-

Posts

48 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Posts posted by tomatl

-

-

On my K 231 I have a three-blade prop, which gives nice glide control due the increased drag at low rpm.

Do you have a 2- pr 3-blade?

Sent from my iPhone using Tapatalk -

Thanks,

I'll share it with the mechanics. Mine does currently not have any cooling line like this going to the alternator.

Best,

Tom

Sent from my iPhone using Tapatalk -

There should be a scat hose from the rear baffle to a plastic cover on the alternator that directs fresh air from the upper plenum to the alternator. My 1985 M20k has this line, his 1979 M20K has the fitting on the baffle and the plastic cover on the alternator but no line connected.

Hope that helps. If you Still have questions, PM me and I will take a picture tomorrow.

Thanks, I‘ll check with the shop. A picture would be great.

Sent from my iPad using Tapatalk -

Helping a friend troubleshoot a similar issue in a 231. Recent engine rebuild and alternator rebuild. We found the cooling line was not reinstalled and are hoping the intermittent issues are heat related. Next step is to reinstall cooling line.

Can you elaborate which "cooling line" you are referring to.

Sent from my iPhone using Tapatalk -

Seems to best option is to get all new/refurbished coupling and let the mechanic deal with it. When taking the alternator off, another problem emerged. Some of the safety wires inside the engine appear to be broken and need to be replaced. (The engine itself has no sign of problems.) Anyone an idea of what could have caused that?

Sent from my iPhone using Tapatalk -

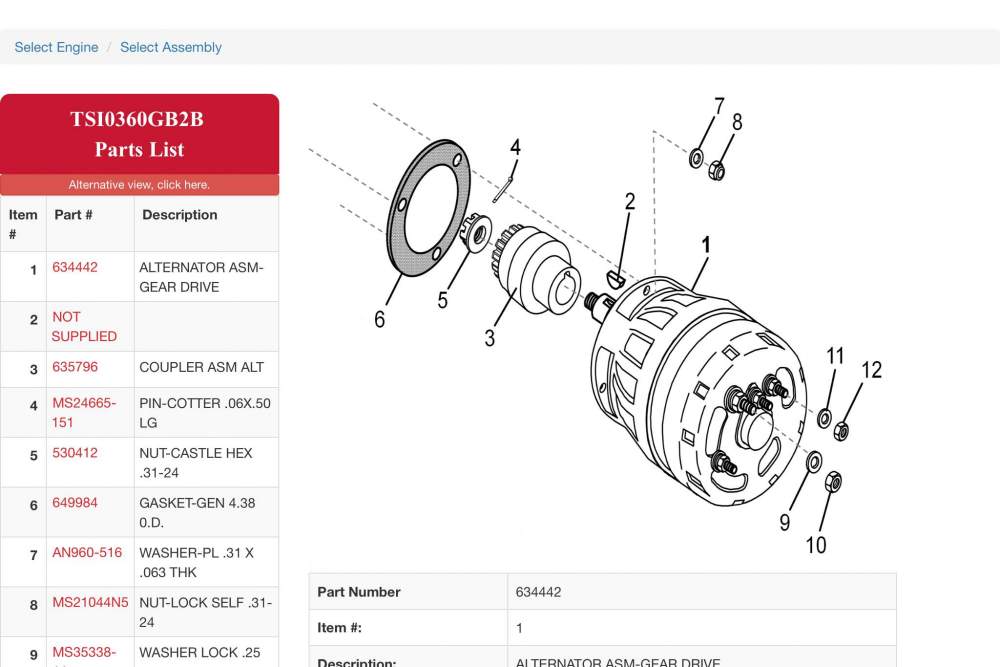

These are pictures of the polymerized clutch. It is the black rubber inside the metal housing. If memory serves, the clutch replacement does not include the gear. I don't see this part in the picture you posted. Focus on the small gear in your picture and anything attached that is/was attached to it.

To my knowledge all TSIO 360 GB/LB engines use a gear driven alternator with this clutch arrangement. Has your engine been modified in any way? Check the logbooks?

