-

Posts

821 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Posts posted by 47U

-

-

On 4/14/2024 at 1:49 PM, Oscar Avalle said:

I am considering to get the STC. I was wondering if somebody has a picture of how the instalation looks like. In particular if the baffles que modified.

Oscar… LASAR website says the STC is limited to open baffles (no doghouse), 1967 and later E / F models.

-

2

2

-

-

4 hours ago, Dream to fly said:

Does anyone know where to get new bushings for the main landing gear retract links.

Check with LASAR. Gather up the part numbers and give Heather a call. You might check their website to see if they are in stock. They won’t be cheap, however. About 15 years ago I replaced a handful of gear bushings and they were .3 amu. But, it fixed the main gear from fully retracting and hanging an inch below the wheel well opening.

If you call around other MSCs might have better prices. And, you can type the part number into the search window on controller.com and one of the parts warehouses might have bushings in surplus stock.

-

8 hours ago, jamesm said:

I might be interested... Do you know if there is a shelf life Intake boots? if so do you know how long?

I would think a loooong time, if kept in an air tight bag with desiccant in a dark closet in your house, not the hangar. That would be my plan.

Then, after I’ve passed on, my heirs will find it, wonder what it is, not realize its value, and toss it in the bin. And declare me a hoarder.

I replaced my intake duct in 2010. LASAR had it in stock for just over .3 amu. I’m contemplating ordering one for the future, but mine is in such good shape I’m debating on maybe waiting for the next round. I had to do one small repair where I had allowed the carb air duct to touch the intake duct. It had a pea sized chafe mark on top of one of the reinforcing wires. I repaired it with some fiberglass cloth and high-temp black RTV. That was several years ago and the repair is stable.

If I had an E or F, I think I’d order one, regardless. They appear to be subject to more wear than the B/C/D/G models.

-

1

1

-

-

3 hours ago, cliffy said:

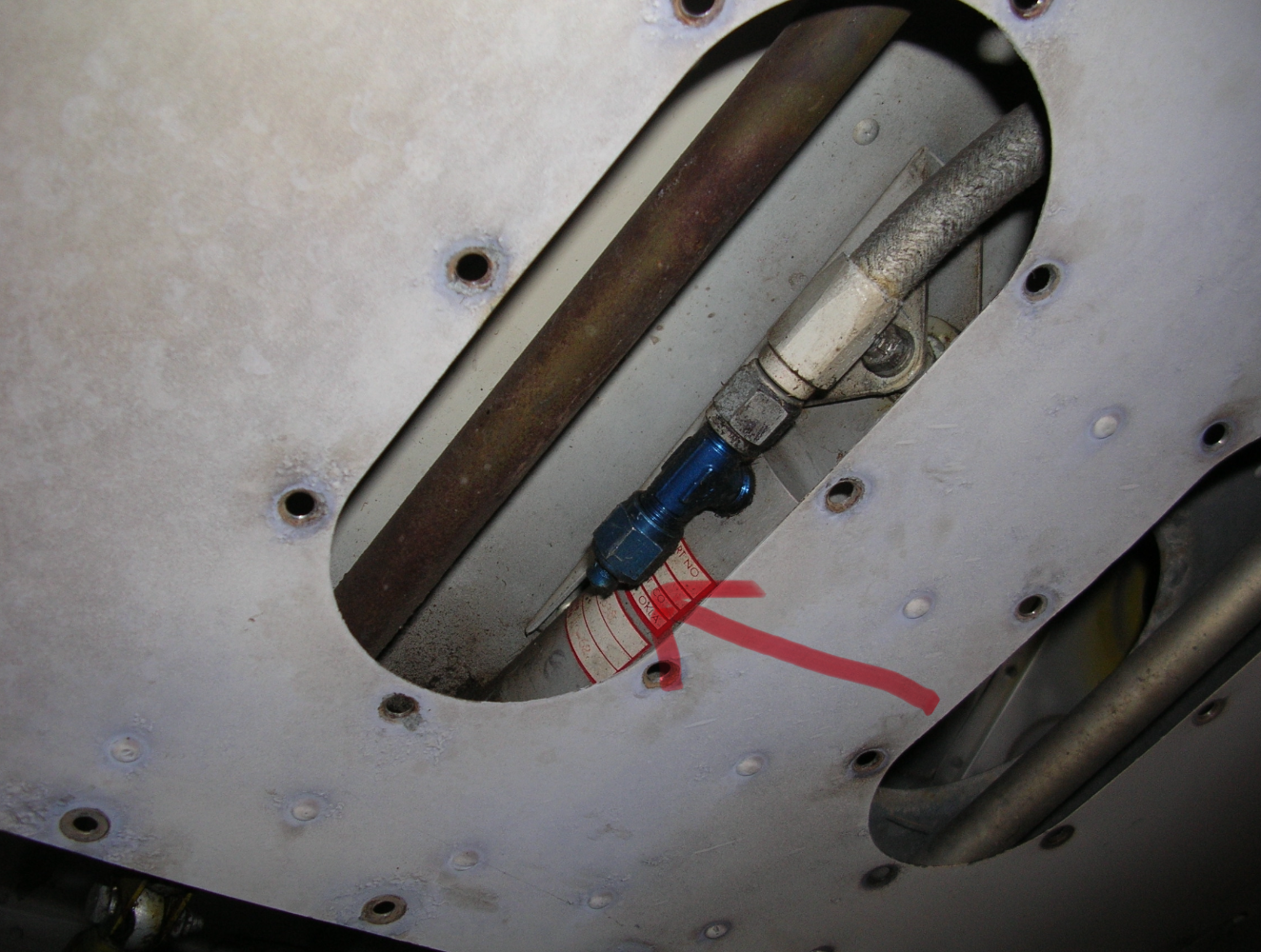

The other line that most forget about is the hyd line to the flaps under the cabin. Have seen several that were date of aircraft manufacture.

Part of the problem here is that Mooney used Stratoflex 193 hose, which isn’t rated for fluid. It rated for low pressure air/vacuum. My friends G model had a puddle of 5606 on the floor of his hangar one day last summer when this hose failed at an adel clamp.

I was surprised it was a 193 hose because when I installed new hoses in my ‘63C, this hose was Stratoflex 111, rated for hydraulic fluid. Someone before me had upgraded the hose from 193 to 111. I initially thought someone had installed the wrong hose in my friends G model, until I looked up the part number. Surprise, surprise. I had some -6 193 hose in work order residue so that’s was we replaced his failed hose with. As for me, I’m sticking with my 111 hose.

-

On 4/1/2024 at 8:05 AM, mike_elliott said:

What day is it again?

That’s not right for you to be picking on poor Mooney like that. April fools day, or not. I’ll bet AI wrote it.

-

17 minutes ago, PT20J said:

It’s a different design than the M20J though.

I had one of those. There’s a wire ‘bale’ welded inside the end of the exhaust pipe that goes into the muffler.

Photo credit to Wag-Aero.

-

3 hours ago, Greg Ellis said:

Can these be rebuilt so I have a spare or is it better just to buy new if I need another in the future?

I’m NOT an expert. But I think it might be better to sell it for the core value. I don’t know what the shelf life is on a pump sitting in box. Five years? Ten years? In a hot hangar in Fort Worth (or Sacramento)? I think I’d rather install a pump either new manufacture, or with a short time elapsed on the shelf since overhaul.

My opinion might be biased, though. The last airframe I worked on in the Air Force, it wasn’t uncommon to go into phase inspection with over a hundred time changes scheduled. And yes, sometimes we had mx induced failures.

-

1

1

-

-

I have this part, if it helps. PN 600028-505.

-

1

1

-

-

14 hours ago, Immelman said:

Previously we used Knisley Welding in CA who did great work for a reasonable cost. My IA told me that they were acquired by Hartzell.

Your IA might have incorrect information. I called Knisley a few weeks ago to inquire about a modification to my muffler shroud. A person who works for AWI in Minneapolis answered the phone. He was attentive to my questions. If you call the old Knisley phone number, your call should be forwarded to AWI. I can PM you an email address to the AWI rep I talked to, if you wish.

Knisley - (800) 522-6990

AWI - (800) 597-4315

Edit: Sooooooo… AWI is a subsidiary of Hartzell. Learn something new everyday (I hope). Thanks Rich!

-

16 hours ago, FlyingDude said:

Hi,

Anyone have pdf copies of the superseded AC43.13-1A and -2A?

