvy. 1) the GAMI sweep is an accurate test, and, 2) the baby jar test is a crude test. Perhaps there is an obstruction, a kink, or an extra bend in the fuel line to cylinder# #4. Another carefully administered baby jar test may reveal something along those lines (no pun intended).

-

The plane is a 1967 M20E. The engine is a Lycoming IO360 A1A. It is turbo-normalized. The engine, prop and all major components have recently been completely overhauled to be "0" time. This overhaul process included the fuel servo, turbo, prop governor, all 4 cylinders, valves, cam shaft, fuel pump, spider, addition of Surefly ignition. For good measure, the GAMI injectors were all replaced with new ones giving us a clean starting point. The jets are, in order from 1 to 4: A A D J. We came up with this selection of injectors based on the GAMI spread seen shortly after the engine was overhauled / broken in. That GAMI sweep showed #4 was STILL the leanest cylinder, just as it had been prior to all the overhaul work. A "baby jar" test was run and showed no appreciable variation in the fuel delivered to the cylinders. (Photo of the jars with fuel in them is attached.) After all of this, the GAMI sweeps are still showing that cylinder #4 is too lean relative to the others. The spreads on the sweeps are .8 - 1.2. The data from the EDM930 was sent to Savvy and they concur that cylinder #4 is STILL TOO LEAN! (See Savvy's report attached.) I checked for induction leaks by doing a GAMI sweep at MP = atmospheric pressure and then another at MP = 10" Hg lower in an attempt to really force the induction leak occur so we could see the difference in the leaking cylinder - no luck. There did not appear to be an induction leak. The only thing I can think of at this time is that the turbo-normalizer setup in my plane "jams" too much air into cylinder#4. Do any of you have a t-n setup in this same engine type and have this same problem? Short story... I am befuddled and I don't know where to go with this investigation. Any suggestions? (On the positive side, the plane is 20-30 knots faster now that it is really running on all 4 cylinders instead of 2.5 cylinders and a bad cam lobe! Maybe I should stop whining about this, fly ROP and enjoy the ride. But what's the fun in that?) 2020-11-23 Scott Winick N3215F.pdf

-

Way too early, but IO-360 A1A is kaput

Moonbat replied to Moonbat's topic in Vintage Mooneys (pre-J models)

Judging from take off data taken from the EDM930, both before and after the O/H on both the engine and prop, it was easy to achieve 2700 RPM, given the turbo-normalizer and low density altitudes prevalent at my home airport. In my particular case, I don't think that there were many clues to be gained from the static RPM measurement. -

Way too early, but IO-360 A1A is kaput

Moonbat replied to Moonbat's topic in Vintage Mooneys (pre-J models)

Thanks - very helpful comment. I'll pass it on to the mechanic this morning. -

Way too early, but IO-360 A1A is kaput

Moonbat replied to Moonbat's topic in Vintage Mooneys (pre-J models)

Thanks - very helpful comment. I'll pass it on to the mechanic this morning. -

Way too early, but IO-360 A1A is kaput

Moonbat replied to Moonbat's topic in Vintage Mooneys (pre-J models)

The engine was last overhauled in 2006. Assuming the CAM shaft was part of that overhaul. Without digging further (which I will do later) that's the best answer I can give right now. -

Way too early, but IO-360 A1A is kaput

Moonbat replied to Moonbat's topic in Vintage Mooneys (pre-J models)

