-

Posts

8,430 -

Joined

-

Last visited

-

Days Won

114

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Posts posted by LANCECASPER

-

-

50 minutes ago, Sixstring2k said:

Just making sure I am reading this correctly (if wrong please correct me) and that this hopefully helps someone, the clamp that should be put in place and complies with the AD is 670105? Or at least gets someone flying again for 500 hrs. If so air power has them available as of this morning.

https://www.airpowerinc.com/670105What model Mooney do you have?

-

I don't like the idea of the hardware and software backing up the same hardware and software. I've seen panels with just two GI-275s and that's it. Having one backing up the other would scare me. Especially after a new software release. That doesn't strike me as a real back-up solution and how they ever got that approved is beyond me.

Here's one where two GI-275s failed - thankfully he had more instruments (5th post in the thread)

-

1

1

-

-

I'm guessing the KC-192 board, but @Jake@BevanAviation is the expert.

I had a '96 Bravo with the exact same symptoms while under warranty. Bendix-King would send a loaner KC-192 A/P computer and it would work great and when I would get mine back, same symptoms. After a few times I called Bendix-King and told them I was keeping their loaner this time. They looked up the history and said that would be fine.

-

On 4/16/2024 at 9:12 PM, Jetpilot86 said:

That’s a fiberglass cowl. At this point it probably wouldn’t be a huge deal to repair the fiberglass. But with a “dent” in fiberglass you can be sure it’s got small cracks in it, which will spread. If that comes apart while you’re flying I’m not sure what the results would be, but i can’t imagine it being good. Plus if it goes beyond the point of being able to be repaired try finding a replacement cowl for a Bravo.

When you find out how expensive it is to fix the cowl and the cowl flaps properly, including matching paint, etc, you may want to make an insurance claim.

-

2 hours ago, hoot777 said:

Final NTSB report is out. No corrosion found. Metal was over stressed. Maybe a higher tech guy can post it here on Mooneyspace Suspect spatial disorientation as they exited the cloud in a tight spiral. May have been passed out from g loading which was at 8.

The final report came out in 2023

Yet another thread on this same accident:

-

16 hours ago, Kerrville said:

I am doing the first oil change on my M20J. My IA told me to remove the oil quick drain and replace the o rings. I removed the part, BJ1000AH4. I can't seem to find any orings on it. Any ideas on how to make this thing not leak?

Also, when I pulled the filter, it made a heck of a mess. My nose gear assembly will not need any lube for a while. Is there any technique that anyone would care to share to keep the filter from making a huge mess when it comes off? I even had a rag under it and it wasn't nearly enough.

The last time I saw one like that was 2017 on a 1993 Mooney M20M that I had - and every indication is that it had been on there since new. It leaked like a sieve. The spring action on the drain wasn't working well. I couldn’t get it loose on my own, so until I could get it in to have someone else get it off I actually put a cork in it. Dugosh heated it up and got it off in a few minutes. They replaced it with one much better (Saf-Air) and never had a leak after that. There are some things worth fixing - a thirty year old quick drain isn’t one of them.

Lots of discussion about quick drains on Mooneyspace:

https://mooneyspace.com/search/?q="Quick drain"&quick=1&updated_after=any&sortby=relevancy

-

1

1

-

-

8 minutes ago, Kerrville said:

Any ideas on how to make this thing not leak?

Replace it

-

2

2

-

-

5 hours ago, Neshi said:

Thanks.

The 730 is being reused. I've had from my old aircraft when we upgraded it to 900 a for a failing analog cluster. (Install & reprogramming cost next to nothing.)

Took quotes on the audio panel as well but as there is no slide in replacement for it could not justify all the money for functionally adding Bluetooth and inteliaudio(its nice but not amu nice).

+1 for doing the upgrade to a JPI900 or a GI275 EIS on this airplane while you're doing your upgrade. The analog engine instruments will fail on this airplane also.