Thank you.If you’re looking for approved methods and practices, the military tech orders can be a good source. The 01-1A-8 is particularly useful for guidance on structures and hardware.

https://vdocuments.site/navair-01-1a-8-structural-hardware.html?page=1

-

2

2

-

-

On 3/18/2024 at 5:17 AM, Greg Ellis said:

Could it be the engine driven fuel pump or a line somewhere else?

I’m guessing the engine driven fuel pump. How old is it? I read on the RV forum that Lycoming recommends a time-change at the 10 year mark. I’m not sure if any of us CBs are actually doing that.

I replaced my (‘63C) engine driven fuel pump three years ago when I was experiencing some fuel pressure/flow fluctuations. That turned out to be a cracked flare on the hardline between the gascolator and the elbow in the pilot’s footwell. The pump is sitting on the shelf in the hangar… I could send it to you for troubleshooting purposes. IF you wanted to go through that much pain to install it, then replace it with a new/overhauled pump if the problem is with your existing pump. It’s really not a fun job. Might be prudent to check how old your hoses are, too, just because you’re in there.

If you’re paying shop-rate to do this work, you might be money ahead to just install a new/overhauled pump to begin with.

Hopefully someone with more experience than me will chime in with a better idea.

-

15 hours ago, Pinecone said:

If I had a plane that needed hand propping, I would put in a glider hook. That would provide a tail tie down until you got running and in the plane.

There was as Piper Pacer with a glider hook two hangar rows over from me… looks pretty simple.

-

7 hours ago, jamesm said:

Didn't want to draw attention or create potential of what category is my ignition switches are they minor or major repair/alteration problem/discussion/conversation .

A valid consideration… I certainly discussed this mod with my IA before I went forward. When working with my IA, it’s better to ask for permission rather than forgiveness.

-

3 hours ago, jamesm said:

I have one installed in '67C a couple of things that bothers me, is start button has no real guard around it. so if you bump the start switch or if a unsupervised/curious person decides to press the red button, because everybody like pressing the red button, especially the red button you are not supposed to press it will turn over the prop. I pull the ignition CB to prevent this. The rocker switches are kind of cheesy and could have deeper guard around them to protect inadvertently bumping the mag switch(es). The other thing is with SureFly ignition installed, the engine runs so smooth on my left magneto it is real easy to start the engine and then taxi forgetting to turn on my right magneto. What is great about the EI CGR30C/P engine monitor has indication above RPM/Tach showing me when the magneto is off. If you have two magneto installed they don't provided you the wring diagram to incorporate the shower of sparks (starter vibrator) circuitry. When going from the Bendix ignition key switch push to start switch to the two rocker switches push to start switch. I have had it installed for about 4 plus years no problems, it works great.

Just my observations.

James

I didn’t have room for the rocker switch ignition panel, so I installed two DPDT mil-spec toggle switches. I put them on top of the radio stack, where nothing else fits. I moved the ship’s Master switch and the ELT panel there, too. I adopted a mag switch schematic I found on a RV’r website.

Both mag switches in the ‘up’ position grounds the right mag and energizes the starter solenoid. The left mag (SureFly) is hot. When the engine starts release the switches, they’re spring loaded back to ‘center’ and both mags are hot. Inflight mag checks are a piece of cake. No more after-fire from not moving the key quickly enough with SureFly latency on the left mag. Shut down is normal… pull the mixture, when the engine stops both switches in the ‘down’ position grounds both mags.

After shutdown, I do have to double/triple check that the mags are cold, both switches down. But, there’s virtually no chance of inadvertent starter actuation because both toggle switches have to be ‘up’ to complete the starter circuit.

-

3

3

-

-

11 hours ago, Shadrach said:

Does not seem like a great value...

No disagreement.

Part of the issue with rebuilding the steering horn in the field (in my opinion) is the lack of the blue-line drawing listing the individual joints, bearings, shims, bushings, etc. that makes the rebuild both functional and compliant.

As the resources to keep our airplanes airworthy dwindle, those resources that remain available will likely command a premium price. I can’t refute your pessimism, it’s just the way it is.

If an owner/pilot is experiencing the 7-second ride, 1.25 amu in parts to get it fixed might be economical compared to the costs associated with repairs due to a runway excursion, or the increase in insurance premiums.

I wish I had a better solution, but I guess I’ll support the resources that are currently available and hope the resources are still there when I need their support in the future.

-

1

1

-

-

5 minutes ago, Echo said:

Thickness on that RTV? 1/8"?

