M20GforMe

Verified Member-

Posts

30 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Store

Everything posted by M20GforMe

-

Don’t recall the exact number, but it was somewhere in the very high 700’s/very low 800’s range I agree that it seems odd. The engine shop is still in business, Aero Engines of Winchester, but they were useless when I called. They’re called Aero Services of Winchester now. I’m fearful of this, but going to have savvy give a second opinion. The pushrods all being bent at least gives some answer if true. It feels insane to think an engine shop would do this though and put it out in the world in a certified aircraft

-

I think I answered my own question, but will always welcome more information (hopefully posting here saves the next sucker that goes through the same thing as me some pain) Source Document: https://www.lycoming.com/sites/default/files/attachments/SI1060U%20Push%20Rods.pdf Looks like lengths -34 through -37 are allowed on the O-360-A1D engine with the Flat Tappets and -28 through -34 lengths would have been allowed on the engine with Roller Tappets I called, and the shop told me that half my original pushrods were -34, the other half were -35, and all of them were allegedly bent a bit so that could explain why there were no metal shavings. They bent themselves into fitting apparently. They said I had Flat Tappet's so I wouldn't be able to use the shorter pushrods unless I was able to show they were approved for that engine configuration.

-

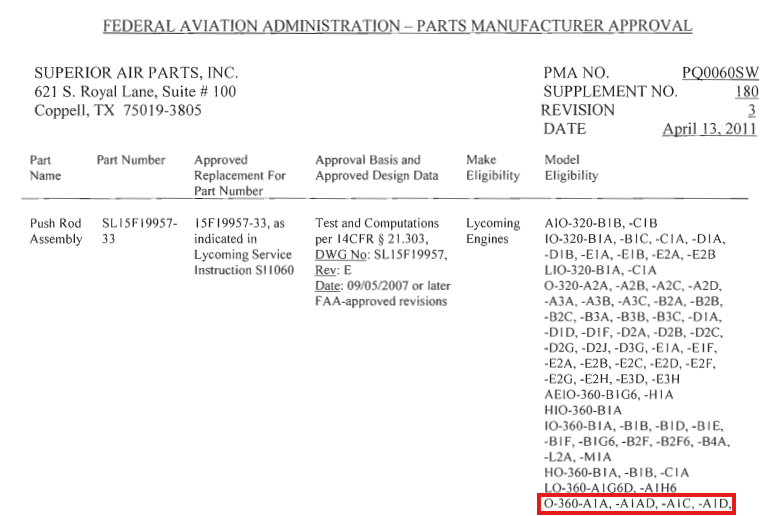

Spoke with them again today. They are not in Savvy's program, but said they would be willing to work with Savvy. Theyre still convinced the Case is milled beyond acceptable tolerances. Savvy's initial response was "Dry lifter clearances that are too tight will result in a failed camshaft due to the excessive load on the valve train. Something's not adding up here. Have them inspect the hydraulic lifters in accordance with attachment 2 of Lycoming Service Instruction 1011N (link below), then verify and adjust the dry valve clearance in accordance with Lycoming Service Instruction 1060U. (link below) https://www.lycoming.com/sites/default/files/attachments/SI1011N%2520Tappets%2520and%2520Lifters.pdf https://www.lycoming.com/sites/default/files/attachments/SI1060U%2520Push%2520Rods.pdf Let me know what they find." The A&P shop said they had followed those instructions when doing it initially. Savvy is reaching out to the A&P Shop to become one of their partner shops I believe, if they sign up, I will have Savvy work directly with them to give a second opinion before any brash decisions are made. The bad news is that the A&P shop said they're not comfortable signing a ferry permit, according to them, if they put the engine back together, even with the shorter pushrods, or the original parts, they think it'll tear itself apart. In other news - I did see that there were shorter pushrods on Superior Air Parts that said they were eligible for this engine https://www.superiorairparts.com/~superior/SuperiorEligibilities/SuperiorPart.php?strPartNum=SL15F19957-33 I called superior to ask if they could actually be used on a certified O-360-A1D, and they said it could. They directed me to a PMA that shows eligibility for this engine, (seen below), but I believe this only means it can be substituted for the original 15F19957-33 part, correct? The Lycoming Push Rod Identification Service Bulletin only calls out the -34, -35, and -36 lengths to be used on the O-360-A1D engine. The below is an excerpt from the Lycoming Push Rod Identification Service Bulletin (Image Source: https://www.lycoming.com/sites/default/files/attachments/SI1060U%20Push%20Rods.pdf) Since I can not find anything saying this -33 size pushrod can fit in my O-360 outside of this PMA, I cannot legally have them use it on a certified aircraft, correct?