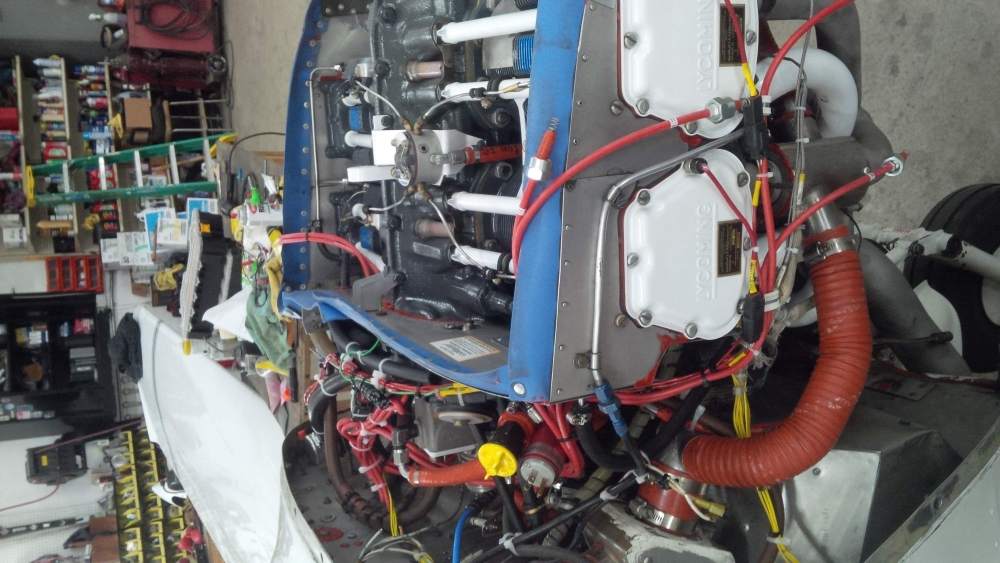

Engine was overhauled in the local shop. I really wanted to see the entire process myself, and help where possible. We also want to support the local FBO during the Wuhan virus times. The re-assembly included pre-lubricating ALL components by hand. The engine sat for only 6 days waiting for a couple of fittings that were left off the shipment from the crankcase overhauler. I’ll answer the “cost” question in detail later, but it included the crank case, new cam shaft, overhauled cylinders, overhauled pistons, rings, valves, seats, push rods, lifters, turbo, fuel servo, governor, exhaust tubes, replace one Bendix with Slick, replace other Bendix with Surefly electronic ignition, overhaul 3-blade MT12 composite prop, new baffling, sand/paint engine mount, new engine mount rubber. The cost of all of this with shipping, parts, labor will come in about $35K. Ran the engine today! One problem with setting the timing on the Surefly was the only issue we had that prevented a first time firing. Once corrected, whoosh... and off we went to begin break-in. 3 separate 4 minutes runs with the cowling off, cooled the engine to 100F after each time. Looking for leaks and weeps and any abnormal temps or pressures anywhere. Most significant finding was an over pressure on the fuel pressure. It was hovering around the 30psi mark, which is the limit between the normal range and the alarm range. It did not fluctuate with RPM or MP. The FF was normal and looked “about right” for the various power settings. We bled out a bit of air from the fuel line, but the pressure remained around the 30psi mark. More investigation required. Then we cowled up the engine, and did another run-up including a 2000 RPM test, then a full take off power test, then the first flight following guidance to run at high RPM and 75% power for 20 minutes, then varying power settings for the remainder of the first hour - all full rich mixtures. 60%-85% in slow, five minute intervals, then back down and on in for a high power landing. Flown at 3.5K and 70F OAT. Slowing for landing was the hardest part, even with speed brakes. EGT/CHT were very even throughout. CHTs were generally 308-330, all recorded on the EDM900. More break-in flying tomorrow and I hope over the Labor Day weekend too. -

Way too early, but IO-360 A1A is kaput

Moonbat replied to Moonbat's topic in Vintage Mooneys (pre-J models)

Today we spun the new engine with no spark plugs in it to pressurize the oil through throughout the engine. Tomorrow is the first engine run. So excited to get going again. New Surefly, and just about everything else is either new or newly overhauled: turbo, fuel servo, prop governor, cylinders, pistons, bearings, valves, cam shaft, 2nd magneto, ignition cables, overhauled MT-12 prop, baffles and aluminum airflow deflectors, exhaust tubes, and more. The engine has never looked so well organized, clean, tidy. Wish us luck! (I apologize in advance for the rotated photos.) -

