-

Posts

46 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by BRBENNETT

-

.thumb.jpg.ed6aafa91f819cec0d83fd72d0471094.jpg)

ALTERNATOR TROUBLESHOOTING ?

BRBENNETT replied to DCarlton's topic in Vintage Mooneys (pre-J models)

I had this problem recently and solve it by going from prop to tail checking all of the alternator related connections, ie voltage regulator, battery cables, related grounds, etc. Found some that were questionable. After torquing everything down....problem solved itself. Note, this was AFTER I spent $1300 on a new alternator. The same model you have! Hope this helps! -

1967 M20F....using Aspen 2500 ProMax.....No Vac pump. Installed STC electric step kit actuator also.

-

I had this happen to my engine back in 2015. I did. complete overhaul and my shop found reconditioned case halves. Consider your self lucky you found this! I used Triad Aviation / Burlington, NC airport. They are a certified r/b shop for Lycoming and have a prop shop, H&H as well. http://www.hhtriad.com/hhpropeller

-

Same here....i had them installed in 2012. had the water problem....replaced no charge. All still running great! i have the wingtip strobes, Suntail strobe, & PAR46 landing light. I removed by belly beacon.

-

.thumb.jpg.ed6aafa91f819cec0d83fd72d0471094.jpg)

An We Discuss IO360A1A Fuel Flow?

BRBENNETT replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

Have you double checked your actual fuel burn with reported fuel burn by the JPI? Perhaps the K factor may be off? just another possibility since you had an overhaul. -

.thumb.jpg.ed6aafa91f819cec0d83fd72d0471094.jpg)

Throttle to idle, small pops on final

BRBENNETT replied to PierceM20F's topic in Vintage Mooneys (pre-J models)

in my engine (same as yours 1967 M20 F, IO360-A!A), I had the same issue with oil streaking out of the flange of intake tube. it turned out to be a bad valve guide. my engine only had about 300 hrs on it at the time. it was a factory defect part. -

.thumb.jpg.ed6aafa91f819cec0d83fd72d0471094.jpg)

1967 Mooney M20F Panel upgrade

BRBENNETT replied to Jesse20's topic in Vintage Mooneys (pre-J models)

There are STC kits out there. When I bought M20F, it had one installed from Southwest Texas Aviation, https://www.swta.net. I upgraded my avionics and had a new front panel cut. Attached is a current picture of my setup. My picture cut off the right side of the panel of which are circuit breakers. -

.thumb.jpg.ed6aafa91f819cec0d83fd72d0471094.jpg)

Possible cracked oil drain tube...

BRBENNETT replied to BRBENNETT's topic in Vintage Mooneys (pre-J models)

I found this old thread... I recently had an annual where they removed and cleaned the injector nozzles. I got a feeling the weep hole is located in a different position and thus this is why I am seeing the blue deposit in a place I didn't see it before. https://mooneyspace.com/topic/10383-leaking-fuel-injectors/ thanks again to everyone helping me understand the issue!! -

.thumb.jpg.ed6aafa91f819cec0d83fd72d0471094.jpg)

Possible cracked oil drain tube...

BRBENNETT replied to BRBENNETT's topic in Vintage Mooneys (pre-J models)

Thanks to all for your comments. Just as everyone thought, the blue is fuel dripping from the nozzle above. In fact...all of the nozzles have a bit of blue around them. I have noticed this over the years. This sounds a bit normal according to your comments. I'll keep an eye on it for now and check it more often to if the condition is stable or is getting worse. -

Mooney M20F, Lycoming IO360-A1A I ran across this on a routine oil change. See pictures. it appears the oil drain tube has a hole or is cracked on cyl#4. I am also noticing some oil on the #2 cylinder intake tube and on the side cowling panel. I am thinking the oil from #4 could be "blowing" around in the cowling and just sticking on #2 and the panel. Anyone ever seen this happen? I can't confirm until I remove the tube that this is the issue. Weird that it almost looks like fuel due to the blueish color. Any comments are welcome!!

-

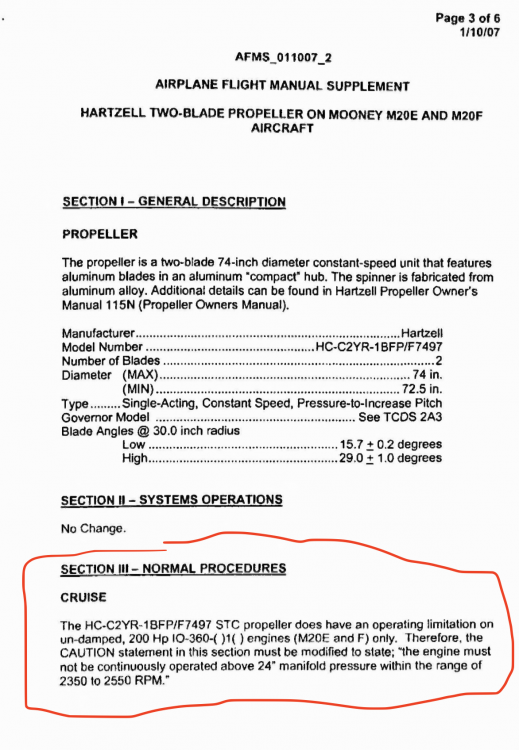

Hey guys, I had questions on this topic today and read this thread. The answer for me lies in the propeller AFMS. I have attached a copy of what mine looks like. Hope this helps!!