These were all the parts that where on the drive. The small gear, as much as I (or the mechanic) could see, did not have a polymerized part or surface to it.

Sent from my iPhone using Tapatalk -

Here are some pictures of the alternator that is installed in the airplane. It is still not clear to me (or the mechanic) where the polymerized coupling is that may start to slip. Maybe I am slow, but could someone please explain. Thanks!

Sent from my iPhone using Tapatalk -

8 hours ago, carusoam said:

Did you consider T/O without instruments? (Not recommended)

You should be able to check MP, and RPM, with FF as a back-up additional piece of information...

Power would need to be on in most newer Mooneys for this to happen...

With hot weather, performance will be down as the DA has changed....

Then there are those days... When things don’t feel just right... takes more practice to get over these kinds of days...

PP thoughts only, not flying mechanic...

Best regards,

-a-

Thanks for the advice! I brought her home with Master OFF but on mine tach or TIT gauges, for example, don't work then. More importantly, I have next to the Aspens no backup airspeed indicator. I would not mind in cruise, but for T/O and Landing, I want a bit of a cushion before losing primary instruments. (The Aspen Emergency Backup Battery will last for a while though.) I am generally more on the conservative side and don't take off on shorter runways when something feels odd.

-

Thanks everyone!

-

As you can tell, there is considerable experience concerning the coupler and alternator on the 231. Two footnotes. First, the bushing is apparently not called out in the service manual as a separate, numbered part. It is there, but is considered part of the coupler. When assembled improperly, as by the newest mechanic in the shop, the IA cannot see or detect whether the bushing is present or not. So have a conversation directly with the guy who is going to do the work if you can, to make sure he understands that bushing must be correctly installed. There have been too many cases where it was left out. It looks like Clarence posted the relevant manual section, very good guy to have around.

Second, if you are going to fly the plane somewhere to get it repaired, just remember your PPL training - you can fly the plane with the Master off. If you get to cruise and get power set up you can go a long way with no Master on. Its a way to save what is in the battery to extend the gear and use the radios when it is time to land. Not as scary as it sounds, but obviously VFR only. Its worth trying a reset of the Alt Fld breaker but the usual rule is try once and stop.

Thanks! I tried to do that today (flying with Master Off to the MSC). On takeoff, the plane did not seem to accelerate properly so I abandoned the plan and put it back into hangar. I hope it's not the "cotter pin and nut into the engine" scenario elaborated here. Definitely in need of a good Mooney mechanic in Western NY.

Sent from my iPhone using Tapatalk -

Thanks everyone for all the good advice. If possible, I'll try to ferry the plane over to the MSC who installed the alternator and will report back as soon as I know what's going on.

Sent from my iPhone using Tapatalk -

As others have said, the alternator is driven by an internal gear coupling. This coupling has an internal rubber slip clutch, which is known to slip after some time.

With the cowls off, you can stick your finger into the side of the alternator and hold the internal cooling fan, very carefully turn the propeller, if you can hold the fan without cutting off the tip of your finger the clutch is slipping.

If it doesn’t slip you have further troubleshooting to do.

Clarence

Where in this schematics is this bushing that sometimes is not correctly installed?

Sent from my iPhone using Tapatalk -

Which MSC did you use? If the drive coupling isn't the issue, there can be an issue with the alternator or voltage regulator. Having someone who understands how the charging system works will help prevent throwing money at a problem. I had a voltage issue last year (with the same symptoms as your's) and a mechanic at my destination convinced me that my alternator was the issue. He said because it failed near the end of my 2 hour flight, heat was causing my alternator to fail then get better on the ground. It turned out to be the voltage regulator that was heating up and causing the issue.

What kind of voltages are you seeing? My replacement Zeftronics has the voltage steady at 14.1 on the JPI.

I get perhaps 13.5 max when everything is working.

