-

Posts

216 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Posts posted by Emmet

-

-

Hi,

I would like to share my experience with customer support. I had mine ordered last month via UPS 2nd day. Long story short UPS messed it up. JR from customer support was outstanding in helping me with relocating the package and following up the case over a couple of days always monitoring and responding quickly to my mails. After many bad experiences with other companies I can‘t value his help and involvement enough!!

-

1

1

-

1

1

-

-

Quick update to all on out winter hibernation issues.

We found an AMAZING avionics guy, who is an old fashioned electrical engineer. You know those guys who use volte meters etc to measure resistance across circuits. So….

Panel Lights- this came down to a blown fuse. - underneath the panel light rheostat switches, you will see two little grey “tits”. If you unscrew these there are two little SLOW BLOW fuses of 5 amp. One of these had blown. Our guy went further to try and work out why. He discovered a rheostat transistor on the panel was overheating, so this was replaced as well, and soldered in. The Tit Fuses were upgraded slightly to cope with the increased current draw that had been added over the years to 6 amp. All now works beautifully.

- this has been an interesting journey and we have learnt TONS. I can honestly say its been a bit like the no back spring thing. I now know EXACTLY how the BK autopilots work and it really is a brilliant piece of kit.

- So the issue with ours (KFC150) is that post lockdown the AI failed to erect, (at my age, I'm told this is normal). This AI was swapped out for an “exchange reconditioned “ unit. This unit worked well (ie erected and tracked well) but the AP developed a tendency to porpoise. This was definitely a fault of the new AI so a another recon unit was installed. This one, OMG, flies with the FD perfectly, but the moment you engage the AP will pitch down at an alarming 2+k fpm dive, then correct and do the same up, and on it goes. AP as a consequence is useless, but it has helped us keep our IMC manual skills upto date!!!

- So Chris (our new found avionics guy) got to work. He setup a vacuum system, put the plane on jacks and connected the instruments upto the vacuum system he had setup so that the instruments could be operated in an inflight mode, but without starting the engine. He managed to reproduce the fault, always a good start…put the AP system on a rig and tested everything. Previously he had gone through EVERY piece of cabling to test for shorts, and unnatural voltage drops etc. The wiring was good. He found a bit of the loom was rubbing on the yoke pushrod so he tied that back. He also found that the bushes that the yoke push rod goes through were a bit crudded up, so he cleaned those up and lubed it (he felt it could have added resistance to the trim servo). Oh boy are the controls better now, a LOT lighter, something for you all to do perhaps. Makes a huge difference….

- so the AP… on the rig it was discovered that there was no output from the AI for pitch. The AP monitors attitude and altitude and it does this by receiving inputs from the static system, HSI and the AI. All done by measuring the AC signals that these instruments send to the AP. If for example the altitude is off by a few feet the AP will send a signal to the trim to trim down/up a bit, it receives a signal from the AI via an AC sine wave that the AP reads and depending on the strength, length etc of the wave the AP can tell that the correct attitude has been made, if it does not receive this signal it will just continue to apply trim, because it assumes that the plane has not been adjusted yet. Now the BIG difference between the older APs and the later ones is that in the later ones, the trim is only put in for a little while, then if the AP receives no signal, it assumes there is a fault and cuts out the trim. A GOOD safety feature.

anyway we are now looking for another exchange unit that WORKS, while we get the Aspen that we have bought of an old saratoga, upgraded to a max, so we can install that and have the cockpit that we want.

Ill post an update on here when we have one. If anyone knows of a GOOD recon shop for KI units, I would be interested.

Andrew

If you consider all the labour and exchange parts a GFC 500 / G5 would probably have been the cheaper route at the end of the day …

Gesendet von iPhone mit Tapatalk - this came down to a blown fuse. - underneath the panel light rheostat switches, you will see two little grey “tits”. If you unscrew these there are two little SLOW BLOW fuses of 5 amp. One of these had blown. Our guy went further to try and work out why. He discovered a rheostat transistor on the panel was overheating, so this was replaced as well, and soldered in. The Tit Fuses were upgraded slightly to cope with the increased current draw that had been added over the years to 6 amp. All now works beautifully.