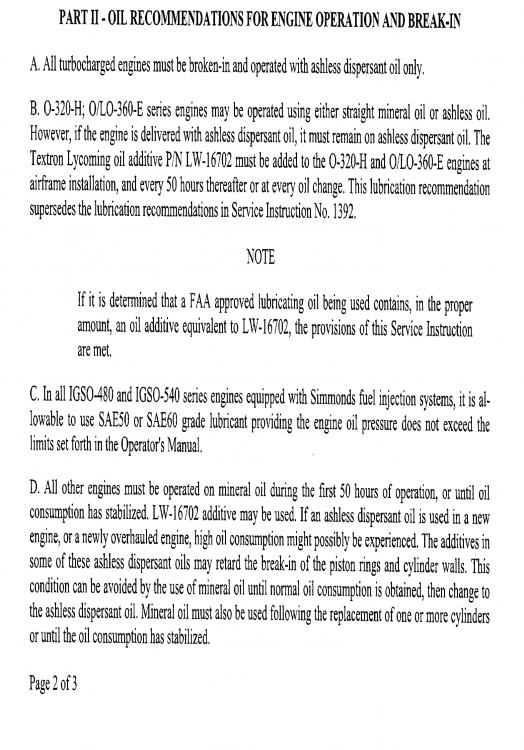

So when reading the Lycoming Service Instruction 1014 (Lubricating Oil Instructions) you're saying that I should consider my turbo-normalized engine as a normal (not turbo-charged) engine? If so, the instruction (D) says I should use straight mineral oil - no ashless dispersants and no other additives - for the first 50 hours. That is not the same as Phillips X/C 20/50, is it?

-

Question is about the lubricant to use for initial break-in of an overhauled to "0" time engine. The Lycoming guidance specifically says that for turbocharged (and I assume that includes turbo-normalized engines like mine) use mineral oil. In other places - including from the mechanic completing the engine overhaul - there are recommendations / statements about using other, ashless dispersant (AD) oils. Can the brain trust offer me some guidance based on your knowledge and experience?

-

Good “catch” to be sure. I really appreciate your posting, and that you included the SB. It applies to my current situation (engine overhaul in process) AND the engine just happens to be off the mounts right now. I spent yesterday afternoon cleaning the firewall and removing obstructions on the engine mount before I was to begin sanding in preparation to re-paint it. But now I may have to go down a different path once I get back over to the plane to see if this SB has been complied with or not. Based on what I’ve seen so far, I’m betting on “not”. I owe you.

-

Way too early, but IO-360 A1A is kaput

Moonbat replied to Moonbat's topic in Vintage Mooneys (pre-J models)

Dreaming of 2200 hours the next time! (In self-defense, I did previously own a 1965 Comanche and was able to get to 2400 hours with no problems. It was not t-n'd or t-c'd. Maybe that's the issue in my case.) -

Way too early, but IO-360 A1A is kaput

Moonbat replied to Moonbat's topic in Vintage Mooneys (pre-J models)

Oil analysis every 25 hours or so. All seemed pretty normal except for one outlier report about two years ago. Savvy Analysis reports really nailed it though. The detailed declining FF, power output, CHT's over time. There was clearly something headed inthe wrong direction. However I was masking some of it by using the t-n system to get some compensated performance out of the engine. Really what I was doing was pushing a sick engine even harder, probably shortening the time to a catastrophic failure. Got to read the tea leaves so carefully! -

Way too early, but IO-360 A1A is kaput

Moonbat replied to Moonbat's topic in Vintage Mooneys (pre-J models)

Here are three shots of the new paperweight, er, old camshaft. The first photo is the entire cam shaft (no yellow arrow). (I couldn’t force it to show properly vertical.) The second has a yellow arrow pointing at the missing intake lobe for cylinders 1 & 2. lobe. It is supposed to protrude to the right. There is a slight bump remaining, but about 1/2” is missing. In the third photo, the cam lobe should be coming right toward you, but all you see is the shiny, mostly flat spot where the lobe used to be. -

Way too early, but IO-360 A1A is kaput

Moonbat replied to Moonbat's topic in Vintage Mooneys (pre-J models)

We (Paul K from Savvy, the mechanic here named Zack) think that the fuel servo was at somewhat the culprit for the FF. It was leaking air at the grommet where the linkage enters the body. It showed a bit of play and bubbled at the input pressure test during the annual six months ago in Dec 2019. The fuel servo is to be repaired / replaced as part of this ongoing overhaul. Max FF (generally take-off) declined from ~18 gph to 14.5 gph over that time. All the while at the other end, the FF was worse for cruise regimes. Up from ~9gph to more like 11gph. The thinking here is that I was probably compensating for the engine's lost power due to it wasn't breathing properly by pushing the MP and RPMs to a higher level to get some performance out of it.