-

Going over the the Superior Air Parts site, their 33 pushrod does have the O-369-A1D listed as an eligibility. https://www.superiorairparts.com/~superior/SuperiorEligibilities/SuperiorPart.php?strPartNum=SL15F19957-33 I’m waiting on savvy MX to get back to me, but my inclination at this time is to have them finish the annual as “unairworthy”, have them put the engine back together, and get a ferry permit to take it to G&N or Poplar Grove to have them look at it. I also asked the shop owner to speak with me tomorrow to make sure they’ll give a ferry permit if we go down that avenue. Seems like the 33 pushrod would potentially solve our problem though if I could get them to install them. I’m just afraid they won’t sign off on the Ferry Permit and I’ll be stuck having them pull the engine and shipping it out

-

I did, I found a good write up on csobeech (I found the link here on MooneySpace) and purchased one of the fluorosilicone Shaw O-Ring kits from Gallagher https://www.gallagheraviationllc.com/Gallagher-Aviation-Shaw-431531-Fluorosilicone-Fuel-Cap-Kit_p_161.html The write up was here https://www.csobeech.com/files/O-RingChange.pdf

-

When the log issue had come up, I thought it may be worse than it was, and didn’t want to tie the issue to my plane on the internet. At the same time though, I’m not looking to cut corners anywhere on ownership, so there’s not really anything to hide. I didn’t expect the traction that this post has gotten, but I’m very thankful for it. I don’t think it’s productive to lose sleep on the log issue anymore, but I did call the engine shop that did the overhaul in 2007, Aero Services of Winchester, to see if they could tell me if they had any information on why the engine was overhauled (was not near TBO) so that I could have an idea of what led to the missing page right before the overhaul. The lady that answered was very nice, but she had me on speaker and somebody (I would imagine an owner) chimed in immediately when I mentioned the overhaul from 2007 and was pretty rude about me asking if they may have an old record. They won’t get a penny out of me ever, although Im fairly certain ownership has changed since the overhaul. I called another shop or two like Bolduc (now Horizon) to get IRAN timelines and estimates if I had to go down that avenue and Kevin there was great, but they were out 6-8 months if I remember right. In case anyone else is looking, Poplar Grove here was out 8 months. Airmark Overhaul was by far the shortest of those I called at about 10-12 weeks.

-

Would this be legal if it’s not specified for that engine? If anybody knows an A&P in the area with good lycoming knowledge that can give a second opinion and can travel to Lewis university (KLOT), I’d be willing to pay their rate for a good second opinion. I called Poplar Grove Airmotive as they’re nearby, (My A&P had also been in touch with them to ask questions on this previously) but they said they are too backed up to have anyone travel off site. The shop it’s at, Coletti, was very friendly about welcoming another A&P in for a second opinion

-

A&P said part numbers from old pushrods were sl15f19957-35, part numbers from new pushrods he was replacing them with are sl15f19957-34 I couldn't tell you, I bought the plane at the end of last year, and its only flown maybe 10 hours since I've had it. My CFI grounded it for a while in January because the nose gear door had some play to it (just needed new heim bearings), but the first A&P shop (Revv at 06C, on my field) took 3 weeks to tell me that they didnt have time to get to it, so then we took it to another shop (Travel Express) at Dupage who fixed that after a week or two. When my CFI flew it back, he said it was running rough, so he flew it back to Dupage, and was going to have his buddy that is an A&P look at it. After 2 weeks in his hanger waiting for his buddy to look at it, his buddy said he didn't have time to take it on (or that it was a bigger project than he could fit in, rather), so my CFI taxi'd it back to Travel Express on the same field, and they found water in the carbeurator. (It was hangered when I bought it, and at my field, but it must have sat outside at travel express for a bit the first time around). They fixed it but that took 3 weeks, and said the engine ran great. Then when I got it back, I checked the fuel tanks and they had water in them. They fixed the water in the carb problem, but not the root cause, which made me decide to not do my annual with them. So then I "may or may not have" changed the seals on the gas caps myself (This isn't incriminating, is it?... I am a PPL student). I was supposed to fly again with my CFI a week later, but when the day came, he said hes not comfortable flying the plane since I (a student) changed the fuel cap O-Rings myself (even though he was there watching me and talking to me when I did it...). So then it sat for another month as my CFI wouldn't fly it until the annual came around, which was April 30th. It's been at the shop since then. The silver lining in all this is that I did tell the A&P to check the gas caps during the annual, he said I did a good job at that at least.... It's been a tough 8 months of plane ownership...