-

.thumb.jpg.ed6aafa91f819cec0d83fd72d0471094.jpg)

Quick leaning opinion - NOT LOP vs. ROP

BRBENNETT replied to FastTex's topic in Vintage Mooneys (pre-J models)

M20F, IO360-A1A, JPI930 W/GAMI Injectors. From the Lycoming manual leaning to EGT ROP (first cylinder to peak), below 75% BHP, run at peak EGT. See page 3-7 and page 3-8 in attached manual 1. LEANING TO EXHAUST GAS TEMPERATURE GAGE A typical cruise for me is 8000 ft with ram air in clear skies, 23" MP, 2350 RPM, 9.1GPH, 150 Kts TAS. LYCOMING OPERATORS MANUAL O-HO-IO-AIO-HIO-TIO-360.pdf -

top notch product! I installed their carpet in my 1967 M20F a couple of years ago. I also had SCS redo my seating in leather. Shipped them the seats and they came back beautiful!!

-

https://www.ebay.com/itm/233390264367

-

yep, had to go thru the pain of removing the lower cowling. Replaced the alternator and life is good!!

-

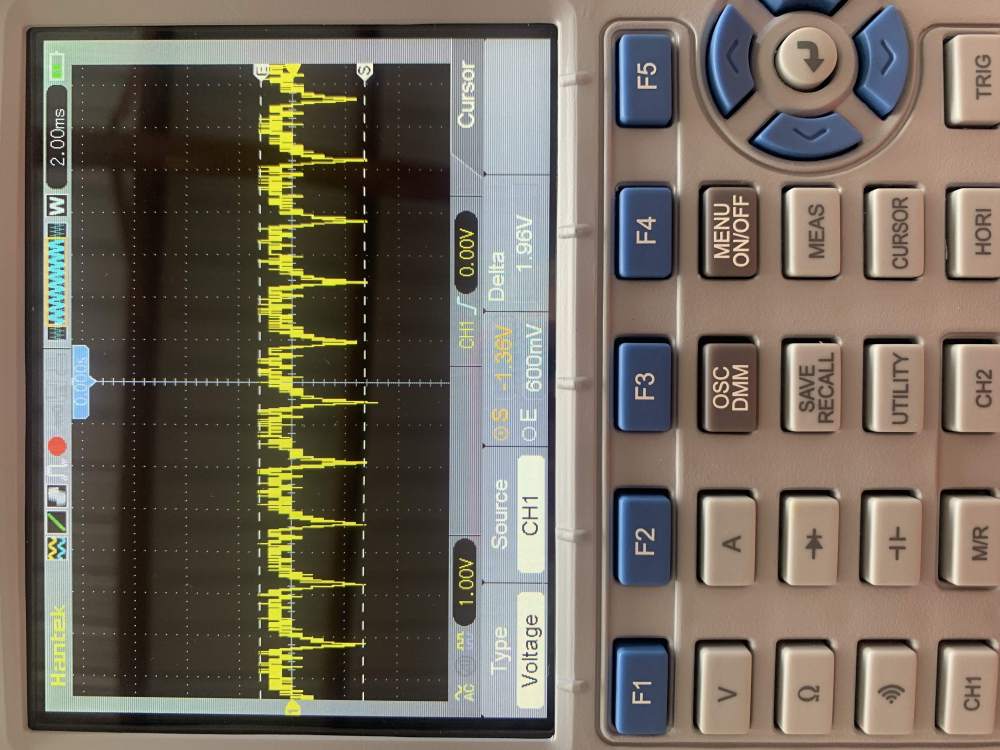

Ran AC traces at 1500 RPM and fully loaded electrical system. 1.96 VAC PTP. At lower load, 1.6VAC. Plane Power says 1 VAC is max allowed and tells me diode failure. Trace attached.

