-

Posts

2,195 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by FloridaMan

-

If you're close to Tampa Bay, I have a set of them that my mechanic is holding onto.

-

Just saw this; I actually kindof prefer the smaller window and thinner windows to the thicker ones; I feel the oversized vents restrict the view with the latches a bit more than I'd like. I haven't tried sticking my dick out the window yet with the bigger ones; if I can pull that off, then maybe they'll be worth it. I don't have the agility to make it work with the smaller windows and I feel that trying it with the door is just asking for it.

-

I got lucky; LASAR just got a new batch of them.

-

I'm pretty pissed about it. The rocket is getting new jugs right now, so my spare is now out of commission solely due to incompetence.

-

Yes. Bent the hell out of it. I was only there for a couple hours and I didn't expect them to move it. I called the manager today and left a message; no answer.

-

Any sources? 12 years and 2500+ hours flying Mooneys and it finally happened at OPF.

-

-

Power settings and performance for rocket (Not cruise)

FloridaMan replied to wombat's topic in General Mooney Talk

It’s the CDT that’s the remnant and I have to watch my EDM900 flash warnings in aggressive climbs on it. Additional things to note. The NB variant, according to the engine manual, can run 100% power continuous, which I do in the climb. At around FL180 I need to use the low boost pump to maintain FF in the climb and I turn it off when level. The Rocket manual says to climb at 1450 TIT at 100% and I think I figured out why. I had always thought it was a safety thing because our planes came with a single probe CHT sensor and runaway could happen quickly at high power settings. In playing with fuel flow, there seems to be a correlation with IAT and CHTs, and higher TIT seems to transfer heat to the intake side as well. Making the mixture extra rich seems to affect CHTs as much as cowl flaps. -

Rocket Engineering offers better support than the Mooney factory.

-

I need to carry a dog crate with me and it’s an absolute pain to get it in the back seat. If I remove the passenger seat, it would be super simple. I can’t find a definitive reference. If it and the dog were a front passenger, I’d be in CG limits, and if they were in the baggage compartment, same. I suspect it's probably ok since the seat is so easy to remove, but if I get ramp checked, I’d like to be able to cite chapter and verse if challenged.

-

Power settings and performance for rocket (Not cruise)

FloridaMan replied to wombat's topic in General Mooney Talk

Just another thing to add, TIT seems to reflect in CHTs; my guess is that higher TIT means higher turbo housing temp, which means higher discharge temp and higher IAT from the air that gets BTUs added to it from the turbocharger. And likely why the rocket manual says to climb at 1450 TIT at 100% power and you can cruise at 1600-1650 at low power settings. I’ve heard that the redline temp limitation is about the cast housing of the turbo, but without adequate cooling airflow from slower speeds in the climb, CHTs can’t be maintained — and I suspect it’s a combination of cooling air over the jugs and airflow through the intercoolers. -

Power settings and performance for rocket (Not cruise)

