-

Posts

822 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by 47U

-

When was the last time the flight control travel boards have been on the aircraft? I think I’d start there. Flaps, ailerons, and rudder. Then configure fuel/pax for your most common loading and flight test.

-

No doubt as to the benefit of the VSI. But, if you don’t have an alternate static source installed and your static ports have iced over, it’s the VSI glass that gets broken so that the altimeter and airspeed start working again (albeit, with some error factor).

-

M20A Brake Cylinder or push rod

47U replied to Steve Smith's topic in Vintage Mooneys (pre-J models)

Here’s a link to previous discussion that might be helpful with replacement options... -

Which is given as altitude gained over distance traveled, so a conversion to feet per minute is required depending upon your ground speed.

-

https://mikesavionics.com/ I sent my NAV121 to MIke’s to have a frequency gear replaced. It’s been a solid radio. The local shop was overwhelmed with ADSB installs at the time so I sent it down to Mike. I also have a NAV122, but it’s no longer in the panel. I kept the NAV121 instead since I have GS on another nav/com. I considered getting the 122 fixed and selling it, but it had been repaired in the local shop a couple times and I just don’t trust it. I guess I could sell it for parts, but it’s around 40 years old.

-

Looking for trim tab replacement plastic

47U replied to TravelVeteran's topic in General Mooney Talk

This thread from 2017 - 2019 explored several repair/replacement avenues, including a new part from Mooney. My ‘63 C has a metal trim panel, I’d search all the regular salvage places (Loewen Mooney Salvage) to start, to see if one of those is available. Might be a needle in the haystack... The placard is in stock at Aerographics. -

The tug in combination with the proposed tow bar is carrying half the weight of the tow bar, right? The other half of the tow bar weight is on the nose gear. Incidentally, the weight on my C’s nose gear coming out of the factory was 474 lbs.