-

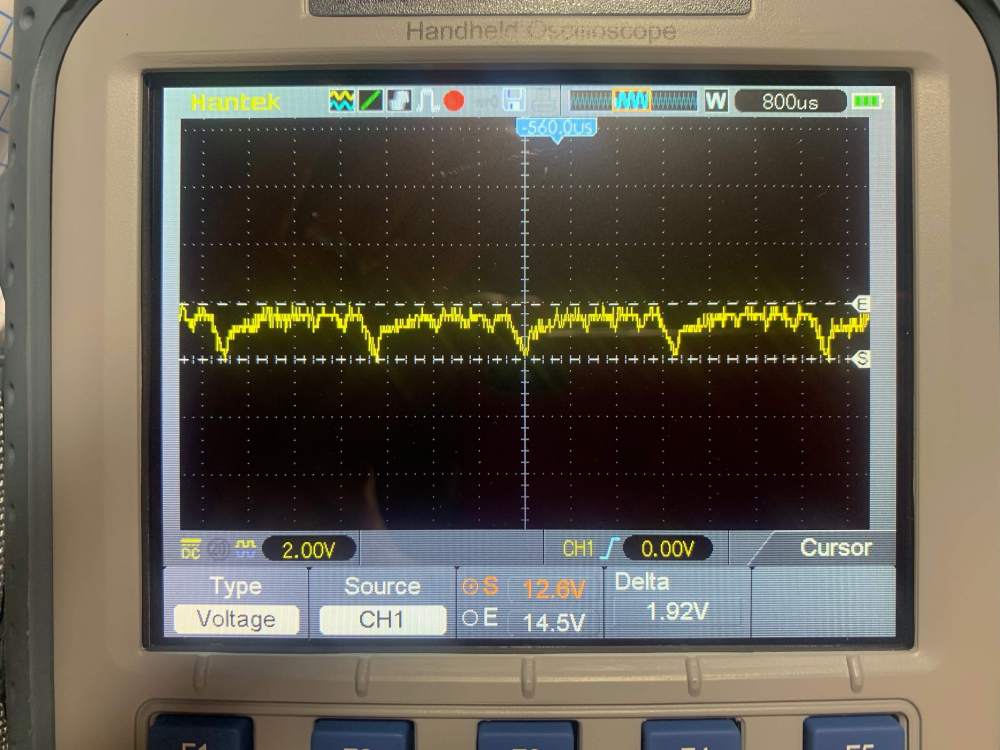

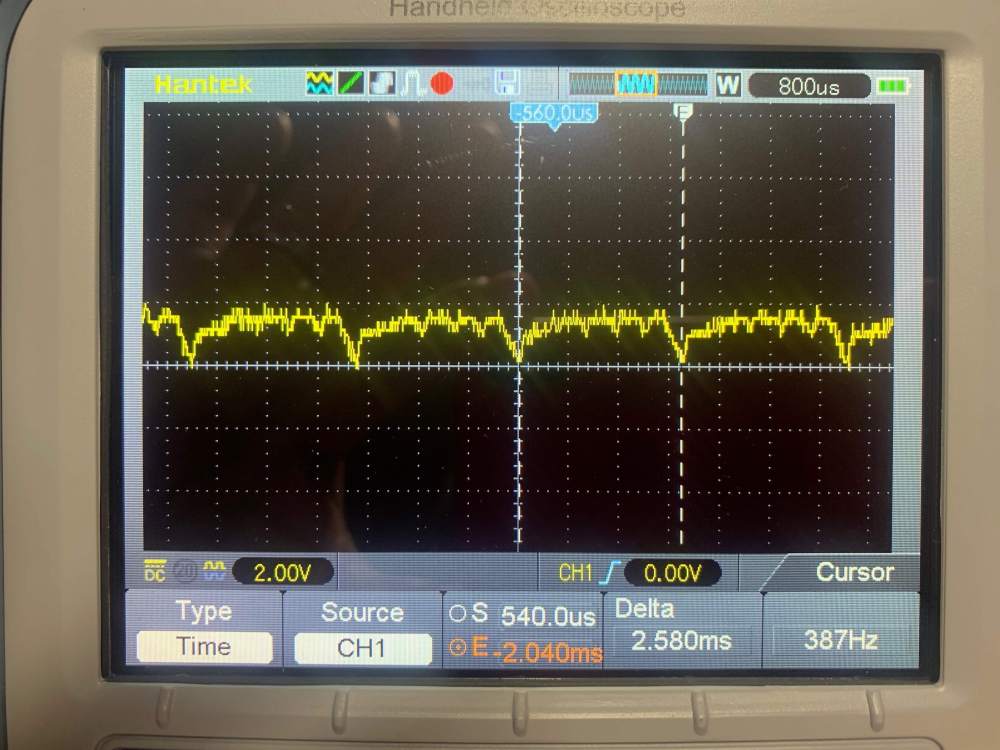

Mystery still unsolved. went thru my entire panel looking for loose / broken wires & found nothing. I decided to take some traces of the DC with an Oscope. According to everything I have read, this should be a straight line, but, I am seeing 1.92v peak to peak, 387hz. I have attached pictures of the traces. Let me know what you guys think.