FloridaMan replied to wombat's topic in General Mooney Talk

I've got around 900 hours in my Rocket over 5 years. A couple operational things really stand out with those numbers. Firstly, I don't fly with gear down and less than prop full forward. If my gear's down, it means I'm on approach to landing, which means I need to be ready for a go around so my prop will be full forward. I also fly my instrument approaches at around 120kts. If it's a GPS approach, MDAs are generally a bit higher and if it's an ILS, I'll have at least a couple thousand feet of runway as airports with ILS approaches tend to have at least 5000ft of runway and I can get rid of that airspeed once I've got the runway in sight. My approach power configuration is prop full forward and 15" of mp. I usually land with the speed brakes extended. Home airport is 2800ft runway with high DA and I have single piston brake calipers and she likes to roll a few hundred feet after touching down. I often will use a little rudder before the touch so I can set one wheel down first to cushion the landing and if it feels like I'm about to plop down, I'll take the rudder out and/or add a touch of power for a smooth touch. When coming in to land with four people and bags from a short flight, when she gets below around 100kts, it sometimes requires full power to arrest a descent with the gear down in a banked turn. Don't be afraid to add as much power as it takes. I climb at 100% power until I reach altitude, even if it's FL240; it needs low boost at around FL180 and I need to climb at over 120kias around that altitude for cooling. The book for the TSIO520-NB variant has the performance shown as rated at 100% power continuous; other variants of the engine are limited to 5 minutes or so. https://www.n57825.com/docs/TCM_TSIO520NB.pdf . I do have an EDM900 that shows all CHTs and I climb to keep them under 400 and I keep TIT under 1600. Here in Florida, I cannot comfortably fly at 105kts in cruise. It feels like slow flight, efficiency drops and temps go up. I'm running a SureFly emag and fine wires, but no gamijectors yet, and it's tough to run LOP smoothly at higher power settings. The SureFly gives what amounts to an effective timing advance by not having the condenser delay and running at lower RPM helps to facility LOP ops, but I don't really have the discipline to go slow. I typically cruise at 2400/32" except in cases where it can mean avoiding a fuel stop, and I'll go 2300/29" or 2200/26" if I absolutely have to. Down low, I get around 16gph at 2300/29 and that goes closer to 19/20gph up high because of the additional work the turbo has to do, which means higher IAT, which translates to higher EGT/TIT. -

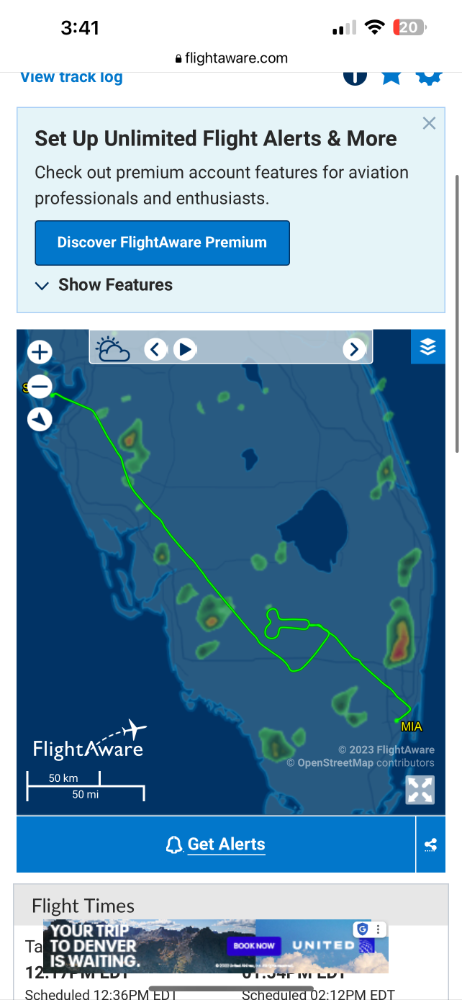

I drew another dick on the flight tracker.

FloridaMan replied to FloridaMan's topic in General Mooney Talk

-

-

I believe I have the political, engineering and manufacturing resources to make an affordable GA airplane. The value in Mooney is the proven airframe and certifications.

-

I was gonna go visit my coonass friends.

-

What's the current status of Mooney. Did somebody buy it?

-

Comments say there’s free GA parking at LFT. Anyone have insight on this?

-

Lock your plane and hangar: avidyne stolen

FloridaMan replied to MoonRiver69's topic in General Mooney Talk

One trick is to steal units and then swap an existing unit with a stolen one and sell the one that wasn’t reported stolen. -

Post annual run-up by IA. He called me and set the prop went full pitch and the engine wouldn't go past 2000 RPM. He pulled the prop and governor and sent it off. Has anyone experienced this? My best guess is an obstruction in the governor causing this, but also, this would be a bad thing to have happen on my 2800ft runway if she decided to feather halfway down my takeoff roll.

-

@gsxrpilotlooks like I’ll be flying in this year.

-

Recommendations for pressure gauges for fuel setup

FloridaMan replied to shawnd's topic in General Mooney Talk

In case you're unaware, there are those fittings in the floor board on the copilot side that are there specifically so you can run hoses to the fittings and sit inside the airplane with the instrumentation.