-

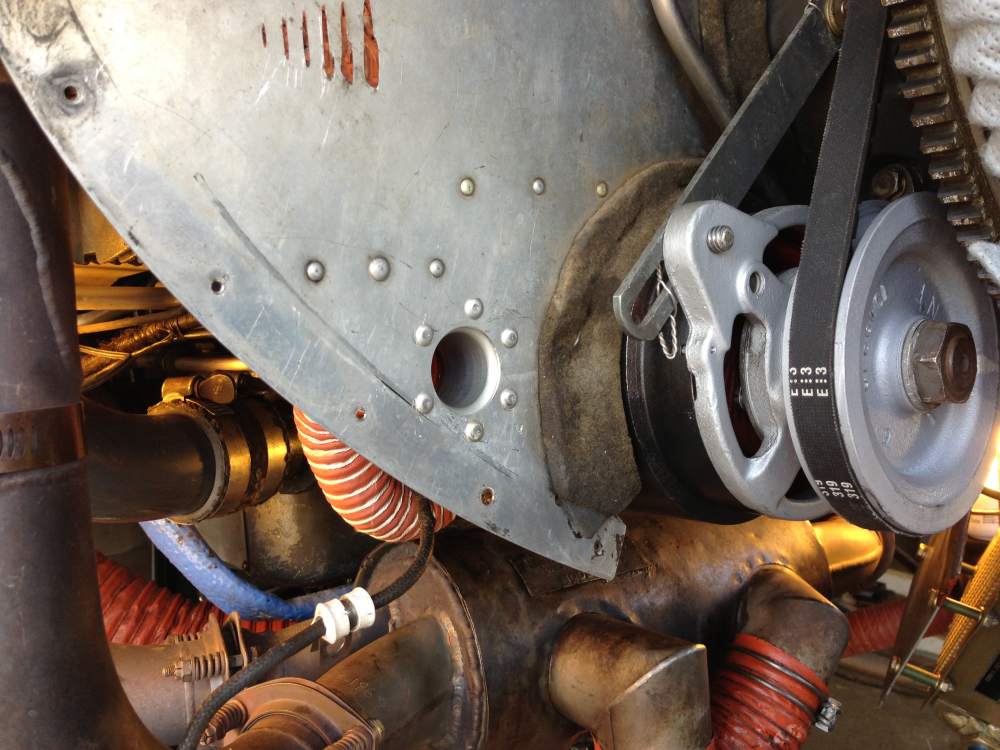

https://mooneyspace.com/gallery/image/37949-img-3033jpg/

-

There needs to be some amount of tongue weight on the ball of the trailer dolly so the tires will have traction. I’m sure that adaptations could be designed and implemented, but then the price point may be approaching a purpose-built aircraft mover. The product description says it weighs 110 lbs. Is that enough weight by itself to provide traction to the wheels? The working load weight limit is 3,500 lbs. Certainly it has the capacity in that regard. Now I’m curious to hear what tug owners think. How much weight does it take so the tug wheels have traction?

-

I would agree that fine wires are optimum for performance and longevity (cheaper in the long run), but the comptroller gets a say, too. I’ve got a BY on the shelf going in my lower #4 next time I’ve got the cowling off. All those pesky screws. Happy to hear Pilot Coyote has provided an endorsement.

-

AC 43-9C is a good review on maintaining required records. Para 11. d., in particular. https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_43-9C_CHG_2.pdf 11. DISCREPANCY LISTS. a. Before October 15, 1982, issuance of discrepancy lists (or lists of defects) to owners or operators was appropriate only in connection with annual inspections under part 91, inspections under § 135.411(a)(1), inspection programs under part 125, and inspections under § 91.217. Now, § 43.11 requires that a discrepancy list be prepared by a person performing any inspection required by parts 91, 125, or § 135.411(a)(1). b. When a discrepancy list is provided to an owner or operator, it says in effect, except for these discrepancies, the item inspected is airworthy. It is imperative, therefore, that inspections be complete and that all discrepancies appear in the list. When circumstances dictate that an inspection be terminated before it is completed, the maintenance record should clearly indicate that the inspection was discontinued. The entry should meet all the other requirements of § 43.11. c. It is no longer a requirement that copies of discrepancy lists be forwarded to the local Flight Standards District Office (FSDO). d. Discrepancy lists (or lists of defects) are part of the maintenance record and the owner/operator is responsible to maintain that record in accordance with § 91.417(b)(3). The entry made by maintenance personnel in the maintenance record should reference the discrepancy list when a list is issued.

-

How to fix broken baggage door link

47U replied to TravelVeteran's topic in Vintage Mooneys (pre-J models)

In the back of the parts manual is a cross reference from old to new part nubmers. The new part number for the short-style arm is 913020-2. I’ve found the part number search on controller.com to be useful. Use the ‘starts with’ option because there are variations in databases, but it appears there might be a couple available in salvage yards. I’d check with Paul Loewen, too. -

These two panels, unless you have a one-piece belly panel and the original riveted panel was removed. Don’t loose any of the washers centering the forward end of the actuator in the mount. Sabermech posted a picture of the belly access with the one-piece belly panel. THAT’S the way to go.