4 minutes ago, Echo said:JB Weld to secure it?

I think you mean 1/8” baffle seal? And a high-temp RTV to secure it, (unless there’s a rivet or screw… I have no knowledge).

-

On 3/6/2024 at 1:10 PM, Brian2034 said:

I know Lasar sell the steering horn.

My question is the horn something that can be repaired (bushings, bolts)?

I talked to LASAR about 10 days ago (I’m told Dan is retired, but Heather was knowledgable to my questions).

LASAR doesn’t have any rebuilt steering horns in stock, but will evaluate yours (for .15 amu) and, if it qualifies, overhaul it (another 1.1 amu). Mooney will make you a new one for north of 2 amu… other MSCs may have different pricing on new manufacture.

The LASAR website shows this as a 1968 and earlier steering horn (what I have on my ‘63C).

LASAR shows this as the ‘69 and later… my understanding is that the older and newer versions are not interchangeable.

So, I sent LASAR my steering horn and am waiting to hear what they say. I wasn’t on the 7-second ride yet, but there it was pretty sloppy when up on jacks. I didn’t see any reference in the logbooks where the steering horn had ever been worked on.

-

2 hours ago, Hradec said:

My airplane has small steel clamps with no rubber cushion on the. Just some friction tape wrapped around the line where the clamp is. Is this original? There is even a spot in the belly where the brake lines run parallel, the sam clamp and friction tape is used. Do you have this on your old mooney.

The same is on my ‘63C.

If I ever replace them, I’ll go with a cushion clamp.

-

2 hours ago, Brian2034 said:

Thank you

I have the service bulletin and have read through it a couple of times.

Just trying to get an idea of the cost to do the upgrade, I'm not worried about the basic nuts and bolts.

Its the Mooney specific items I'm trying to determine for the landing gear upgrade.

She's been sitting 10 years and I'm trying to determine what I need.

So far we have completed or in the works:

repaired carb box to filter boot (probably going to need a replacement boot if there's no other mod available)

Also replaced the manifold pressure line engine side (the 1/8" aluminum line was cracked under an adel clamp at the engine mount tubes)

You couldn't see the crack in the line until the clamp was removed, I've read the S.B. for it but you would think they would add a rubber hose between the engine and mount for the movement instead of a coil in the line.

She needs a rigging update, she drops a wing slightly in flight and on the ground the ailerons are not in the neutral position on both wings.

Going to have to do the digital level process for the rigging, unfortunately I'm to far away from the mainstream to obtain a set of rigging boards

If anybody has any other suggestions at what may need to be looked at please let me know.

The Mooney Chronology website shows sn 2208 as smack in the middle of the 1962 production year, which produced sn 1940-2276. The FAA says that 2208 was exported to Canada?

Take as good a care as you can with the carb intake boot. They are becoming almost impossible to find.

Many manifold pressure lines from the firewall forward have been converted to a -2 hose. Mine hose connects to a reducer on the hardline at #3 cylinder, the MP pickup is off #1 cylinder.

As far as other suggestions… if the interior is in good condition after sitting, it sounds like it was hangared. That’s a positive. Still, SBM20-208B should probably be done if it was kept on the ramp for any length of time to check for corrosion of the fuselage tubes (if the windows leaked) and SBM20-217, inspection of the stub spar for cracks where the flap actuator connects to the flap torque tube. Small cracks can be invisible. It helps to pump the flaps all the way down which puts stress on the stub spar and opens up the crack.

There’s quite a lot written on rigging here on this board… some say you don’t need the travel boards. But, they sure make it a lot easier, I’m sure.

-

4 hours ago, Brian2034 said:

Is there any videos or basic instructions on what parts are required to complete the upgrade??

Welcome, Brian…

The 8 pages of M20-139A are fairly self-explanatory, but I can see where it would help if the person doing this has previously replaced shock discs.

https://www.mooney.com/wp-content/uploads/2020/12/SBM20-139A.pdf

There are parts specified to be replaced, both on the nose and main gear. If your local MSC can’t source them you’re probably relying on sourcing salvage parts. Which will need close inspection to determine airworthiness.

Keep us updated on your progress.

-

1

1

-

-

3 hours ago, Nukemzzz said:

Is there no way to just repair the end?