The PSEngineering 7000 series, which has bluetooth, is plug and play for a KMA24 audio panel. The only thing they'll have to do is make an intercom harness to tie into your existing intercom wiring. https://www.ps-engineering.com/PMA7000_Series.html

-

1

1

-

-

29 minutes ago, EricJ said:

FWIW, Cessna, Beechcraft, et al have been making airplanes with bladders for many decades, and they all age out and need replacement eventually. With a sealed tank you can at least make repairs a lot more easily when it does leak.They sent us another one no charge but a lot of work.

One of the Mooney models I’ve owned (K, M, R and TN) have STCs for bladders so I’ve never had to make the choice.

I helped change out the bladders in a Cessna 182 that I owned with a partner - not a fun job. I learned several new words that weekend . . lol. We finally got it all done and about a week later we discovered that the left one leaked. The company we bought the bladders from replaced it and covered the 2 day freight - but it was a lot of unnecessary work.

I’ve never owned a Mooney model that had an STC for bladders so I’ve never had to make that choice. (I’ve only had K, M, R, and TN.)Two of the seven Mooneys, both Bravos, had small leaks which were easily patched by someone who knew what they were doing (Lone Star Mooney and Dugosh). I’ve never had to contemplate a complete re-seal, but eventually it’s inevitable.

-

1

1

-

-

37 minutes ago, Dwb62 said:

I’m purchasing a 1968 M20G in Kokomo,IN, need 10 hours transition training to satisfy insurance requirements. Does anyone have any knowledge of someone that can provide the training that lives in that area?

Go to this site and click on the link for CFIs: https://themooneyflyer.com/

-

5 hours ago, Tom F said:

This post is to gauge support. M is not going to invest in any G1000 upgrade certification for what ever reason. In speaking with the folks at G, if we had 50 G1000 owners who are interested in upgrading the G1000 to a yet to be defined GXXXX version, they would make it happen. In G's mind M is dead. FWIW I had my avionics shop price a Synthetic Vision unlock thru M and it was north of $10K.

In closing, IF you've got a G1000 and would be interested in upgrading, reply with YES. There is no commitment I am just trying to gauge interest. Cheers!!

Did Garmin hint at a price for a G1000 upgrade price?

-

That’s a Garmin price thing not Mooney. FWIW the Garmin SVT unlock for Cessna, Beechcraft is the same price through Textron. And by the way it is the same part number so will work on any of them plus the Diamond, etc.

-

I've done it both ways. On the Mooneys made in the 90's and on, the stick-on 3M material doesn't look good with the brush-on applied over it. It may look better than it did before, but you can definitely tell someone has re-done it. If it's a Mooney made before that, where the wingwalk brush-on stuff was used originally, then maybe. When I tried it on my first Mooney and I was finished it looked a little bit like a pretty decent roof repair. I'm not looking for that look or a truck bed look, although that stuff did work great on my Toyota Tundra. The look I'm going for with the flat black spray paint is un-touched OEM new, and it looks that way when I'm done. The first one I did was very faded and I didn't have a lot of faith that this would work. I did it over the weekend and when my IA saw it on Monday he said that was the best job of replacing the wingwalk that he had ever seen. When I told him I didn't replace it, I had a hard time convincing him. I wish I would have thought of doing it this way but I picked up the idea on Mooneyspace over 10 years ago after doing it the other way before.

Most of the time it's not necessary, but If part of the stick-on material is actually damaged and you ever have to just replace the 3M anti-slip stick-on material Mooney used in the 90's and on, use a hair dryer or carefully use a heat gun, and then peel off about an inch or two at a time with some encouragement. Then some 3M Adhesive Remover to get the residue off - they make two versions, I like the citrus version for this use.

Koffler sells both the 3M product originally used and a product sold under their name, which I like better, it stays looking new longer. (https://kofflersales.com/product/anti-slip-abrasive-tape). I've done it on different long body Mooneys that I've owned and made a template out of poster board the first time so I could do it easily if I ever had to do it again. When you re-apply the new material make sure you have another set of hands since the material is basically ruined if you let the adhesive side stick to another area of adhesive side.