Sent from my iPhone using Tapatalk -

Thank you! The installation of the alternator was done last year at a MSC but I did not have good experiences with them in the past. A faulty installation would not surprise me.

Sent from my iPhone using Tapatalk -

Thank you! The installation of the alternator was done last year at a MSC but I did not have good experiences with them in the past. A faulty installation would not surprise me.

Sent from my iPhone using Tapatalk -

A couple of days ago I experiences a low voltage situation with my 231. The voltage warning light was blinking and the ammeter shoed a significant discharge (right on the line between 0 and -70A). I turned back home,

turned off as much as possible,

and reset the alternator. After a while the alternator came back online but quit again after 10' or so. Today, I ran up the engine and the electrical system was operating normally. The mechanics suggested to replace alternator and regulator. (The alternator is just a year old.) Does anyone have a suggestion what the issue might be and how to troubleshoot?

Thanks,

T

Sent from my iPhone using Tapatalk

-

Smart fix!

-

I have not looked at the design of this latch but I assume that is similar to the "over center leverage" of the door or the cowl flaps. On both of these I had malfunction due to bad adjustment by a mechanic. Based on these experiences, I don't assume the baggage door will always latch properly. My baggage door opens from the inside, which is good enough for me. Locking it is on my preflight checklist, and it stays there unless someone has a really strong argument against it.

Sent from my iPhone using Tapatalk -

56 minutes ago, flyboy0681 said:

And all you need is one wayward bird to ruin it.

Just for fun: Assume you are hit by a small, 1 pound, waterfowl while flying at 120 knots. If the total momentum is transferred while the plane travels into the bird (assume 8 inches), the force on the windshield is about 8.5 kN, or equivalent to almost 2000 lbs. This is an order of magnitude more than what you can achieve pushing with your feet (at least for me).

-

To add some numbers to the discussion: I found six reports in the NTSB database that include an unlatched/open baggage door in a Mooney. Half of them with fatalities. Would be interesting to know how this compares to rescues through the back. Mixed bag ...

Sent from my iPad using Tapatalk-

1

1

-

-

I lock it. However, mine has the upgrade allowing unlocking from the inside. Off course, rescue could not enter from the rear ... Difficult question.

Sent from my iPhone using Tapatalk -

The CO monitor is a Drager PAC 6500. I trust the readings. The air is intruding not from a seam in The floor - they are all taped - but rather up from the square opening that the trim wheel chain penetrates through the floor. I have a one piece, smooth belly skin, and things look appropriately installed. It, of course, was off, during annual, and I also had he landing gear actuator services. I’ve looked through the parts manual, but don’t see any seals that could have been missed. Anyone have any pictures with the belly pan off or know of any seals that could have been missed?

Thanks for all the help.

I had exactly the same problem with my M20K (I also have the same monitor, which is very precise.) After weeks of investigation, I found the culprit. In my case it was a single missing belly panel screw in the exhaust path. Caused readings up to 60ppm. A small hole in the wrong place can make quite a difference.

Sent from my iPad using Tapatalk-

2

2

-

-

I rewatched the video again today, and I am still impressed about the great airmanship of the crew! Really well done!

Question to the community: on my K, I always lock the baggage door before each flight. It’s on my checklist after reading about incidents such as this one. However, there are also good reasons not to lock it (supporting rescue, not fully trusting the inside escape mechanism, access to life support equipment, etc.) What is the balance of arguments, lock or not lock?

-

Great job getting the plane down safely!

Looking at a M20K 231

in Modern Mooney Discussion

Posted

I am the proud owner of a 231. It is a wonderful airplane - but I would not buy one with a GB engine without the necessary upgrades.

Mine has the LB engine and the intercooler, waste gate, GAMI, etc. upgrades. It runs relatively cool, and has great climb performance. The turbo is definitely a plus. Still, even in this configuration, I would expect mid-time cylinder and turbo replacements, which mine had done before I bought it. What I don't particularly like is the fact, that takeoff is not with full throttle, which takes time to get used to.

Sent from my iPhone using Tapatalk