-

I went to the shop today and I took some videos of the A&P explaining their process and logic, so that they are not lost in translation. What happened was there was a bent push rod housing, they replaced it, removed the rocker, saw the rocker valve side face had wear in it, and thats where this snowballed from I broke it down into three short videos Video 1: (2 minutes) Breakdown of how he came upon the issue and what they found. Damage to rocker valve side face shown Video 2: (38 seconds) Explains the bleeding process they did for the hydraulic lifters. They share that the rocker arm is wearing itself into a clearance. (Can anyone verify if this process sounds like it was done correctly?) Video 3: (2 Minutes) Explains the measurements they took that made them believe the crank case has been machined past acceptable tolerances. (I'm not convinced the measurements they did were the most accurate since it looks like theyre measuring from a score line, but maybe someone can glance at the housing and see if it looks milled down beyond normal). PS - we did look at another engine, but it had more washers on the crank case bolts, so the "counting threads" approach was debunked Feedback is appreciated! They're waiting for me to give me the next steps as of the moment

-

Thank you for the input - I spoke with a savvy member and they said it’s a bit late for them to get involved, past the point of where they could be much help. I’ll speak with the shop owner directly and see if they can get it put back together with original parts. Maybe I can invest in an engine monitor instead for the time being. Would anyone happen to know if the attached alternator would have ever been acceptable on the plane? This was the one on the plane that the A&P said was automotive and was illegal to have. He said they were trying to find correct brackets for it because it was misaligned originally, but then they saw the label and said it was illegal

-

Doing some more digging here, is there a way you would recommend approaching this? Do I need to buy a certain level of their plan and then ask for Mike? Or is it not Mike specifically that I need, but just anyone from Savvy? Would I need to schedule a time with them and my A&P together? Sorry just trying to get my ducks in a row before I reach out to Savvy. I don’t want to use anyone’s time inefficiently. Thank you!

-

As the 32 year old who has to pay for a wedding this year too, I figured it was best to plan for extra seats in the future I trust myself behind a wrench pretty well, but I don’t know enough about aviation to take it all on myself, and it’s not the place I want to take risks. I think I’ll spend the next year finding an A&P that will let owners assist, and get my paws greasy to learn more. The guys over at DACY seemed like they were genuine lovers of aviation and would have let me get my hands dirty, but I was never able to get on their schedule the 2 or 3 times I tried

-

Don’t get me wrong, I don’t think that was a $405 task by any stretch of the imagination. As for parts markup, everyone will have a varying answer on this. If it’s 15% up to maybe 30% then it’s probably not far off base. I wouldn’t be able to afford a plane if I sold things at cost at my dayjob either. I also think the acceptable markup percentage varies by cost of part. I don’t want to pay an installer 100% more on a $6K EFIS in addition to the labor. But I also doubt the avionics guy is paying retail for the avionics either. At the same time, if he charged me $2 for a screw that he got for $1, I wouldn’t be complaining. But nothing costs $1 in aviation so I guess that’s a moot point