-

2 hours ago, William Munney said:

The Story:

I bought an Ovation last October that needed some attention. My son and I are going to travel in it and he is building time for a flying career. It had a new and very nice glass panel in it but everything else was well used. The airplane flew about 35 hours in the last 5 years. The paint was very oxidized, carpet old and dirty worn through and the seats looked like a frat house couch. Both wings had fuel leaks. It had been well maintained but it was tired when i bought it. I used the Winter months from then until now to refurbish the airplane. I tackled a bit more than i wanted to but my thinking was to fix everything now and fly it versus fly-it-and-fix-it etc…..

So, this is what we did:

Firewall forward is all new. Every line, hose and connector. Factory new IO-550. New engine isolators. Stripped and painted the engine baffles.

Prop Governor Overhaul

Prop Overhaul to include new internals.

Compete external light conversion to Whelen (WATT) LED’s. New wingtip and taxi/ landing light lenses.

New tires and tubes.

New batteries (2)

New O2 bottle and fill.

Polished the spinner and took the dents out.

18 hours with a buffer and ceramic wax to bring the paint back to life.

Complete fuel tank seal scheduled for this year.

New Interior. (I started with the just carpet but I had to take the seat out to take out the carpet………and one thing led to another and i just took everything out). I also removed most of the old adhesive, cleaned every inch of the inside and added insulation and sound proofing to the interior.

FIRST FLIGHT:

Accomplished the first flight and first two hours of engine break-in yesterday. The new engine and prop are powerful and smooth. Everything else mostly worked as advertised. After the first hour I landed. We took the cowlings off to inspect. No leaks. We adjusted the prop governor for full take-off thrust and the gear warning horn on the throttle cable. We flew another hour and I got two more landings in since it had been awhile in GA for me. I would have added 4 more hours to the break-in except i was limited to lower altitudes and high power settings for the break-in and it was VERY windy. TAS was 176-178 on 24/24 at 3500” so I am guessing 180-185 higher. It was a rough ride.

I have a fuel pump that needs overhauled so that is going out. I also have a small box in the avionics bay that controls glareshield and panel lighting that needs overhauled. Maybe one EGT probe as well. Otherwise, for the amount of work we did on the airplane……everything went well.

Looks great!

One more easy thing to make the appearance pop is to mask off the wing walk area (and windows on that side) and take some flat back spray paint and hit the wing walk. It turns out looking brand new when you’re done.

-

44 minutes ago, takair said:

Unfortunately, his clamp had cracks.

As much as I hate the clamp shortage, the AD may have just saved a life. You do not want that clamp giving way.

-

1

1

-

-

I almost went this route in 2019 on the Bravo I owned, but couldn't pull the trigger. I didn't like the answer I got when I asked what the gears were like inside of it.

As much as we all want Electronic Ignition, the challenge is trying to put it on a 1940's-technology tractor engine, which happens to be FAA certified. No one has come up with a solution yet that I'm comfortable with. I still feel that the original mags with an IRAN every few hundred hours is still the most reliable - staggered so both mags don't get IRAN'ed at the same time by the same tech and subject to the same error. Someday I hope General Aviation gets modern engines with modern ignitions, but I wouldn't bet the farm on it in my lifetime.

-

1

1

-

-

3 hours ago, DonMuncy said:

Lance,

Did your schedule get sorted out enough to see about coming up and picking up the MAPA Logs, etc. ?

I sent you a private message

-

I have seen this airplane in stages of completion and it is a “better than new” Ovation in every possible way. With Steven’s attention to detail and Brian’s workmanship you will not find a better Ovation on the planet. You couldn’t come close to duplicating it for the asking price.

-

3

3

-

1

1

-

-

29 minutes ago, C.J. said:

Has anyone tried this? Avionics tech pitched this product as the least costly of two possible solutions.

Running wiring through the PC access in the left yoke horn is no longer an option.

This is the company that makes them. https://controlyokecovers.com/grips.html

They look much better in the pictures than I have seen them look on people’s airplanes.