-

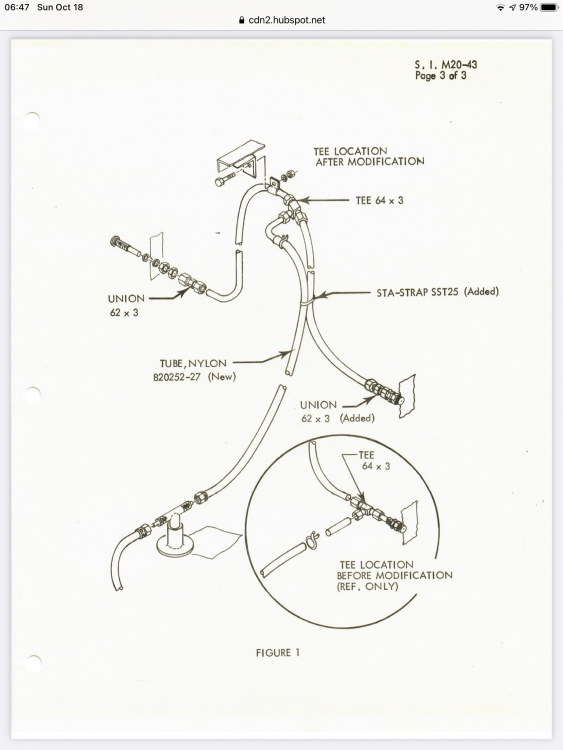

There’s a change to the location of the ‘T’ in the static plumbing in M20-43. Not sure if it applies to the G, but some C, J, and K serial numbers are included. Not sure why the G and F are not listed in the applicability. https://cdn2.hubspot.net/hubfs/4147179/technical_documents/service_instructions/sim20-43.pdf

-

Don't throw away your Generator!

47U replied to moodychief's topic in Vintage Mooneys (pre-J models)

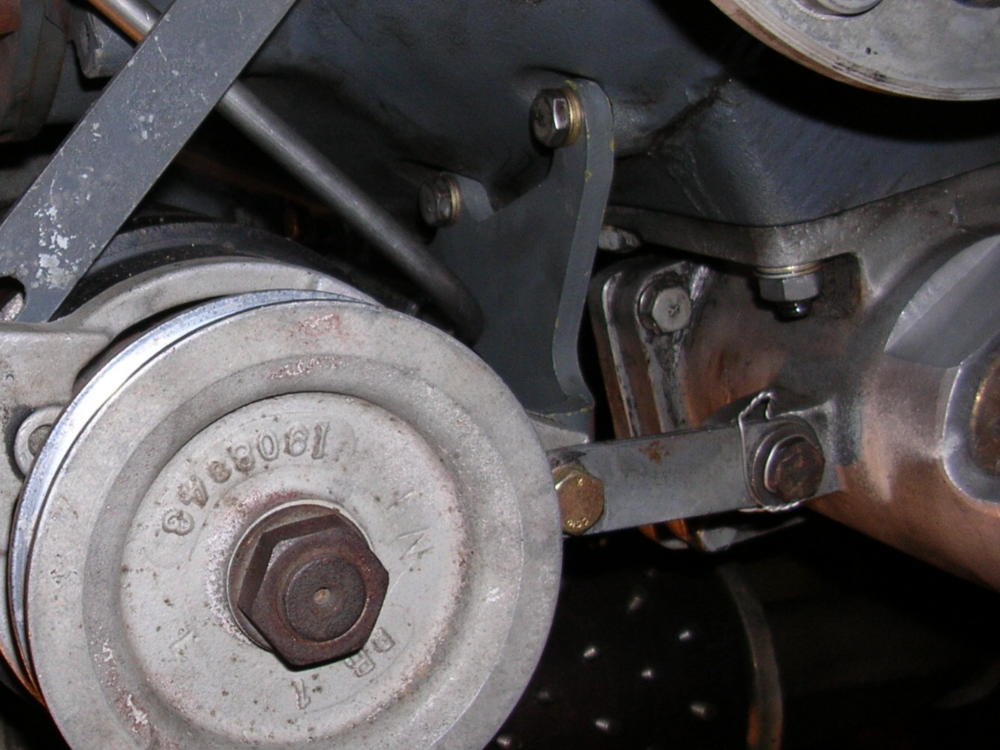

Yes urgent. I was changing out the prop oil line (per the AD, 10 years ago) and found the aft hole in the generator mount broken. It had been welded and broke again. The prop line adel clamp hid the crack. Dan (LASAR) sold me a new generator mount, much beefier thickness. Check the Lycoming manual for case bolt torque specs. It’d be a bad thing to warp the mating surface and create an oil leak, or worse, induce a crack in the case. -