-

No servo issues at all - and I think I was one of the first to have it installed in a Mooney.

-

1

1

-

-

I noticed ACG’s website is in German only. Do they reply to emails in English ?

I am pretty sure they do -

... and the A380 is - from a passenger perspective - the most comfortable plane I have been flying in..

-

1

1

-

-

No, it is on the bracket. It will not affect the pitch servo despite the fact that if the plane is out of trim the pitch servo has to work harder and if forces exceed certain limits the AP will disconnect.

-

Hi, I am working through some new AP or trim issues and trying to understand the baseline condition that I might have never noticed in the past.

The issue:

AP drops out with a flashing 'trim' alert when trying to maintain in ALT mode or in attitude mode. Electric trim works fine when no on AP. Heading and Nav modes work fine. Note that I don't seem to get the four beeps when pushing the test button anymore. Not sure what the beep codes mean.

When on AP and before the drop out, the manual trim wheel cannot be turned by hand; is this normal as I have never noticed. It cannot be overwhelmed by hand, it feels locked and not the same feeling as pulling through the clutch when fighting against it in electric trim mode. This same sensation can be simulated on the manual wheel when only the left hand trim switch is activated, which I understand engages the clutch in the servo.

Thoughts:

Is this an AP issue or a trim/servo issue?

The Trim indicator no longer comes on when I turn the elec trim switch/breaker on, but again unsure if that is normal or not.

I have been poking at the bulkhead transition that the wiring pass through beside the battery box as it had a big gap and I am still chasing a potential CO issue. Broken or chafed wire perhaps?

Any thoughts on where to look or likely culprits? Going into annual soon, but also would like to ensure I can point in the right direction versus random guess and test.

Thanks,

It looks exactly like the issue I had with mine. Long story short - the cause was the bearing on the trim torque tube below the trim servo. It seldom sees some lube during annuals, gets stuck and produces what you are experiencing.-

1

1

-

-

ADSB out is not required for our Mooneys in Europe, but you need Mode-S.

I am not sure if you have to disable the 978 ADSB out. -

-

Mmh ... I thought the primary purpose is to destroy airflow ...

-

Joe,

you should have a schematic of your bus architecture in your POH.

In my 231 the busses are made up by a simple connection bar connecting the CBs. That is the location of the busses.

Primary engine instruments should be connected to the main and not the avionics bus for obvious reasons.

-

1

1

-

1

1

-

-

36 minutes ago, fuellevel said:

Looking at the picture I would suspect that the sealant failed around the domed captured nut in the tank

allowing fuel Ito travel down the attachment screw. Mooneys have undersize sender attachment due to the need to

isolate the inbd sender in a resistive sender system. So the gasket is not tight around the screw as it is in other aircraft

so yes the gasket could have failed but not likely more like a sealant failure

We will look at this ... The senders have been installed just after the new reseal.

-

That ist part of the Soundex multilayer insulation/sound proofing

-

-

On 2/20/2020 at 11:52 AM, Hyett6420 said:

-

Fine - it is not worth the discussion. I don‘t feel the need to convince anybody and wish you good luck ..

-

5 hours ago, Hyett6420 said:

no you are incorrect in the latter part, that was my error, they were going to replace them as part of the refurb so deliberately had not covered them as a consequence.

Interesting ... you said differently in the thread about your refurbishing...

So what - I can only offer experience and try to help others not to make mistakes I did - judge yourself ..

-

11 hours ago, Hyett6420 said:

Emmet I know about your experience and there are two sides to every story, ne c’est pas?

A friend of mine for example just took his new to him ovation to aeroskill and he texted me today and quote “ im not usually an emoji sort of person but I have to say that aeroskill is F...ing awesome, I think im going to be a customer formlife, their attention to detail is amazing”

On a personal level ive never had an issue with them and I concur with my friends comments.

Andre

There are always two sides of a story - but I know of at least one more person having trouble for more than a year..

I have worked on special mission aircraft for a couple of years so I consider myself reasonable competent.

I will not discuss this in a public forum, but I have lots of pure technical and not emotional detail and fortunetly that has only one side.

Anyhow it is everybodys own decision and the only thing I wanted to point out is that there are different opinions than yours.