-

1

1

-

-

29 minutes ago, dkkim73 said:

Thank you for the clarification. I will look.

It would seem a good idea to buy a bunch (larger length) of said tubing, 0.75" ID. Any advice where? (generic source vs. actually looking for a matching part # and aviation-based source) This seems dead-simple, is it generally considered within the scope of preventive maintenance (as owner-operator)?

David

Details about the hose are in the above post. It's only $10 a foot at McMaster. You have to buy 50 feet from another company to get it down to $8 per foot and I think it would end up getting brittle before you used it all.

It sure seems like preventive maintenance to me.

-

2 minutes ago, dkkim73 said:

@LANCECASPER to circle back to the hoses, you said that one of the hoses in the picture needed to be replaced (from oil filler to side of oil/air separator). Was this a suggestion, or was the color indicative to you of an incorrect hose?

It was the correct hose (yellow Tygon material) but since it is that dark it very likely should be changed out. I would be surprised if it wasn’t hard and brittle due to the heat. They can be rinsed by removing the hose and pouring mineral spirits through the hose, but once you’ve gone to the trouble of taking the hose off, just cut a new length of Tygon and change it. The service bulletin that was mentioned tells you what diameter of Tygon hose you need.

-

38 minutes ago, natdm said:

For what it's worth, my K has an aftermarket onboard O2 from when I bought it. It's got a leak above our heads somewhere in the interior. All the MX's I've talked to said they can troubleshoot it but it'll be stacks of cash, and the interior won't look the same. They troubleshooted everything up to that, which was already $$$.

We switched to a portable one and it's nicer just having it there. Don't feel like you've lost much if you don't go the onboard route.If they can't put the interior back to look the same, they have no business troubleshooting anything on your airplane.

-

1

1

-

-

1 hour ago, dkkim73 said:

Good news! Here's an abbreviated most recent update:

They lapped exhaust valves #3 and #4 in place, ring flushed each 3x, which addressed the audible blow-by and valve leaks.

"1st Compression check after initial run complete #1 70/80 #2 70/80 #3 32/80 #4 60/80 #5 74/80 #6 72/80.

2nd Compression check after lapping and ring cleaning, COLD engine #1 70/80 #2 70/80 #3 70/80 #4 64/80 #5 74/80 #6 72/80.

3rd Compression check after final run-up: HOT engine #1 70/80 #2 70/80 #3 74/80 #4 70/80 #5 74/80 #6 72/80.

Borescoped engine and found no evidence of broken rings or any visual cracks, any cylinders. ..."They also replaced the rotocoil for #3 (thought there was likely a failure to rotate [insert Cool Hand Luke joke]). Oil change, etc.

So the hoped-for "happy path" of a minimally-invasive approach (endorsed in this case by several Savvy folks and a few others incl. BK) seems to have yielded good results. Meta-bonus is developing a relationship with a pretty solid-seeming local shop at one end of my commute.The isolated eddy current findings (between the spark plug and injector bosses) do not correspond to any visible defects on inspection, and so the recommendation was to watch. If anyone has a good contact at Continental to bounce the question off, I'm all ears.

To one of @LANCECASPER's points, the down tube from the oil/air separator was checked recently at annual (about 32 hrs ago now).

Hope this anecdote is useful to someone,

D

That is so good to hear. I have thought for years that many of the Acclaim cylinders were replaced unnecessarily. Mechanics have been so used to pulling a cylinder as soon as they see low compression. In some cases cylinders need to be replaced but I'm glad this is getting some traction. Any idea what the cost was for the valve lapping and ring flush?

-

2 hours ago, rturbett said:

Was happy to have a conversation with Sure Fly-

The magneto draws lest than an amp per hour off the battery- meaning 10 plus hours of operation should the alternator fail.

That takes care of half of my worrying.

Just make sure you have a good Concorde battery. Friends don't let friends fly with Gills.