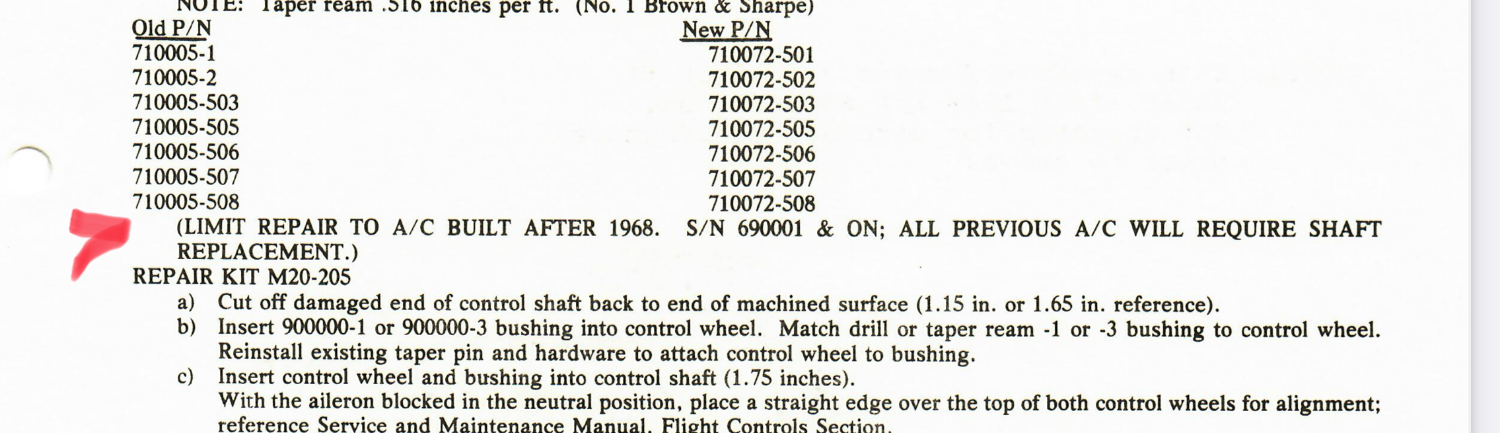

The ‘end repair’ method of compliance (and retire the AD) is applicable only to F models sn 690001 and on.

The Mooney replacement shaft’s part numbers spec’d in the SB will use the original yokes, but I do think they are 2” longer. A couple years ago, an acquaintance with a ‘65 (66?) E model ordered them and Mooney manufactured them. They weren’t cheap, though. I’m thinking it was two or three amu’s.

-

2 hours ago, Sabremech said:

All signs so far are of a clean solid wing.

That’s positive. Surely it has a metal empennage… ?

-

2 hours ago, Kesk said:

When people say they are using a pressure pot, what are they actually connecting to on the actuator and how?

I have an automotive brake bleeding pot I got from the auto parts store. Some have used a cheap garden sprayer. It doesn’t need to be very big.

To bleed the flaps, the connection is made at the T on the flap actuator. It’s a male -4 AN flared fitting. Appropriate fittings to connect the hose off the pot to the T can be sourced about anywhere, including Aircraft Spruce and your local auto parts or hardware store.

I found that it works better to loosen the flap retract rate screw (with the big jam-nut) on the flap pump in order to flow more hydraulic which helps push the air out of the system. Of course then, you’ll be adjusting and readjusting the rate screw forever, until you get it ‘just right.’

-

1

1

-

-

2 hours ago, phxcobraz said:

The spread is quite a lot, but from reading that is normal on carbureted engines.

How far down from the exhaust flange are the EGT probes? I think the preferred is between 2” and 4”. Obviously, they should all be at the same distance, but if yours are at the close end of the range, then the temps will be hotter.

As far as the spread, once you’re at cruise altitude, and the air is clean (above the haze, dust, smoke) try pulling a little carb heat. Not nearly enough to drop RPMs, but it induces some turbulence in the carb throat that helps the fuel mix with the air. So I’m told that is the theory. It evened out my EGTs quite a bit.

-

1

1

-

LASAR Ordering Intake Ducts for B/C/D/G and E/F Models

in Vintage Mooneys (pre-J models)

Posted

Heather is still taking orders… I signed up for one. Even if my current one is still airworthy in 10 or 12 years when I decide to hang it up and put 47U on the market, having a spare intake duct should be a huge selling point.