If you can find a Mil Spec keyed switch, I’m in the minor mod camp. I looked all over and didn’t find one. A keyed switch would only defeat the starter, unless you found one with multiple poles that the P-leads are also wired through. Even so, it’s not rocket science to unground a P-lead, keyed switch or not. I’m not sure, is it even possible to hand-prop the injected and/or 6-cylinder airplanes? I decided that locking my cabin door would be sufficient, and strict adherence to the shut-down checklist to double check all three (left/right/master) switches are in the ‘down’ position. If the thief wants your airplane, he’s going to take it. My C probably isn’t going to be a target (maybe for parts?), but other’s here with a lower risk tolerance for theft is valid and understandable.

-

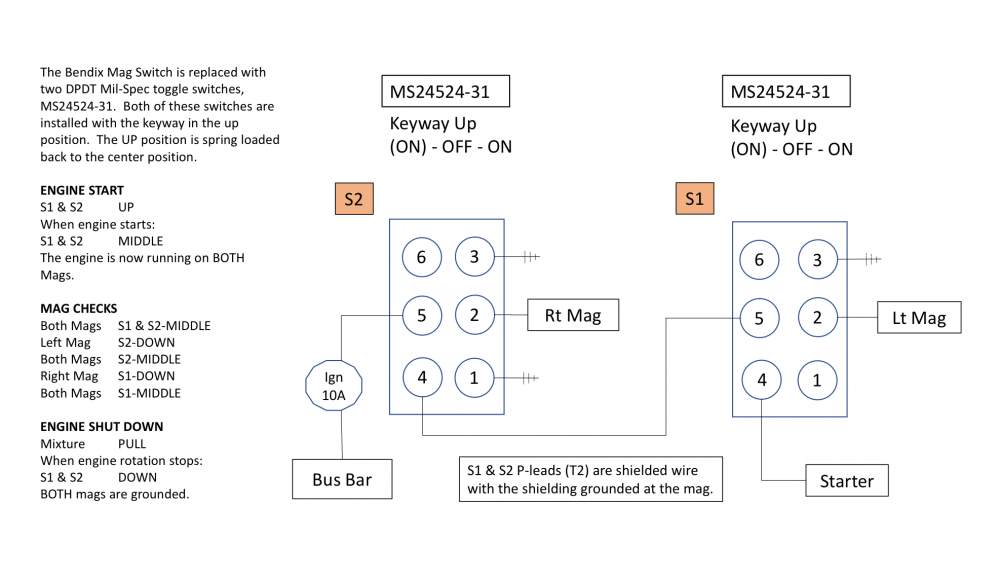

After I replaced my left mag with the Surefly, I was also looking at the Electroair. I couldn’t fit in my panel. My avionics guy told me that lots of twins have the mags controlled by toggle switches. The Citabria, too. I did some searching online and read that toggle switch-controlled mags is common in the RV community. I even found a paper with schematics. Here’s my preferred solution. All switches are Mil-Spec standard parts. Major alteration you say? Talk to your A&P/IA. I think this can be approved as a minor mod. Schematically, it’s basically (key word) the same as manufactured. You’re just changing out one switch (with multiple functions) for a couple (approved) switches that perform the same functions. There is no change to the operation (key word) of the powerplant. If your mechanic is reluctant to sign if off on as minor mod, ask them if they will get it approved on a 337 with the local FSDO. Probably cheaper than paying for the STC’d panel. Two or three MS switches will run you well under .1 amu. As shown, it takes both switches to activate the starter. I think that’s a big safety factor. A separate starter button can be wired in quite easily, if desired. A couple toggle switches takes up a whole lot less space than the Electroair panel.

-

Garmin A/P not for 1964 Cs and before?