-

Hello, I am hoping to collect some suggestions on how to resolve an issue that just popped up. I am getting "noise" in the form of alternator whine and others. The only electrical items touched in the annual were removing the battery and a new set of spark plugs. Though I know the plugs are really not part of the electrical system, they are grounded to the electrical system. Here are a description of symptoms: Whine / noise only occurs when the alternator is online, meaning, the main breaker for the alternator is on AND the enable breaker is on. When either one of these is pulled, the noise goes away. I can also hear other noise when switching on/off an item like a landing light or strobes. The noise remains when switching mags, IE It is present in BOTH, LEFT, or RIGHT. The noise is barely noticeable when just listening. it is horrid when I press the push to talk button and of course this noise is transmitted to ATC. Alternator works perfectly. Items I have reviewed / inspected: Inspected all connections to mags, alternator, regulator (even swapped this out with a new spare I had), etc. Disconnected, inspected, retorqed all battery connections. Removed, inspected, reconnected all spark plug wires. Checked all antenna connections on back of radios. Alternator -- put RMS digital meter on system, the only AC passing was around 200mVAC. I am leaning toward the spark plugs. After I reconnected the spark plug wires and started up the comms were clear. I immediately shut down thinking I beat the problem. I started up a few days later only to find it again. Has anyone experienced this and have any suggestions? I know shielding / grounding is critical on ignition wires and I have not thoroughly inspected that aspect of the harness. Could the ignition system be radiating noise to the alternator? As I mentioned, everything worked perfectly up to annual. Thanks to everyone in advance! Feel free to ping me with any questions if you think you can help.

-

Call Paul Beck, WeepNoMore. Last price was $3500 per wing which is a strip & seal. Uses chemical process. It’s so good that Mooney adopted his seal methods for new production.(320) 295-1671. Great folks, they know Mooneys!!

-

.thumb.jpg.ed6aafa91f819cec0d83fd72d0471094.jpg)

A&P Says "Oh no a Mooney?!!"

BRBENNETT replied to Tcraft938's topic in Vintage Mooneys (pre-J models)

Find a good Mooney service center and develop a good relationship. Whenever I had a non-Mooney shop work on my plane they are always calling the service centers to get repair information, thus, taking up more time and billing out more time. Service centers generally have Mooney parts in stock or know where to get them fast. I don't evaluate the cost of the service / repair as much as I evaluate the time it took to fix it or do an annual. Taking 2-3 weeks for an annual is absurd and that has been my experience at a non-Mooney facility. For my annuals, I fly from KY to Wilmar, MN (Oasis Aviation). They are a service center and I hang out with them for 1-2 days for an annual. These guys are good, they know what to look for because they are the experts!! -

.thumb.jpg.ed6aafa91f819cec0d83fd72d0471094.jpg)

Flying on Instruments with No PC

BRBENNETT replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

Flying without a PC or auto pilot on a solid IFR trip is exhausting! I owned my Mooney M20F for about 4 years, around 600 flight hours. I made some long trips with some of them in solid IFR nearly the whole way. The one trip that convinced me to spend to $$ on an autopilot was a flight from Washington DC to Georgetown, KY. 2.5 hours in soup without any horizon reference! The autopilot saves your mental ability during cruise so you have plenty of bandwidth for the approach. I still, however, fly my approaches by hand. Not that I don't trust AUTO, I just like the challenge & satisfaction of flying a procedure. Installed an STEC 30 system, 2 axis w/altitude hold -- money well spent! To date, I've logged over 1400 hours in this bird! -

.thumb.jpg.ed6aafa91f819cec0d83fd72d0471094.jpg)

Introduction, and new (to me) Mooney under contract!

BRBENNETT replied to Moobie's topic in Vintage Mooneys (pre-J models)

I've had my F for 10 yrs, 1500 flight hours! Enjoy, it is an awesome airplane. I have done about everything you can think of to this plane, paint, avionics, interior. I'm going to fly it, fly it, & fly it!! -

.thumb.jpg.ed6aafa91f819cec0d83fd72d0471094.jpg)

TANKS - Weeping - Patch - Nuance

BRBENNETT replied to joekinnc's topic in Vintage Mooneys (pre-J models)

I paid $7k back in 2010 to WeepNoMore. Paul Beck is the owner and really knows his stuff. Well worth it! Subsequently I had a leak and they took care of it. Great people and they know the Mooney aircraft very well. http://www.weepnomorellc.com. I would definitely work something out with your seller to negotiate on the price. -

If you can somehow create the geometry, 3D printing is a great option