-

This is correct - I was trying to not name names, as I don't think there was anything to gain/lose by naming the A&P as of current. It's a newer shop. From my understanding, the owner Brenden Coletti worked at 06C, then when the FBO at 06C was taken over by Revv, he didnt like the way Revv was operating things and left to start his own shop. I had my plane at Revv previously and was definitely not satisfied with their process/work. To my knowledge, 06C was a Mooney Service Center up until Revv took over. (I believe the FBO was Schaumburg Flyers back then) There has been an M20K at Revv thats been grounded since November, and since then, Revv has gotten the boot (or left on their own accord, don't know the full story) from the field and its been taken over by Holiday Airways, who has not yet opened their A&P shop. Given that my Flight School owner said he would trust Colletti, and that I couldn't get another A&P to commit to taking on the annual (except Travel Express at Dupage, with whom I have had a not great experience with already), I took the plane to Colletti. I will say, besides having to have a wallet that can handle it, breaking into aviation without a pre-existing aviation "network" has been tough. That being said, everyone has been welcoming and very helpful, but it took a while to meet the guys in town who have Mooney's, I could've used their wealth of knowledge and network sooner. Having a Mooney in a world of Cessna's definitely can feel like driving a Porsche in the middle of Chevy Country.

-

I may have misspoke, I had him send me a photo, it was a Fram filter, but doesn’t look like it’s in the fuel system. I’m going to swing by the shop tomorrow, get a detailed explanation and photos of the rocker situation, and see if I can share them here for some additional guidance. A big thank you to everyone who has provided some input already. I’ll record the mechanics explanation of the situation so nothing is lost in translation when I post the update here. Also someone touched on the serial plate number before - I asked about this a few weeks ago. The serial plate is where it’s supposed to be, I watched videos of other G’s and found the plate to be in the same location. I had intentions to fly the plane to Canada and back. When I asked the A&P to leave it as is and remove from the quote, they said “The data plate is in the original spot. I wasn't going to remove the original one. I was going to stamp and install another one on the pilot's side tail. If you weren't planning on flying out of the country, we would not worry about it. But since you do plan on it. It has to be secured to the exterior fuselage, near the on the rear of the fuselage near the tail surfaces”

-

To the shops credit - when they dropped the initial quote on me, they didn’t just send it to me. They had me come in, showed me everything on the quote on the actual plane, and walked me through them line by line as they presented the quote. I do think they’re knowledgeable, this was not meant to be slander against the A&P shop. At the end of the day, I want a safe aircraft and I’m not doubting that they will deliver that. I also don’t doubt that they’re experienced. The owner of the shop used to work at the shop at my now home field, which used to be a Mooney Service Center. (I’m not sure how much overlap there was though either) I also totally understand parts being marked up within reason, sourcing and such have costs involved. I obviously don’t think I’m getting the best deal on the block, which I’m okay with, but I don’t want to be getting screwed over either which I don’t think they’re trying to do. I think they’re airing on the side of caution but also trying to run a business What’s going to stink is being $125k into a plane worth $80k at the end of this, and also not having a plane for 6 more months. But I’ll appreciate having a plane I can trust with my life when I do finally get to fly it

-

I believe that replacement rockers were sourced, sending them out to be repaired wasn’t an option presented to me. I was just sent some photos, the prop and alternator are off and a lot of the rest of the plane hasn’t been put back together yet but I think those repairs are about done and they could be reassembled. The engine is not removed but is partially disassembled for the rocker replacement

-

I don’t believe the engine is removed, I’ve asked for photos of its current state. If I had to guess the prop hasn’t been reinstalled and I’m unsure if the new alternator has been installed yet. Engine would most likely be disassembled for the rocker replacement. Everything on the quote is about done. Since they were almost all airworthiness items I didn’t think I really had an option besides approving.

-

I guess I should ask what my options are at this point. The plane is at their shop, it’s out of annual now (wasn’t when they got it). It’s been a royal pain in the ass finding an A&P in the Chicago area. I called many places and got everything from “we don’t have the bandwidth” to “call us next month and see if we’re available”. These guys had a few mooneys in their shop when I took it there so it installed some confidence. Do I tell them to put it back together and get a ferry permit to have it taken somewhere else? Or am I screwed by the fact that’s it’s in their possession and out of annual (which was my original thought and why I’ve been saying yes to everything). The annual was supposed to be done in about a week with all the squawks on the original quote I shared. (They’ve had it for about 5 weeks now) They seem experienced and like they know what they’re doing, but they definitely aren’t the cost effective guy on the block. It’s at KLOT right now if anyone has advice in this area.