47U replied to GMBrown's topic in Vintage Mooneys (pre-J models)

Wasn’t ‘65 the first year that Positive Control was available? Is that the same year the lower surfaces of the ailerons were no longer had a concave curvature? That change (whatever year it happened) lightened up the control forces, right? -

That’s a start... what career field? Jets? Hydro? E/E? Crew Chief/Aero Repair? How long ago? Recips? That’s key to have an A&P onboard to approve your work. Demonstrating to your mechanic your ability to adhere to airworthiness standards is paramount. I like the idea of a ‘rebuild log’ with hours and activities. You could easily log enough time to qualify for the A&P.

-

No provision for generator cooling in my ‘63 C. My ‘62 Cherokee had a 1” blast tube pickup off the front baffle running to the generator. When I overhauled my generator some 7 years ago...

-

-

How to fix broken baggage door link

47U replied to TravelVeteran's topic in Vintage Mooneys (pre-J models)

Not sure where you’re located, send Paul Loewen an email Loewen Mooney Salvage... paulloewen98@gmail.com Tom -

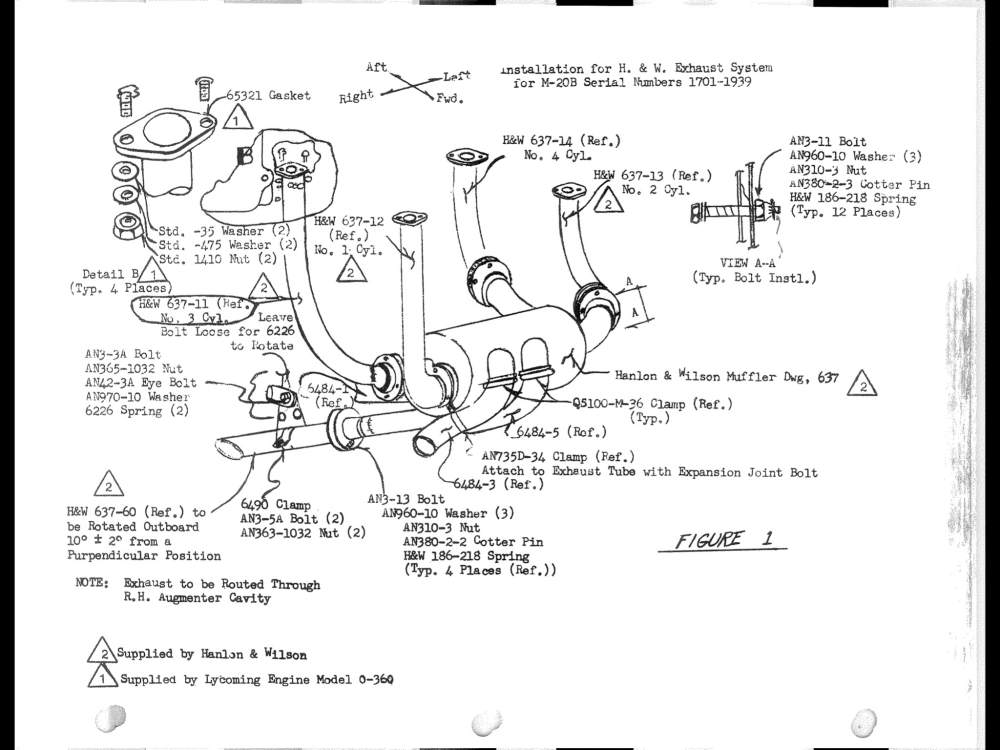

I’ve replaced one spring in the 12 years I’ve owned my ‘63C, about 6 or 7 years ago. No idea how long it had been in service. When I called Dan to order the spring, I asked him if I should convert to the rubber hanger per SBM 20-144, he said, “No.” I found any guidance on the spring hangar in SBM 20-86 (22 Dec 1961) which provides for installation of the Hanlon & Wilson exhaust on the M20B. The clamp on the tailpipe is snug and there are no standoffs