-

Posts

16 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by chooch

-

Lucky you. My linkage to governor was checked when governor came back from overhaul. Oil filter is clean but perhaps it's good idea to check also oil screen. BTW: anyone has an idea how to remove this screen tube? Space seems very tight and I doubt I will be able to retract the screen

-

Help! As mentioned in another thread, I've been facing prop overspeed beyond 2700 rpm red line - on the ground all seems fine but when airborn and oil gets warm the prop overspeeds (noticed 2 times during initial climb). I had governor overhauled but it did not solve the problem. So I did the test described in Lycoming SI 1462A and...it failed (I did it with engine at ambient temperature but I dont think it impacted the results anyhow). So, I got the prop dismantled and inspected plugs at the crankshaft end - seems like they both sit tight. Next, I machined tight plastic cap with gasket, bolted it to the prop flange and made Lycoming pressure test again - still no pressure buildup and distinc oil gurgling heard inside the engine case. Then, I disconnected hose delivering oil from the governor to front of the engine case, pluged the fitting in the engine case and supplied air pressure through the plastic cap bolted in place of the governor - also no pressure buildup and oil gurgling inside the engine :-( Any ideas what else I could check to find cause of the issue other than worn front bearing requiring splitting the engine?! Any suggestions more than wellcome! thanks in advance, Marek

-

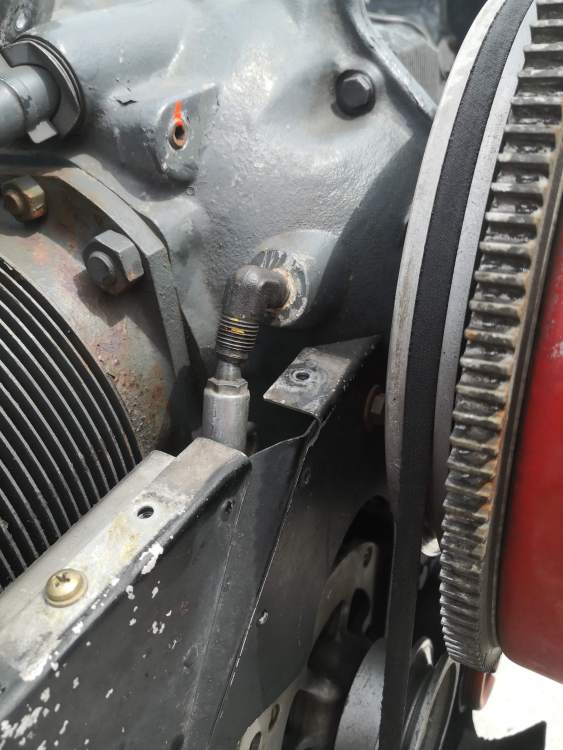

On my picture you can see tip of air gun pushed against fitting in engine's case - I did it to test if prop blades would move when supplied with airflow higher than through the leak detector. Main difference is that your engine has oil cahnnel from the governor to prop made of steel or aluminium tube while in my engine this connection is done with flexible hose - both versions are mentioned in Lycoming Parts Manual (steel tube is better as it has no lifetime limitaions while hose or aluminium tubes require periodic replacement). regards, m.

-

Was the test done with engine and oil warmed up or at ambient temperature? What pressure did you achieve?

-

Comming back on my issues with rpm control in my '77 J: background: on the ground and with cold oil all seems to work fine, propeller responds to movements of blue lever but once in the air and oil gets warm I lose rpm control and engine overspeeds beyond 2700rpm with no response to blue lever movements (fortunately I spotted the issue on time and immediately reduced thrrotle to stay below 2700rpm). I got governor overhauled but problem still not solved. Yesterday I performed leak down test according to Lycoming SI 1462A but with engine and oil at ambient temperature (no engine run up prior to the test) - with 40 psi on Gauge #1 of the leak detector there was only 1-2 psi on Gauge #2 and I could hear clear gurgling inside the engine. Prop blades didn't move so I twisted them back and forth couple of times together with turning the prop - all I managed to achieve at some point was short (30 second) indication of 20 psi on Gauge #2 but it happend only once and for short time - afterwards pressure on second gauge stayed just slightly above 0. I also checked passage though prop control oil hose (from governor prop control port to front engine port) and there is no blockage in it. Also when I pushed air gun to engine front port (see one of attached photos) and supplied compressed air the blades moved but gurgling in the engine was even louder. So, before moving to next step i.e. pulling the propeller off, couple of questions: 1. Is there any chance that repeating Lycoming leak test but this time with engine and oil warmed up to normal operating temperatures will give better results? 2. @carusoam: If it turns out that the aluminium disc in the crankshaft is leaky or gone, is it something what can be fixed in the field, without dismantling the engine? My Lycoming guys told me that this requires the crankshaft to be sent to Lycoming for this fix and quoted it for over 13.000 USD.... :-( BTW: it's item #7 on attached drawing from Lycoming parts manual,. right? thanks in advance for any hints or help, regards, Marek

-

-

Thanks for update @EricJ. Hope that everything will go well with overhauled governor. I'm having the test plate machined this week (any workshop can do it - it costs $50 in Poland, most of it being price of 1/8" NPT taps not so common in Europe). If everything goes as planned the pressure test is scheduled next week. regards, Marek

-

Hi @EricJ. Thanks for sharing your thoughts and the link - interesting reading. Are you experiencing any issues with rpm control or just want to do the pressure test as you have the governor removed anyway?

-

I'm planning to do that if results of test described in Lycoming Service Instruction 1462A are OK. Although I doubt if there will be any blockage by sludge since with cold/viscous oil and on the ground all works fine and problem occurs only once oil gets warm and only in flight....

-

Thanks for detailed explanation. I already spoke with the guys who overhauled the governor - they confirmed that it was tested after OH, before shipment back to me and all worked fine. So next step is to look somewhere else - engine or prop hub.... My plan is to start with pressure test as described in Lycoming SI before I decide to remove the prop....

-

Has this been really solved by greasing? I'm expecting overspeed issues and lack of rpm control in flight, when oil gets warm (on the ground everything works fine). Governor was overhauled and installed IAW M20-120 Service Instruction but problem did not disappear I have 3-blade Hoffmann prop and there is nothing mentioned in the maintenance manual but perhaps your solution could be also applied here.... Which page of 115N manual described the procedure you applied?

-

@carusoam Could you elaborate a bit more on this internal shaft seal? Where is it located and how to check if it's ok or not?

-

Seems like an old post but similar issue just happened to my '77 M20J - overspeed when oil is hot and no response to rpm control lever while in flight. Everything works perfect when on the ground. Just had gov overhauled but the problem still exists - during test flight after gov OH I made 2 circuit patterns with no issue but in 3rd pattern I lost rpm control again and had to reduce rpms using throttle level going with MP below 15 inHg to stay below 2700rpm. Immediately after landing I made check on the ground with full power set and everything went back to normal - proper response to rpm lever movements. No oil leakages nor starvation. Any hints where to look for the cause?

-

Hi there, anyone can advise if and how I can get English version of AFM for M20J s/n 24-3178? The plane was sold with French version of AFM - Edition no. 2, January 15, 1994, valid for s/n 24-1686 to 24-3200, 24-3202 and following. thanks in advance for any hints. regards, Marek