-

1

1

-

1

1

-

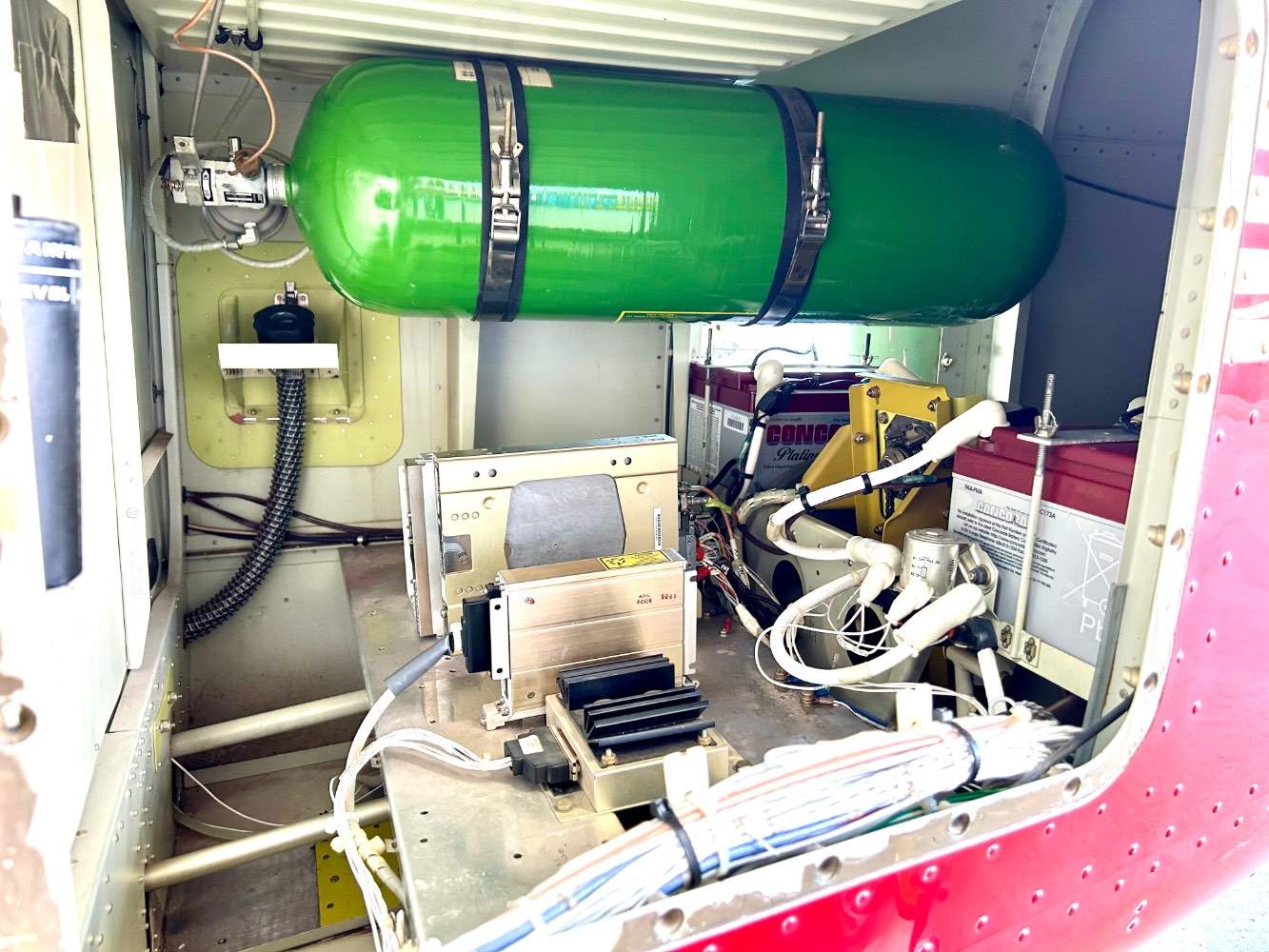

77 cf Oxygen Tank from a Mooney M20K 231-Recent Hydrostatic Test

in Avionics / Parts Classifieds

Posted

The two options are steel and kevlar.