If I remember correctly they painted your pucks, because they forgot to cover them before spraying ... and fortunetly they had to be replaced anyway ...

-

1 hour ago, M20Doc said:

Several decades and beyond would be expected in normal service. Think of how long the factory sealing lasted before requiring replacement.

Andrew Hyett, a member from the UK takes his Mooney to Holland for work at Aeroskill. https://www.aeroskill.nl/

Clarence

I would recommend to ask others about their experiences

-

I have the same problem as Nico and mine were resealed in a shop in Europe as well. Dealing with that shop was the worst maintenance experience I ever had.

We should probably check if it is the same ...

-

-

4 hours ago, donkaye said:

Thanks for pointing out the documentation. Now I remember reading it, but forgot about it. I guess that tells you how important I think it is. I've been sitting here trying to figure out when it would be useful, but haven't come up with a good reason yet. I will try it out when I get my airplane back from Annual, as a novelty. Maybe I can come up with a reason after I try it.

flying 360s without moving the heading bug all the time

-

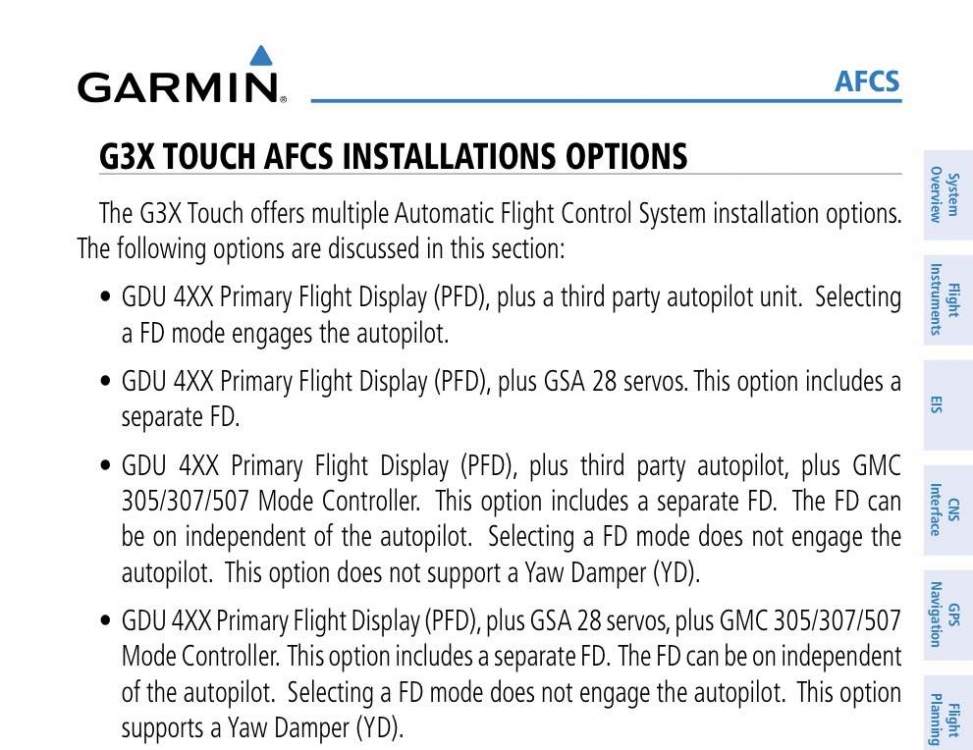

.. or the G3X Touch ..

-

I would call that additional and not really wasted screen ... yes it displays the same information, but depending on the placement it reduces eye and head movements which can beneficial. And talking about redundancy you have two devices with different software which will not fail with the same software bug ..

Looking at the dual Aspens in comparison to a G500txi or G3X you have additional bezels that waste space which cannot be used for display area.

You also cannot combine them to a single display area which limits the HMI capabilities ...

At the end it is all about preferences

Just my 2 cents ..

-

3

3

-

Trim servo issues?

in General Mooney Talk

Posted

There is a third one that is often overseen (ask me how I learnt about it) : There is a bearing just below the trim servo where the torque tube runs through. That is supposed to be lubed regularly but probably doesn‘ t get the attention it deserves…