between the clamp and the spring (pn 6226). I think standoffs would only push the tailpipe down further into the slip stream exerting more force on the springs and creating drag. The AN3 bolt that goes through the eyebolt holding the top loops of the springs is not tight, so the springs can move around a bit. And (I had forgotten this) the tailpipe outlet should be rotated 10 +- 2 degrees outboard to direct exhaust away from the nose gear door and perhaps not send as much CO directly under the fuselage where it might work its way into the cabin. When putting all this together, I try to get the springs and tailpipe clamp lined up loosely and directly underneath the eyebolt so there’s as little preload on the springs as possible. I use a longer AN3 bolt at the top and put a couple AN960 washers as spacers to minimize the preload on the spring at the eyebolt. Tom

-

This might work....... It might be cheaper to cut up a cheap box end wrench and weld a ratchet extension to it. Interesting (to me anyway), my ‘63C (sn 2552) has a hardline between the boost pump outlet and the bulkhead T-fitting. Tom

-

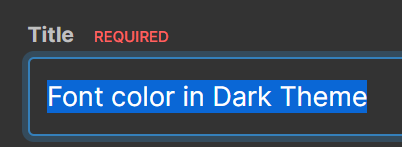

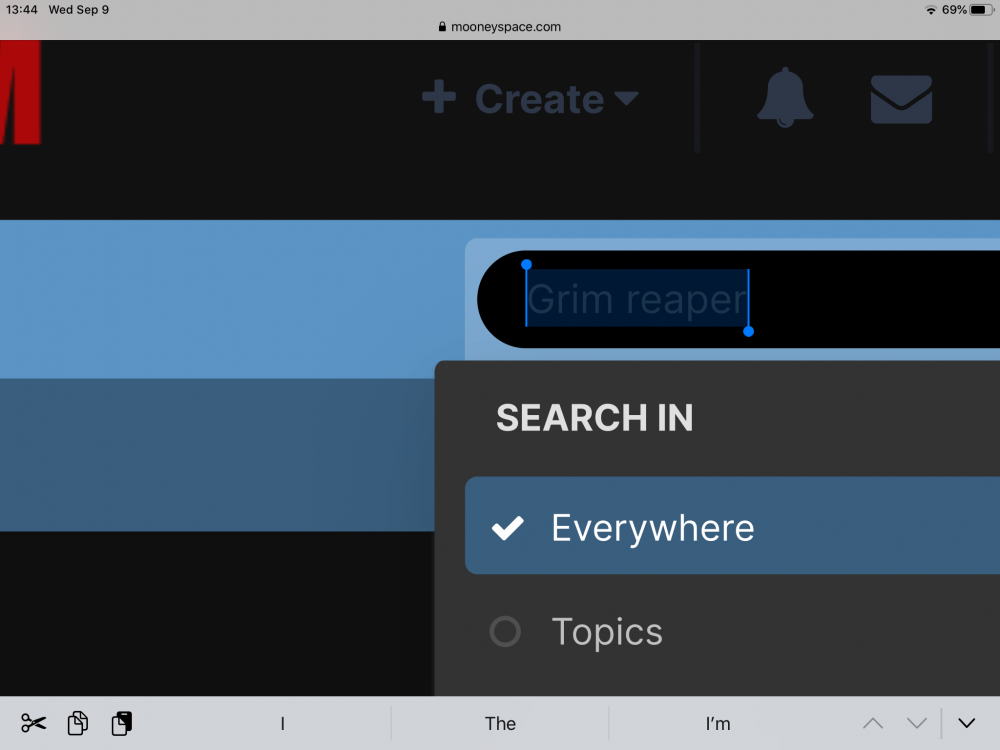

In dark theme, the font color in the Title window (same with Subject in Private Message) seems to be the same color as the window background. In order to see what you typed, you have to highlight the text. See screen snip below. EDIT: The above was on my laptop, same applies to my iPad. The topic SEARCH function is affected, also. Font is the same color at the field. I like the dark theme, though!